Patents

Literature

116results about How to "Full coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterborne metallic paint and preparation thereof

The invention provides a water metallic paint and a preparation method thereof. The paint mainly comprises the components of 30-60wt% of acrylic resin, 4-15wt% of amine resin used for paints, 10-40wt% of pigment, 3-10wt% of stuffing, 0.5-5wt% of lacquer solvent, 0.5-3wt% of addition agent and 20-50wt% of water. The components are weighted according to mixture ratio, mixed according to certain charging sequence, and then subjected to the working procedures of dispersing, grinding and the like, thus obtaining the water metallic paint. The paint takes water as a solvent, is added with a small amount of lacquer solvent, is environment-friendly, and has the main advantages of simple production technology, low cost, good levelability, high adhesive attraction, high luster, resistance to yellowing, high solid content, low viscosity, good heat resistance and capability of being used for a long time at the temperature of 180 DEG C.

Owner:中山创美涂料有限公司

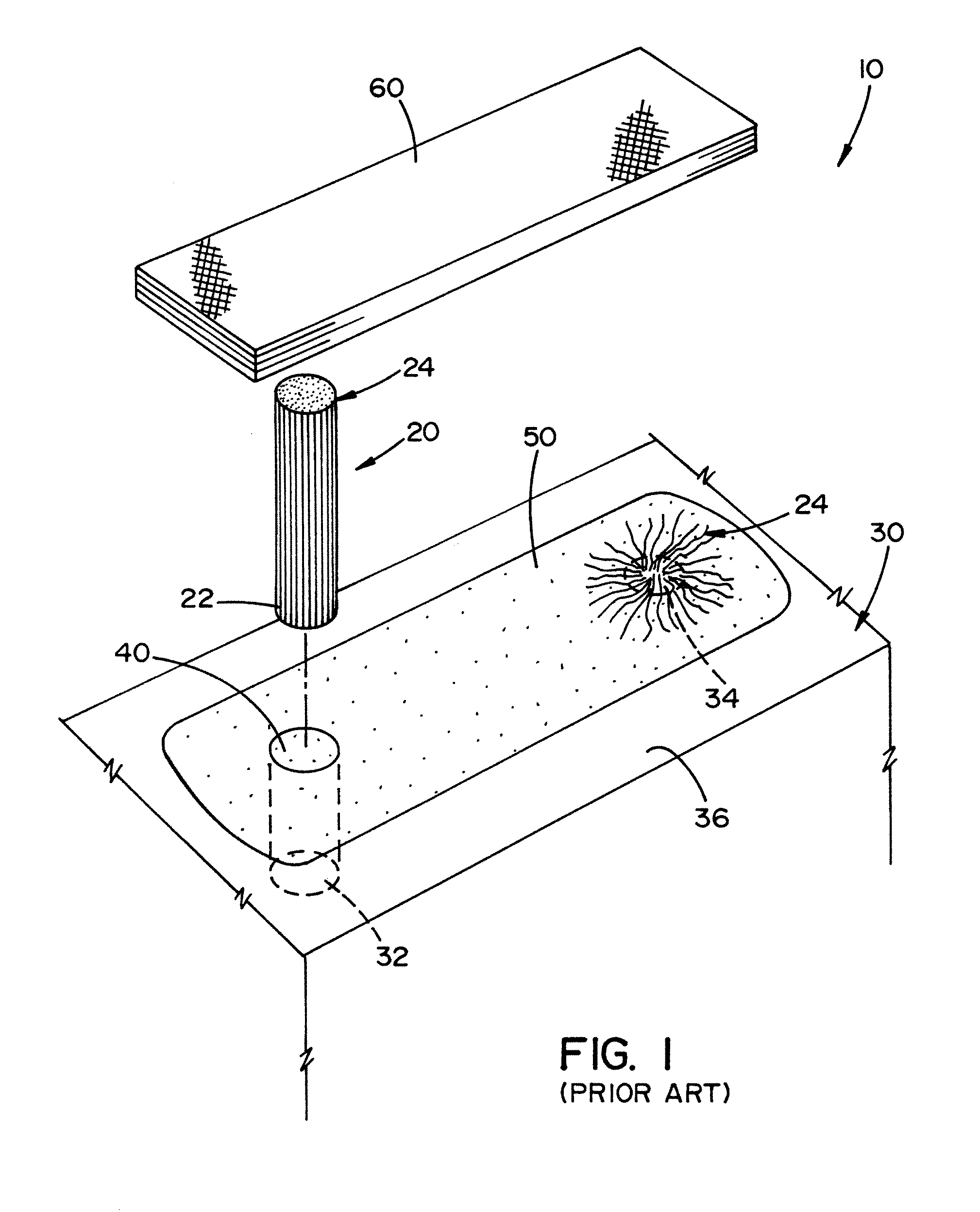

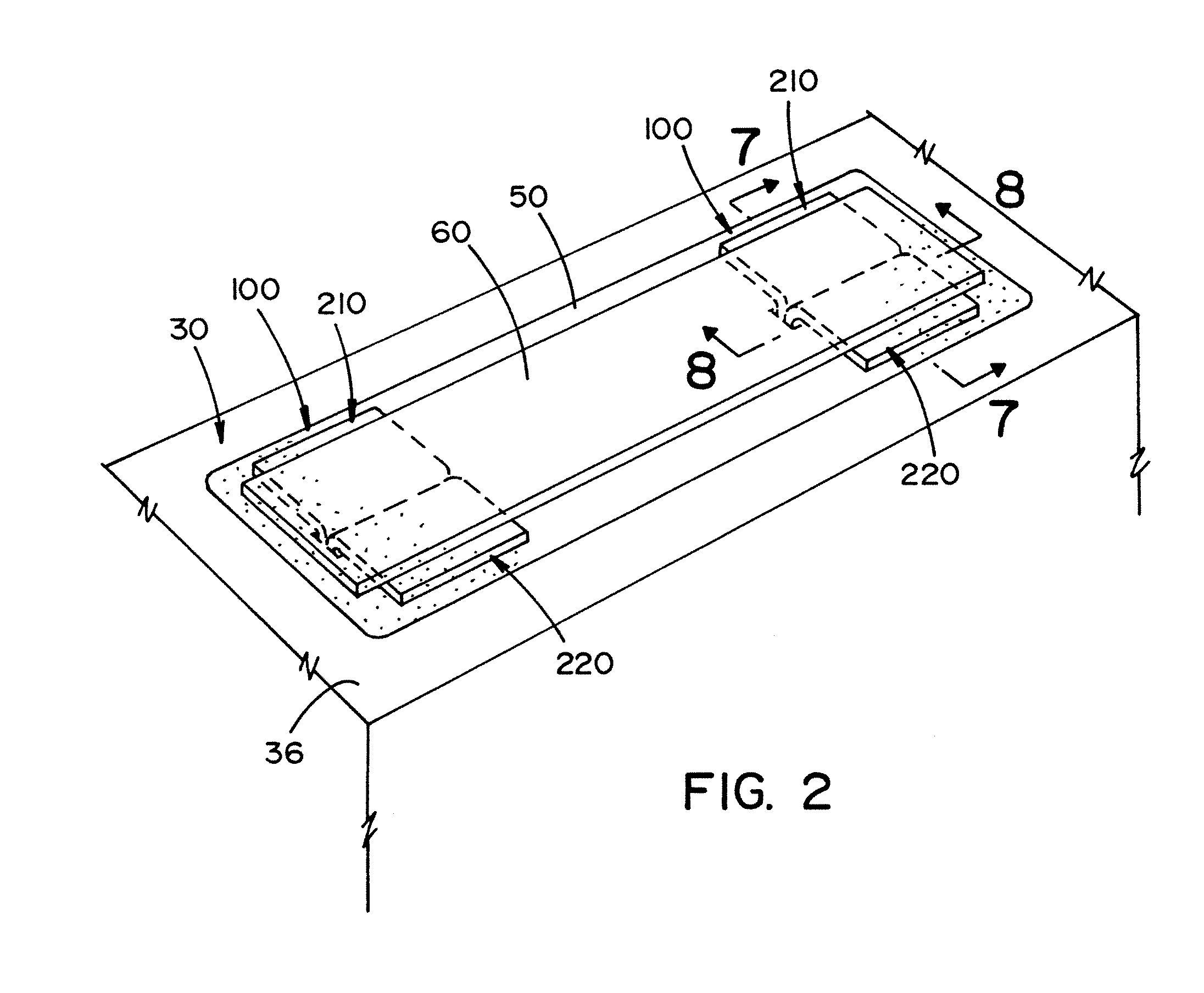

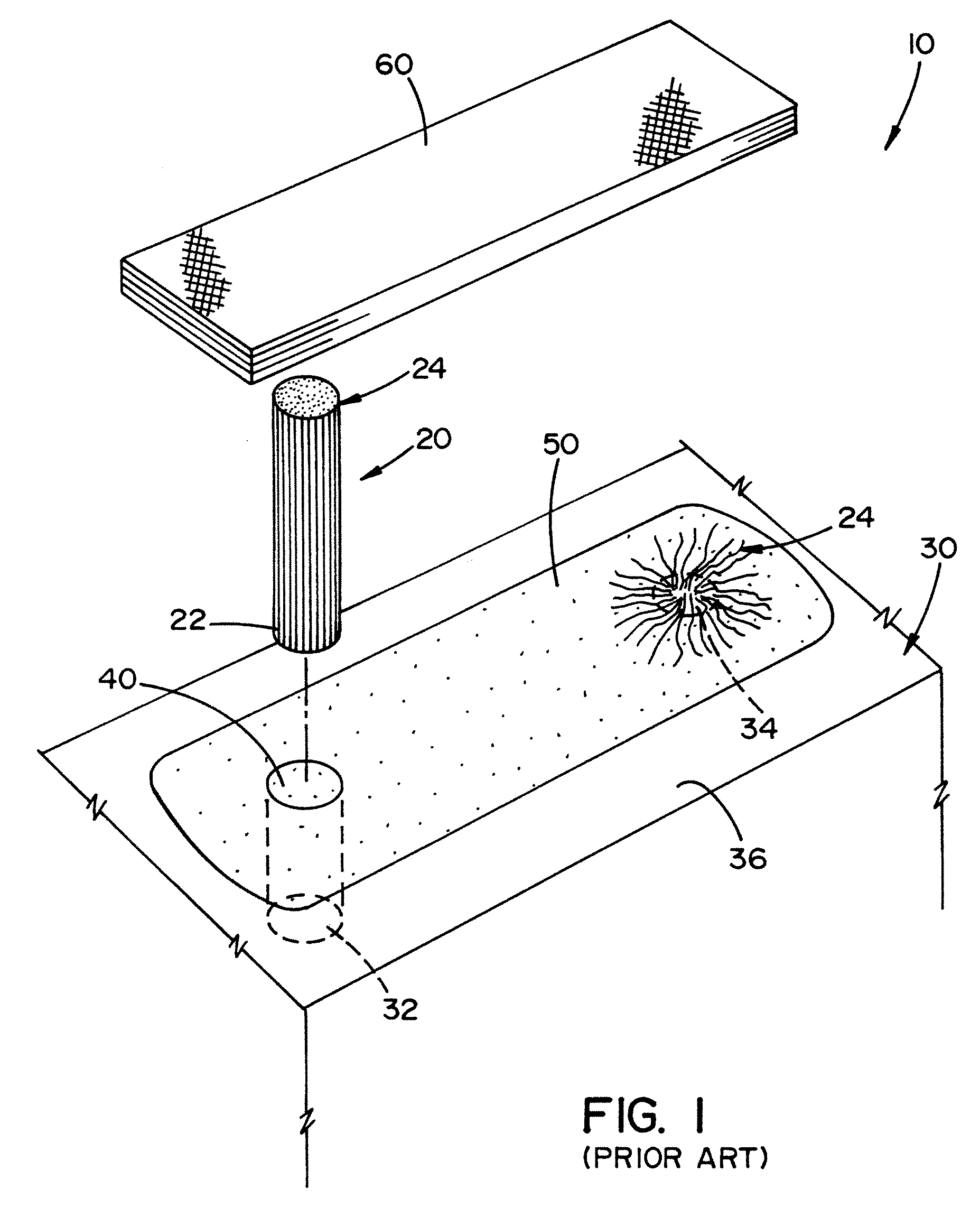

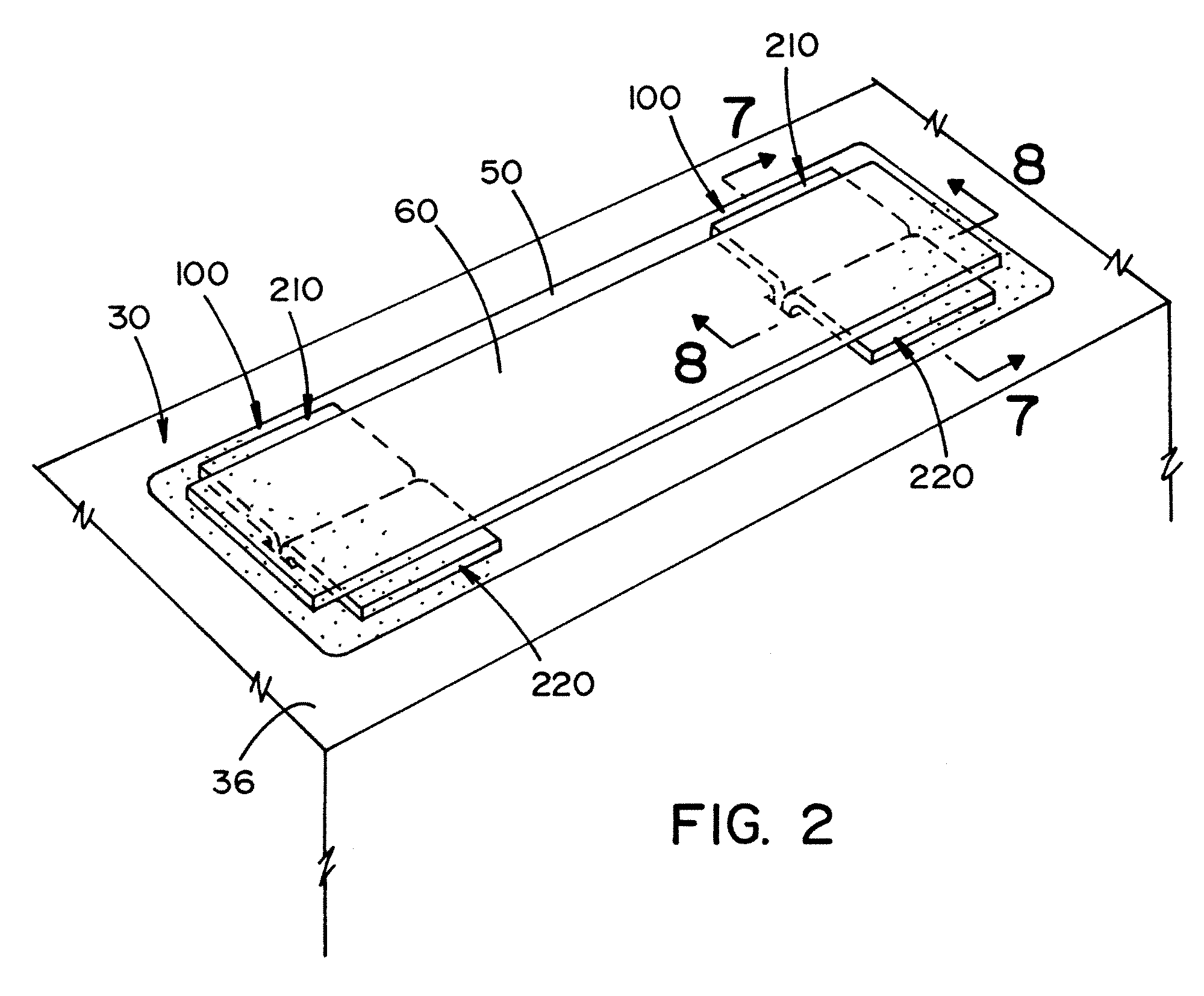

Method and apparatus for repairing concrete

ActiveUS20120110940A1Easy to implementStrongBuilding repairsFoundation repairCivil engineeringArchitectural engineering

Owner:GARLAND INDS

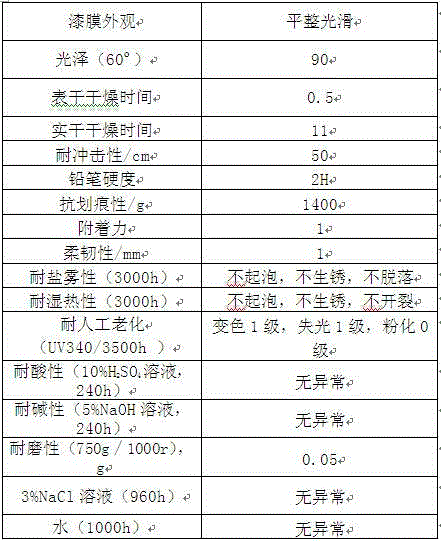

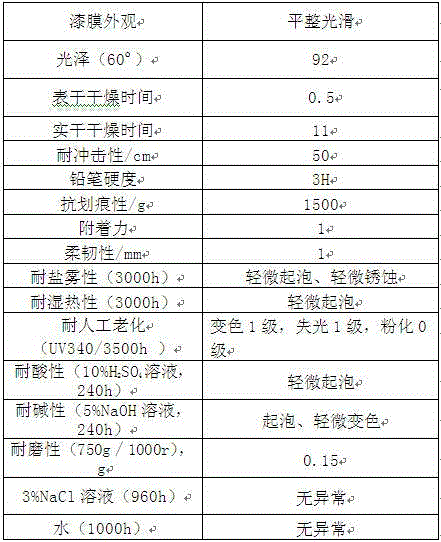

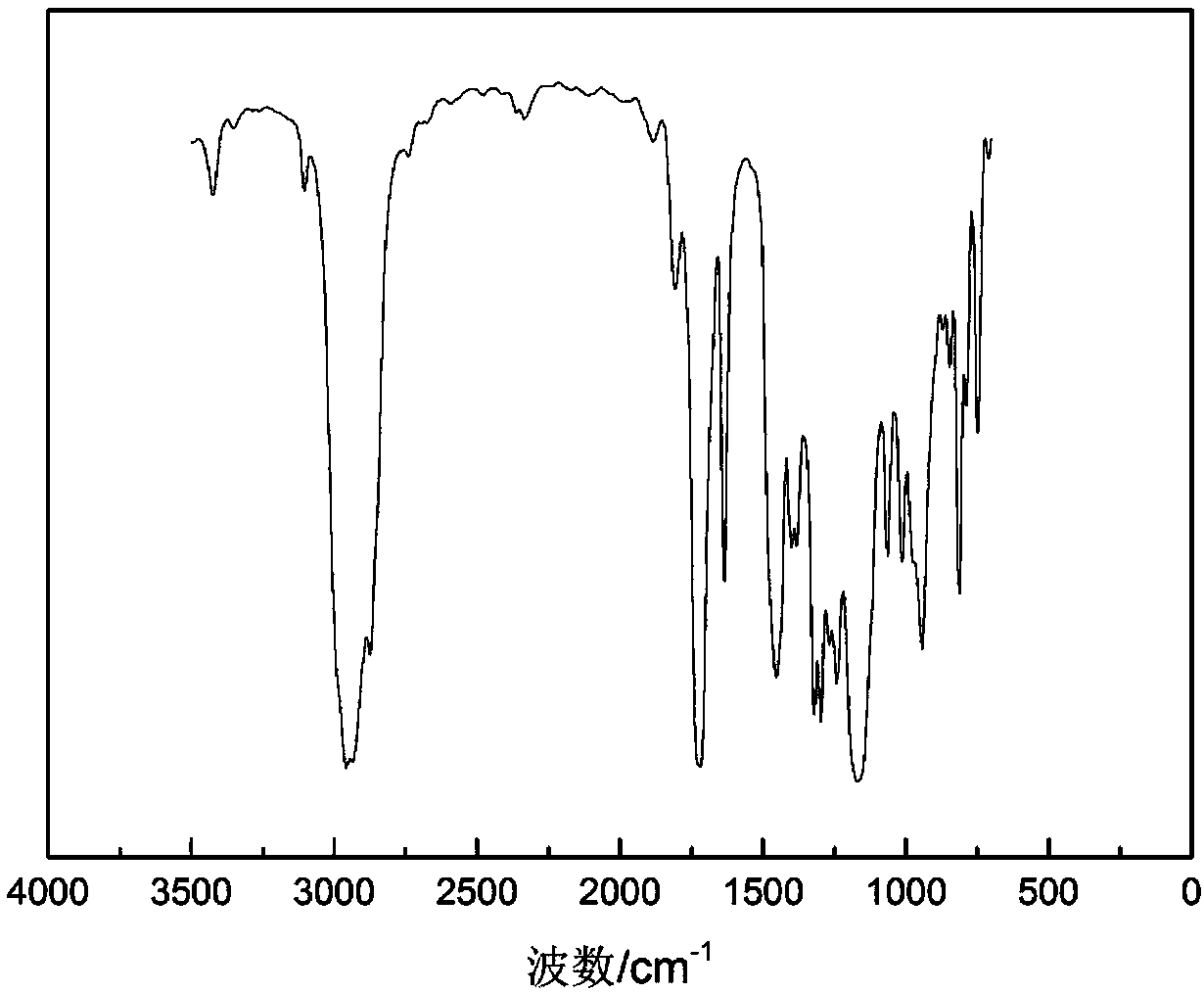

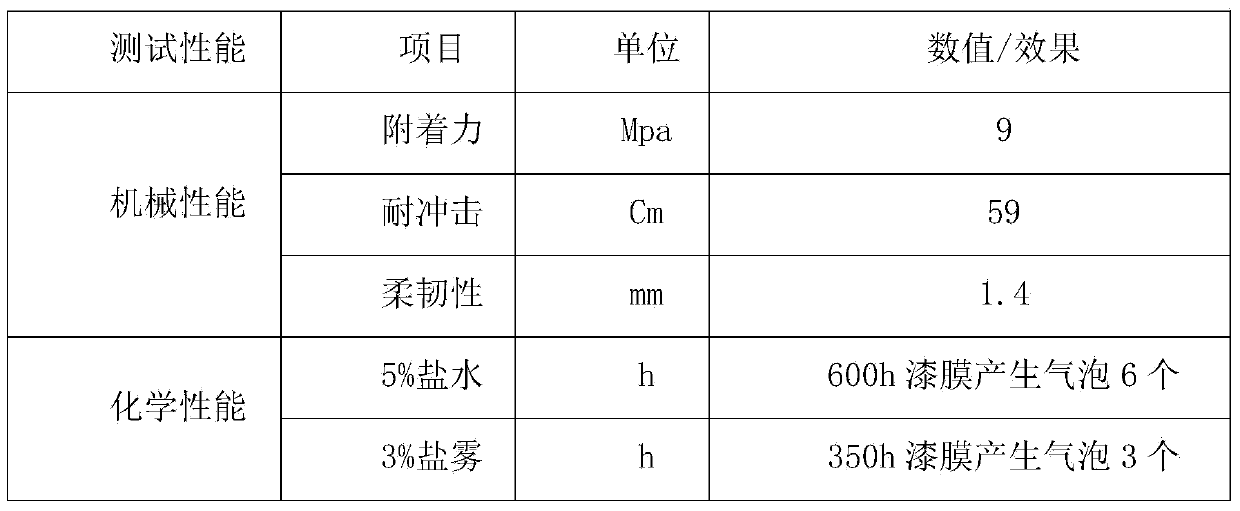

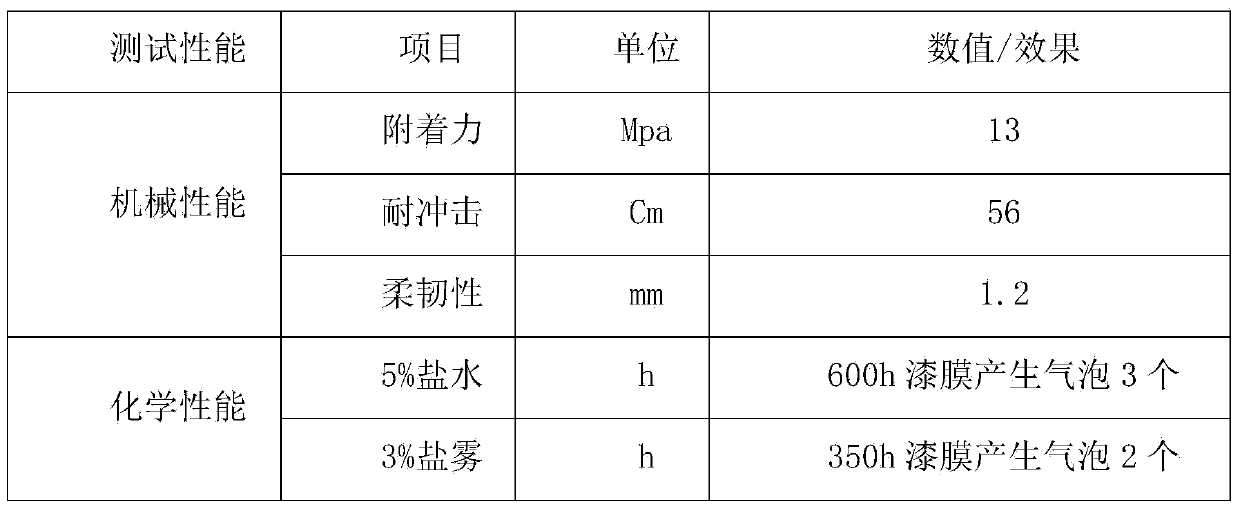

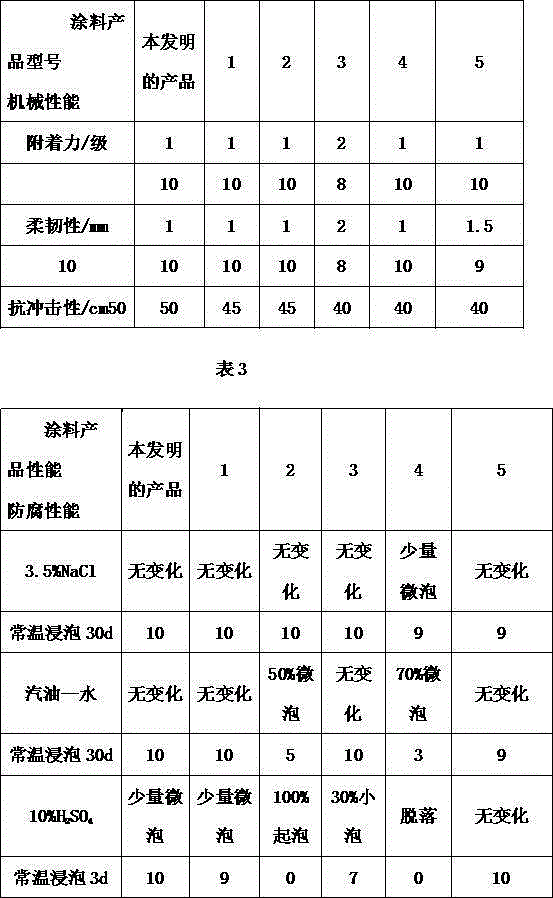

Organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating and preparation method thereof

