Conductor winding rod

A technology of conductor winding and winding, applied in the shape/style/structure of winding insulation, shape/style/structure of winding conductors, etc., which can solve problems such as high cost and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

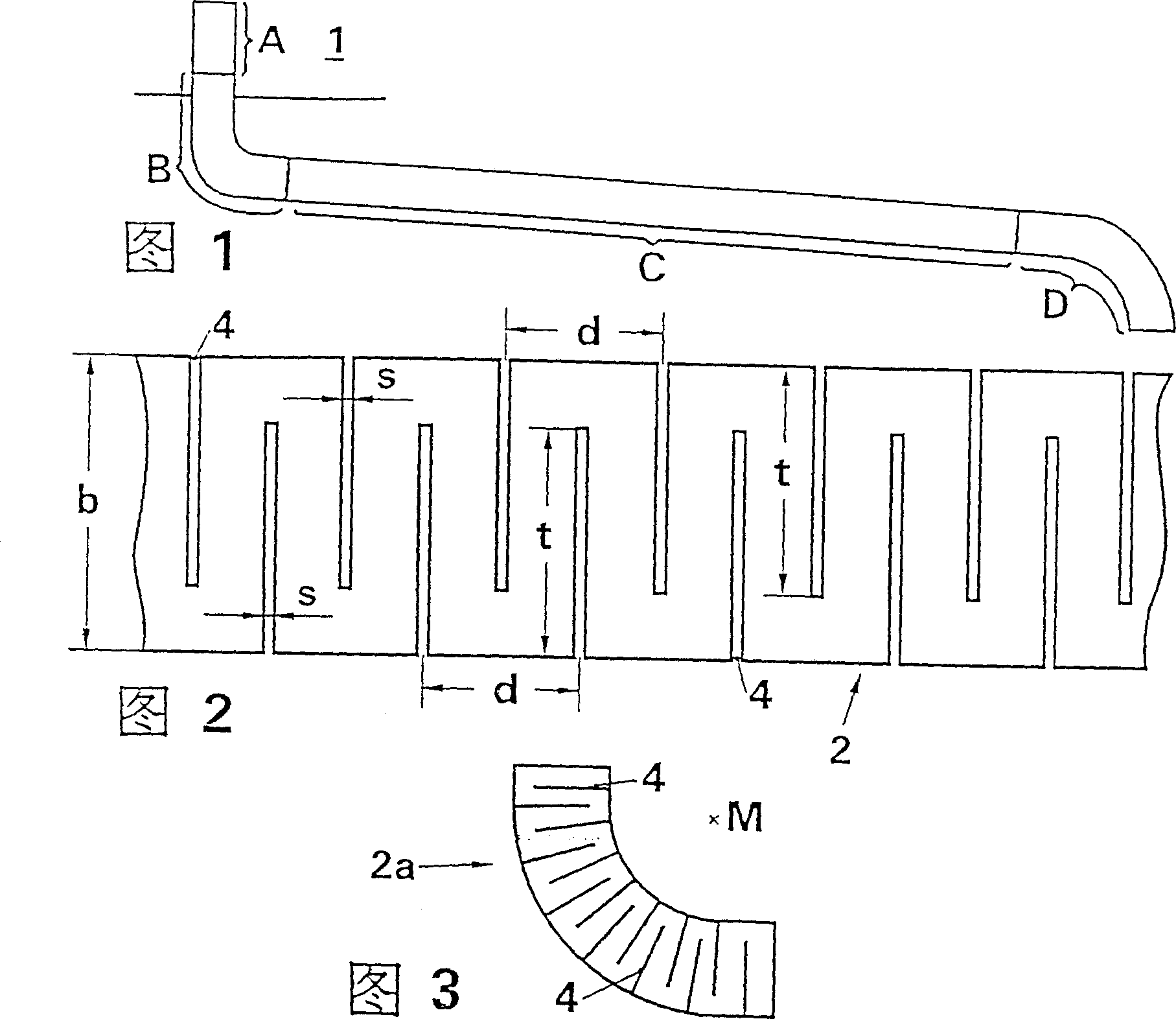

[0022] The stator winding bar of a large electric machine such as a turbo generator mainly consists of four parts: the slot or core part A, the more curved part B after the exit from the stator laminated core 1, and the less curved part about 150 cm or longer length portion C and a further more curved portion D adjoining portion C from which further connections of the semiconductor strips are made.

