Piston motion speed matching method for improving concrete pumping material suction performance

A technology of piston movement and concrete pump, applied in chemical instruments and methods, pumps, pump control, etc., can solve problems such as reducing the performance of concrete suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention is further described below with reference to the specific embodiments.

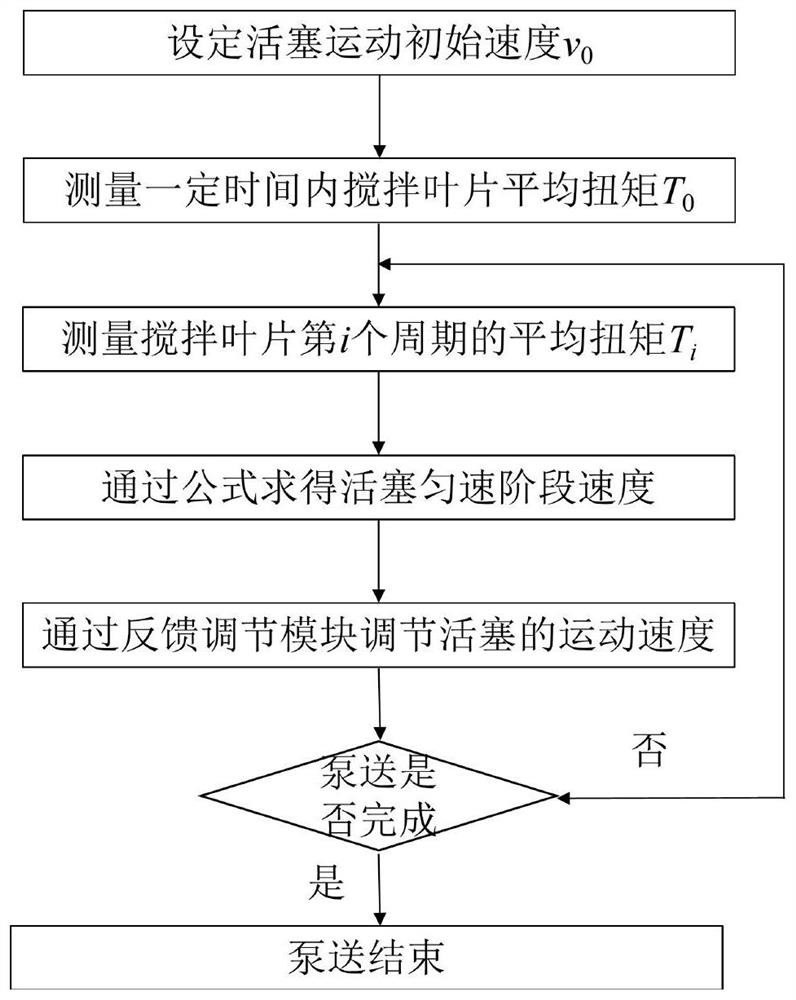

[0028] A method for performing speed matching method for concrete pumping suction properties, detailed steps are as follows:

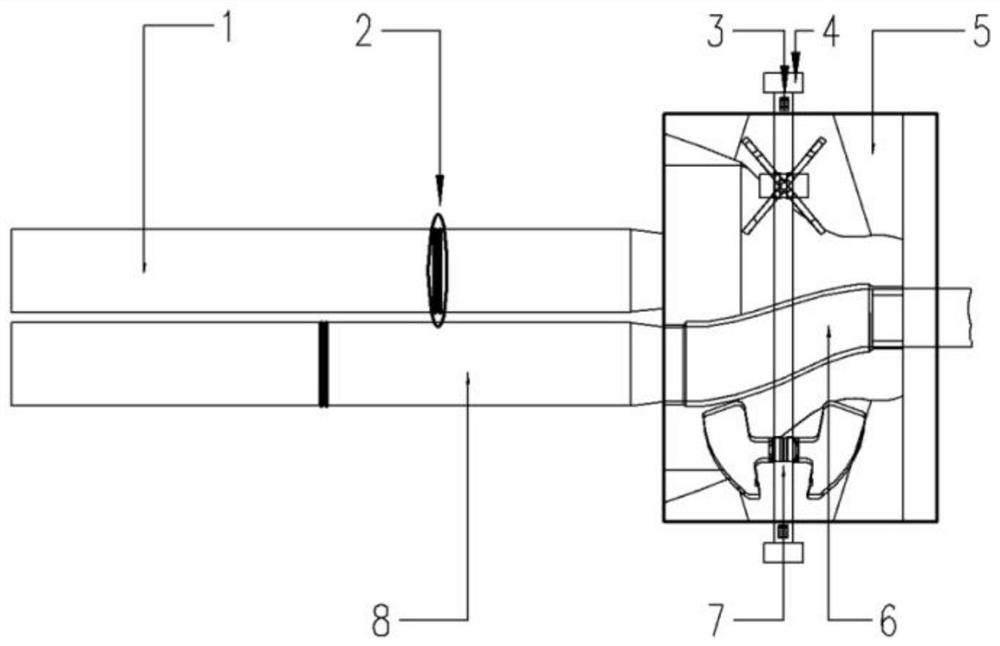

[0029] (1) Provide a concrete mixture suction system;

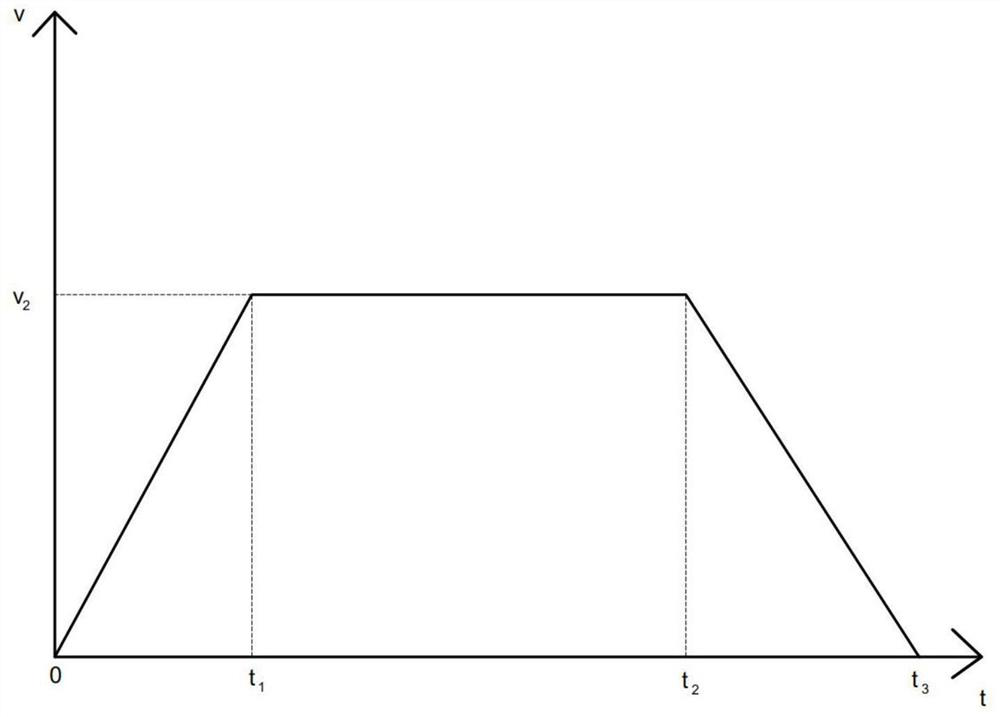

[0030] (2) When the concrete is added to the mixture, the stirring means is activated. When the concrete is added to the mixture to the hopper, the initial movement speed V of the suction cylinder piston is set. 0 = 1M / s, let the piston start moving, pumping begins;

[0031] (3) Torque sensor detects the average torque T of the stirring blade at the current rotational speed at a certain period of time 0 , And record T in the data storage unit 0 Numerical;

[0032] More specifically, the average torque T of the piston single-absorbing time 2.5S under the stirring blade rotational speed 25R / min detected by the torque sensor 0 = 355N · m.

[0033] (4) Repeat step (3), the average torque T in the i-th cycle u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com