ActiveCN104673039ALow priceGood alkali resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinAcrylic coating

The invention discloses an acrylic coating and a preparation method thereof, and particularly relates to an organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating and a preparation method thereof. The invention provides the organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating which has free TDI content less than 0.15% after blended, is capable of reducing the pollution hazard on the environment and has preferable film-forming property and a preparation method thereof, aiming at overcoming the defects of the prior art. The organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating comprises the following components in parts by weight: 40-60 parts of fluorine-silicon modified acrylic resin, 0.2-0.5 part of dispersing agents, 10-20 parts of pigments, 10-20 parts of fillers, 0.2-0.5 part of defoaming agents, 0.2-0.5 part of levelling agents, 10-15 parts of solvents and 8-14 parts of aliphatic polyurethane curing agents, wherein the proportion sum is 100 parts.

Owner:ZHEJIANG TIANNU GROUP PAINT MFG

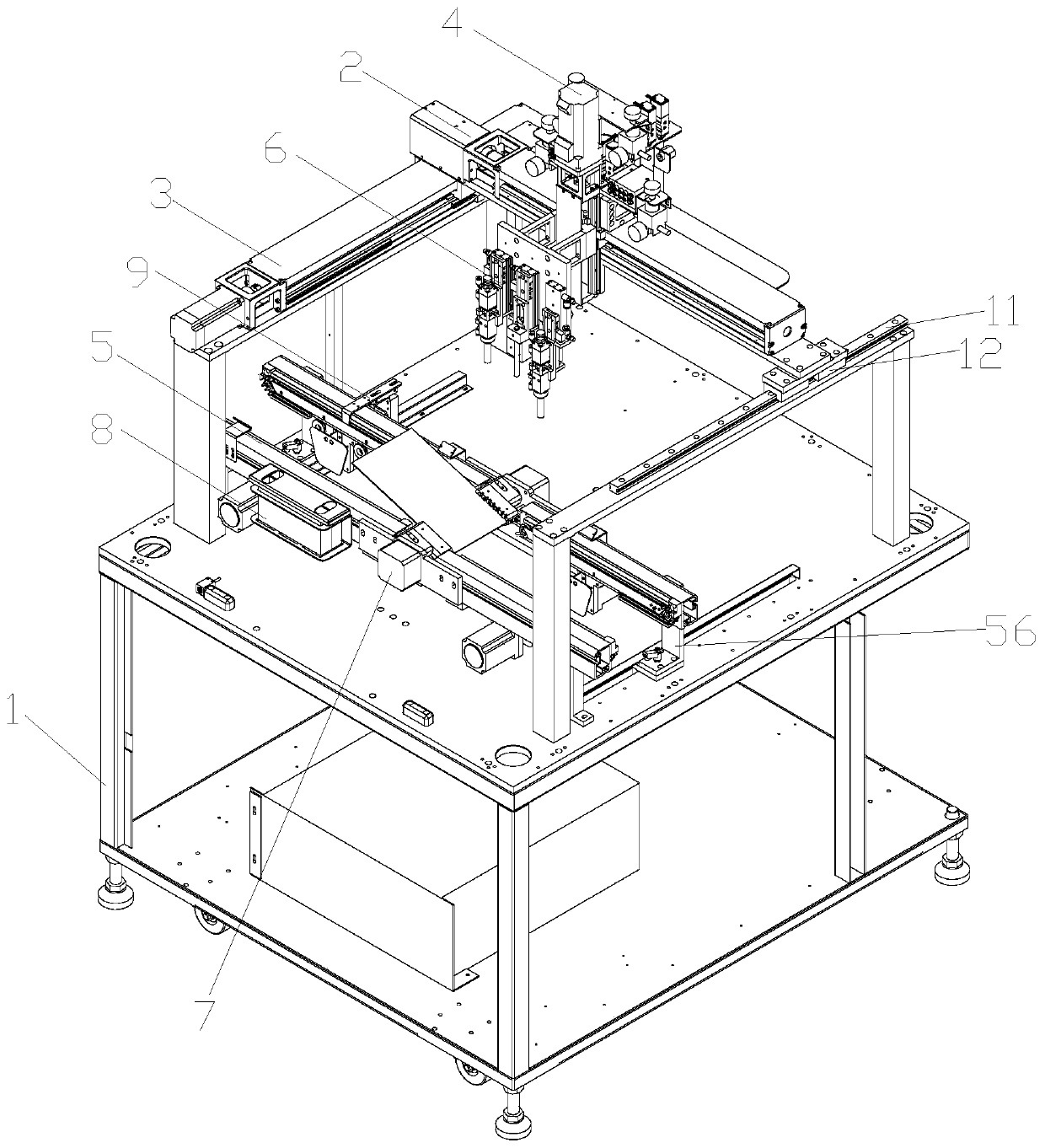

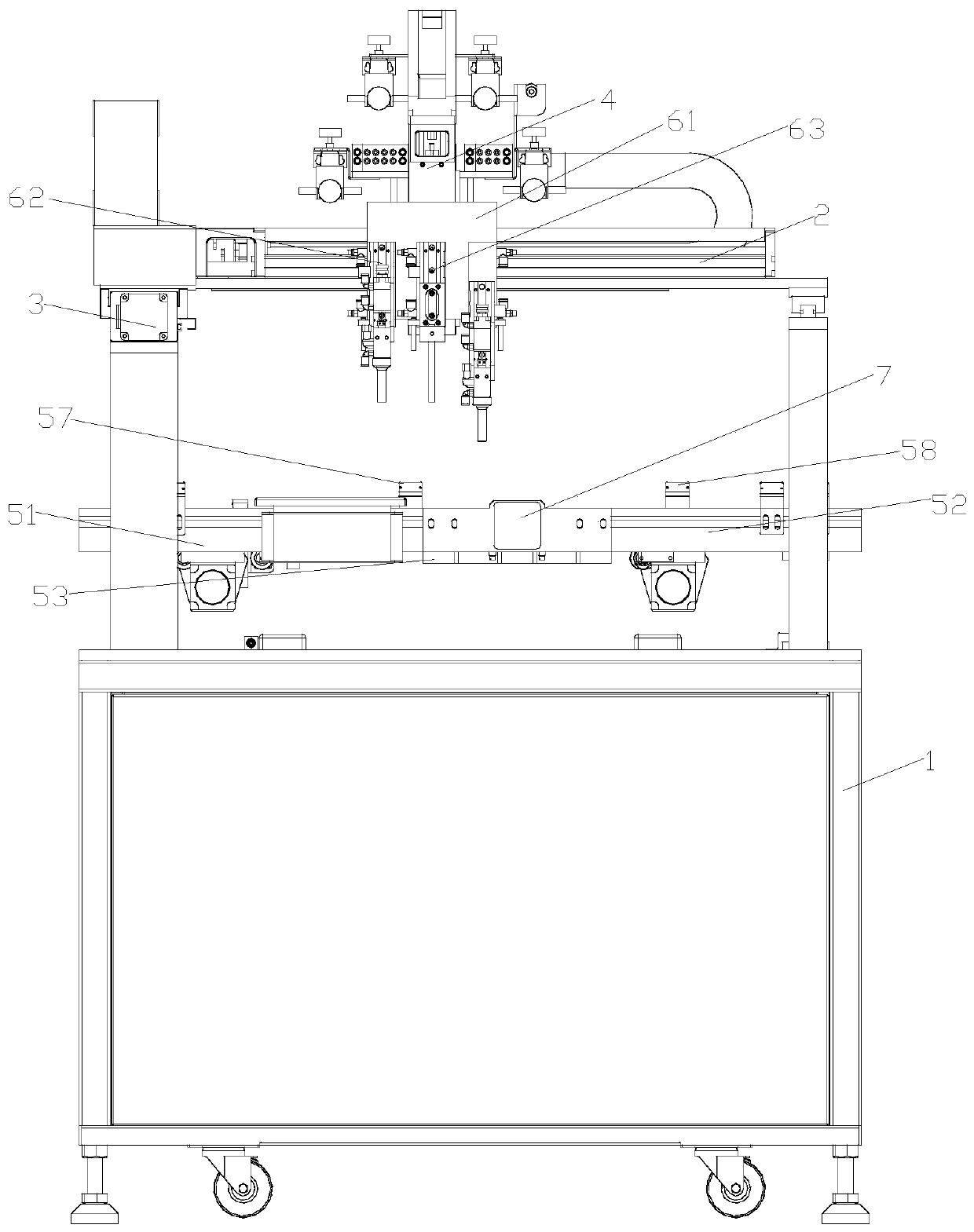

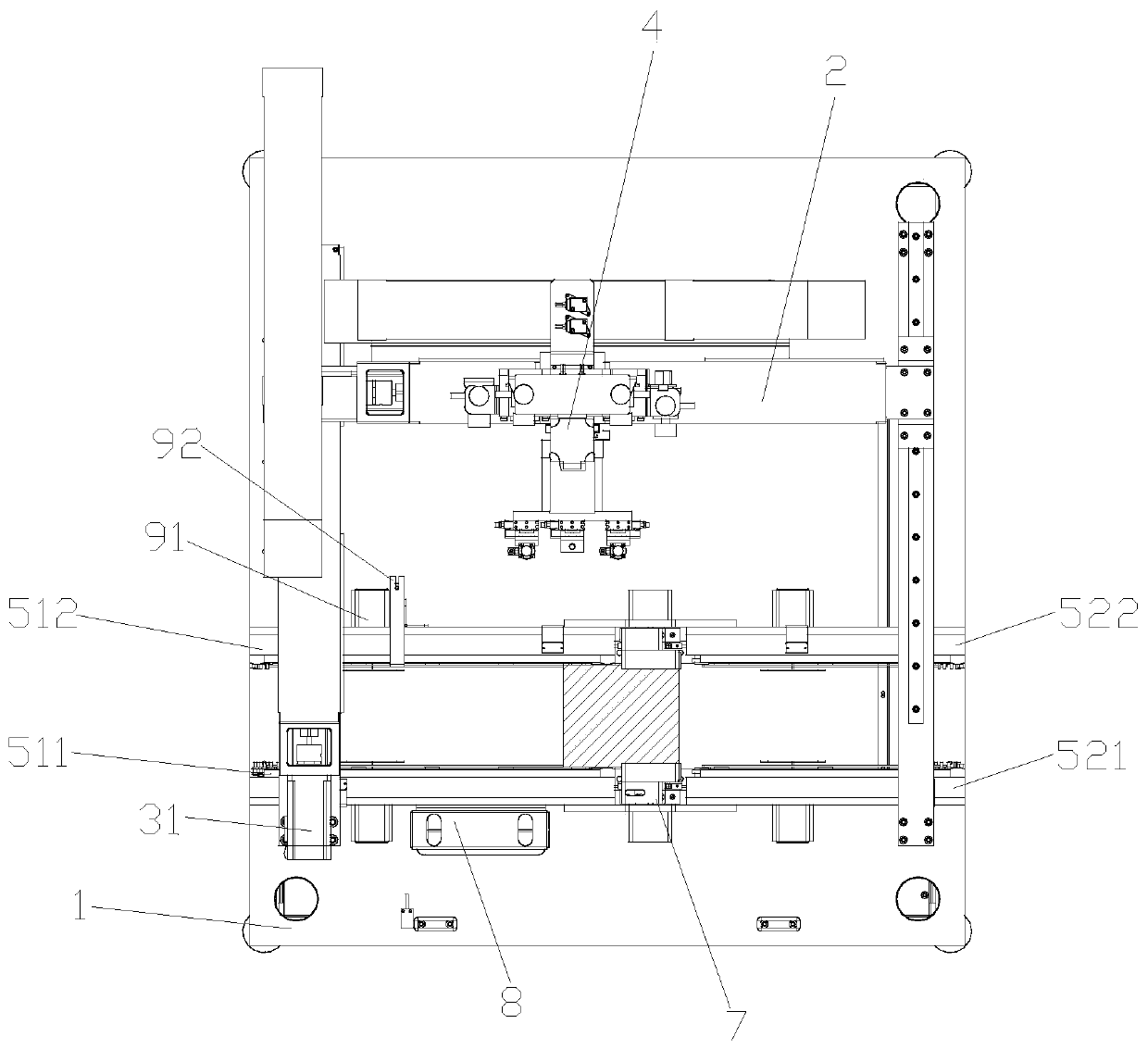

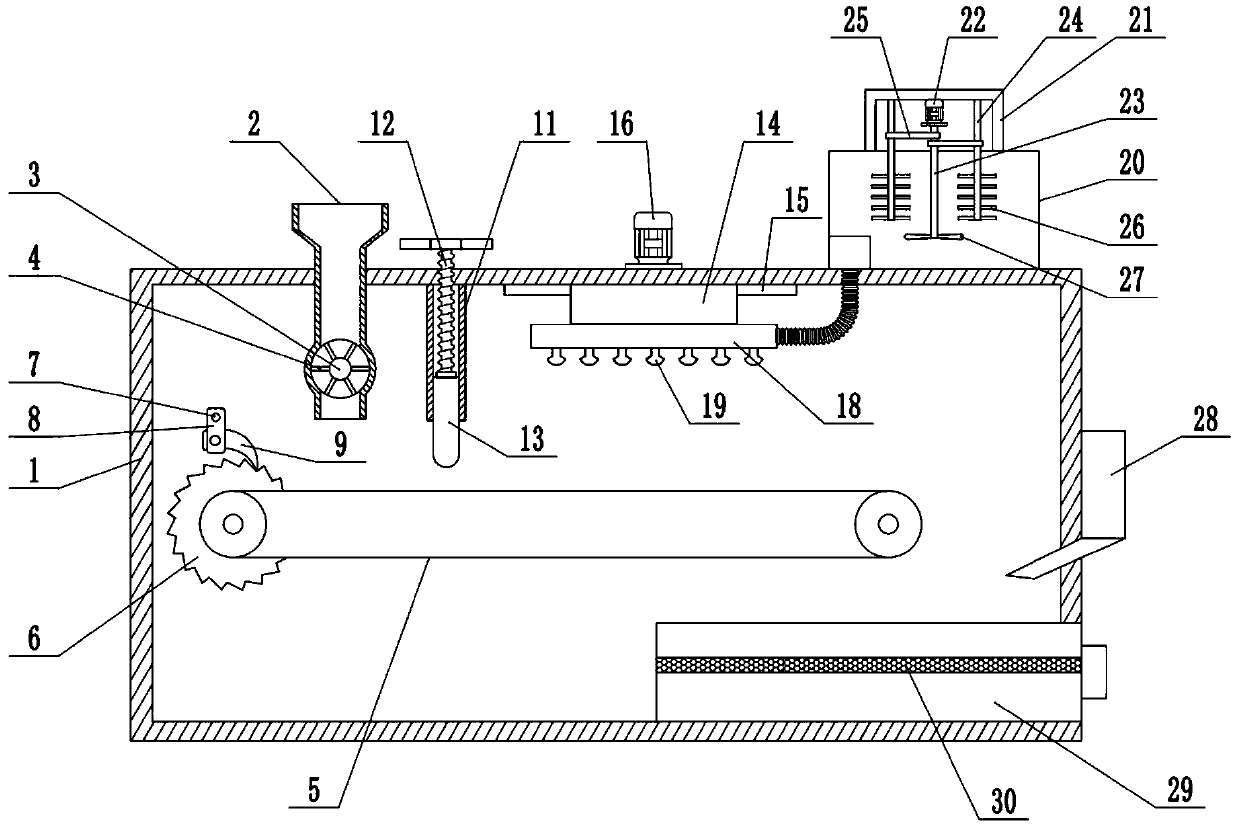

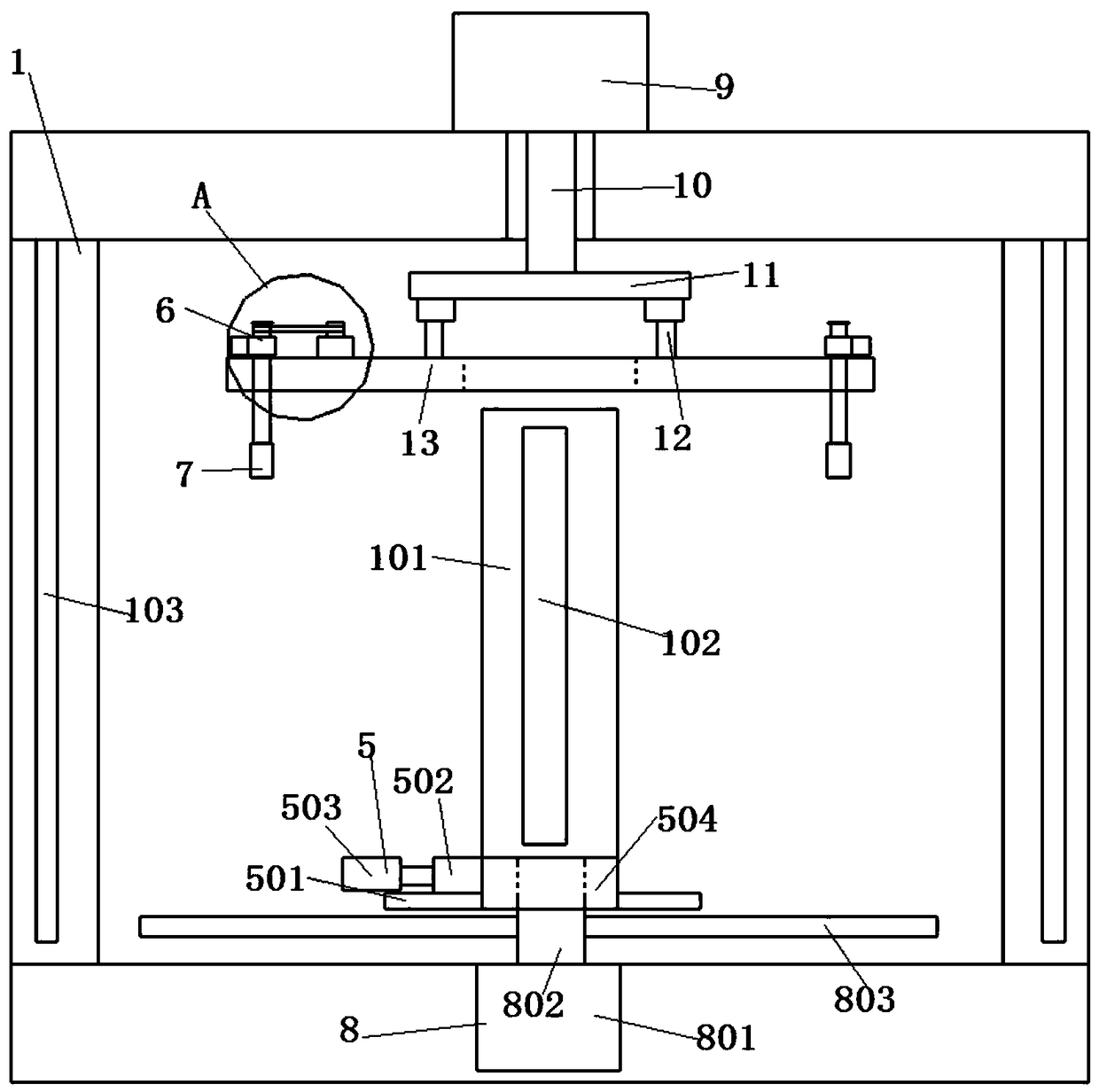

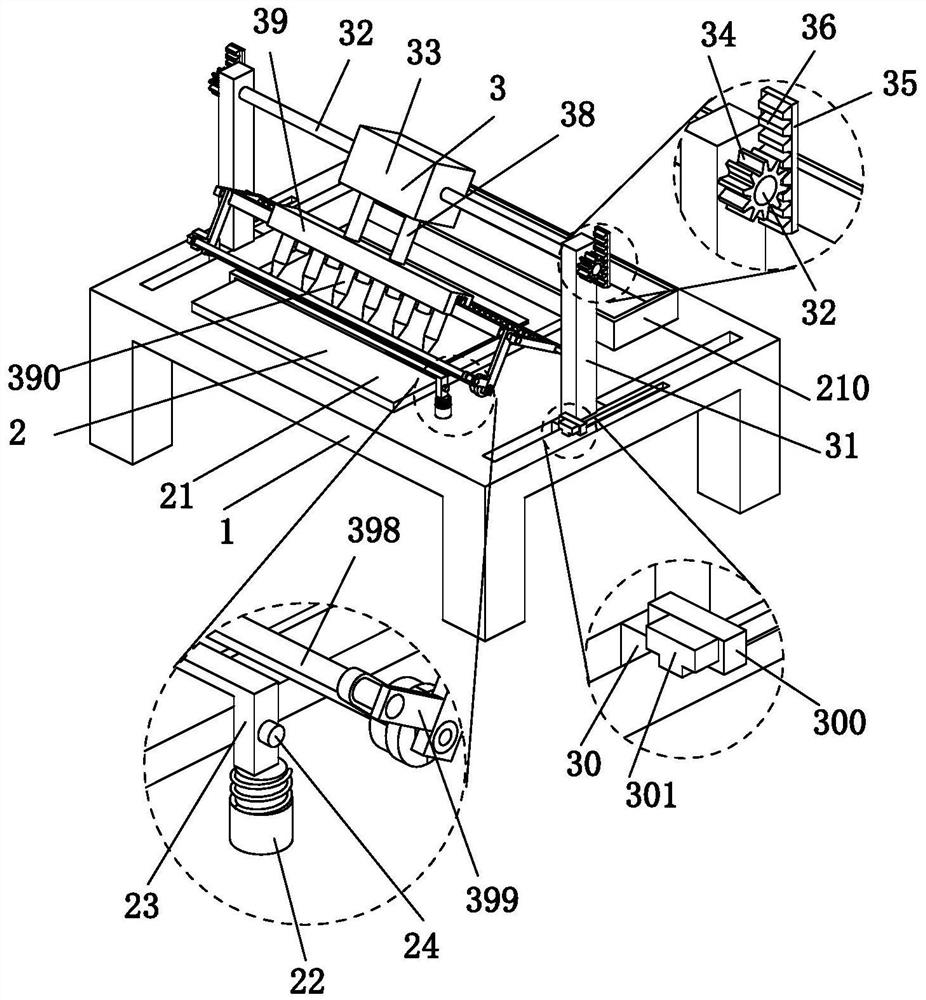

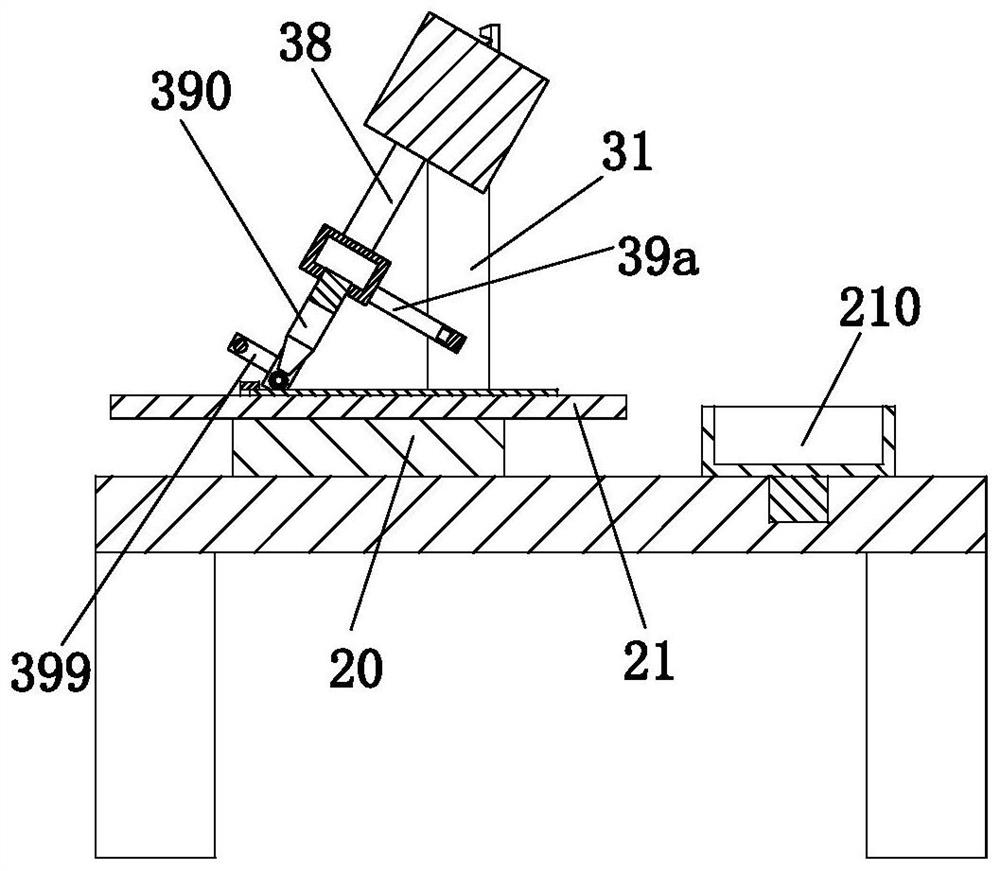

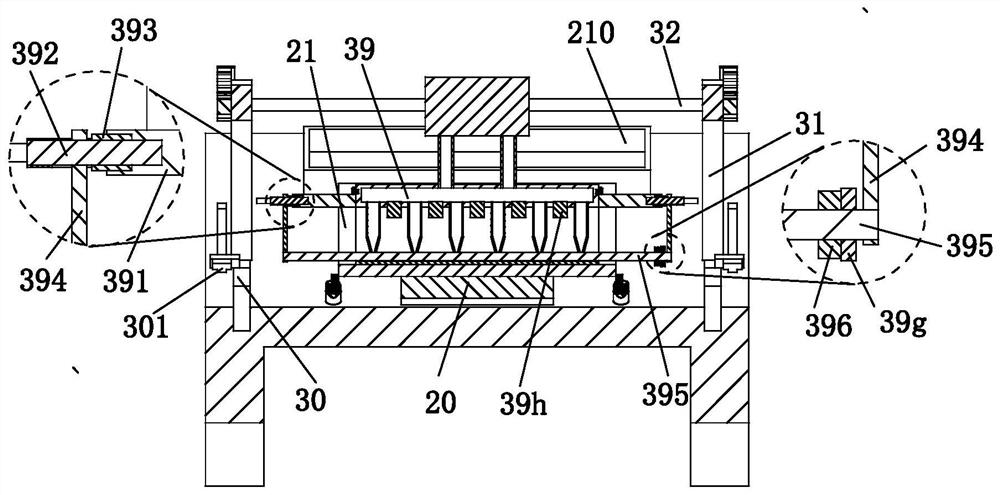

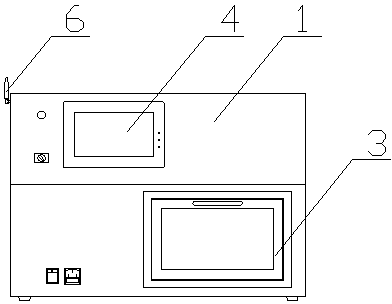

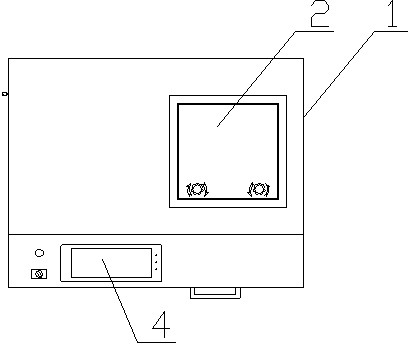

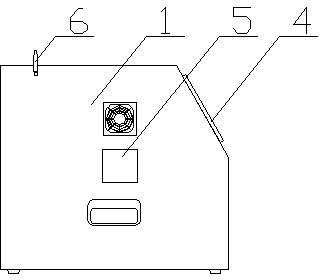

Automatic circuit board double-sided spraying equipment

The invention discloses automatic circuit board double-sided spraying equipment. The equipment comprises an equipment rack, an X-axis module, a Y-axis module, a Z-axis module, a conveying mechanism, aspraying mechanism and an overturning mechanism; the Y-axis module is fixedly mounted on the equipment rack, the X-axis module is mounted on the Y-axis module and driven by the Y-axis module to movefront and back; the Z-axis module is mounted on the X-axis module and driven by the X-axis