Slide bearing

A sliding bearing and relatively sliding technology, which is applied in the direction of sliding contact bearings, bearings, and rotating bearings, etc., can solve the problems of increased friction torque, unsatisfactory design, and increased wear design, etc., to achieve excellent assembly and simple structure , The effect of long bearing life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 3、 comparative example 1 and comparative example 2

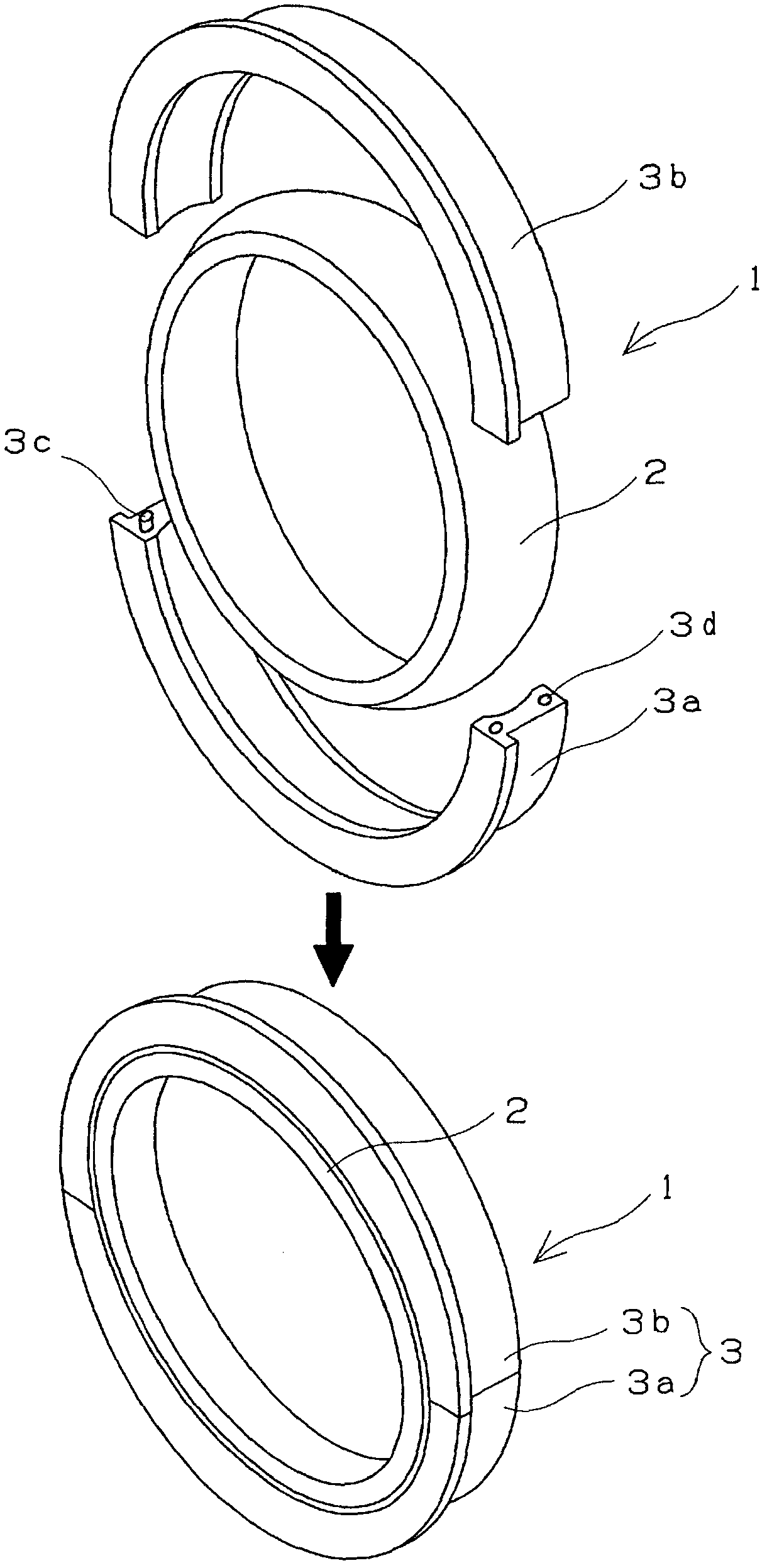

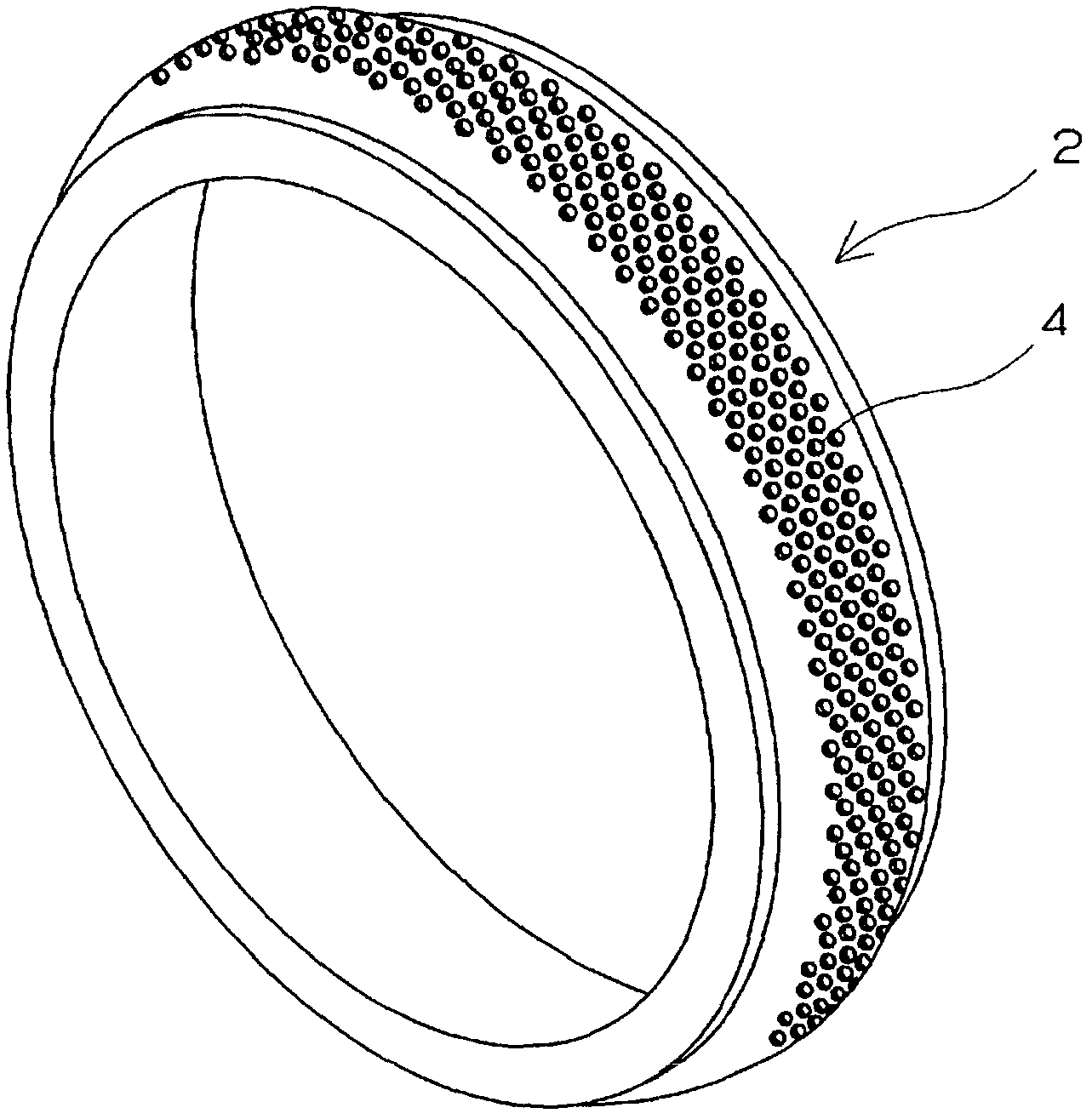

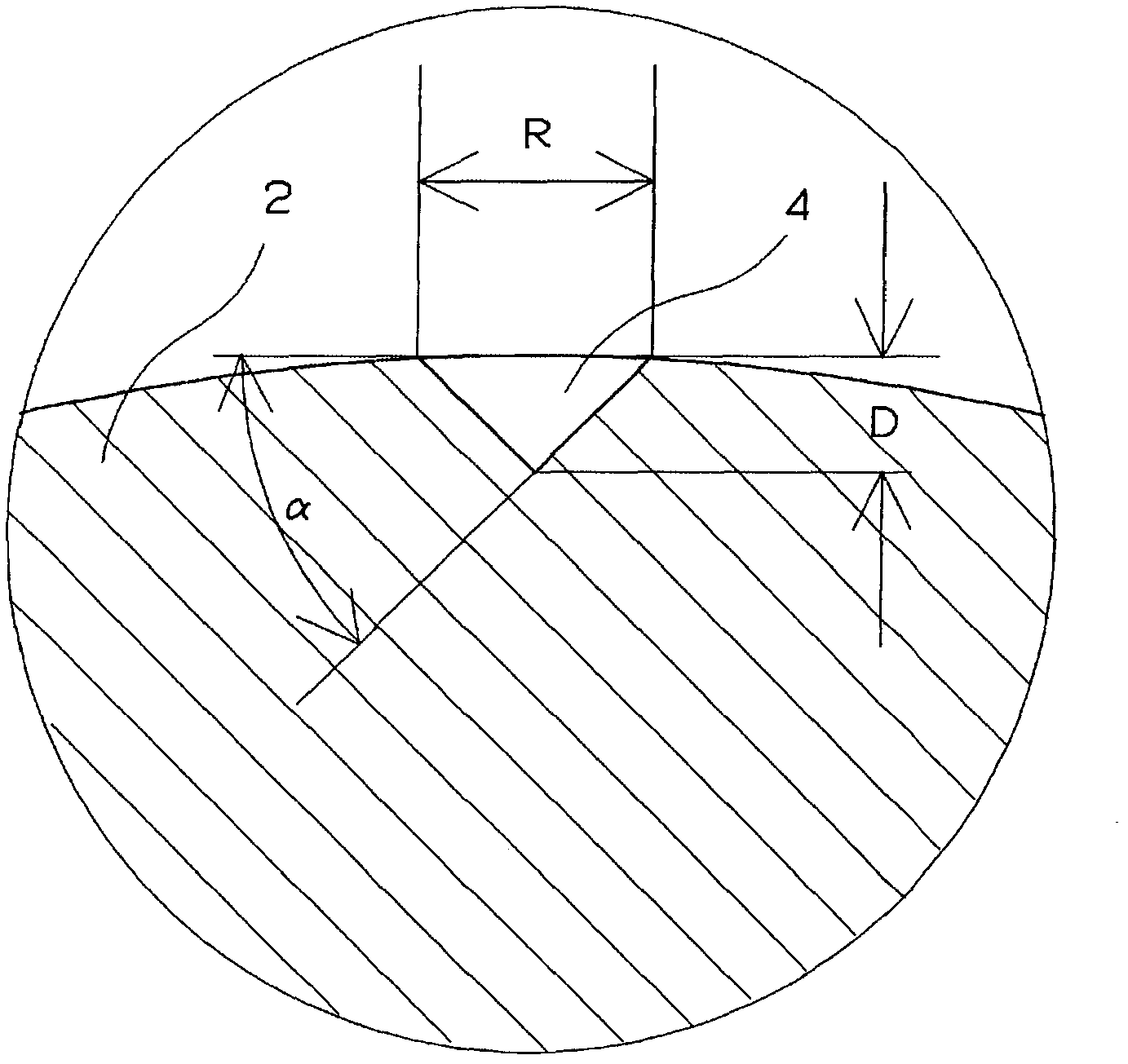

[0074] Prepare synthetic resin, sintered metal, fluorine grease, and grease retaining recess shown in Table 1. Inner ring inner diameter φ25mm (convex curvature R15.5mm), outer ring outer diameter φ37mm (concave curvature R15.5mm), and width 7mm Sliding bearing test piece ( figure 1 plain bearing shown). This test piece was subjected to the friction and wear test shown below, and the coefficient of dynamic friction was measured. The results are written down in Table 1 together. In addition, the amount of grease in Examples 2, 3, and Comparative Example 2 was 1 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com