Patents

Literature

61results about How to "Low fluorine content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating and preparation method thereof

ActiveCN104673039ALow priceGood alkali resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinAcrylic coating

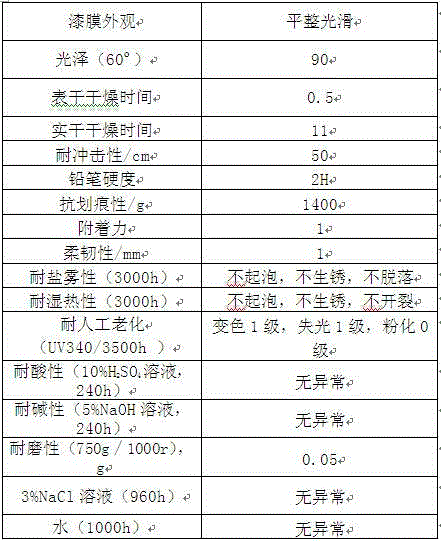

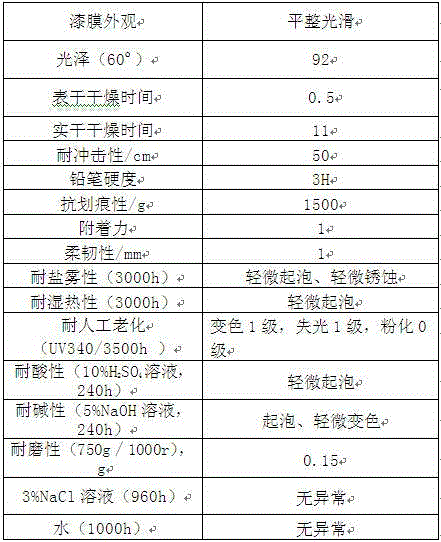

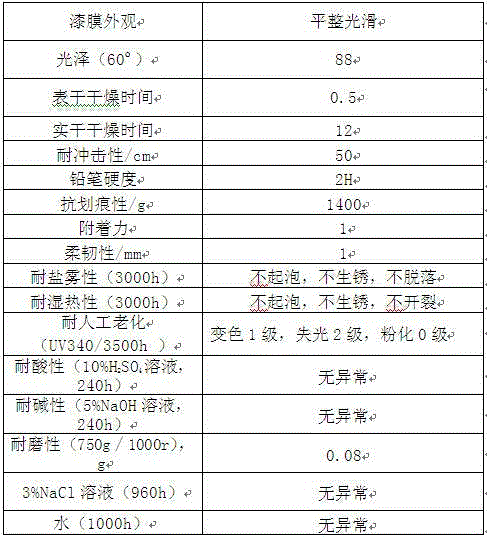

The invention discloses an acrylic coating and a preparation method thereof, and particularly relates to an organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating and a preparation method thereof. The invention provides the organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating which has free TDI content less than 0.15% after blended, is capable of reducing the pollution hazard on the environment and has preferable film-forming property and a preparation method thereof, aiming at overcoming the defects of the prior art. The organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating comprises the following components in parts by weight: 40-60 parts of fluorine-silicon modified acrylic resin, 0.2-0.5 part of dispersing agents, 10-20 parts of pigments, 10-20 parts of fillers, 0.2-0.5 part of defoaming agents, 0.2-0.5 part of levelling agents, 10-15 parts of solvents and 8-14 parts of aliphatic polyurethane curing agents, wherein the proportion sum is 100 parts.

Owner:ZHEJIANG TIANNU GROUP PAINT MFG

Method for preparing lanthanum-enriched rare earth chloride from bastnaesite

The invention relates to a method for producing lanthanum-enriched rare earth chloride by using bastnaesite as a raw material. The method comprises the following steps of: mixing the bastnaesite and sodium hydroxide and then roasting, carrying out sodium hydroxide alkali conversion on the bastnaesite to remove fluorine, washing the bastnaesite subjected to alkali conversion with water, and carrying out hydrochloric acid optimum solution to obtain lanthanum-enriched rare earth chloride liquid. In the alkali conversion process, the ratio of NaOH to REO (Rare Earth Oxide) in the bastnaesite is (0.10-0.40):1, the alkali conversion is carried out at 300-600 DEG C, and then the bastnaesite subjected to the alkali conversion is washed with water 3-8 times of the bastnaesite by weight proportion. In the optimum solution process, the weight ratio of 31% of industrial hydrochloric acid by weight to the REO in the bastnaesite is (1-1.5):1. In the alkali conversion process, the fluorine in the enriched lanthanum is preferentially subjected to the alkali conversion to obtain lanthanum-enriched hydroxide which is dissolved with acid, acid-soluble lanthanum-enriched rare earth is dissolved in a solution, and cerium is reserved in slag with large amount of fluorine, therefore, the purpose of separating the cerium and non-cerium can be achieved easily. In the whole process, the step of solid-liquid separation is reduced, the consumption of auxiliary materials is lowered, the yield per unit of equipment and the yield of rare earth are improved, and the production process has less pollution.