module to move left and right; the spraying mechanism is mounted on the Z-axis module and driven by the Z-axis module to move up and down; the conveying mechanism is fixedly mounted on the equipment rack for conveying circuit boards; the overturning mechanism is fixedly mounted on the conveying mechanism andoverturns the circuit boards by 180 degrees; and the spraying mechanism is located above the overturning mechanism and coats the circuit boards. According to the equipment, the functions of a coatingmachine and a board overturning machine are integrated, double-sided coating can be conducted, the equipment cost is reduced, the equipment occupation space is reduced, and adjustment and later maintenance do not take a lot of time.

Owner:SHENZHEN HENGHU TECH CO LTD

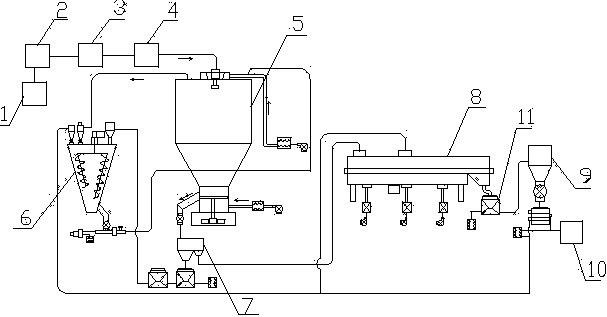

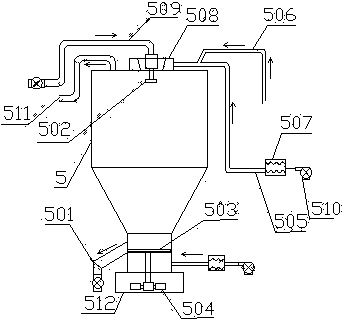

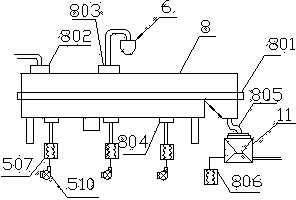

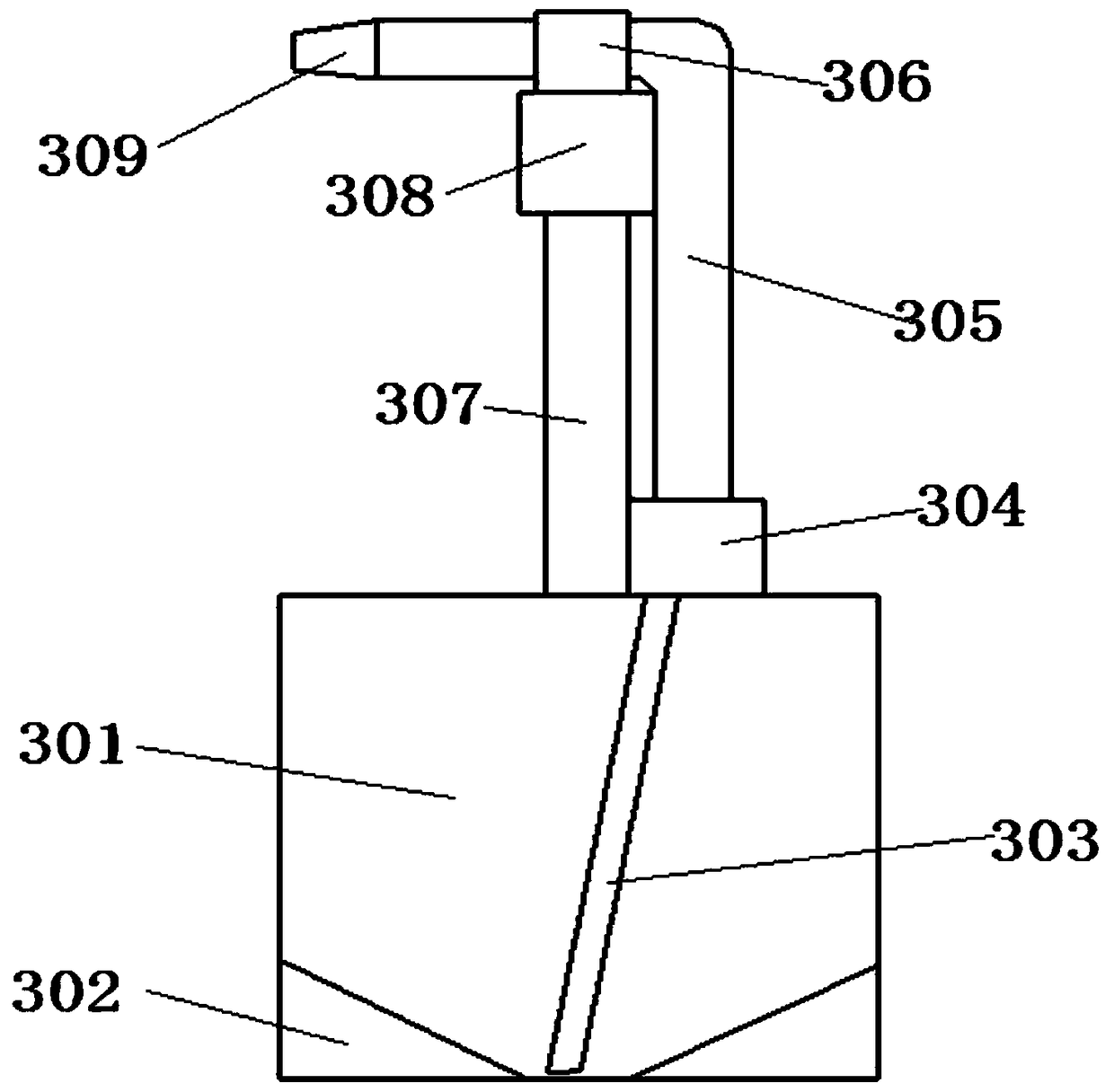

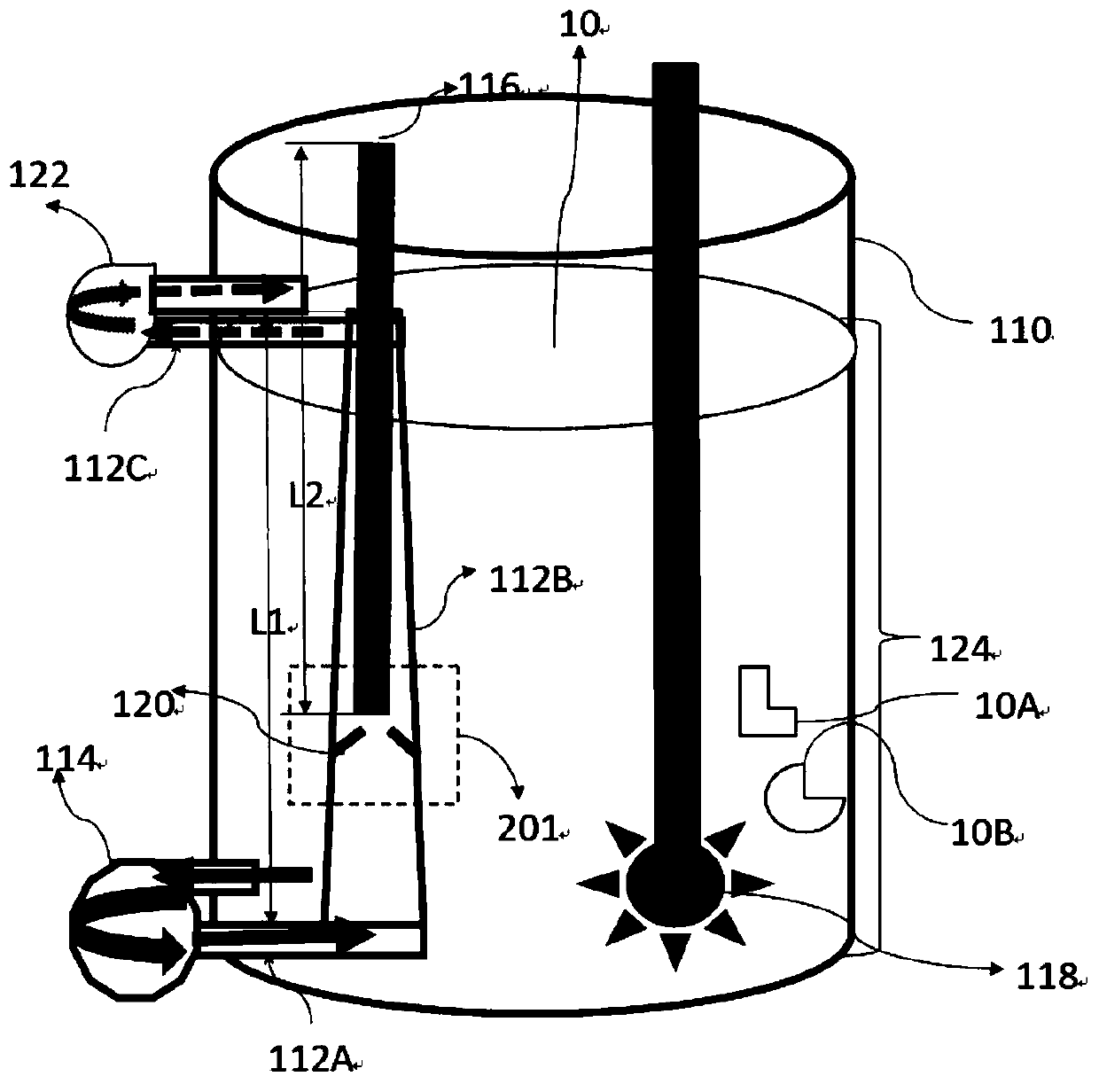

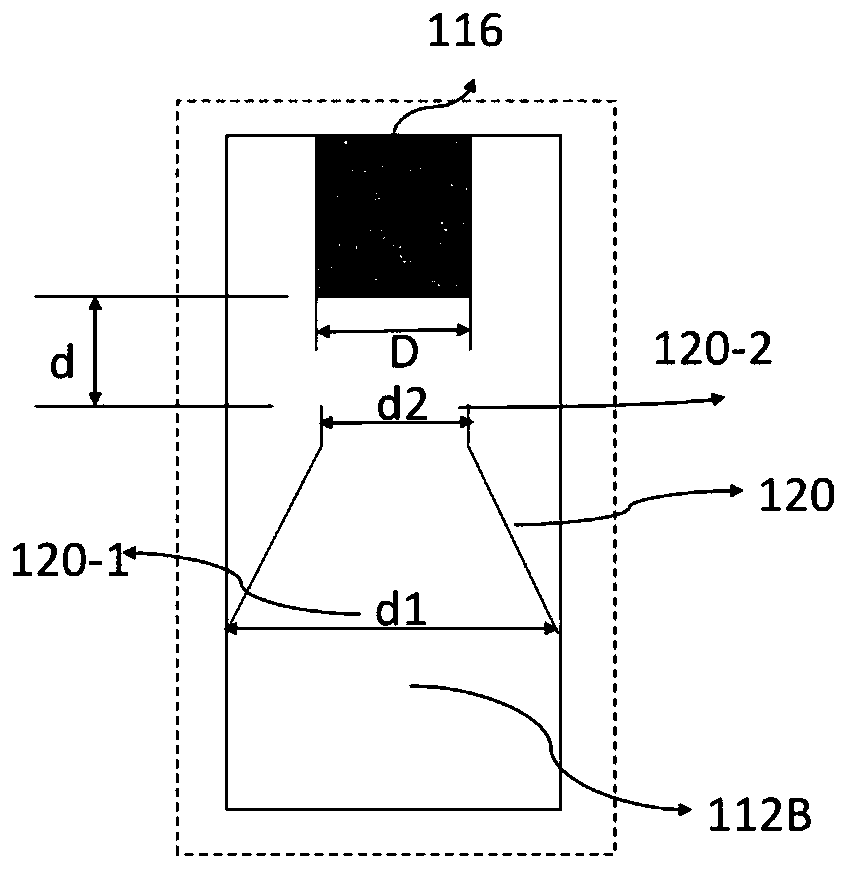

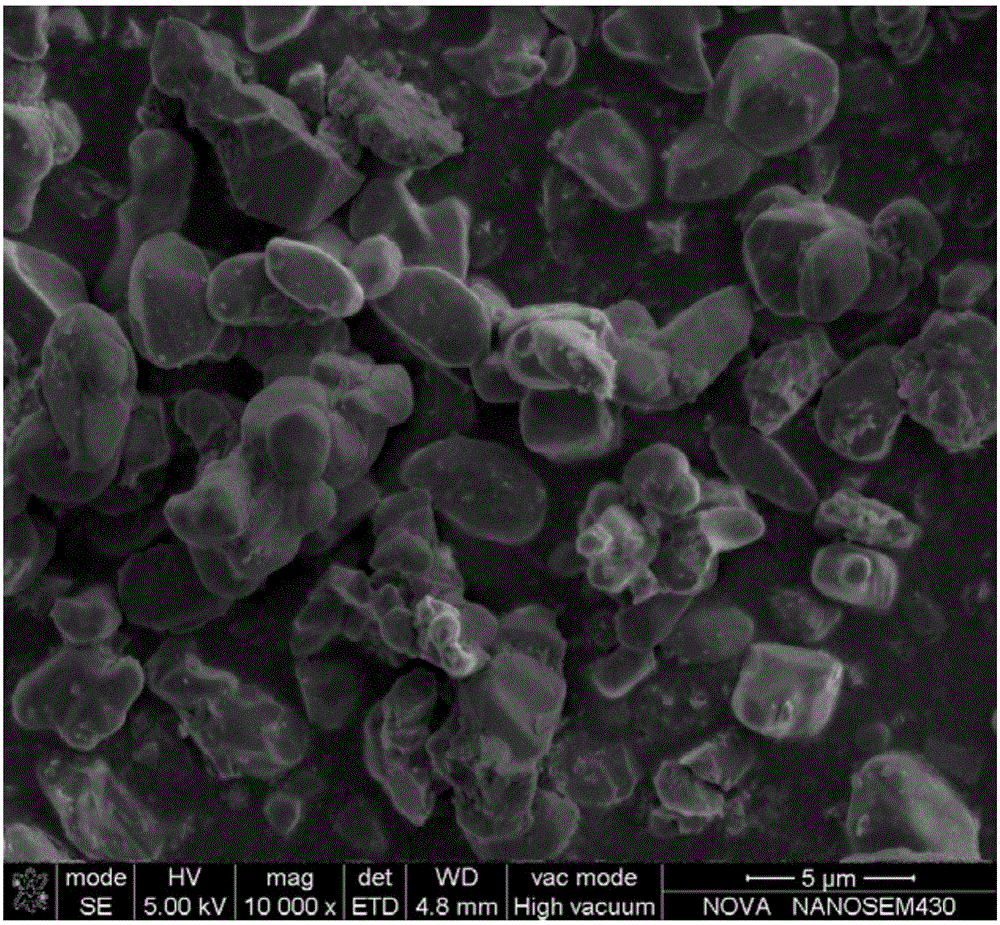

Preparation process and device of vitamin D3 microcapsule powder

ActiveCN104306353AImprove liquidityGreat tasteOrganic active ingredientsPressurized chemical processCalcium biphosphateSolubility

The invention relates to a preparation process and a preparation device of vitamin D3 microcapsule powder. In the preparation process, VD3 oil, sunflower seed oil or corn oil, medicinal starch, maltodextrin, modified starch, white sugar, calcium phosphate and 2,6-di-t-buty-4-methylphenol (BHT) are used as main raw materials. The preparation process and the preparation device are reasonably improved and optimized, the production time is greatly shortened and the whole production process is controlled; through layer-by-layer drying and step-by-step recycling, the prepared vitamin D3 microcapsule powder has smooth and flat surface, and the safety, the fluidity, the mouth feel and the water solubility of the vitamin D3 microcapsule powder are greatly improved; the waste of resources is reduced, the continuous large-scale production is implemented, and the production cost is reduced.

