Low-surface treatment rusty rust inhibiting primer and preparation method thereof

A low-surface-treatment, rust-based primer technology, used in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as unachievable coatings, and achieve full coating film, excellent low-surface-treatment rust coating Excellent construction performance and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

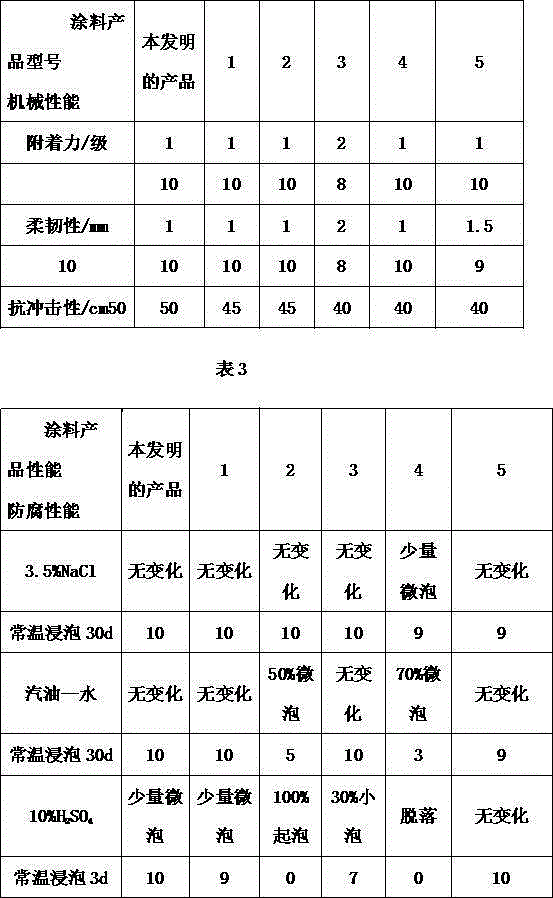

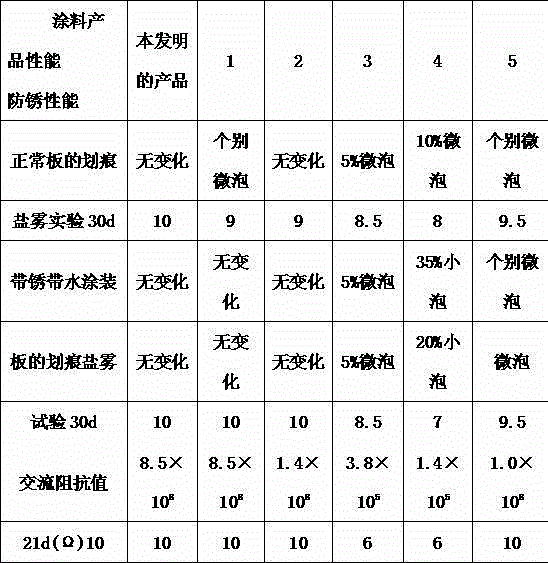

Embodiment 1

[0023] Embodiment 1, a kind of low surface treatment band rust primer: A component comprises the raw material composition of following parts by weight: epoxy resin 5, filler 5, rust converting agent 1, antirust pigment 1; B component comprises following parts by weight Composition of raw materials: curing agent 30, accelerator 1, silane coupling agent 1, components A and B are prepared separately, and components A and B can be used after mixing evenly during construction.

Embodiment 2

[0024] Embodiment 2, a kind of low surface treatment band rust primer, A component comprises the raw material composition of following parts by weight: epoxy resin 50, filler 50, rust converting agent 10, antirust pigment 50; B component comprises following parts by weight Composition of raw materials: curing agent 80, accelerator 10, silane coupling agent 15, A and B components are prepared separately, and A and B components can be used after mixing evenly during construction.

Embodiment 3

[0025] Embodiment 3, a kind of low surface treatment band rust primer, A component comprises the raw material composition of following parts by weight: epoxy resin 28, mixed solvent 23, dispersant 0.1, defoamer 0.5, thixotropic agent 0.2, anti-sedimentation Agent 1, penetrating agent 0.1, rust conversion agent 2, antirust pigment 25, filler 20; B component includes the following raw materials in parts by weight: curing agent 65, toughening agent 4, accelerator 2.5, silane coupling agent 2, Mixed solvent 25 is prepared separately for components A and B, and can be used after mixing components A and B evenly during construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com