A planning method for sole glue spraying path based on attitude control

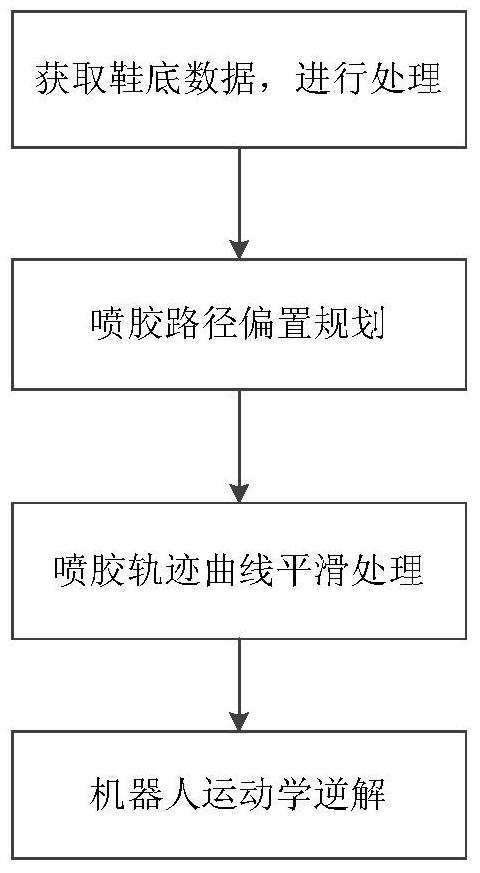

A posture control and glue spraying technology, which is applied in the planning field of shoe sole glue spray path, can solve problems such as uneven glue spray path, influence of glue spray continuity, and uneven glue spray, so as to improve glue spray efficiency and reduce replacement The number of orientations and the effect of prolonging the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

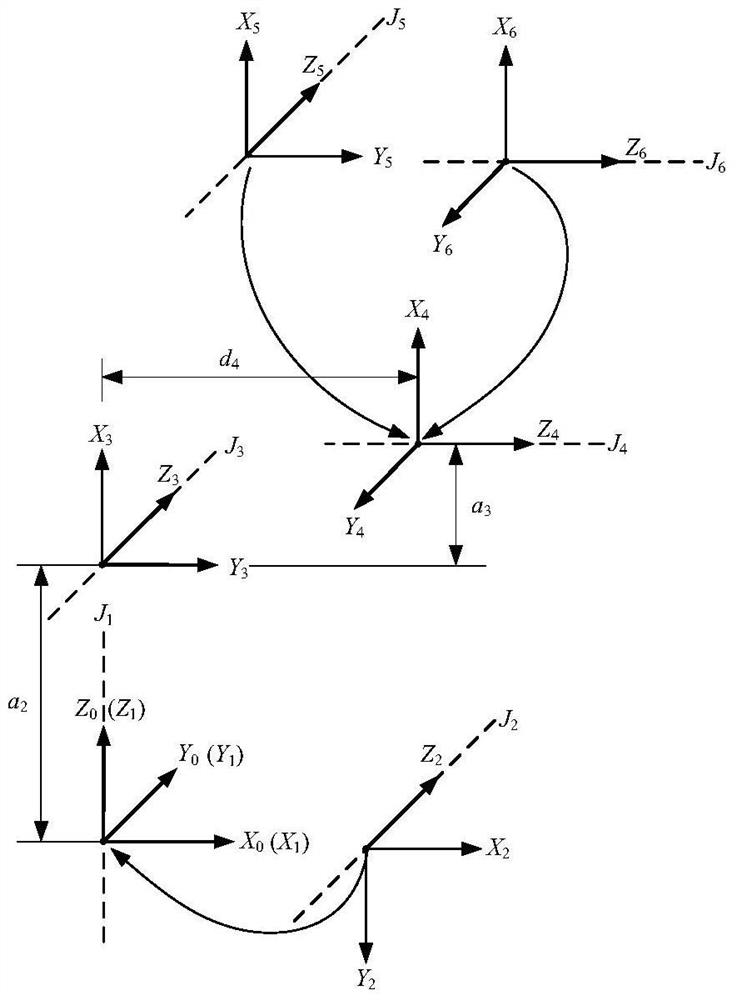

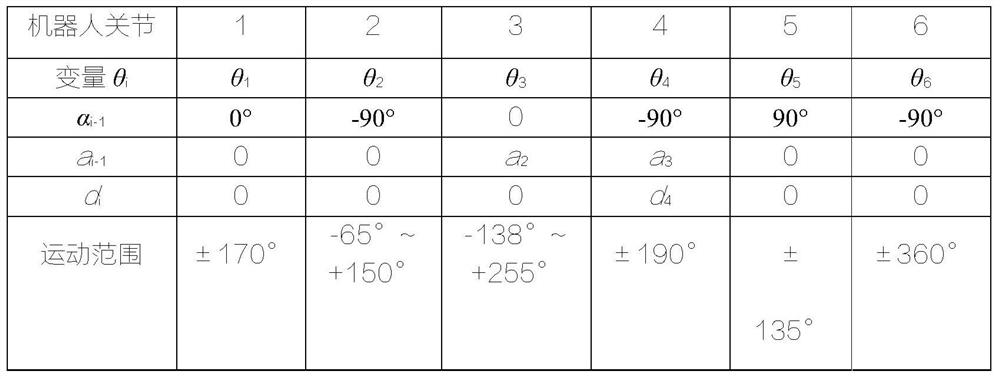

Embodiment

[0051] The laser profile measuring instrument scanned to get the three-dimensional point cloud data of the sole, see Figure 4 And processed three-dimensional dot cloud data to extract the outer ring profile curve of the sole, such as Figure 5 As shown, the bias plan is biased based on the outer ring contour curve of the sole. According to the spray amount of the glue and the contour width of the sole, the distance is set to D = 5 mm (biased to the inner normal), offset The number of times is 4 times, and the sole spray trajectory curve obtained by the formula (1), such as Image 6 As shown; the method of using the second order polynomial fitting is smoothly treated, respectively, with a 4-turn spray trajectory as an object, approximate the ten equivalent, and the spray trajectory obtained after fitting. like Figure 7 As shown, the split trajectory curve relative to the curve before the fitting, the curve slope changes smoothly. In order to determine the quality of the fit, the root...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com