Spray type seed coating device

A spray type and seed technology, applied in the field of spray type seed coating devices, can solve the problems of insufficient contact between seeds and seed coating agent, uneven coating, etc., achieve uniform coating operation, prevent precipitation, and expand spraying range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

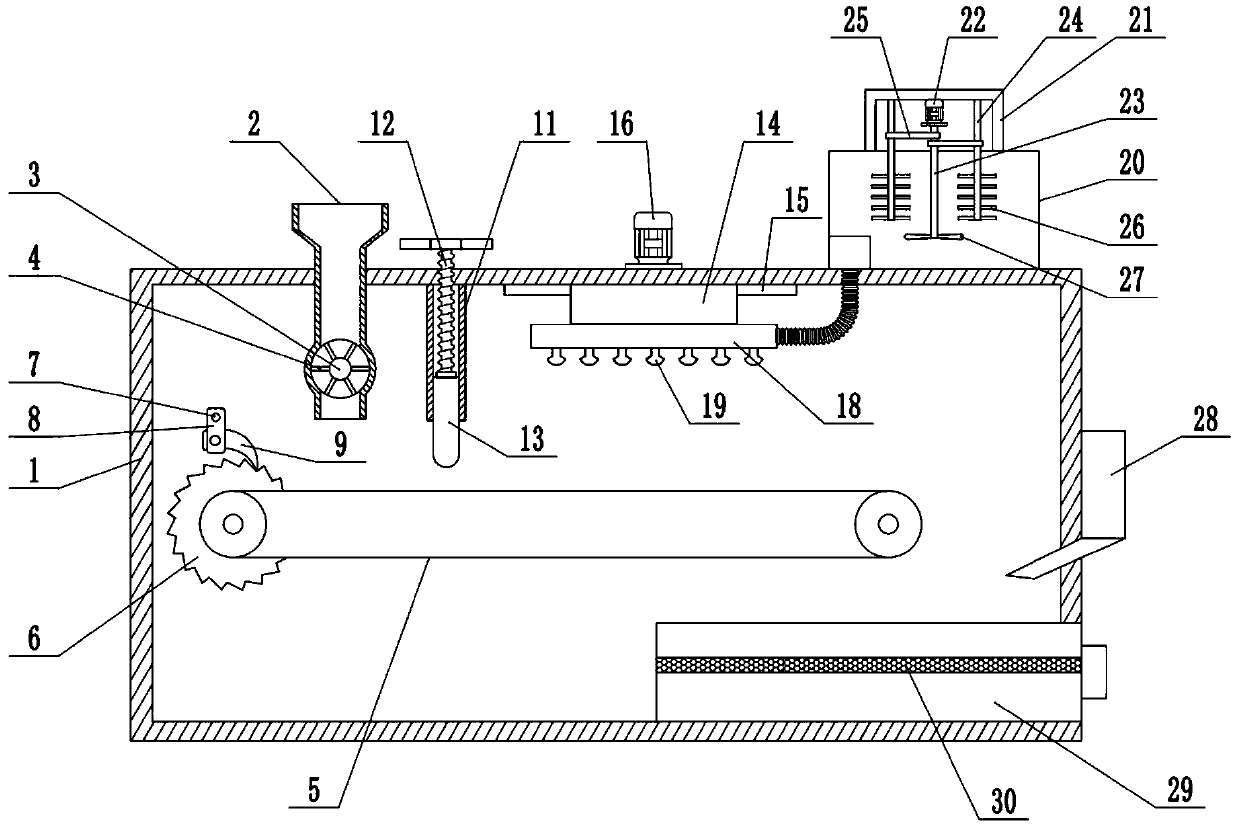

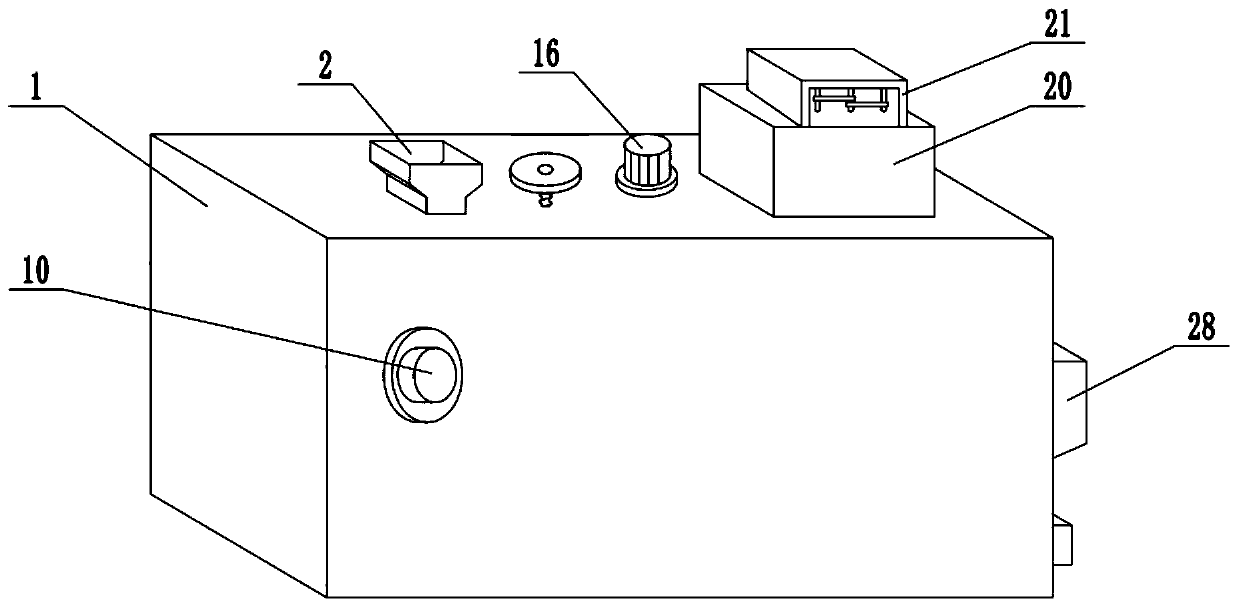

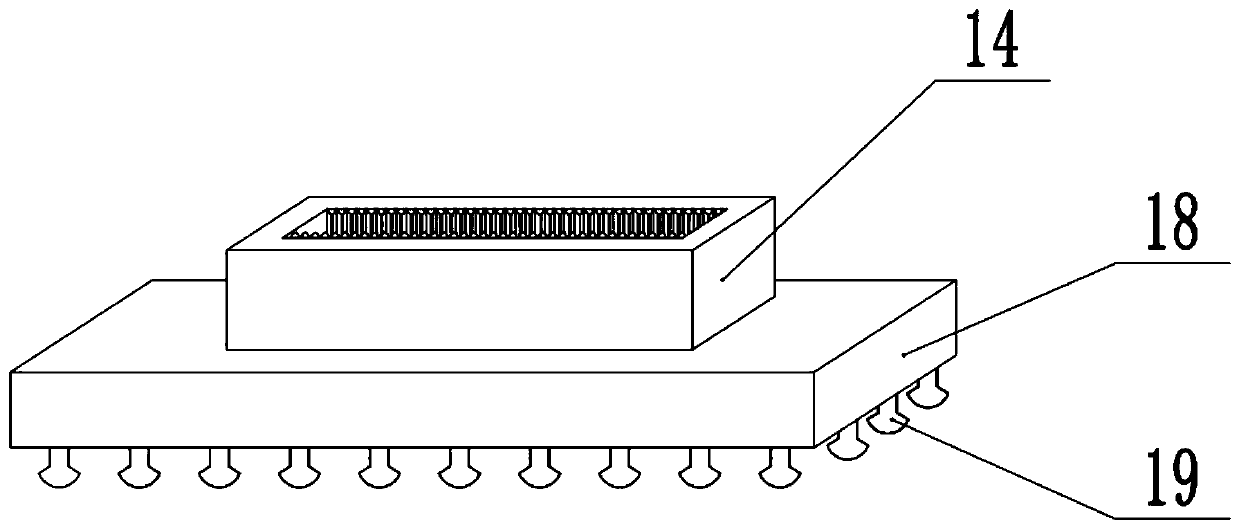

[0022] see Figure 1-4 , in an embodiment of the present invention, a spray type seed coating device comprises a housing 1, a feeding pipe 2, a conveyor belt 5 and a liquid medicine tank 20, the top of the housing 1 is fixedly connected with a feeding pipe 2, and the inside of the feeding pipe 2 is installed with The uniform feeding mechanism includes a rotating shaft 3 and a dispersing plate 4. The two ends of the rotating shaft 3 are rotationally connected with the side walls of the feeding pipe 2. A number of dispersing plates 4 are evenly distributed on the rotating shaft 3. The seeds are thrown into the feeding pipe 2 and dropped Between the two dispersing plates 4, a motor for driving the rotating shaft 3 is installed on the outer wall of the housing 1, which drives the rotating shaft 3 to rotate, so as to realize uniform feeding of the seeds. A conveyor belt 5 is installed inside the housing 1, and the conveyor belt 5 is located in the feeding area. Below the tube 2, th...

Embodiment 2

[0026] On the basis of Embodiment 1, the top of the liquid medicine tank 20 is fixedly connected with a fixed frame 21, the lower surface of the fixed frame 21 is fixedly connected with a stirring motor 22, and the shaft extension end of the stirring motor 22 is equipped with a