Atomizing film plating device

A technology of coating device and atomizing box, which is applied in spraying device, liquid spraying device, and device for coating liquid on the surface, etc., can solve the problems of inability to connect, increase cost, and inconvenience for people, so as to speed up drying speed and improve efficiency. Component content and uniformity, good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

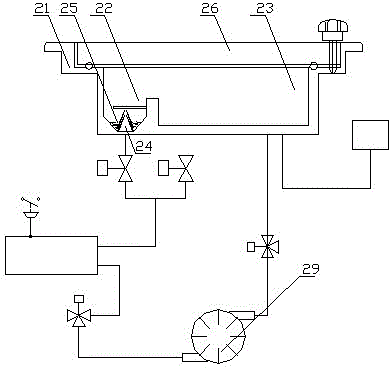

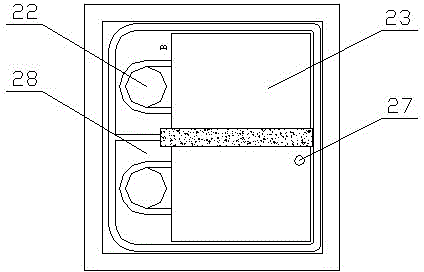

[0014] As shown in the figure: an atomization coating device includes an atomization box 21, the top of the atomization box 21 is provided with a sealing cover 26, and the atomization box 21 is provided with a liquid medicine storage chamber 28 and a coating chamber that communicate with each other 23. The liquid medicine storage chamber 28 is provided with more than one medicine pool 22, the bottom of the medicine pool 22 is provided with an atomizer 24, the medicine pool 22 is equipped with a liquid nano-polymer material 25, and the coating chamber 23 is provided with a pumping hole 27, the pumping hole 27 is arranged on the side away from the medicine pool 22 in the coating chamber 23, the pumping hole 27 is connected to a vacuum device 29, the atomizer 21, the pumping hole 27 and the pumping The vacuum device 29 forms a gas flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com