Owner:豆源和(山东)食品饮料有限公司

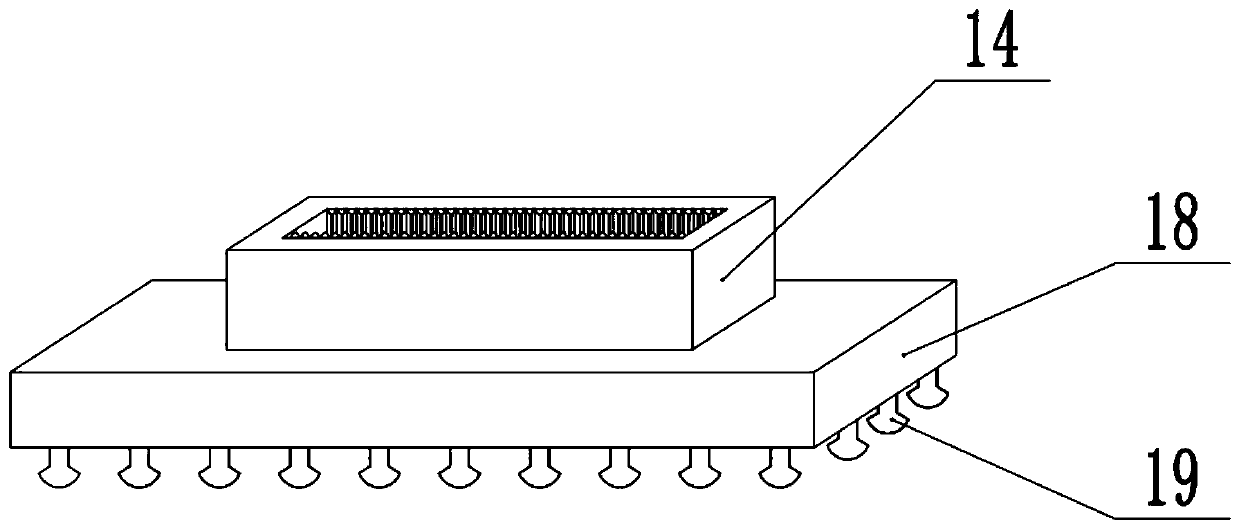

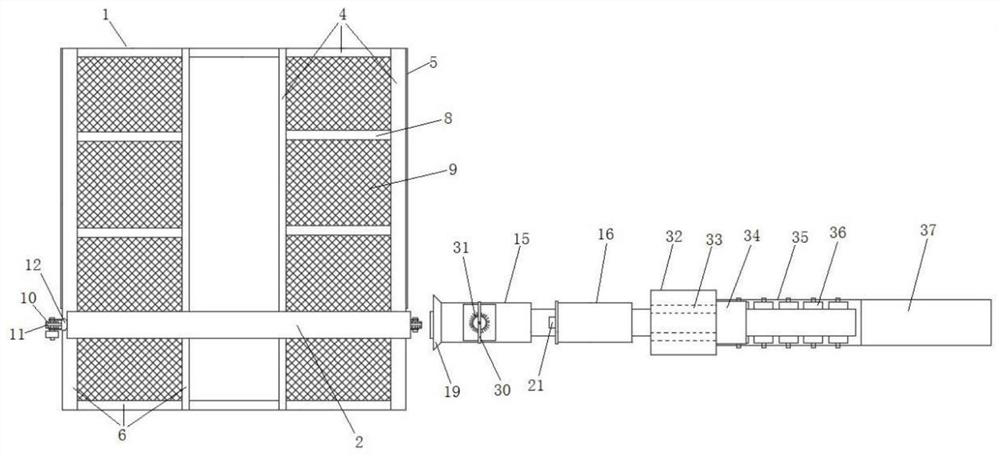

Spray type seed coating device

InactiveCN110235557AUniform feedingFull spraySeed coating/dressingSpray nozzleAgricultural engineering

The invention relates to the field of agricultural mechanical equipment, in particular to a spray type seed coating device. The device comprises a shell, a charging pipe, a conveyor belt and a liquid pesticide tank; the charging pipe is fixedly connected to the top of the shell, a uniform feeding mechanism is installed in the charging pipe, the conveyor belt is installed in the shell, an intermittent driving mechanism is installed at a driving end of the conveyor belt, a sliding rail is installed in the shell, a rack frame is slidingly connected to the sliding rail, a spray tray is fixedly connected to the lower surface of the track frame, and the liquid pesticide box is fixedly connected to the upper surface of the shell; by arranging the uniform feeding mechanism, seeds are scraped through a scraper to be spread on the conveyor belt; by means of a booster pump, a seed coating agent is conveyed to the spray tray by means of the booster pump, then the seed coating agent is uniformly sprayed to the seeds through a spray nozzle, and the seeds can make full contact with the seed coating agent, so that the coating operation is more uniform, in the coating operation process, the spray tray moves left and right, the spray range is expanded, and the seed coating agent can be more uniformly sprayed to the seeds.

Owner:周燕

Method for manufacturing nano-coating with microwave absorbing and radiation functions

InactiveCN103044981AIncrease concentrationFull coatingMagnetic paintsRadiation-absorbing paintsMaterial DesignMicrowave

The invention belongs to the field of material science, relates to a nanotechnology, a sol technology and a nano-film manufacturing technology and relative application, and discloses a method for manufacturing a nano-coating with magnetism and infrared radiation performance. According to the method, a material design technology is applied to designing and preparing nano-powder with special components and structure and magnetism and nano-powder with the infrared radiation performance, the nano-powder is mixed with nano-sol to prepare composite nano-sol which is coated on the surface of a base material, and after gel is cured, a nano-sol film is formed. The method can be suitable for being used on the surfaces of an organic polymer material, an inorganic nonmetallic material and a metal material, the base material is provided with the microwave absorbing performance and the infrared radiation performance, so that the method can be widely applied to the surface modification of various materials.

Owner:上海迪道科技有限公司 +1

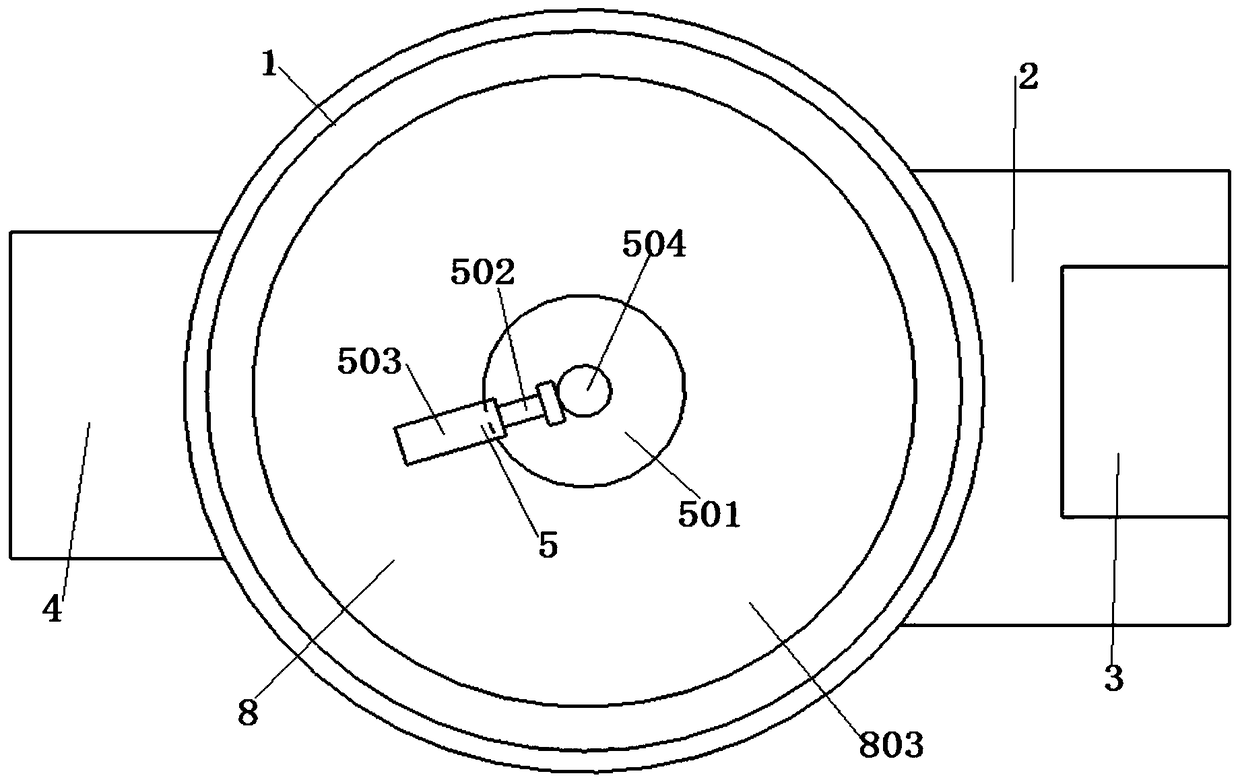

Protective spraying device for PCB (Printed Circuit Board)

ActiveCN109382241AEasy to relaxEasy clampingPretreated surfacesLiquid spraying apparatusEngineeringPrinted circuit board

The invention discloses a protective spraying device of a PCB, which comprises a drying cylinder, wherein a spraying chamber is fixedly welded on one side of the drying cylinder, a spraying mechanismis arranged in the spraying chamber, a discharge port is fixedly welded on the other side of the drying cylinder, a connecting plate and a rotating circular plate are arranged in the drying cylinder,the lower end surface of the drying cylinder is provided with an output component, the output component is fixedly connected with a path changing component, the drying cylinder is provided with a first motor, the output end of the first motor is connected with a first rotating shaft penetrating through the upper top surface of the drying cylinder, the lower end of the first rotating shaft is fixedly welded with a connecting plate, the lower part of the connecting plate is fixedly connected with the rotating circular plate through a first electric telescopic push rod, clamping components are evenly distributed at the upper edge position of the rotating circular plate, and a turnover component which is in transmission connection with the clamping components is arranged on the upper end surface of the rotating circular plate. The protective spraying device for PCB (Printed Circuit Board) is convenient for both the quick and highly effective coating and the quick and complete drying of thetwo sides of the coated PCB plate, so that the PCB is efficiently conveyed and the production efficiency of the PCB is improved.

Owner:ANHUI SHENZE ELECTRONICS TECH

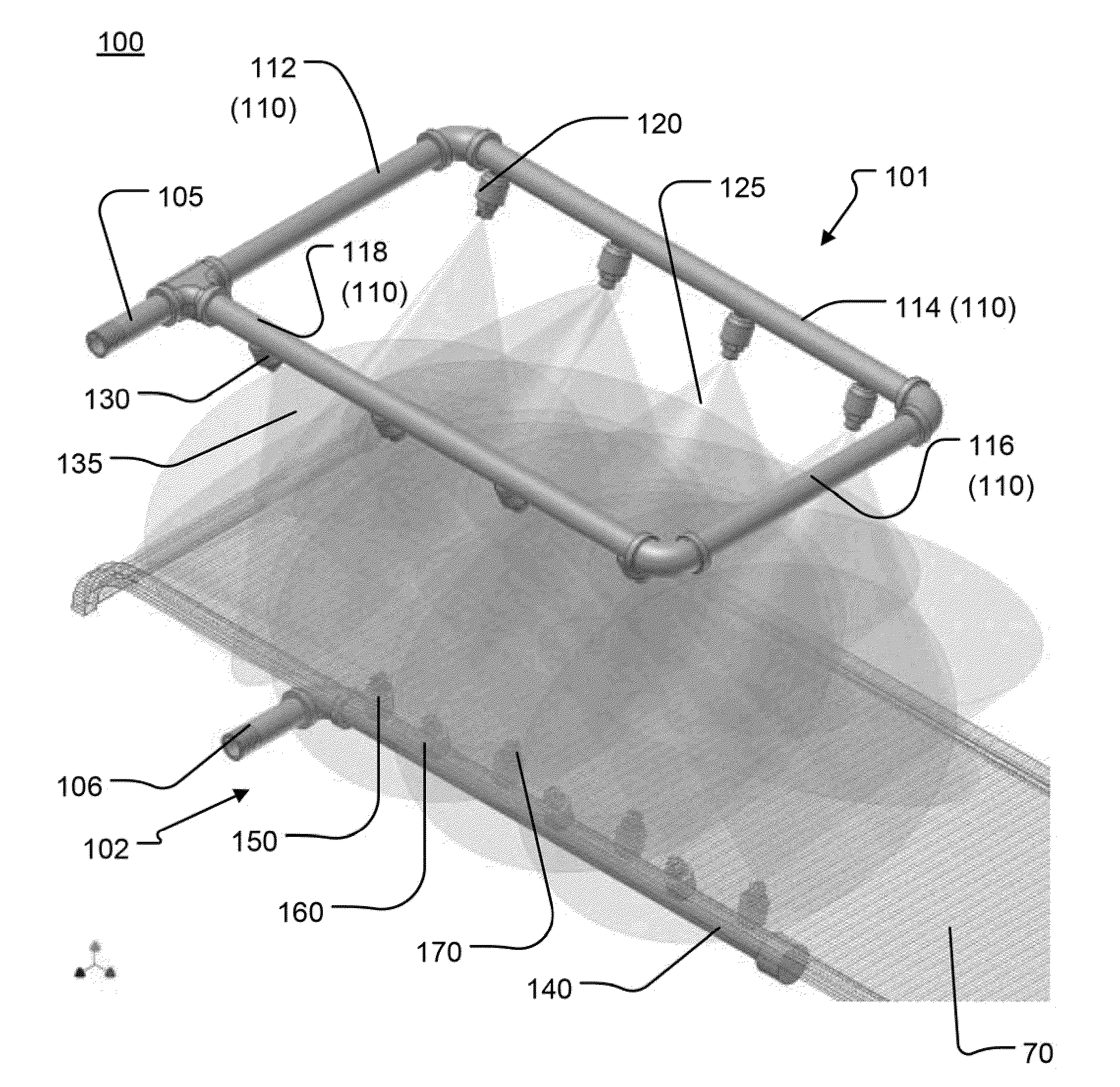

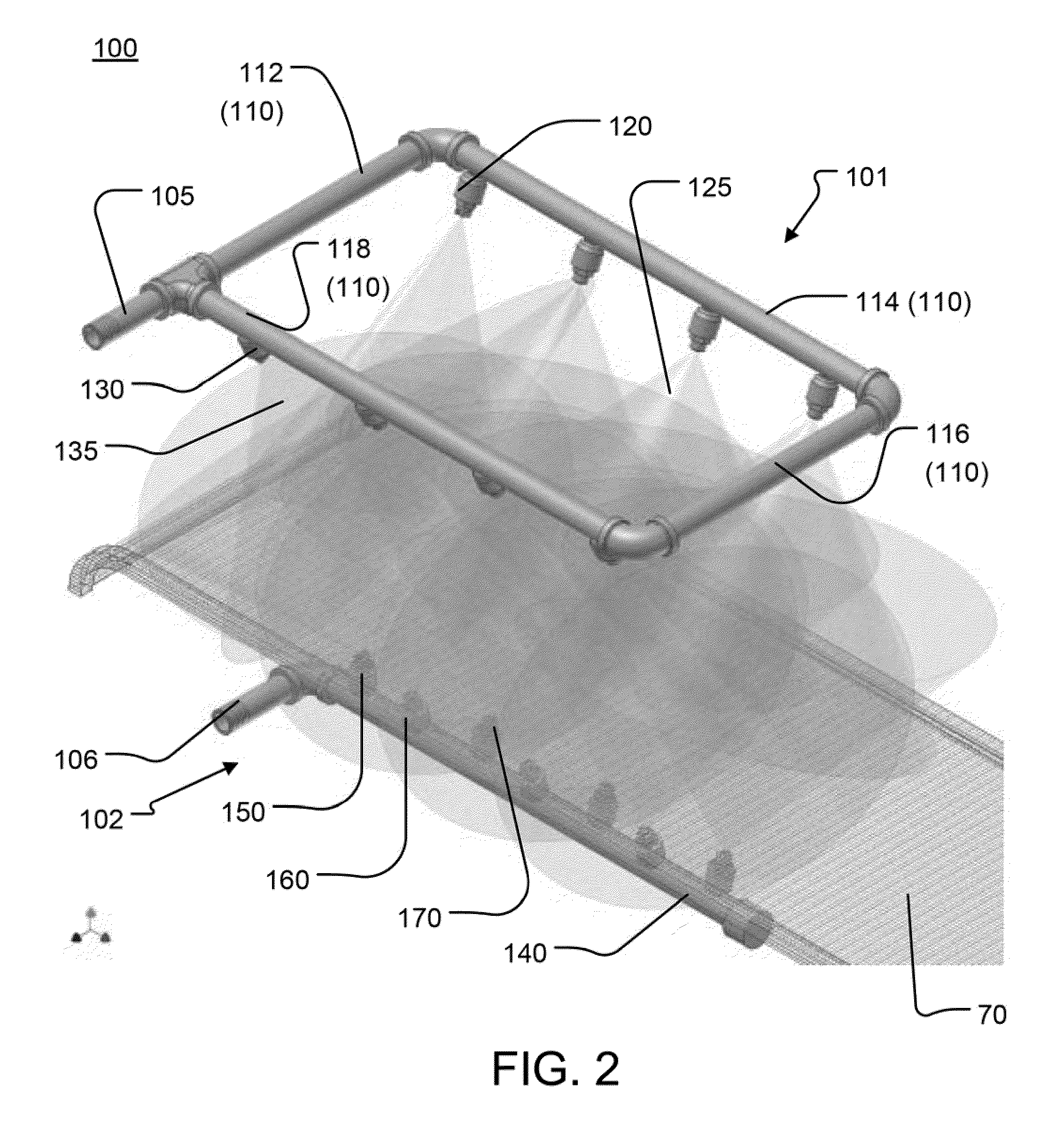

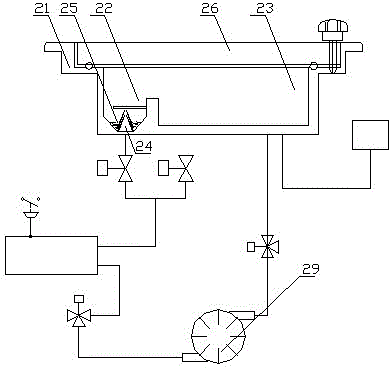

Integral intervention system

An intervention system for treating a food product in a food conditioner. The system comprises a tank that receives and buffers an intervention solution from a mixing system, a pump that receives the intervention solution from the tank and pressurizes the intervention solution to output a pressurized intervention solution, a flow monitor that receives the pressurized intervention solution from the pump and monitors a predetermined characteristic of the pressurized intervention solution, a first applicator that receives a first portion of the pressurized intervention solution from the flow monitor and ejects a first mist in the direction of the food product, and a second applicator that receives a second portion of the pressurized intervention solution from the flow monitor and ejects a second mist in the direction of the food product.