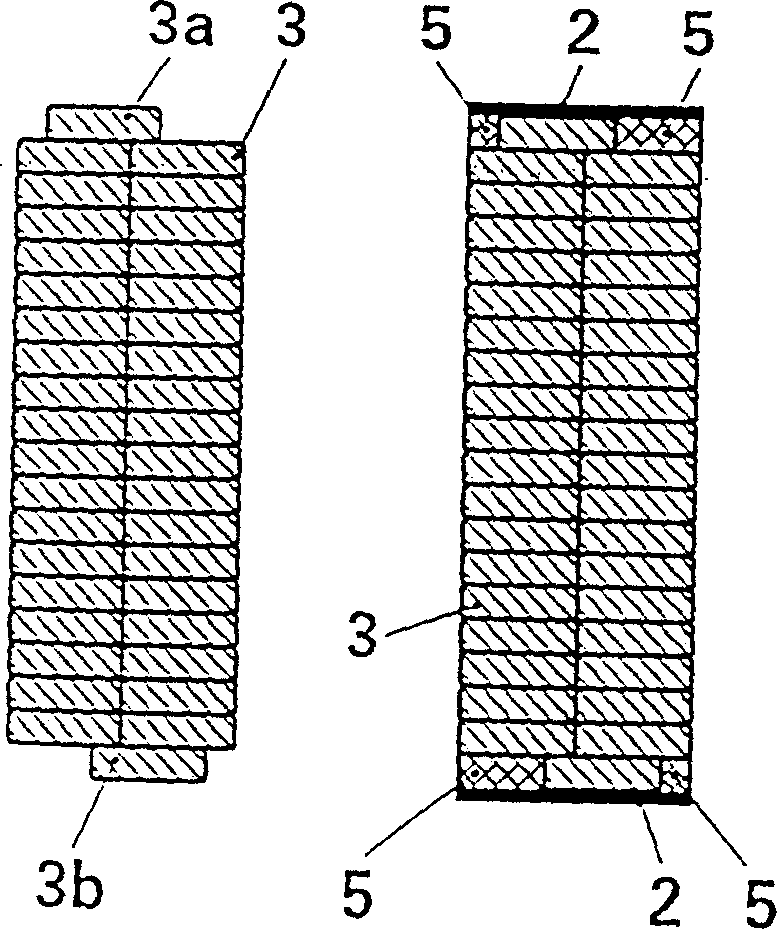

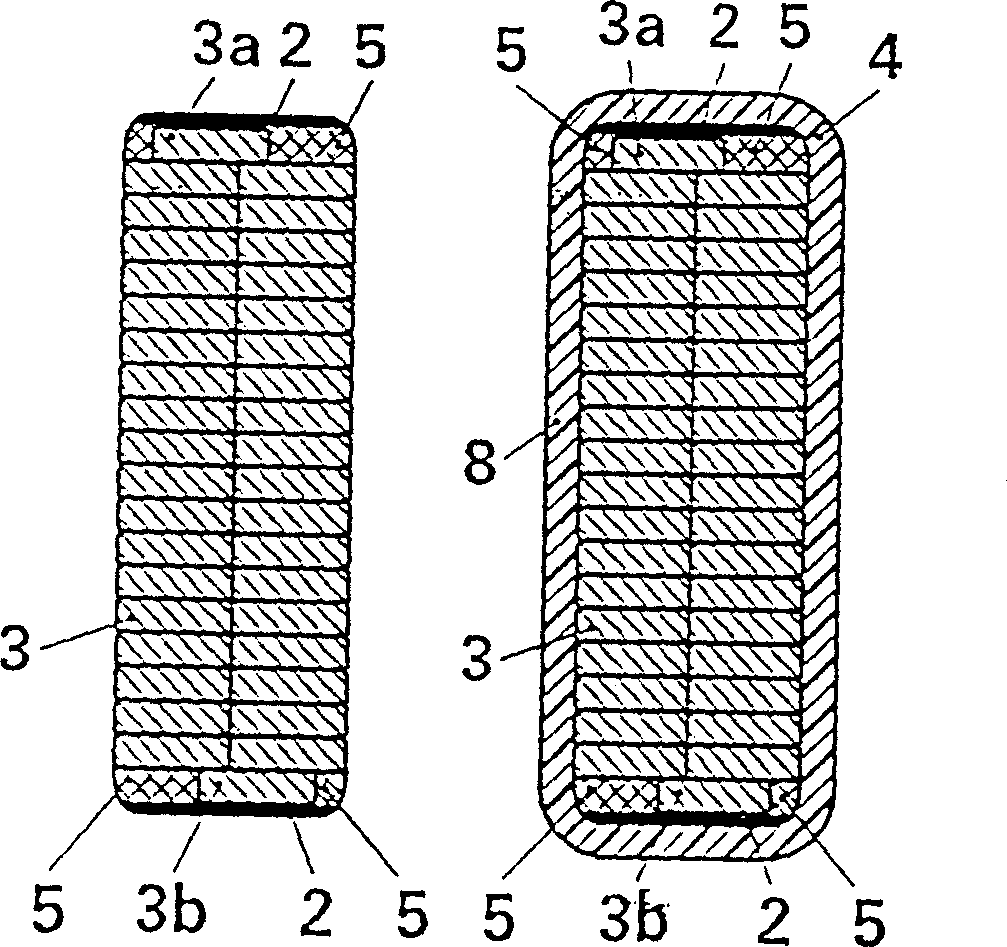

[0023] During the manufacture of the conductor winding bars it is important that the surface of the conductor winding bars be as flat as possible, which is especially important for motors with indirect cooled stator windings. In the case of this model, the heat generated by the conductor winding rods is dissipated via the radial and / or axial cooling channels of the stator laminated core 1, so that, in the slot part A, only the comparative The wide sides guarantee good heat transfer, while the narrow sides of the semiconductor strips squeeze optimally into the grooves. Furthermore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com