Owner:CHINA MINMETALS BEIJING RES INST OF RE

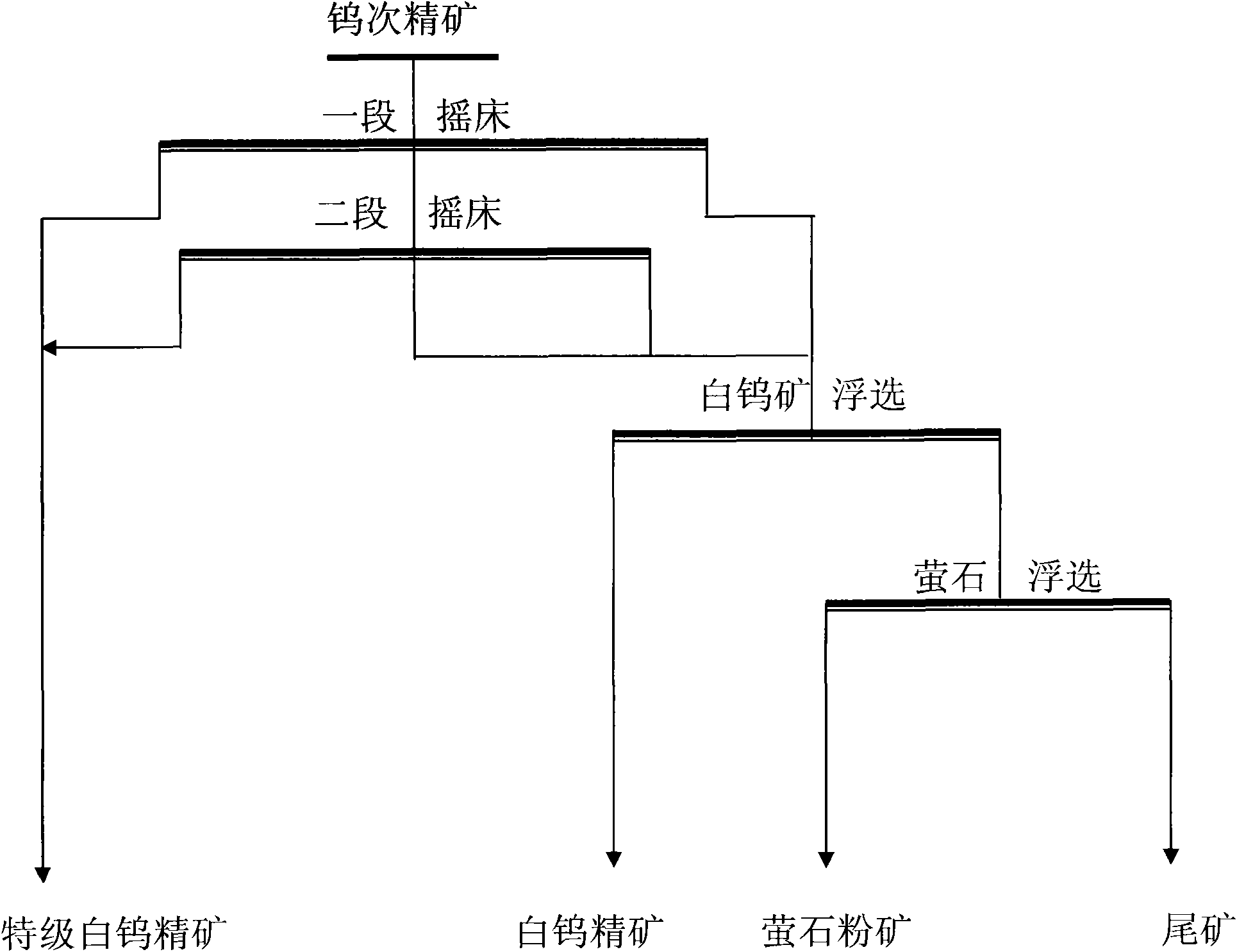

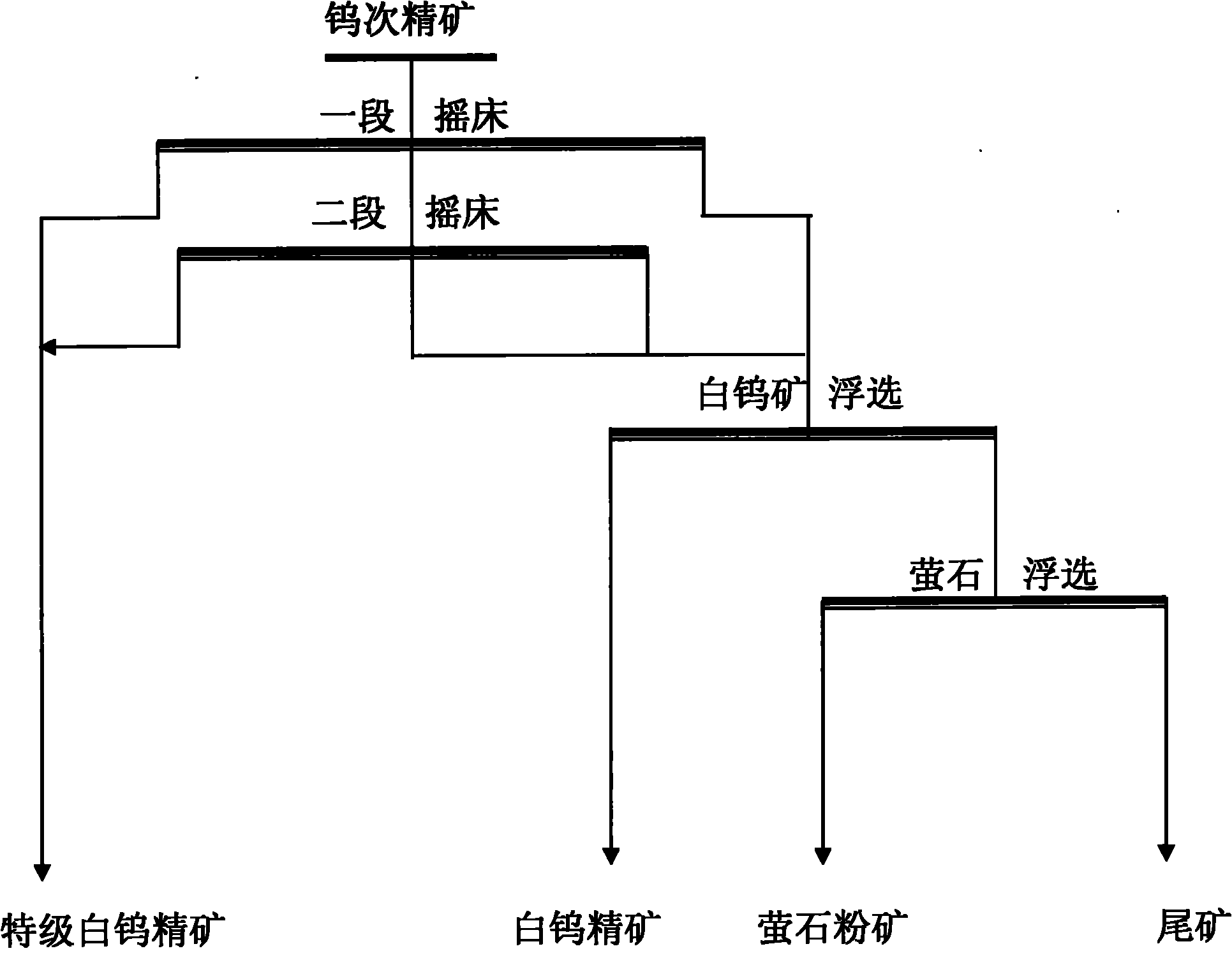

Method for separating scheelite from fluorite

InactiveCN101979145AReduce contentLow fluorine contentFlotationWet separationAmmonium paratungstateTungsten trioxide