Owner:ROSS IND

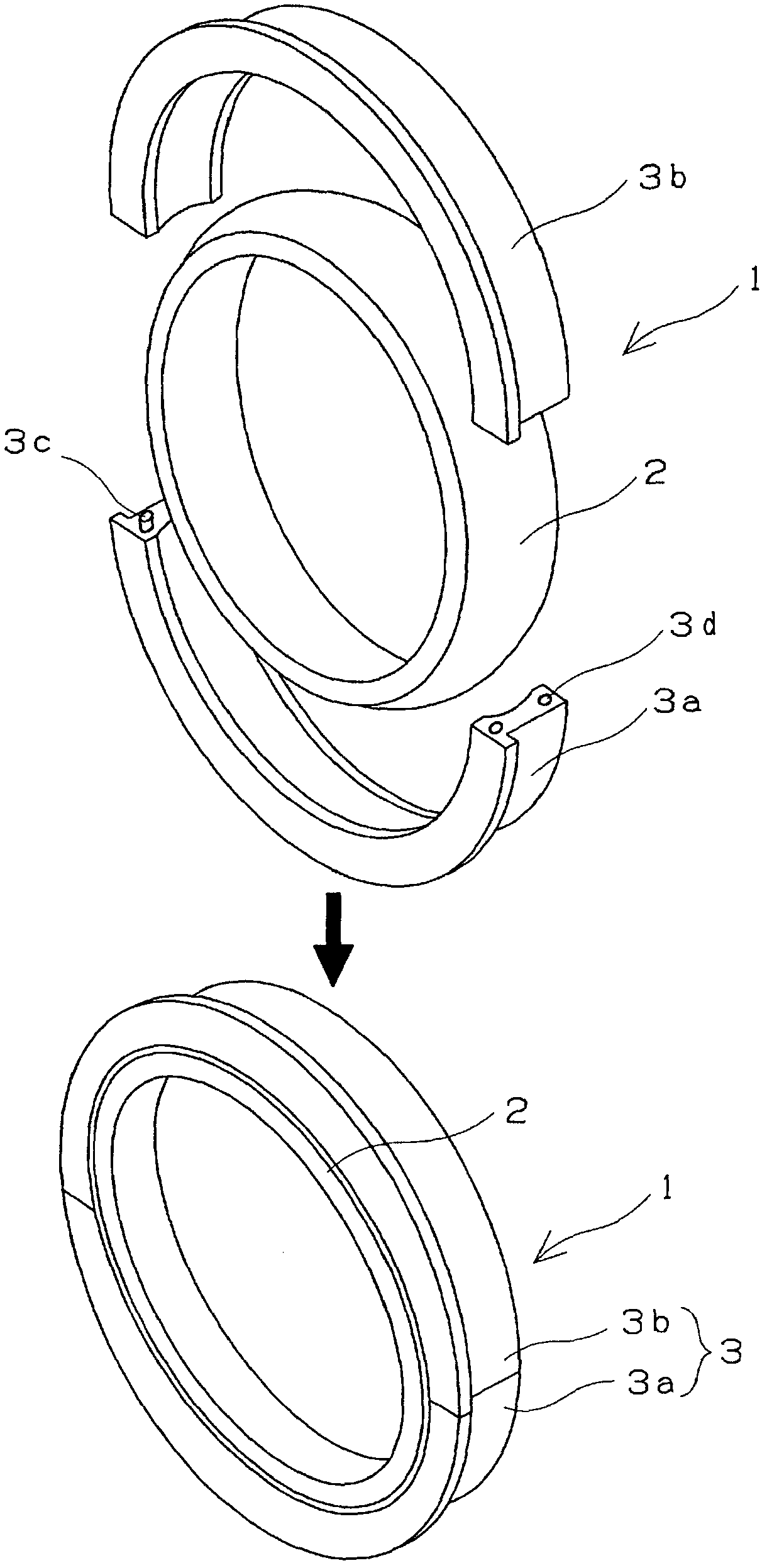

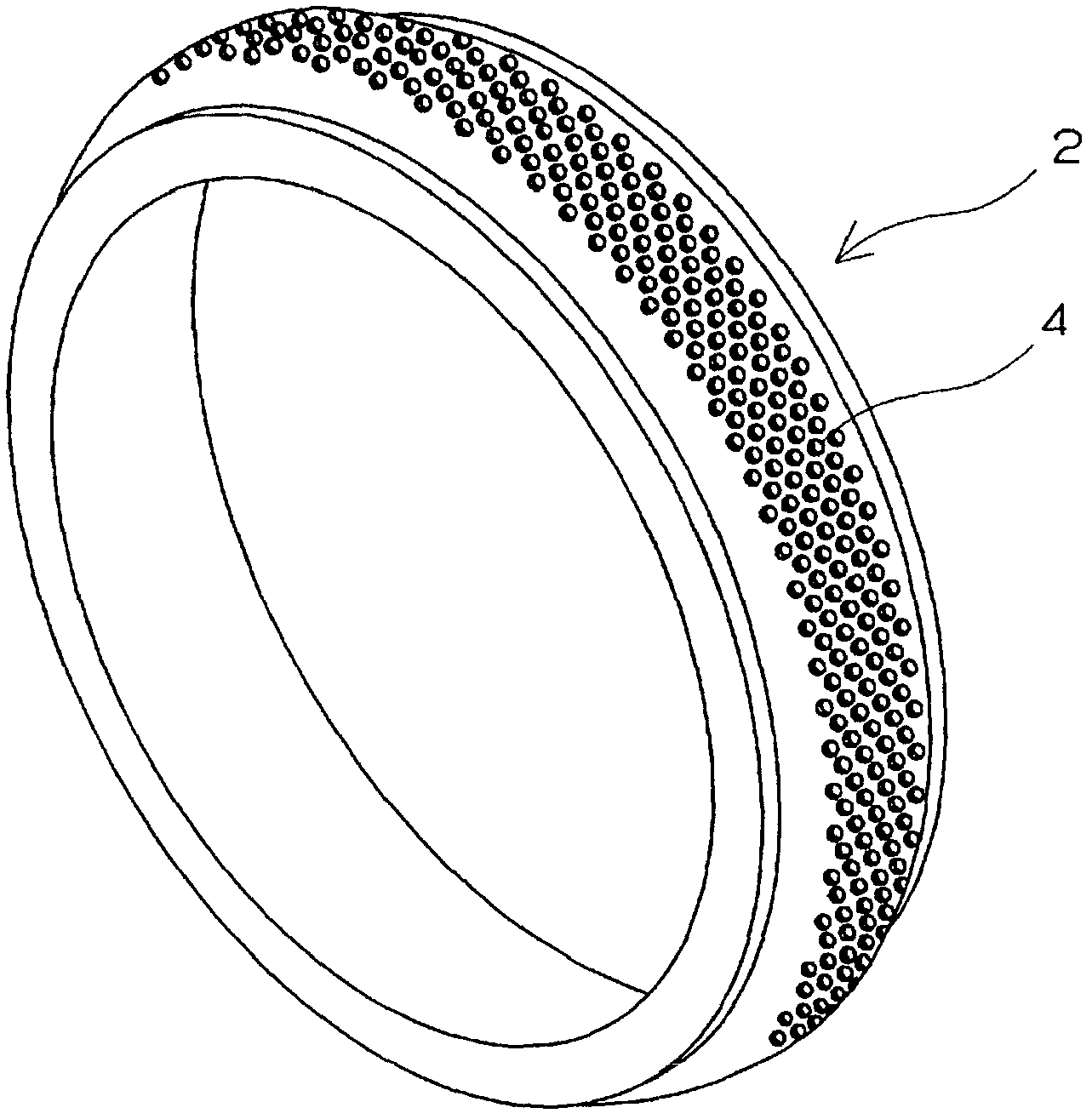

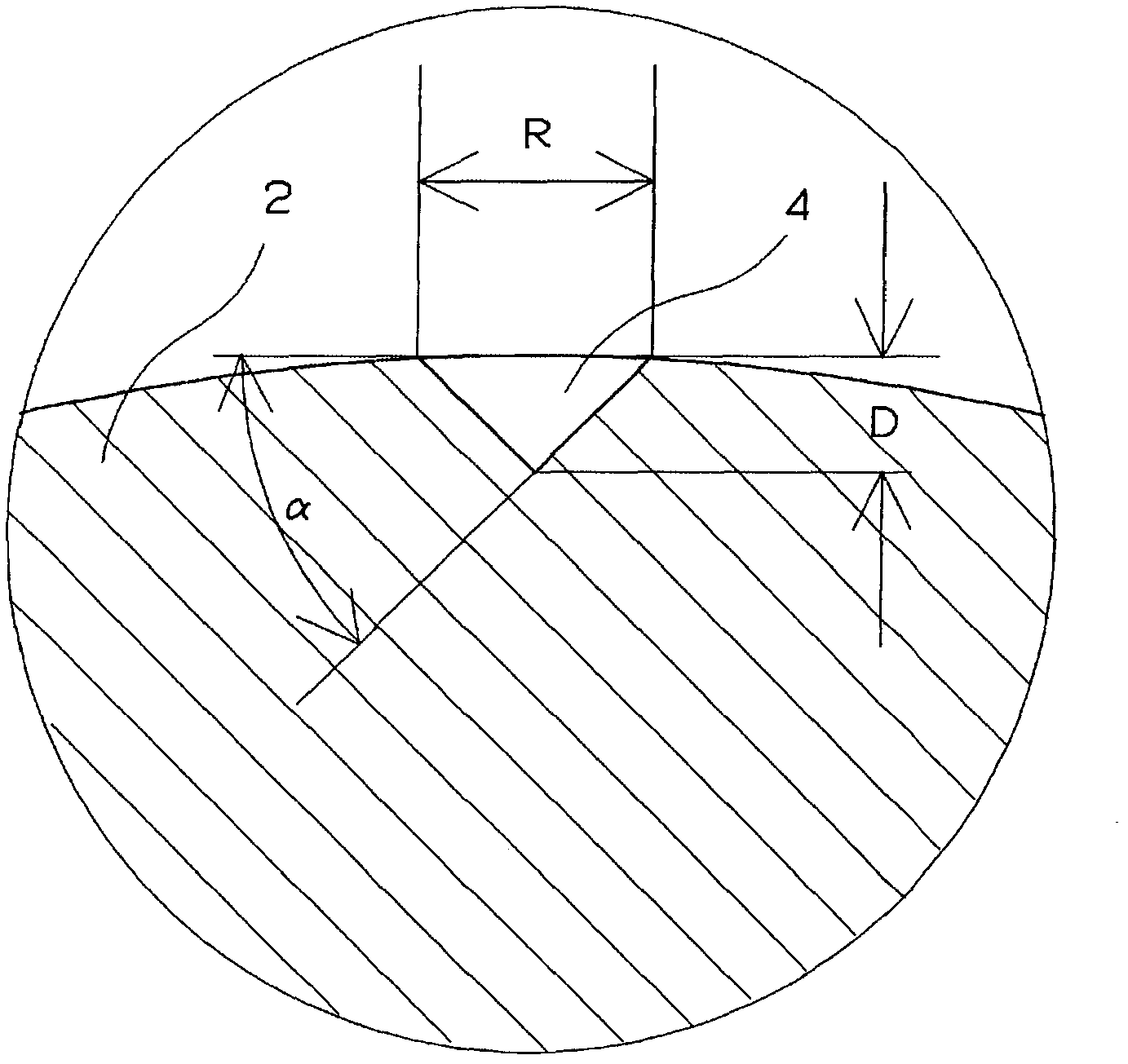

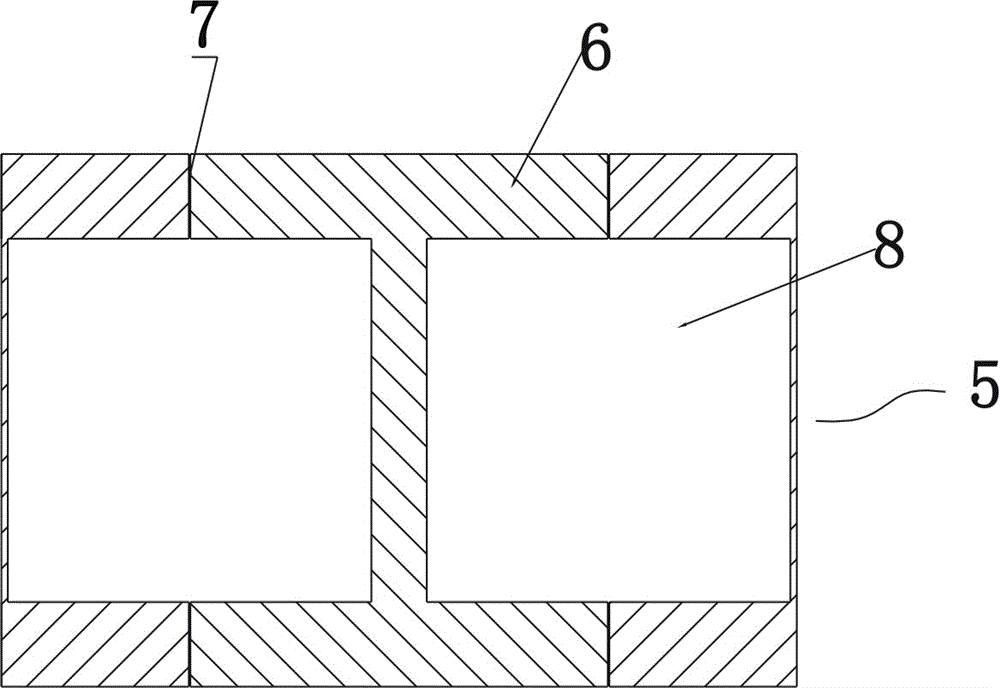

Slide bearing

InactiveCN102549281ASolution to short lifeLow thermal efficiencyShaftsBearing componentsEngineeringSliding contact

A slide bearing having a simple configuration and low friction torque. A slide bearing (1) for supporting heat rollers, such as a fixing roller and a pressing roller which are used for an image forming device, the slide bearing (1) comprising an outer ring (3) and an inner ring (2). Either the outer ring (3) or the inner ring (2) consists of resin, and the other consists of a sintered metal. The outer peripheral surface of the inner ring (2) is a convex surface, and the inner peripheral surface of the outer ring (3) is a concave surface corresponding to the convex surface. The outer ring (3) is bisected in the radial direction, and the inner ring (2) is sandwiched between the bisected halves of the outer ring (3). The inner peripheral surface of the outer ring (3) and the outer peripheral surface of the inner ring (2) are in sliding contact with each other.

Owner:NTN CORP

Method for manufacturing coating corrosion prevention heat exchanger

InactiveCN101214611AGood anti-corrosion effectEasy to checkAssembly machinesCorrosion preventionProcess engineering

The present invention discloses a fabrication method of a heat exchanger, in particular to a fabrication method of a heat exchanger with erosion-proof coats. The method includes the following steps: (1) parts composing the heat exchanger are processed according to the requirements of a design; (2) the processed parts are coated with erosion-proof coats; (3) after the erosion-proof coats are solidified, the quality of the erosion-proof coats is checked; (4) the parts are assembled, and a heat-exchanging pipe and pipe plates are fixed by applying a method of splicing. Compared with the prior art, because each part composing the heat exchanger first undergoes the erosion-proof process before assembly, the coating of the erosion-proof coat of each part of the heat exchanger produced by the method is thorough, the range of usable coats is wider, the phenomenon of deficiency does not exist, the erosion-proof effect is good, the examination of the erosion-proof quality of the coats is easy, the service life of equipment is long, and the cost of operation is low.

Owner:王玉红

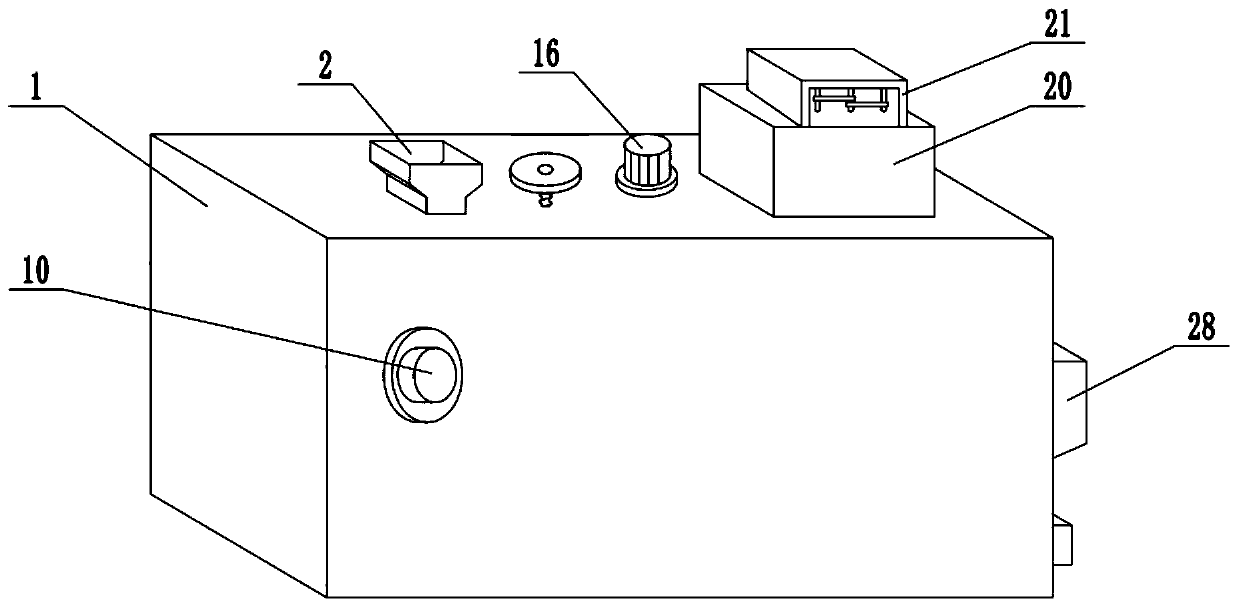

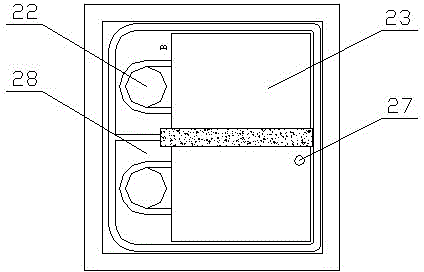

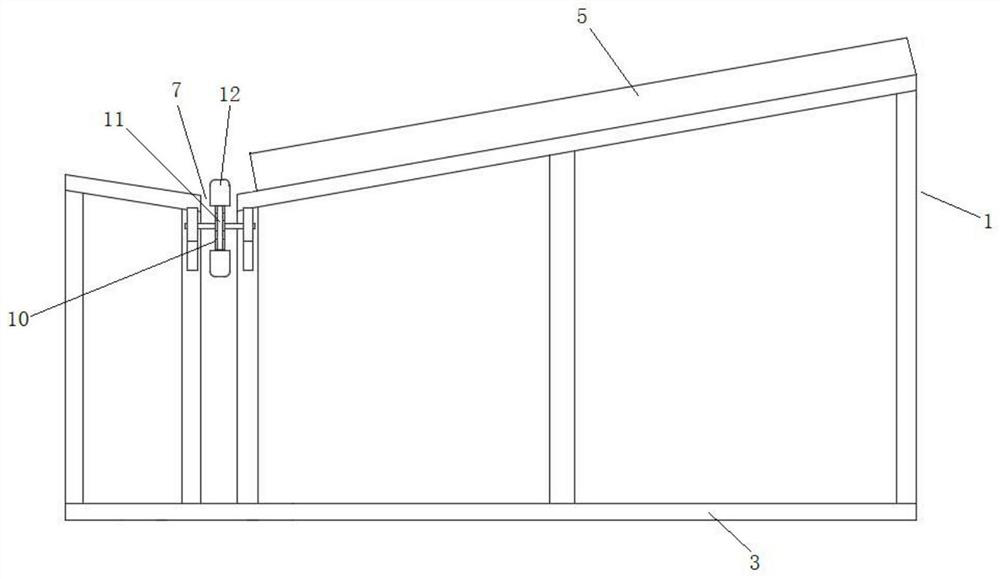

Disposable heating patch gluing processing system

InactiveCN113182113AReduce wasteQuickly adjust the spraying rangeLiquid surface applicatorsSpraying apparatusAdhesiveProcess engineering

The invention relates to a disposable heating paste gluing processing system. The disposable heating paste gluing processing system comprises a workbench, a placement unit and a gluing mechanism, the placement unit is arranged at the upper left end of the workbench, and the gluing mechanism is arranged at the upper right end of the workbench. The disposable heating paste gluing processing is conducted by adoption of a multi-control design concept, the spraying height can be adaptively adjusted through the gluing mechanism according to the thickness size of the middle of the heating patch, the waste rate of an adhesive can be reduced, and meanwhile the spraying range of the adhesive can be rapidly adjusted according to the size of the heating patch due to the movable combination connection mode.

Owner:江苏恬然环保科技发展有限公司

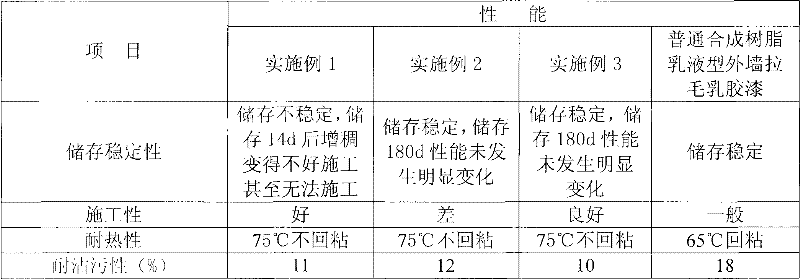

A kind of composite elastic brushed exterior wall latex paint composition composed of silica sol-polyacrylate emulsion

The invention belongs to a brushed latex paint applied to building exterior wall decoration. The latex paint is made of elastic polymer emulsion and silica sol as main raw materials. In order to improve the heat resistance, stain resistance and aging resistance of the synthetic resin emulsion type exterior wall brushed latex paint, the present invention adds silica sol in the formula, so that the organic exterior wall brushed latex paint becomes an organic-inorganic composite latex paint. This composite brushed latex paint for exterior walls has the comprehensive performance advantages of heat resistance, stain resistance, aging resistance of inorganic coatings and high bonding strength of organic coatings, stable storage and good paintability. In order to solve the storage of the exterior wall brushed latex paint after adding silica sol, add ammonia (or AMP-95 multifunctional additive) and OP-10 emulsifier or commodity wetting agent in the formula; Construction performance, adding high-viscosity cellulose ether to the formula to replace the ordinary viscosity cellulose ether currently used in exterior wall brushed latex paint.

Owner:ANHUI INST OF BUILDING RES & DESIGN

Method for manufacturing ultra-thin nano-coating for surface modification of organic polymer material

InactiveCN103013191AIncrease concentrationFull coatingLiquid surface applicatorsCoatingsMicro nanoLow temperature curing

The invention discloses a method for manufacturing an ultra-thin nano sol film, which is applied to the surface of an organic polymer material, can stably store micro-nano sol for a long period of time, and can be cured at low temperature. The invention discloses a correlation technique for stably storing the sol for a long period of time, curing the sol film at low temperature and obtaining the ultra-thin nano coating. The nano sol and the ultra-thin nano film disclosed by the invention can improve the surface property of the organic polymer material, so that the nano sol and the ultra-thin nano film have excellent properties such as high hardness, rub resistance, scratching resistance, chemical resistance and weather fastness, dirt resistance and water repellency and the like.

Owner:上海迪道科技有限公司 +1

Organic silicon modified cationic light cured alicyclic epoxy resin paint and application thereof

ActiveCN107936746AImprove toughnessImprove waterproof and antifouling performancePretreated surfacesCoatingsUltraviolet lightsReactive diluent

The invention discloses organic silicon modified cationic light cured alicyclic epoxy resin paint and application thereof. The paint comprises the following components: 70 to 100 parts of alicyclic epoxy prepolymer, 1 to 25 parts of organic silicon modified alicyclic epoxy monomer, 0 to 15 parts of a reactive diluent, 0.2 to 1 part of a defoamer, 0.3 to 1 part of a flatting agent, and 0.1 to 2.5 parts of a cationic photoinitiator. The paint has the advantages that acrylic ester is copolymerized into alicyclic epoxy resin prepolymer, and flexible groups are led into the alicyclic epoxy resin prepolymer, so that the toughness is improved; in addition, the organic silicon modified alicyclic epoxy monomer is added, the surface performance and the water and stain resistance of the paint are improved. The paint can be rapidly crosslinked after being irradiated by ultraviolet light, and is energy-saving and efficient. The cured paint has excellent adhesive force and water and stain resistance.

Owner:NANXIONG MATERIAL PRODION BASE OF CHINESE ACADEMY OF SCI GUANGZHOU CHEM +2

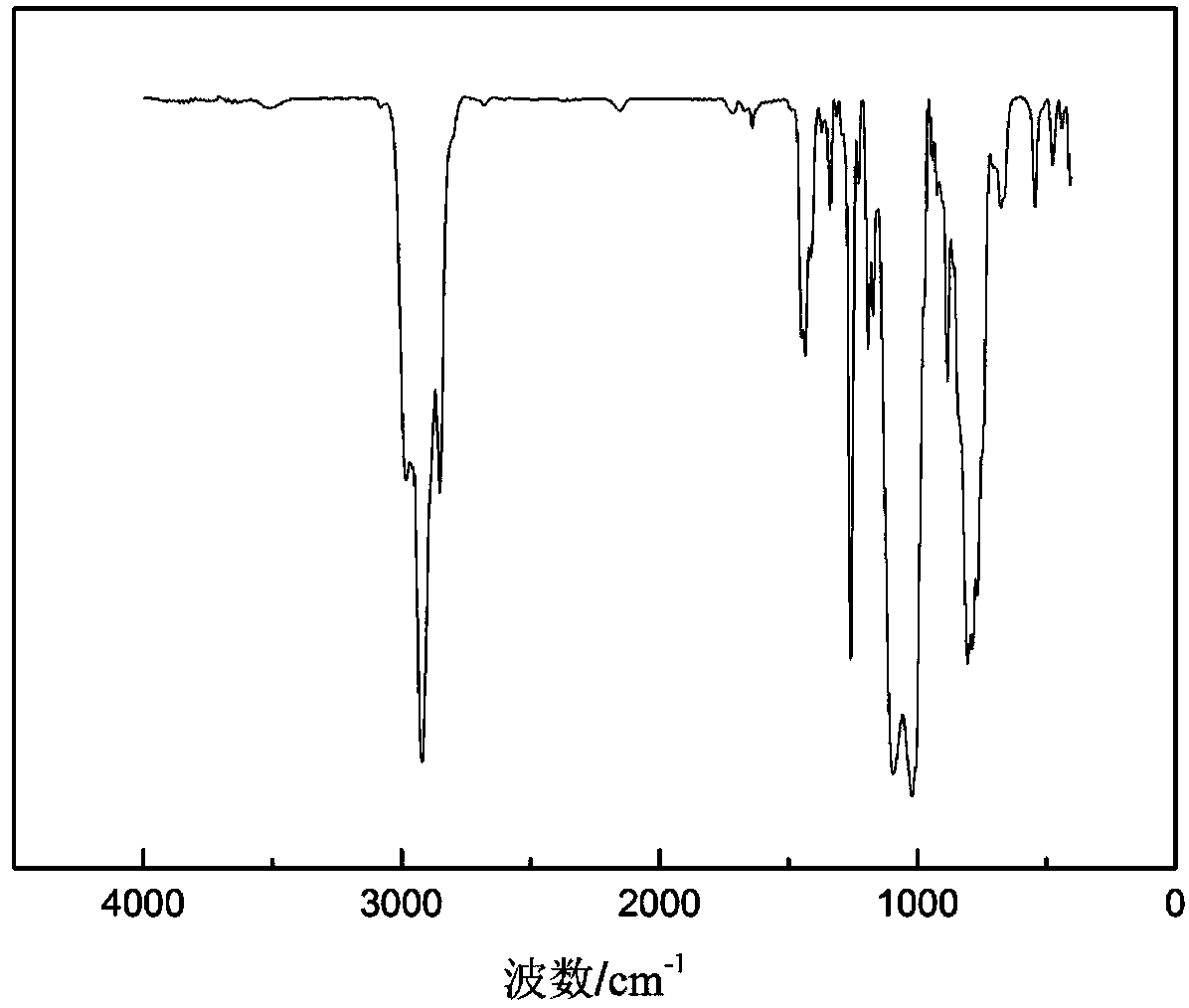

Anticorrosion high-temperature resistant coating and preparation method thereof

ActiveCN104212299AExtended service lifeImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention discloses an anticorrosion high-temperature resistant coating. The anticorrosion high-temperature resistant coating is prepared from the following components in percentage by weight: 15-18 percent of epoxy resin, 35-38 percent of petroleum resin, 12-15 percent of a resin plasticizer, 2-4 percent of a surfactant, 17-20 percent of a solvent, 3-5 percent of a multi-functional auxiliary, 0.6-0.9 percent of composite rare earth and the balance of modified acrylic resin. The invention also discloses a preparation method of the anticorrosion high-temperature resistant coating. Therefore, the anticorrosion high-temperature resistant coating has corrosion resistance and high-temperature resistance, is long in service life and does not have the problems of blistering, cracking, white specks, delamination and the like.

Owner:JIANGSU MARINE VICTORY COATING

Nicotinamide mononucleotide and herbal extract microcapsule with limited component proportion and preparation device thereof

InactiveCN111387481AHigh activityPromote generationRotary stirring mixersTransportation and packagingBiotechnologyImmune resistance

The invention discloses a nicotinamide mononucleotide and herbal extract microcapsule with limited component proportion. The capsule can maximize the immune resistance function. The preparation devicecomprises a container for accommodating nicotinamide mononucleotide, herbal active extract and an extraction solvent, and a return pipe, wherein the return pipe is provided with a feeding pipe, a delivery pipe and a connecting pipe; and a necking assembly is arranged in the connecting pipe. The device also comprises an ultrasonic assembly arranged in the connecting pipe, which can generate ultrasonic waves to quickly and uniformly mix the nicotinamide mononucleotide and herbal active extract in the mixed solution. The novel preparation process is utilized to uniformly fuse the herbal plant concentrated solution and excipient / emulsifier by a microencapsulation technique, thereby being different from the traditional excipient or emulsifier which is only coated on the outer layer, enhancingthe functional component proportion, lowering the excipient content and increasing the bioavailability requirements of the nicotinamide mononucleotide and herbal active extract.