driving shaft 23, and the driving shaft 23 extends Into the liquid medicine tank 20, the left and right ends of the driving shaft 23 are provided with a driven shaft 24, the upper end of the driven shaft 24 is rotatably connected with the fixed frame 21, the driven shaft 24 is connected with the driving shaft 23 through a transmission belt 25, and the driven shaft 24 is distributed with some stirring rods 26, and the lower end of driving shaft 23 is equipped with stirring blade 27, drives driving shaft 23, driven shaft 24 to rotate during stirring motor 22 operation, utilizes stirring rod 26, stirring blade 27 to stir seed coating agent, prevents The seed coating agent produces precipitation, and a boost...

Embodiment 1、 Embodiment 2

[0027]In combination with Embodiment 1 and Embodiment 2, the working principle of the present invention is: the seeds are put into the feeding pipe 2 and fall between the two dispersing plates 4, and the rotating shaft 3 rotates to drive the dispersing plates 4 to rotate, thereby realizing uniform feeding of the seeds , the seeds fall on the conveyor belt 5, the conveyor belt 5 is used to transport the seeds, start the drive motor 10, drive the drive shaft 7 to rotate, thereby drive the pawl 9 to reciprocate, use the pawl 9 to stir the ratchet wheel 6 to rotate intermittently, thereby driving the conveyor belt 5 intermittently Movement, drive the seeds to move to the right intermittently, use the scraper 13 to scrape the seeds flat, so that the seeds are spread on the conveyor belt 5, adjust the height of the scraper 13, the thickness of the seeds can be adjusted according to actual needs, start the booster pump, Utilize the booster pump to transport the seed coating agent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com