Production method for chamfering lock floor

A production method and flooring technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems that the base material cannot be effectively protected, chamfer width and angle are limited, and the service life of the floor is damaged. Achieve good hot-pressing composite effect, large chamfer angle, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

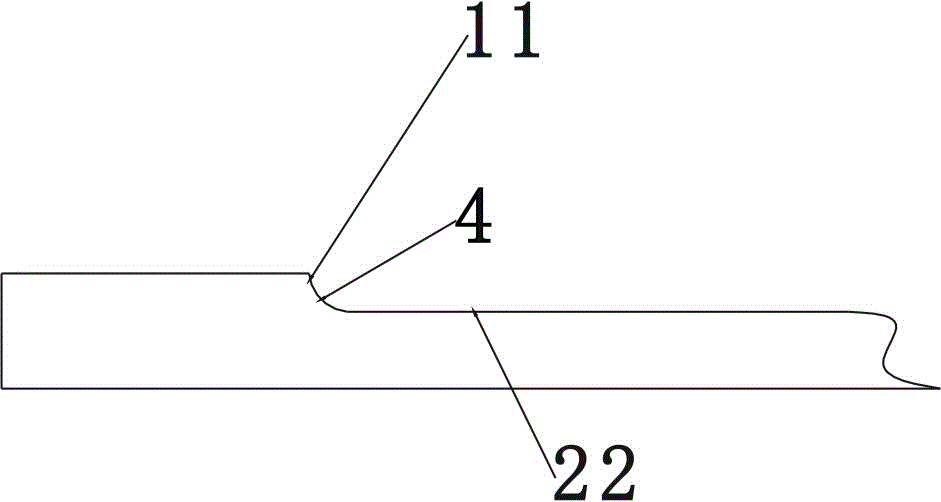

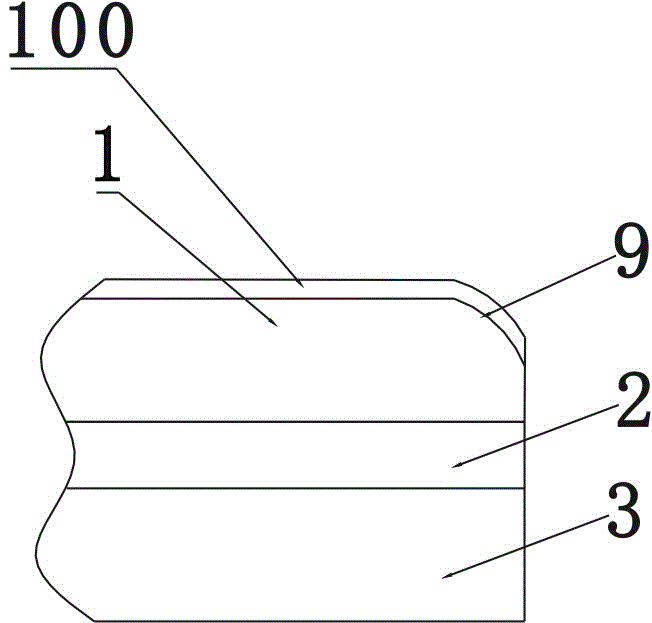

[0022] The wear-resistant layer 1, the color film layer 2, and the substrate layer 3 that make up the chamfered locking floor of the present invention are sequentially laid up, and 5 pairs of chamfering templates with a fillet radius of 0.4 mm are used for the arc chamfering 4 The laid-up floor is chamfered; the chamfering template is a shallow basin, and a radius of 0.4 is set between the first inner wall of the inner surface of the shallow basin and the second inner wall of the inner surface of the shallow basin. mm arc chamfering, the first inner wall 11 is the side wall of the shallow basin, and the second inner wall 22 is the bottom of the inner surface of the shallow basin; wherein, the temperature during hot pressing is 135°C (the positive and negative deviation is 5°C), the hot pressing time is 1800 seconds (plus or minus 20 seconds). When hot pressing, the floor will sink into the template by 1mm from top to bottom to form a completely closed shape. In order to solve t...

Embodiment 2

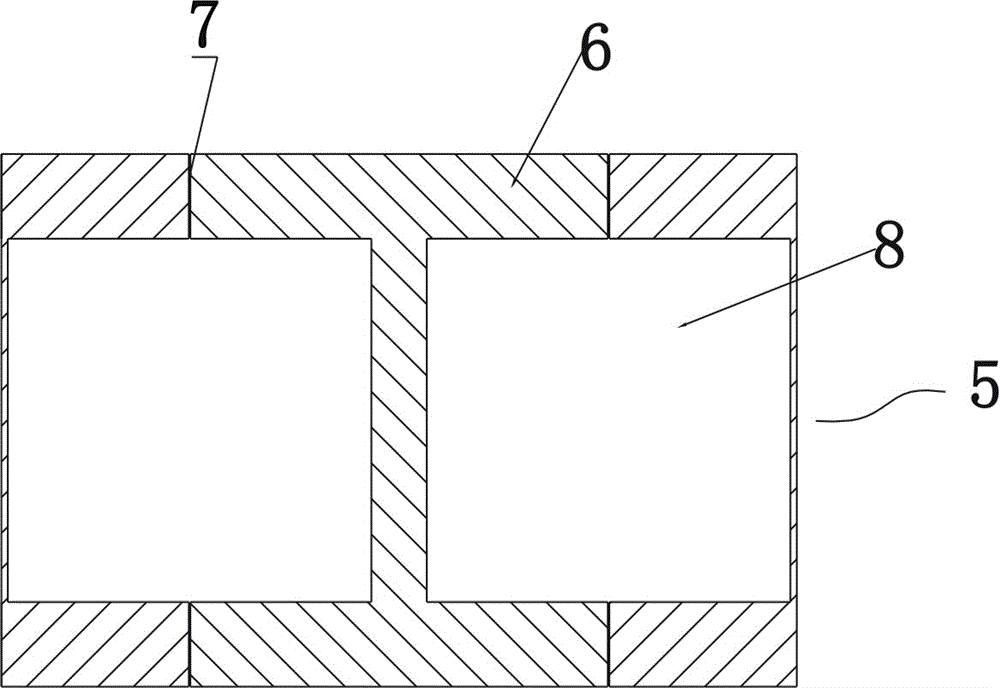

[0024] The wear-resistant layer 1, the color film layer 2, and the substrate layer 3 that make up the chamfered locking floor of the present invention are laid up in sequence, and a chamfering template with a rounded corner radius of 1 mm is used for arc chamfering (not marked) 5. Chamfer the laminated floor; among them, the temperature during hot pressing is 125°C (with a plus or minus deviation of 5°C), and the hot pressing time is 2000 seconds (with a plus or minus deviation of 20 seconds). , the floor will sink into the formwork by 1mm from top to bottom to form a completely closed shape. In order to solve the problem of exhaust in the formwork, four exhaust holes 7 are symmetrically arranged on the basin wall of the chamfered formwork. The air hole 7 of the vent hole has an inner diameter of 2mm; then, use a rubber roller with a hardness of HB 20° (with a positive and negative deviation of 2°) to UV-coat and cure the floor surface obtained above to obtain a UV film 100; fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com