Owner:山海昌容有限公司

Waterproof coating device

InactiveCN104338656AFast dryingImprove effectivenessPretreated surfacesCoatingsAirflowHOLDING CHAMBER

The invention relates to a waterproof coating device, which comprises a machine body; an atomization device and a drying unit are arranged in the machine body; the atomization device comprises an atomization box; the top part of the atomization box is provided with a seal cover body; a liquid drug holding chamber and a coating chamber which are communicated with each other are arranged in the atomization box; at least one drug pool is arranged in the liquid drug holding chamber; the bottom in the at least one drug pool is provided with an atomizer; a liquid nanometer high-molecular material is held in the at least one drug pool; one or more than one air exhaust hole is formed in the coating chamber; the one or more than one air exhaust hole is connected with an evacuating device; the atomizer, the one or more than one air exhaust hole and the evacuating device form an airflow loop. By utilizing the drying unit, atomized liquid drug is promoted to be further concentrated, and the drying rate of a coating is accelerated; the effective component content and the uniformity of the coating are improved; the simultaneous, uniform and moderate coating on the interior and the outer surface of an electronic product is facilitated to the maximum degree, and the coating effect is good.

Owner:JIANGSU LIQUID NANO TECH DEV

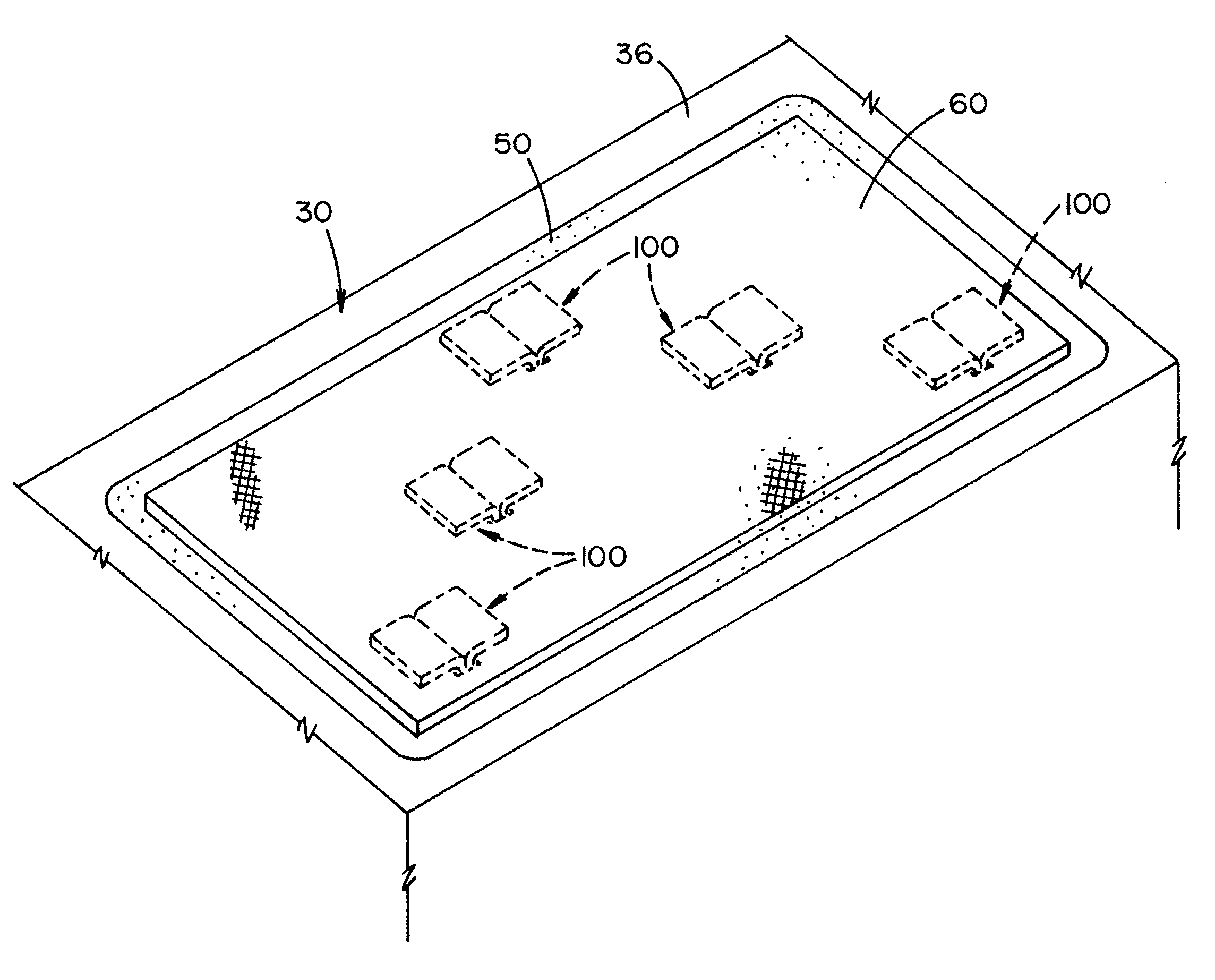

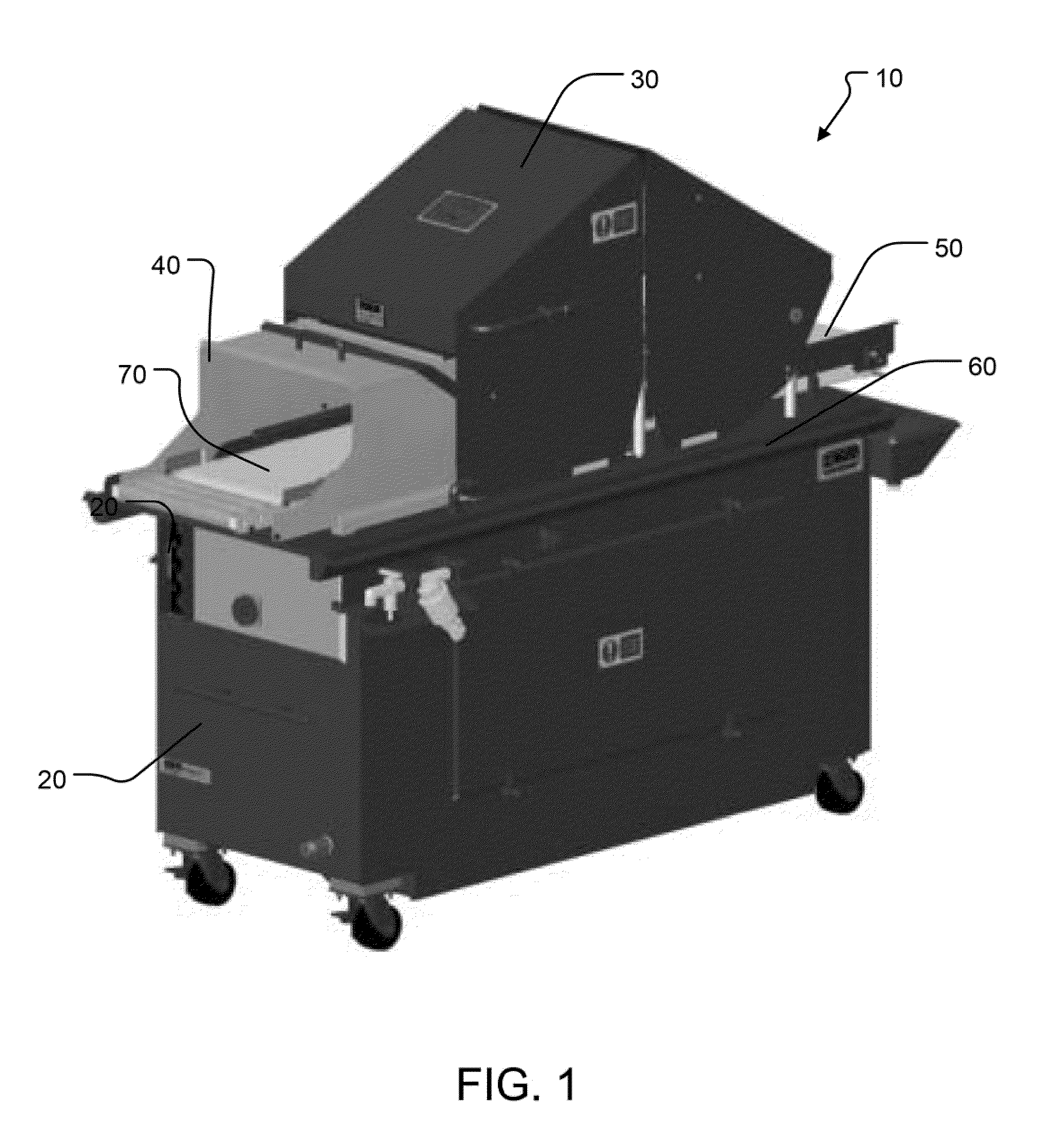

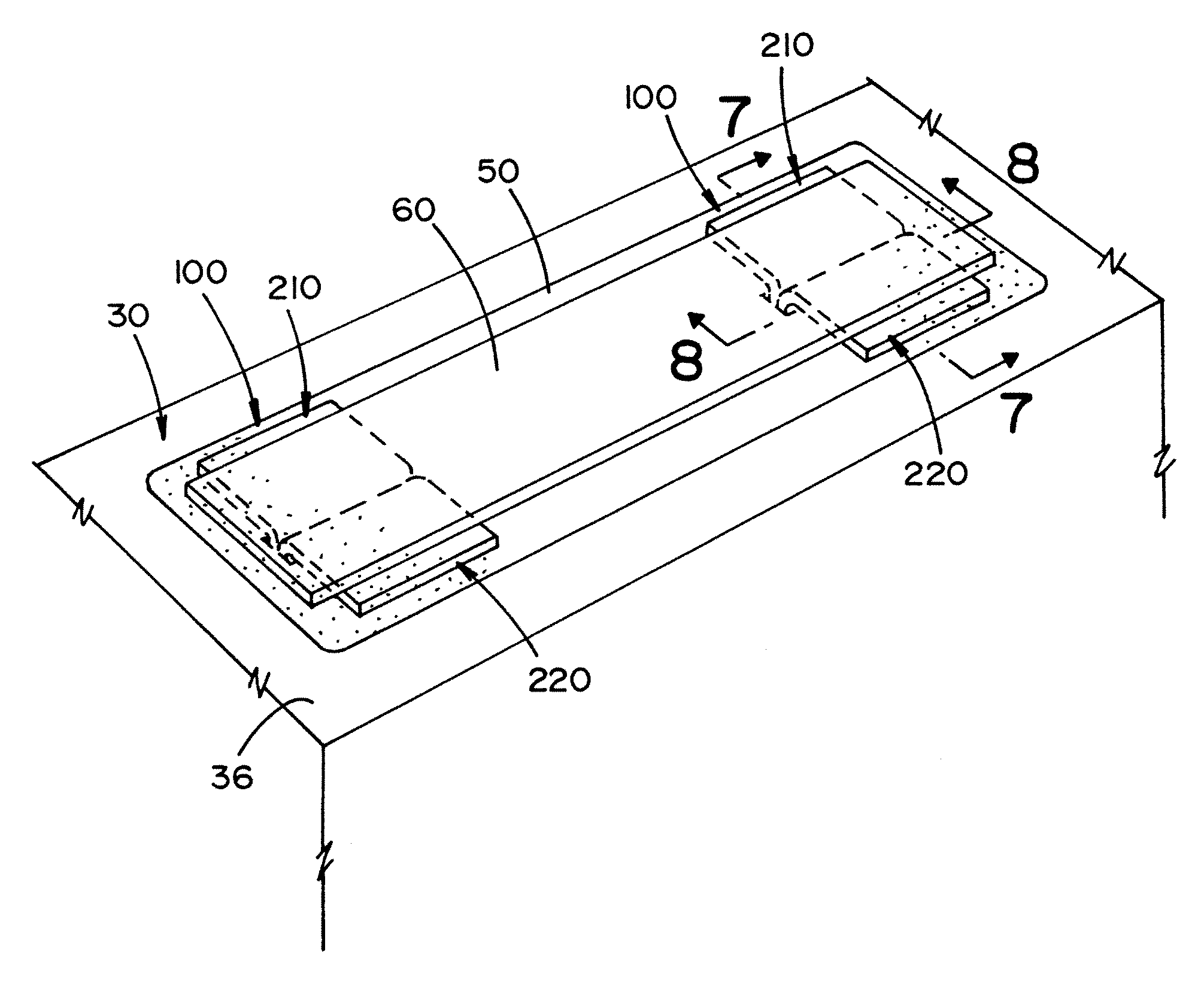

Method and apparatus for repairing concrete

ActiveUS9194140B2Easy to implementLess expensiveBuilding repairsFoundation repairArchitectural engineeringRebar

Owner:GARLAND INDS

Atomizing film plating device

InactiveCN104384040AFast dryingImprove effectivenessLiquid surface applicatorsLiquid spraying apparatusLiquid stateMolecular materials

The invention relates to an atomizing film plating device. The atomizing film plating device comprises an atomizing box, wherein a sealing cover body is arranged at the top of the atomizing box; the atomizing box is internally provided with a liquid medicine storing room and a film plating room which are communicated with each other; the liquid medicine storing room is internally provided with more than one medicine tank; an atomizer is arranged at the bottom in each medicine tank; a liquid-state nano high molecular material is contained in each medicine tank; the film plating room is internally provided with one or more than one exhausting hole; each exhausting hole is connected with a vacuumizing device; an air flow loop is formed by the atomizer, the exhausting hole and the vacuumizing device. According to the atomizing film plating device, a drying device is utilized so that atomized liquid medicine is further concentrated and the drying speed of a coating is accelerated, and the content of effective components of a coated film and the uniformity are improved; the simultaneous, uniform and proper coating of the inner part and the outer surface of an electronic product can be promoted to the greatest extent, and the film plating effect is good.

Owner:JIANGSU LIQUID NANO TECH DEV

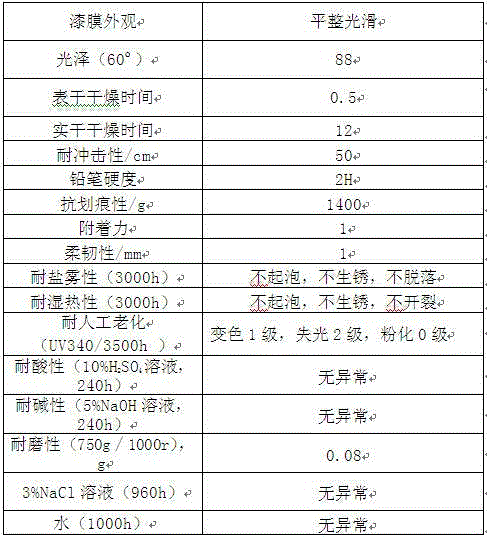

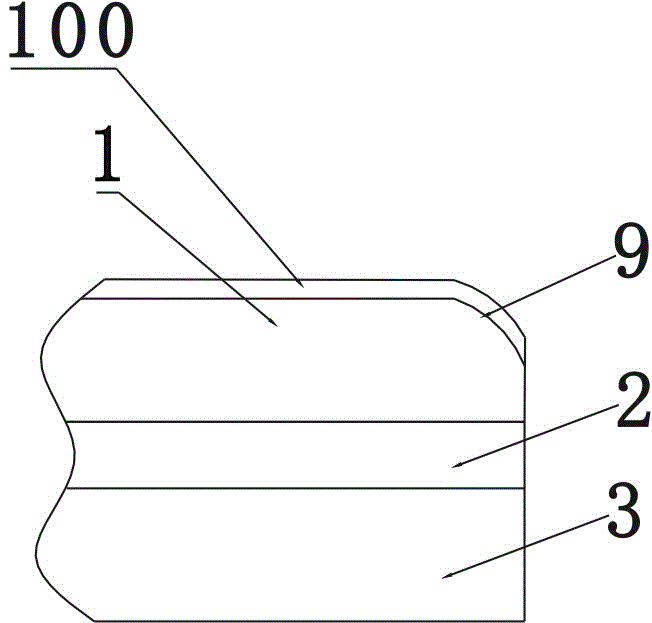

Coating with electroplating appearance effect as well as preparation method and construction process for coating

InactiveCN104927549AImprove the level ofIncrease coveragePretreated surfacesAnti-corrosive paintsWeather resistanceHardness

The invention discloses a coating with an electroplating appearance effect. The coating consists of priming coating, intermediate coating and finishing coating. The invention further provides a construction process for the coating. Tests prove that after the coating is formed into a film, the film is full, smooth, high in hardness, strong in wear resistance, excellent in weather resistance, and very high in scrape and damage resistance. The product has relatively high hardness and excellent wear resistance, and the surface is lustrous in long time, so that the function of protecting the surface of the product is achieved.

Owner:QINGYUAN YAKOO CHEM CO LTD

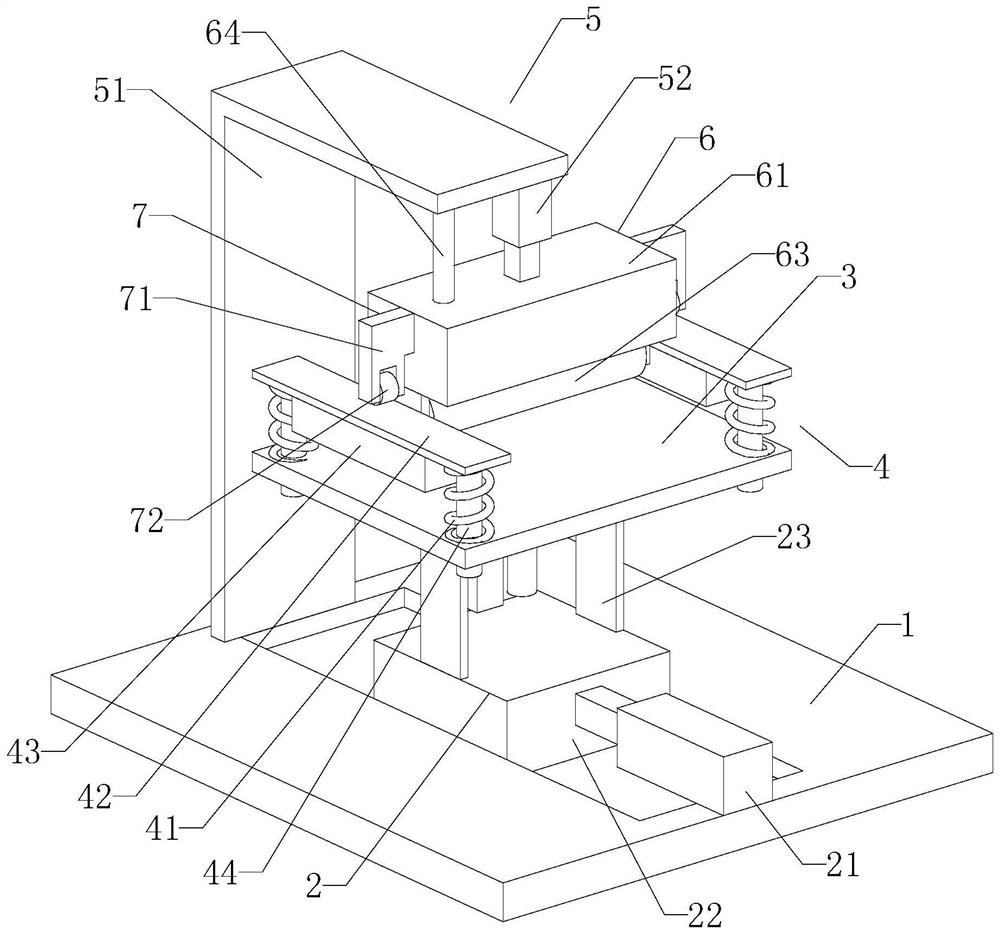

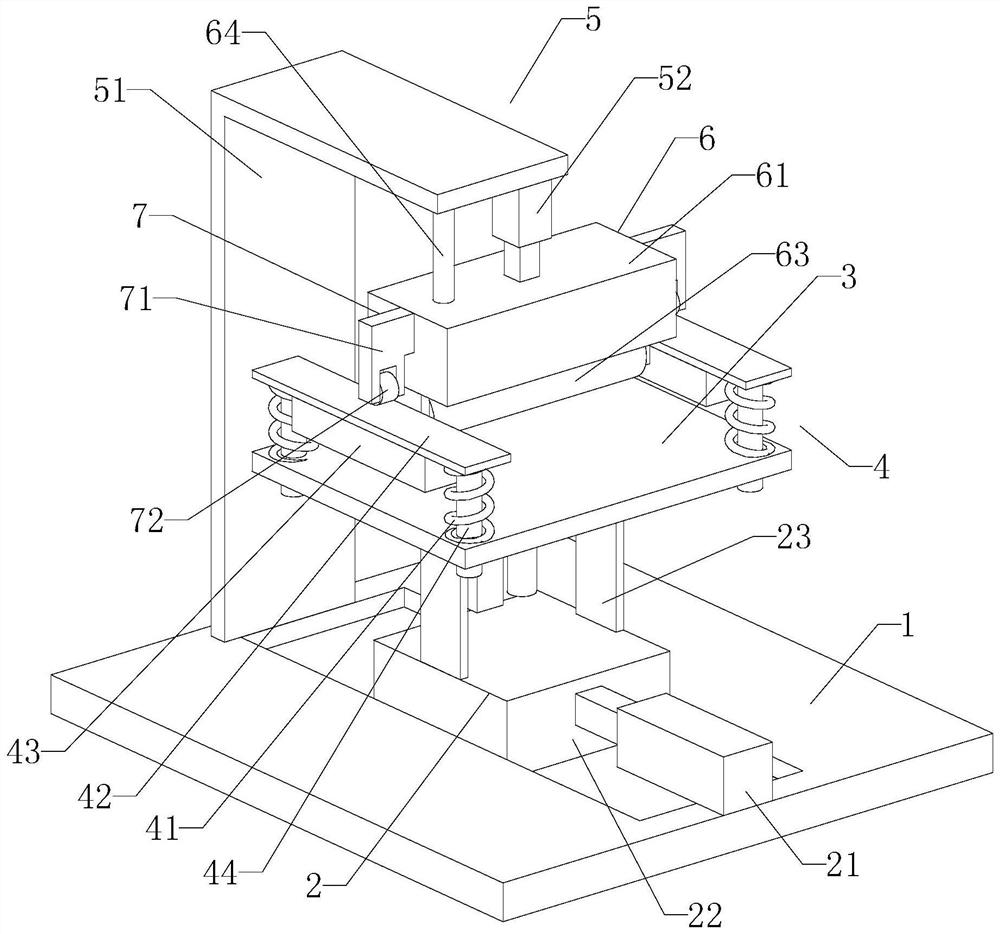

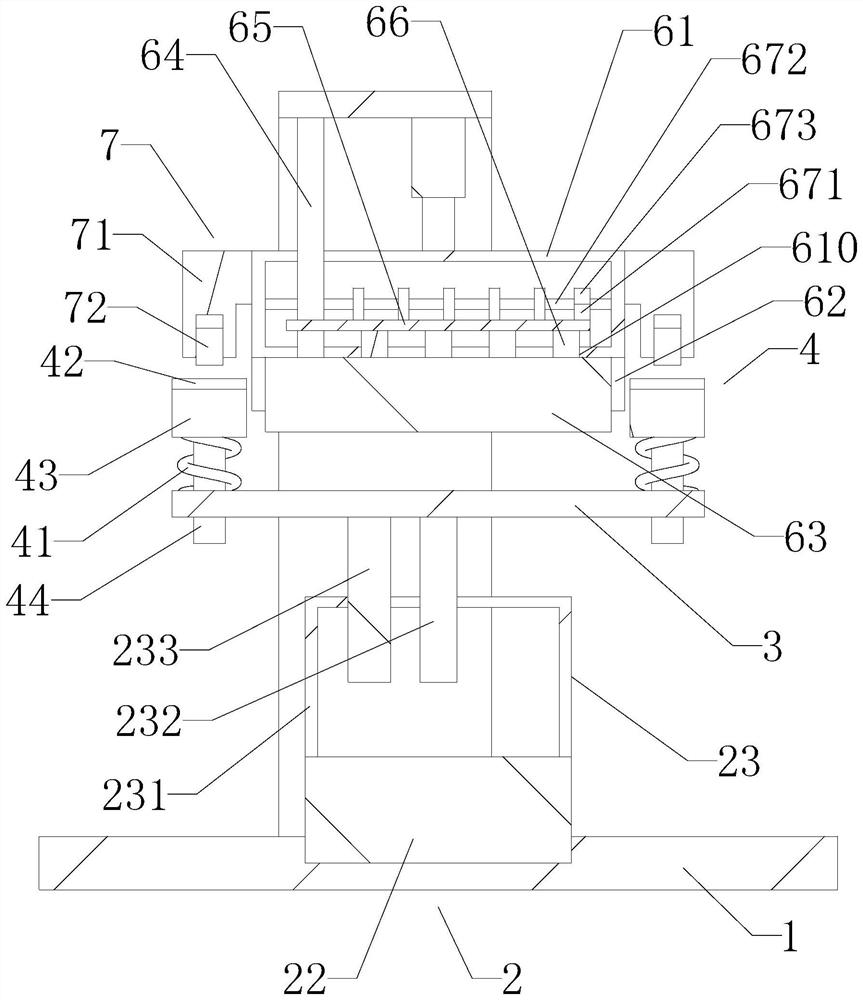

Preparation method and device of sterilization type sealable gummed paper

InactiveCN114798307ALifting heightFull coatingLiquid surface applicatorsCoatingsReciprocating motionAdhesive glue

The invention relates to the technical field of gummed paper preparation devices, in particular to a sterilization type sealable gummed paper preparation method and device which comprises a base, a driving mechanism, a placement table, two fixing assemblies, a lifting mechanism, a gumming assembly and two pressing pieces. The fixing assembly comprises two springs, a rail and an anti-skid pad. Glued paper is placed on the placement table, the lifting mechanism drives the gluing assembly and the two pressing pieces to move downwards, the two pressing pieces make contact with the track firstly and push the track and the anti-skid pad to move downwards, the anti-skid pad presses and fixes the glued paper to the placement table, and meanwhile the gluing assembly makes contact with the glued paper to coat the surface of the glued paper with glue. The driving mechanism drives the placement table to do horizontal reciprocating motion, so that the gummed paper does reciprocating motion along the gluing assembly, the surface of the gummed paper can be comprehensively coated with glue, and when the gummed paper is glued, workers do not need to manually fix the gummed paper.

