Organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating and preparation method thereof

A technology of acrylic and organic fluorine, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficulty in forming a three-dimensional network cross-linked film, poor water resistance, poor stain resistance, and lack of cross-linking in linear molecules Points and other problems, to achieve the effect of high price, plump coating film and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

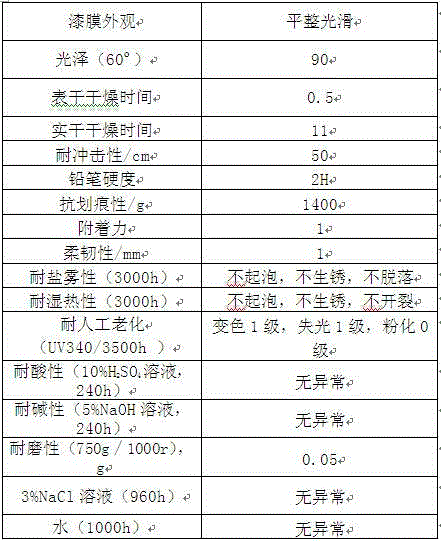

Embodiment 1

[0018] A kind of organosilicon organic fluorine modified acrylic heavy-duty anticorrosion coating described in this embodiment, it is made of the barium sulfate that contains weight ratio 500g fluorosilicon modified acrylic resin, 120g titanium dioxide, 8g carbon black, 5g iron oxide red, 100g, 50g Calcium carbonate, the mixture of 4g foam breaking polymer and polysiloxane, 4g polyether modified polydimethylsiloxane copolymer solution, 150g butyl acetate, xylene and propylene glycol methyl ether acetate mixed solvent and 150g Aliphatic polyurethane curing agent; Wherein, fluorosilicone modified acrylic resin consists of 9.40g of trifluoroethyl methacrylate, 17.2g of methyl methacrylate, 4g of butyl acrylate, 3g of butyl methacrylate, 11.2g of hydroxyethyl methacrylate, 9.5g of styrene, 3g of methacryloxypropyltrimethoxysilane, 0.5g of acrylic acid, 0.8g of azobisisobutyronitrile, 28g of toluene, 0.2 g of azobisisobutyronitrile, 3g of toluene and 10.2g of xylene.

[0019] A ki...

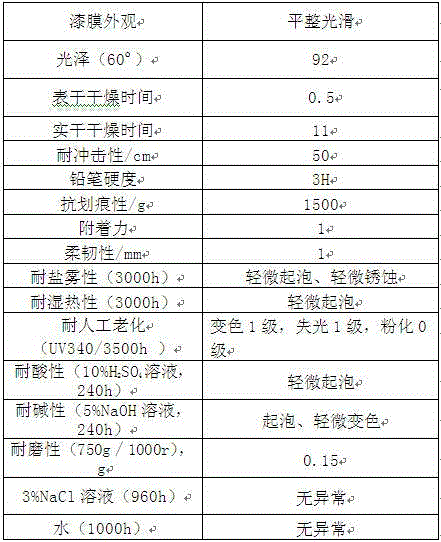

Embodiment 2

[0025] A kind of organosilicon organic fluorine modified acrylic acid heavy-duty anticorrosion paint described in this embodiment, it is by the fluorosilicon modified acrylic resin that contains weight ratio 500g, 4g modified organosilicon carboxylate amine salt, 120g titanium dioxide, 8g carbon black, 5g iron oxide red, 100g barium sulfate, 50g calcium carbonate, 4g mixture of foam breaking polymer and polysiloxane, 4g polyether modified polydimethylsiloxane copolymer solution, 50g butyl acetate, xylene and Propylene glycol methyl ether acetate mixed solvent and 150g aliphatic polyurethane curing agent; Among them, the fluorosilicone modified acrylic resin is composed of 22.1g of methyl methacrylate, 8g of butyl acrylate, 5g of butyl methacrylate, 11.5g Hydroxyethyl methacrylate, 9.3g of styrene, 3g of methacryloxypropyltrimethoxysilane, 0.3g of acrylic acid, 0.8g of azobisisobutyronitrile, 28g of toluene, 0.2g of Azobisisobutyronitrile, 3g of toluene and 8.8g of xylene.

[...

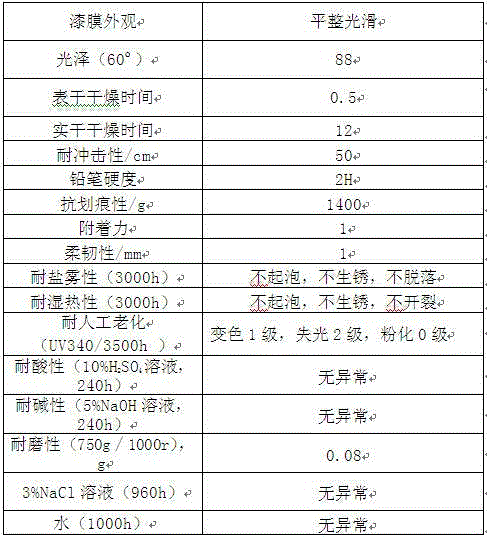

Embodiment 3

[0032]A kind of organosilicon organofluorine modified acrylic acid heavy-duty anticorrosion paint described in this embodiment, it is made of containing 500g fluorosilicon modified acrylic resin, 4g modified organosilicon carboxylate amine salt, 120g titanium dioxide, 8g carbon black, 5g by weight Red iron oxide, 100g barium sulfate, 50g calcium carbonate, 4g mixture of foam breaking polymer and polysiloxane, 4g polyether modified polydimethylsiloxane copolymer solution, 50g butyl acetate, xylene and propylene glycol Methyl ether acetate mixed solvent, 150g of aliphatic polyurethane curing agent; Among them, fluorosilicone modified acrylic resin is composed of 9.4g trifluoroethyl methacrylate, 19.2g methyl methacrylate, 5g butyl acrylate, 4g formazan Butyl acrylate, 10.50g hydroxyethyl methacrylate, 9.5g styrene, 1g acrylic acid, 0.8g azobisisobutyronitrile, 28g toluene, 0.2g azobisisobutyronitrile, 30g toluene and 9.6g xylene composition.

[0033] A kind of organosilicon org...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com