Owner:江苏建中医用材料有限公司

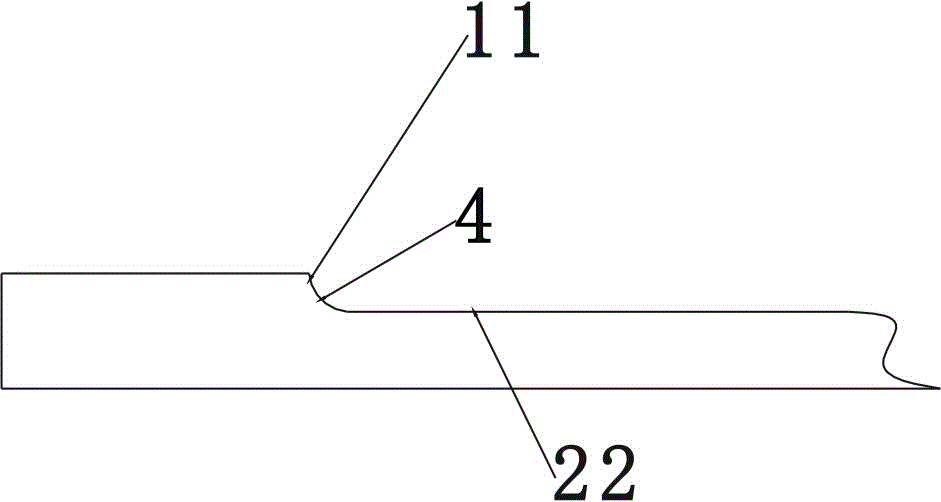

Production method for chamfering lock floor

ActiveCN104912297APrecise rounding processingImplement roundingLamination ancillary operationsLaminationEngineeringUV coating

The invention discloses a production method for a chamfering lock floor. The production method is characterized in that the production method comprises following steps: a, laying up all layers forming the floor in order; b, utilizing a chamfering template to the floor laid well in the step a to carry out chamfering operation in a hot-pressing state; c, adopting a rubber roll to carry out UV coating and curing operation to the surface of the floor obtained in the step b; d, slotting and mortising the floor obtained in the step c in order to obtain a finished product. The edge of the chamfering template is provided with a circular arc chamfer. The production method for the chamfering lock floor has following beneficial effects: with no chamfering tool at high production cost required, the lock floor which enables a wearing layer to be thinner has a larger and wider chamfering angle so that product quality is improved.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

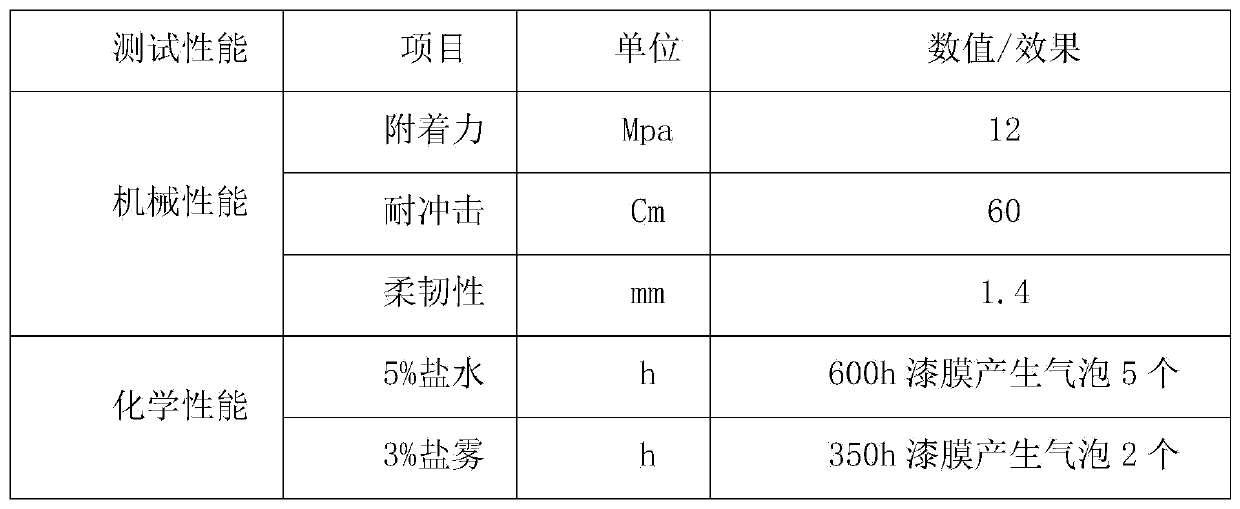

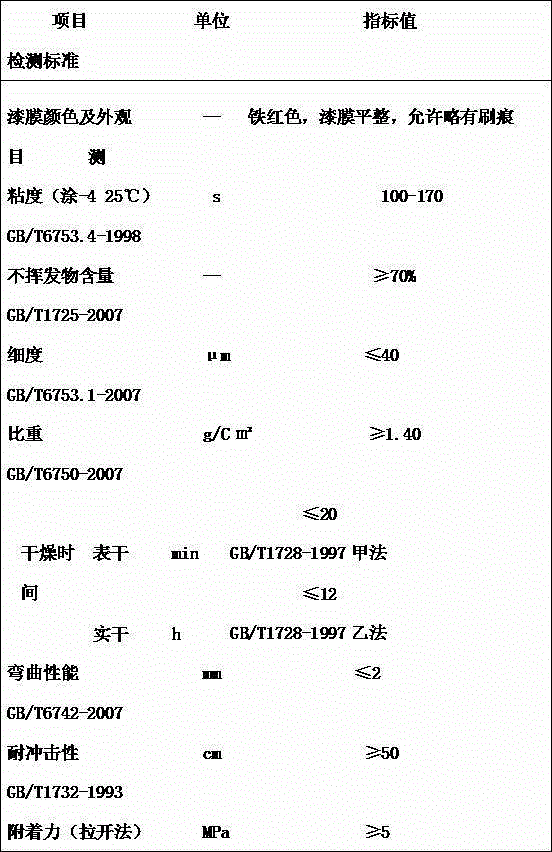

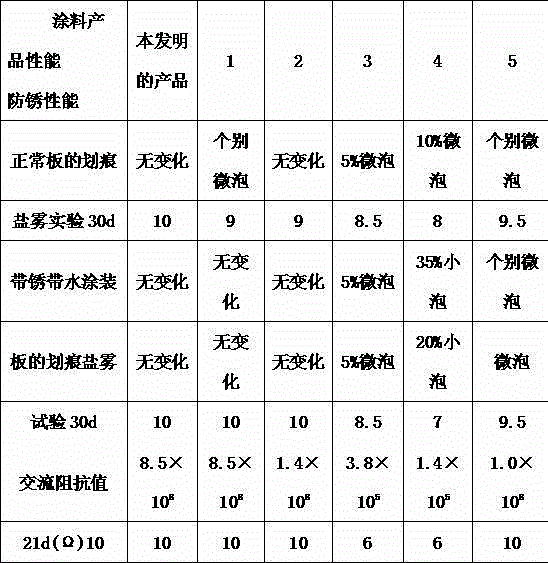

Low-surface treatment rusty rust inhibiting primer and preparation method thereof

InactiveCN106752659AStrong adhesionExcellent anti-corrosion and anti-rustAnti-corrosive paintsEpoxy resin coatingsEpoxyLacquer

The invention relates to a low-surface treatment rusty rust inhibiting primer and a preparation method thereof. The low-surface treatment rusty rust inhibiting primer comprises a component A and a component B; The component A comprises the following raw materials in parts by weight: 5-50 parts of epoxy resin, 5-50 parts of a filler, 1-10 parts of a rust-converting agent, and 1-50 parts of an anti-rust pigment; and the component B comprises the following raw materials in parts by weight: 30-80 parts of a curing agent, 1-10 parts of a promoter, and 1-15 parts of a silane coupling agent. The low-surface treatment rusty rust inhibiting primer has good adhesion and excellent physical machinery, corrosion and rust protection as well as low-surface treatment performance, the construction performance is good, the low-surface treatment rusty rust inhibiting primer can be taken as a low-surface treatment primer by cooperating with a conventional protection paint, and can be individually used as a functional rusty primer.

Owner:HENAN RUNNAN PAINT IND

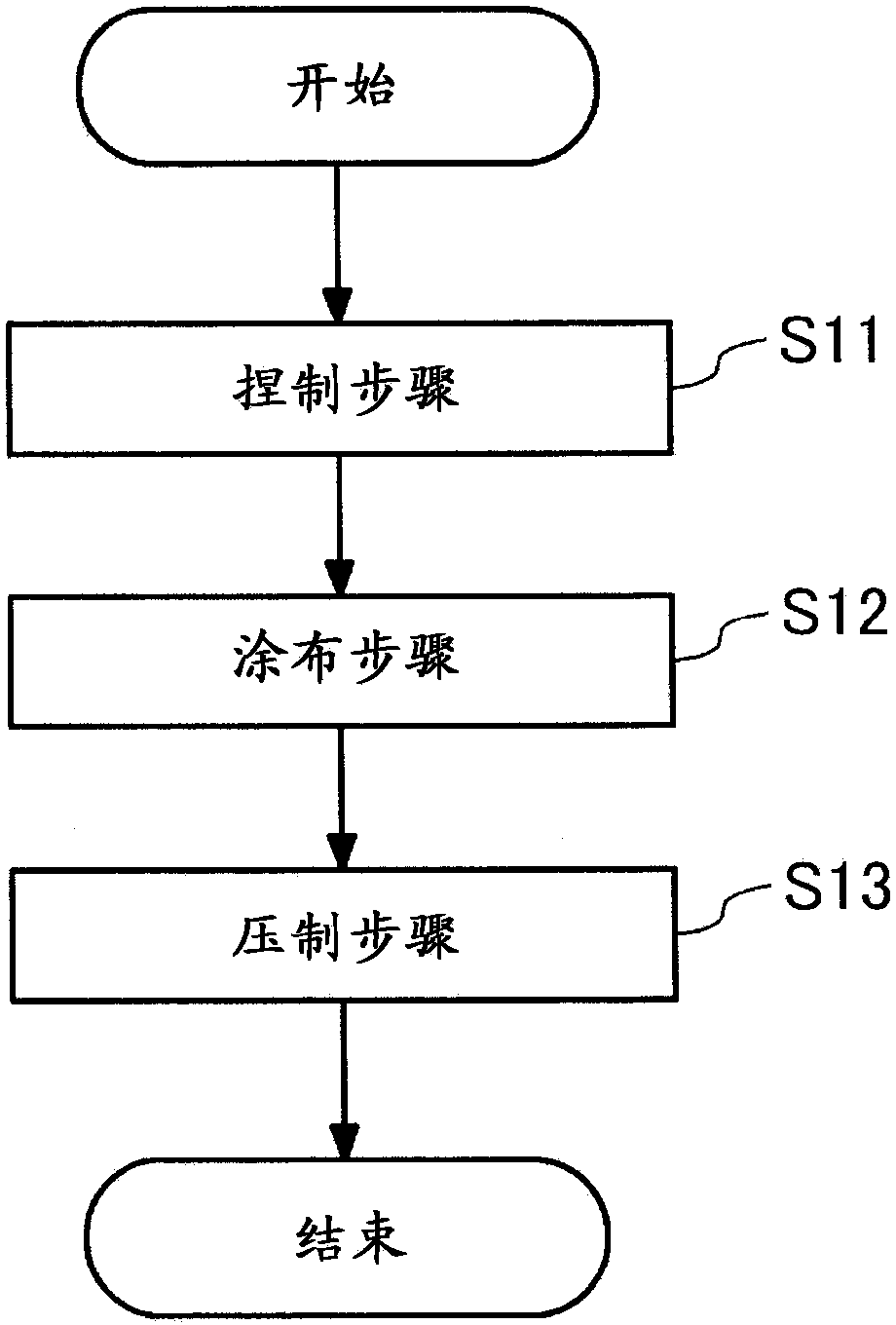

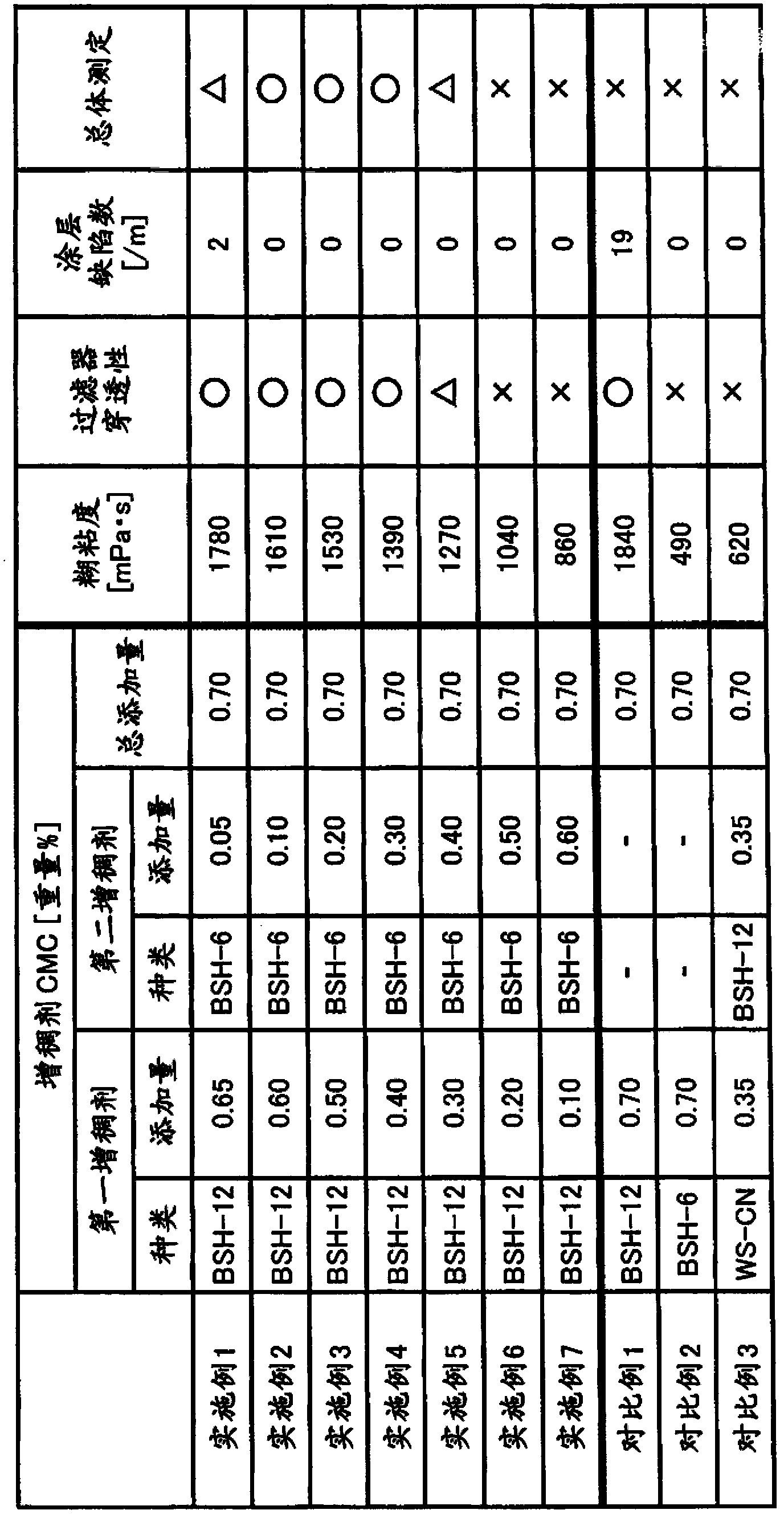

Manufacturing method of electrode, and battery

InactiveCN103456917AFull coatingElectrode collector coatingNon-aqueous electrolyte accumulator electrodesElectrical batteryAqueous solution

An electrode includes a current collector formed in a sheet and an electrode mixture layer formed on the surface of a current collector. An electrode mixture containing an active material is prepared by using a kneading machine. The electrode mixture on a surface of the current collector is coated. The electrode mixture coated on the current collector is pressed to form the electrode mixture layer on the surface of the current collector. A first thickener and a second thickener are added to the active material when the electrode mixture is prepared. A 1% by weight aqueous solution of the first thickener has the viscosity of equal to or larger than 5000 and equal to or smaller than 9000 mPas. A 1% by weight aqueous solution of the second thickener has the viscosity of equal to or larger than 2000 and equal to or smaller than 5000 mPas.

Owner:TOYOTA JIDOSHA KK

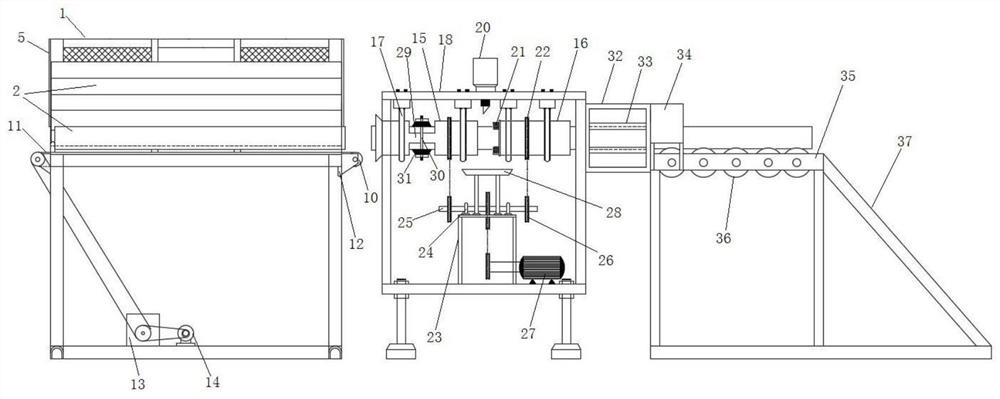

Steel pipe outer wall automatic painting and drying equipment

InactiveCN112221871AReduce labor intensityHarm reductionPretreated surfacesCoatingsEngineeringMechanical engineering

The invention relates to the technical field of painting, and discloses steel pipe outer wall automatic painting and drying equipment. The steel pipe outer wall automatic painting and drying equipmentcomprises an automatic feeding device, an automatic painting device, a drying device and an automatic discharging device, wherein the automatic feeding device comprises a steel pipe transporting structure, and a steel pipe pushing structure is arranged at the transporting tail end of the steel pipe transporting structure; the automatic painting device comprises a rotatable painting channel, a feeding port of the painting channel is matched with and right faces the pushing-out end of the steel pipe pushing structure, the steel pipe pushing structure can push the conveyed steel pipes to be painted into the painting channel, and after the next steel pipe to be painted is pushed out, the end of the next steel pipe to be painted can abut against the end of the previous steel pipe to be paintedto push the front steel pipe to sequentially pass through the painting channel to finish automatic painting of the outer wall of the steel pipe; the drying device is arranged on one side of a discharge port of the painting channel and used for immediately drying the painted steel pipe; and the automatic discharging device is arranged on the outlet side of the drying device. Through the adoption of the equipment, automatic painting can be achieved, instant drying and cooling treatment can be achieved after painting, painting is comprehensive, efficiency is remarkably improved, and the requirement for mass production can be met.

Owner:GUANGZHOU NO 2 MUNICIPAL ENG CO LTD

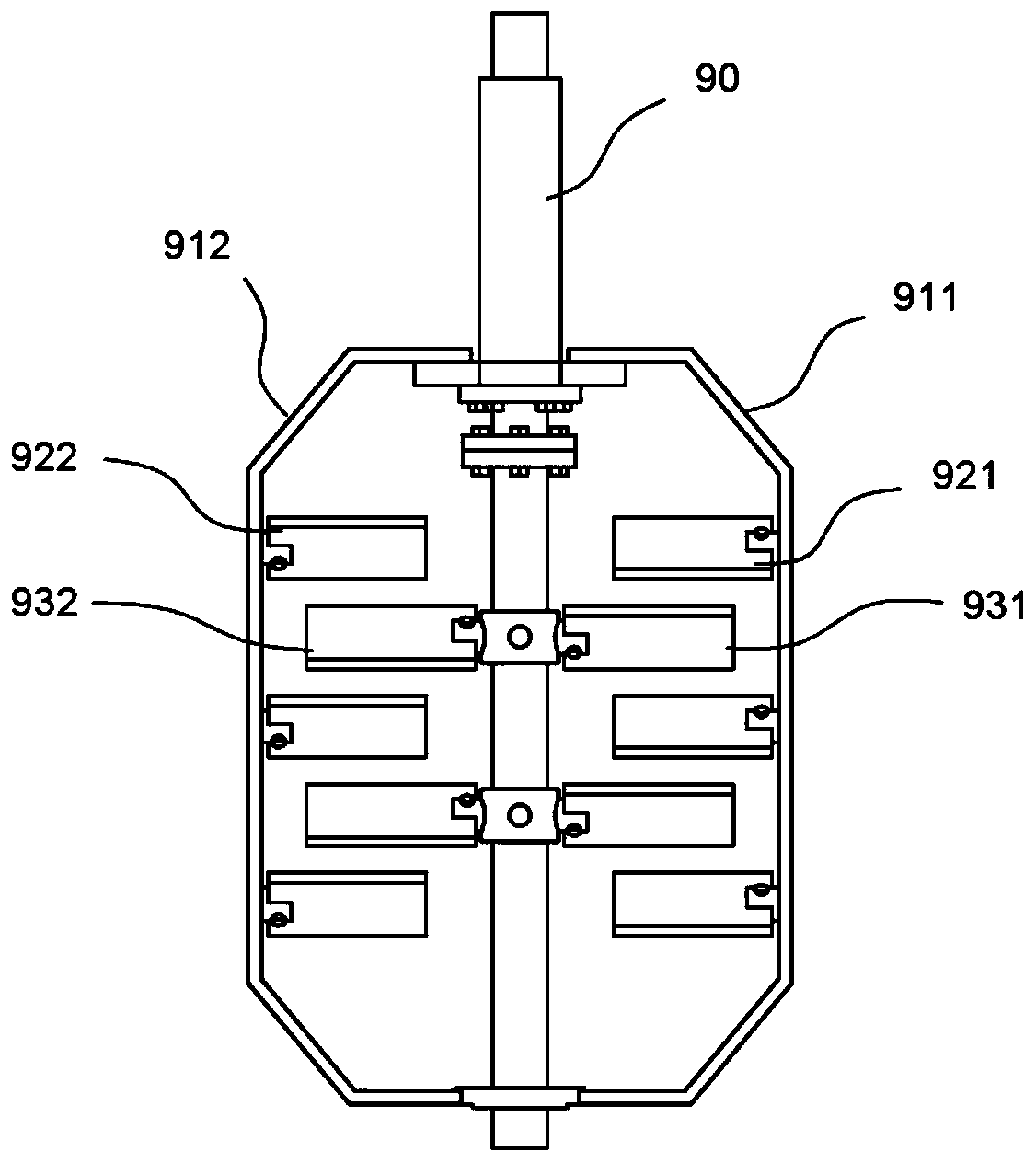

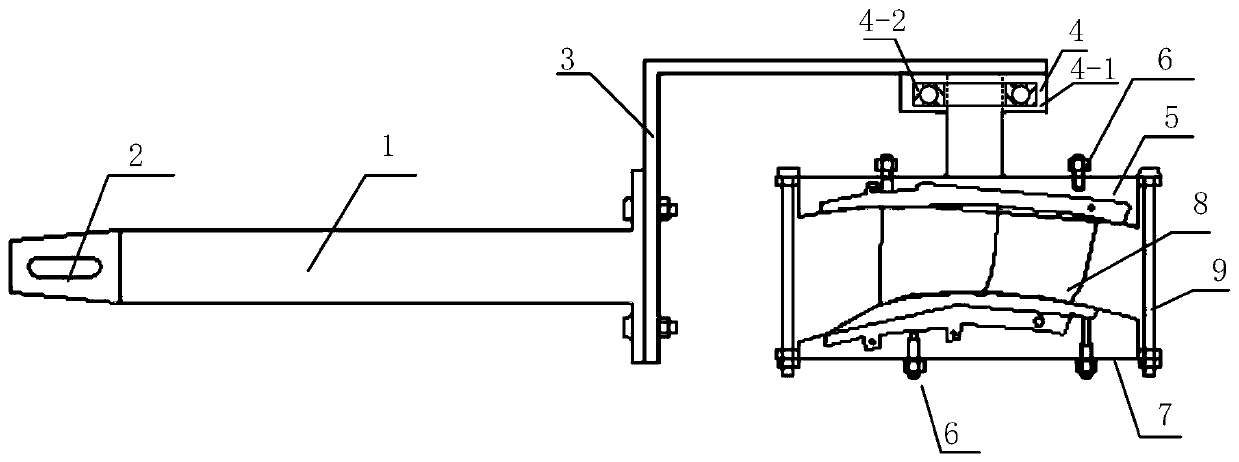

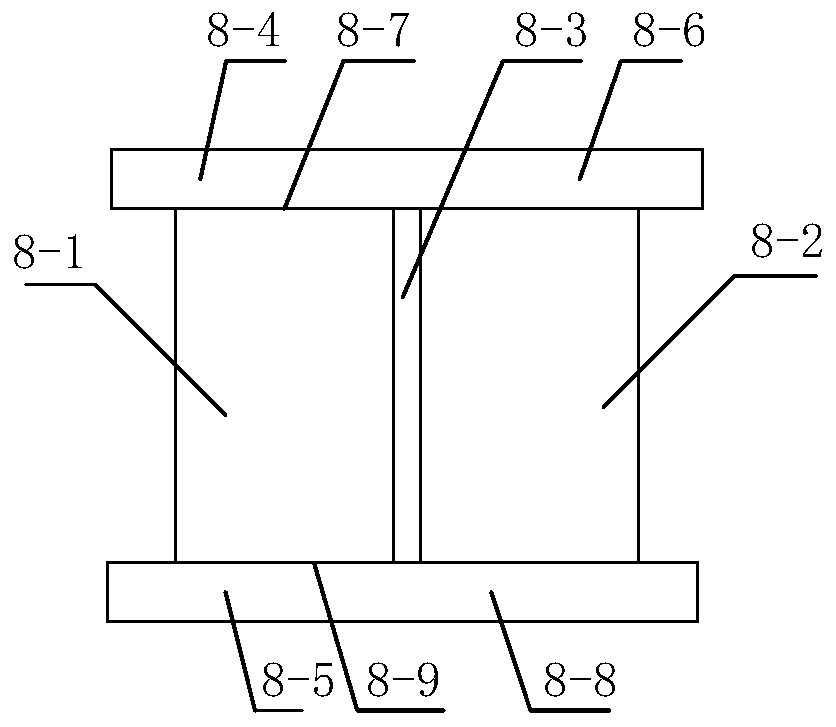

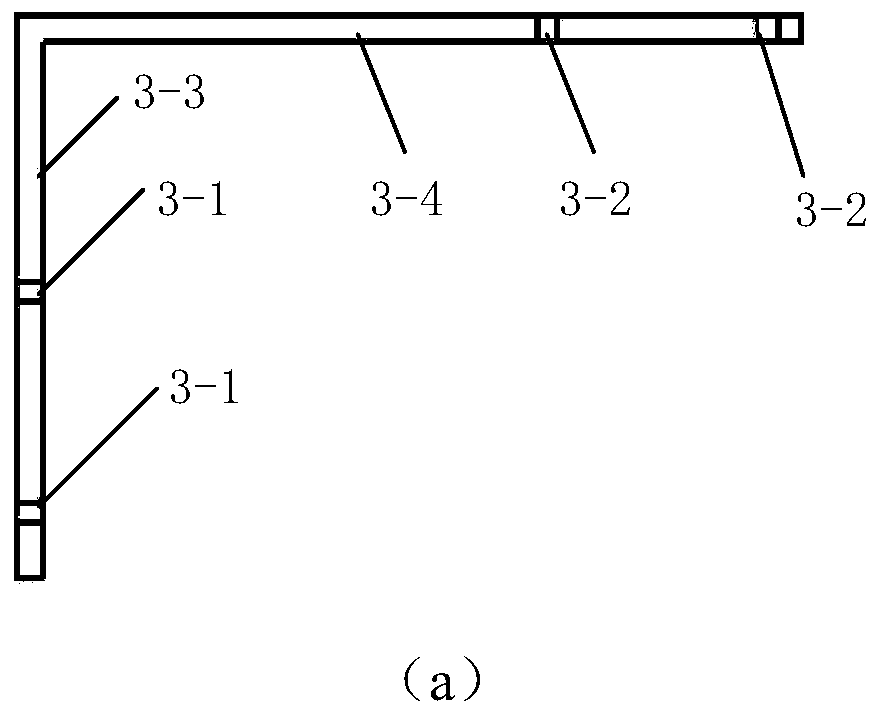

Support device for guiding vane full flowpath face vapour deposition and application method thereof

ActiveCN110158047AImprove temperature stabilityImprove job stabilityVacuum evaporation coatingSputtering coatingGas phaseHeat resistance

The invention discloses a support device for guiding vane full flowpath face vapour deposition and an application method thereof. A clamping device is connected with a rotating shaft through a connecting plate and an L-shaped connecting plate. A guiding vane is mounted inside the clamping device in a clamping manner. The L-shaped is in an L shape, thus, the axis direction of the guiding vane is perpendicular to the axis direction of the rotating shaft; in the coating process, the guiding vane can substantially rotate around the axis direction of the rotating shaft; on the premise that the vanebody surface ceramic coating bonding strength and the columnar crystal structure are guaranteed, the listrium surface bonding strength is greatly improved; an uniform columnar crystal structure is formed; thus, the guiding vane full flowpath face is coated with thermal barrier coating; the heat-resistance temperature of the guiding vane and working stability are greatly improved. The support device is simple in structure; the number of the components is small; product is easy to machine and dismount and mount; and matching design can be conducted on a tool according to the guiding vane structure.

Owner:AECC AVIATION POWER CO LTD

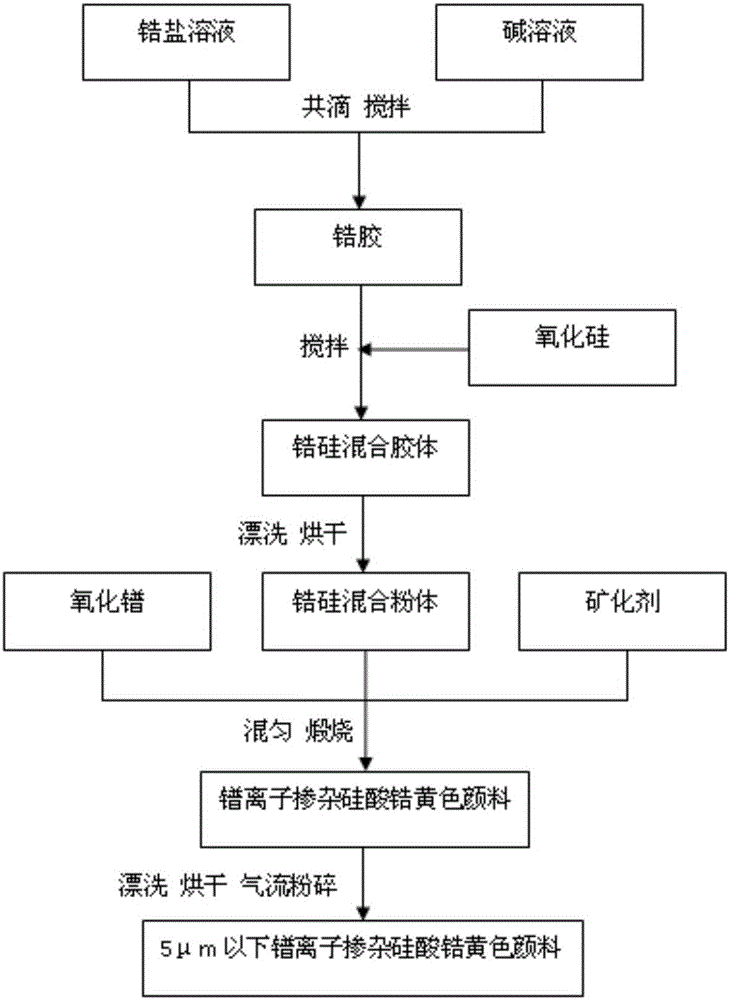

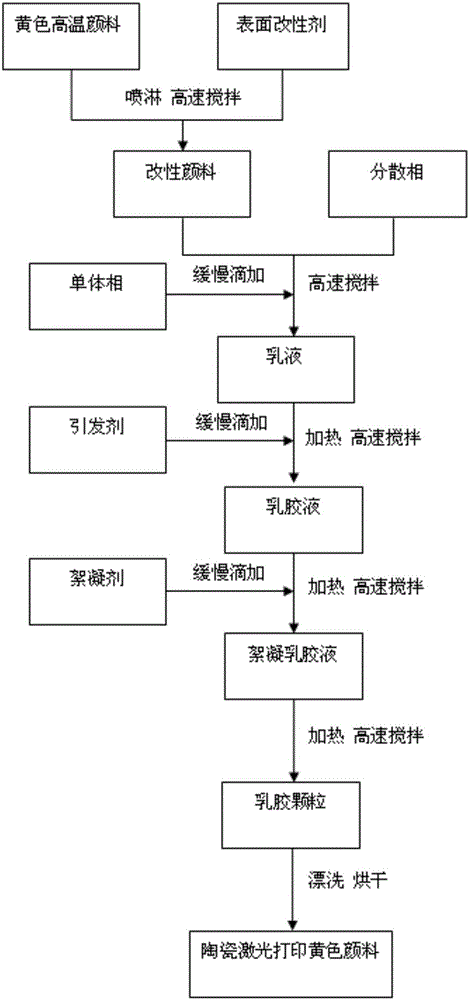

Preparation method of high-temperature yellow pigment for ceramic laser printing

The invention discloses a preparation method of a high-temperature yellow pigment for ceramic laser printing.The preparation method comprises a preparation method for synthesizing a praseodymium ion-doped zirconium silicate yellow pigment by adopting a semi-liquid phase semi-solid phase technology and a method for preparing laser printing ink powder through an emulsion polymerization technology.The preparation method comprises the steps that a zirconium salt solution and an alkaline solution are simultaneously and dropwise added into water to form colloid of zirconium, white carbon black is added, the mixture is stirred to form zirconium-silicon mixed colloid, and filter pressing, washing and drying are performed to obtain superfine zirconium-silicon mixed powder; the zirconium-silicon mixed powder, praseodymium oxide, fluoride salt and chlorizated salt are mixed to be uniform according to a certain mass ratio and then calcined, and the praseodymium ion-doped zirconium silicate yellow pigment is obtained; the synthesized pigment, resin and a charge control agent are mixed to be uniform and then subjected to high-temperature mixing, extruding, cooling, breaking, air flow smashing, cyclone classifying and surface modifying, and the yellow ink powder for ceramic laser printing is obtained.According to the preparation method, by self-making an inorganic pigment and resin, the inorganic pigment and a polymerization coating technology adapt to each other to the maximum limit.

Owner:JIANGXI JINHUAN PIGMENTS

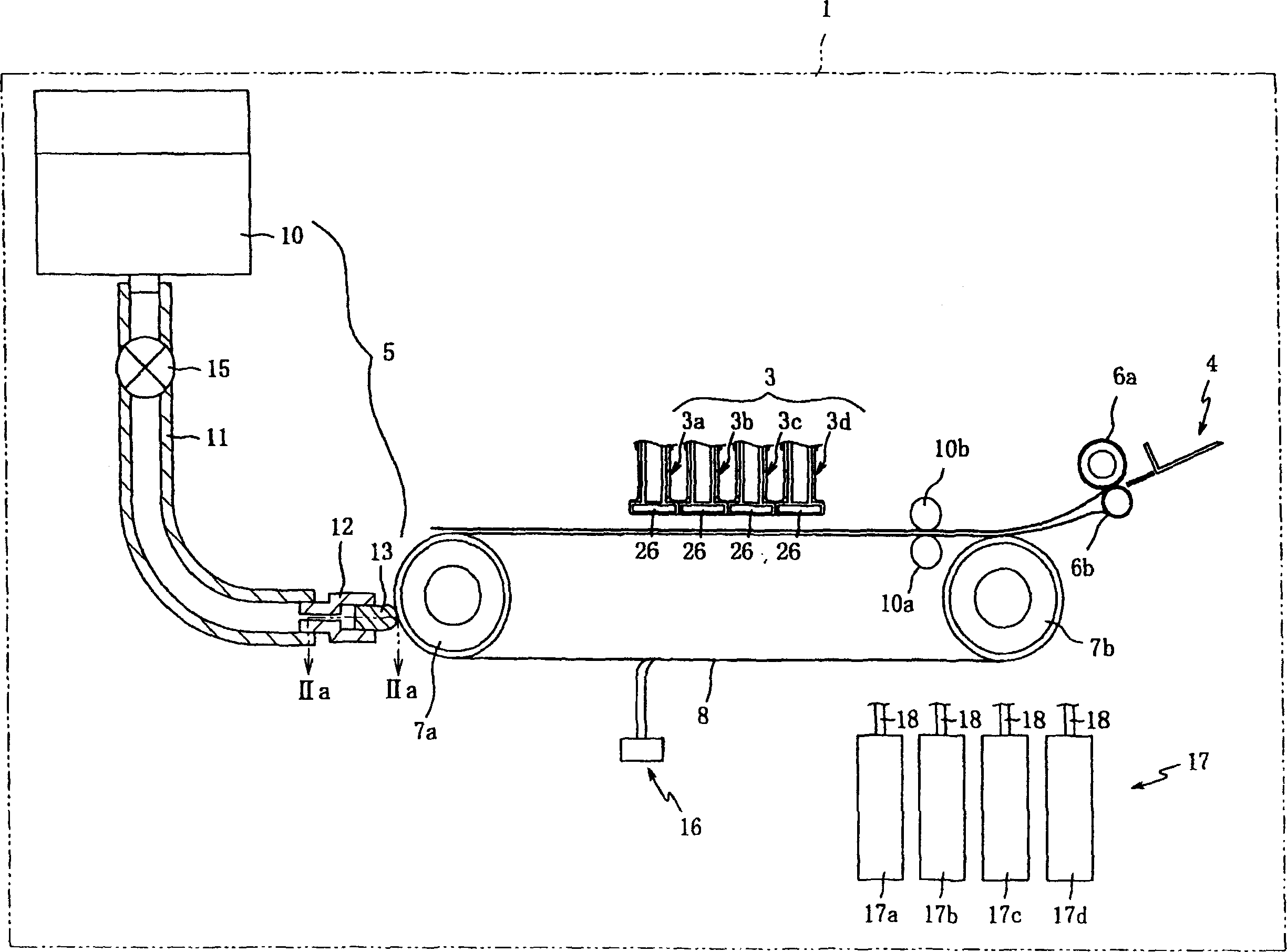

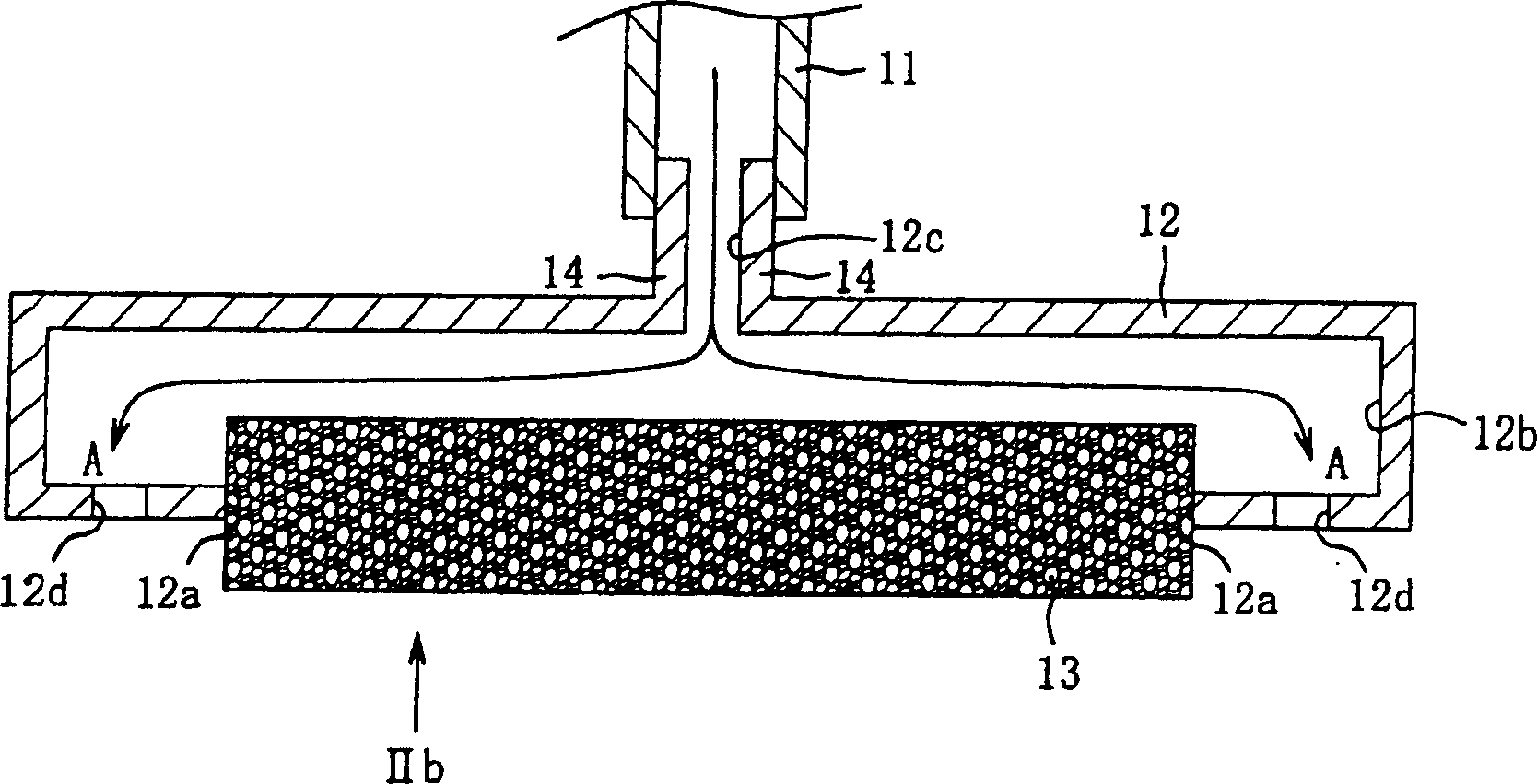

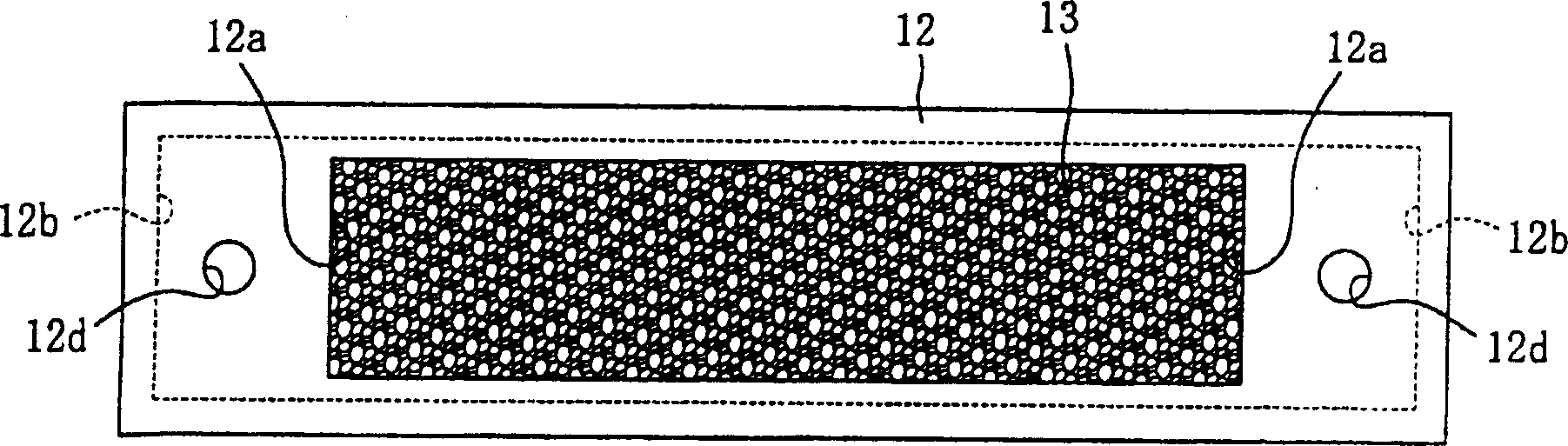

Image forming apparatus

InactiveCN1827387AUniform supplyPrevent leakageCleaningOther printing apparatusEngineeringImaging equipment

Cleaning liquid stored in a first storage tank (10) is absorbed by a sponge (13) via a passage formed in a tube (11) and a holder (12), and then applied onto a conveyance belt (8) when the sponge (13) comes into contact with the conveyance belt (8). Here, even when air bubbles enter into the cleaning liquid supplied to the sponge (13), the air bubbles are discharged to the outside through an air discharging hole formed in the holder (12).

Owner:BROTHER KOGYO KK

Waterproof material for toilet and preparation method of waterproof material

The invention discloses a waterproof material for a toilet and a preparation method of the waterproof material and relates to the technical field of waterproof materials. The waterproof material comprises the following raw materials in parts: 70-80 parts of modified starch, 55-65 parts of inorganic powder fillers, 45-50 parts of cis-1,4-polyisoprene rubber, 35-40 parts of aluminum stearate, 30-35 parts of fly ash, 25-30 parts of nano particles, 15-25 parts of organic fibers, 15-20 parts of dimethyl silicone, 10-15 parts of aids, 5-10 parts of pigments and 120-150 parts of water. The waterproof material disclosed by the invention has excellent waterproof, anti-permeability and antibacterial and anti-mold properties, the raw materials are environmental-friendly and high in affinity, water leakage in the toilet can be effectively prevented, and the waterproof material is difficult to age.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com