The invention relates to a method for separating scheelite from fluorite and belongs to the technical field of mineral dressing of metal mines. The method comprises the following steps of: preparing ore pulp from tungsten secondary concentrate ore containing 30 to 60 weight percent of tungsten trioxide; carrying out two stages of separation by adopting shaking tables; then making middlings of a first-stage shaking table enter a second-stage shaking table to be separated so as to produce special grade white tungsten concentrate ore products containing over 70 weight percent of tungsten trioxide; concentrating the middlings and tailings, which are separated by the shaking tables, to 50 to 60 weight percent in a centralizing mode, then adding water glass and TN into the concentrated middlings and tailings, and uniformly stirring the mixture in a stirring barrel for flotation; diluting flotation pulp to 20 to 30 weight percent, regulating the pH of the diluted flotation pulp to 9 to 10, and adding an inhibitor KJ and a collector YY to produce white tungsten concentrate ore containing over 65 weight percent of tungsten trioxide; and further carrying out flotation on the flotation tailings to obtain fluorite powder ore containing over 85 percent of calcium fluoride. The method has the advantages of high mineral dressing index, simple process, low production cost, environmental protection and capability of better solving the environmental problems of ammonium paratungstate manufacturing enterprises, which are caused by high fluorine content of raw materials.

Owner:YUNNAN TIN GROUP HLDG

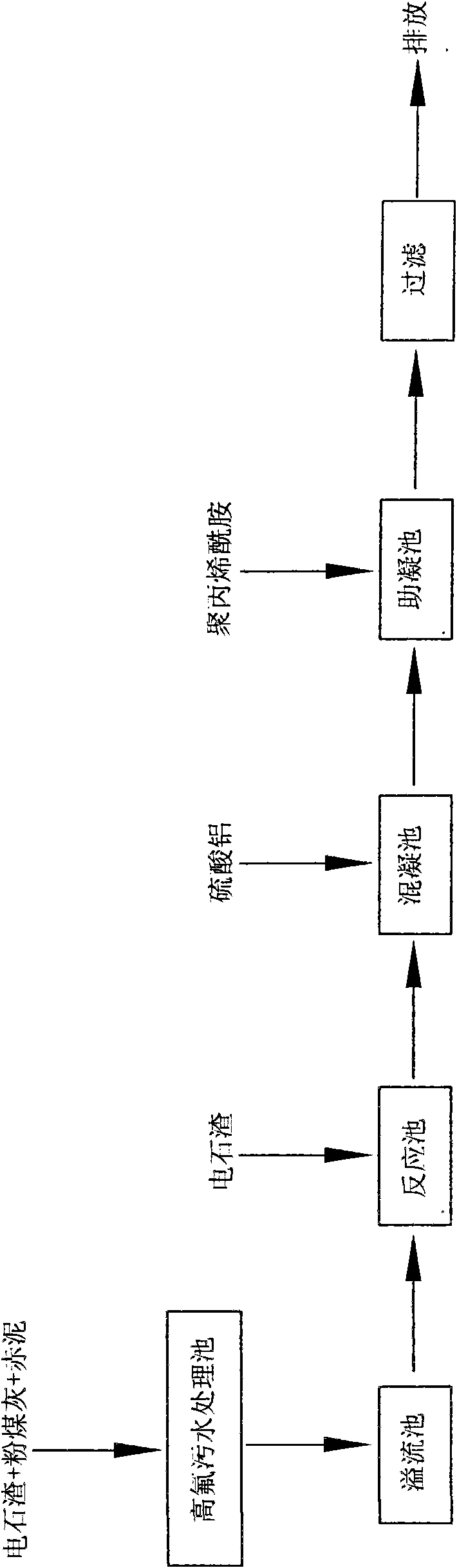

Method for jointly treating high-fluorine sewage by utilizing waste slag

InactiveCN101560006ALow fluorine contentRemove completelyWater contaminantsMultistage water/sewage treatmentIndustrial wasteTreatment pond

The invention provides a method for jointly treating high-fluorine sewage by utilizing waste slag, which comprises the following steps: (1) carbide slag, pulverized fuel ash and red mud are added into a treatment pond containing the high-fluorine sewage and sent into an overflow pond after being stirred and reacting for 10-20 minutes, and clear liquid in the overflow pond flows into a reaction pond; (2) the carbide slag is added into the reaction pond, and the pH is regulated to 9-10; after 10-20 minutes of reaction, a coagulating agent is added to the clear liquid, and the pH is regulated to 6-7.5; after 10-20 minutes of reaction, a coagulant aid is added to the clear liquid; and after 10-20 minutes of reaction, the clear liquid is filtered and drained. The method uses the industrial waste slag for treating the high-fluorine sewage so as to ensure that the fluorine content in the treated sewage conforms to an environmental protection standard specified by the nation, thus the pollution of the high-fluorine sewage to the environment is greatly reduced. Meanwhile, the harm of the industrial slag to the environment is also reduced, thus the method has higher economic benefit and social benefit.

Owner:河南未来铝业(集团)有限公司

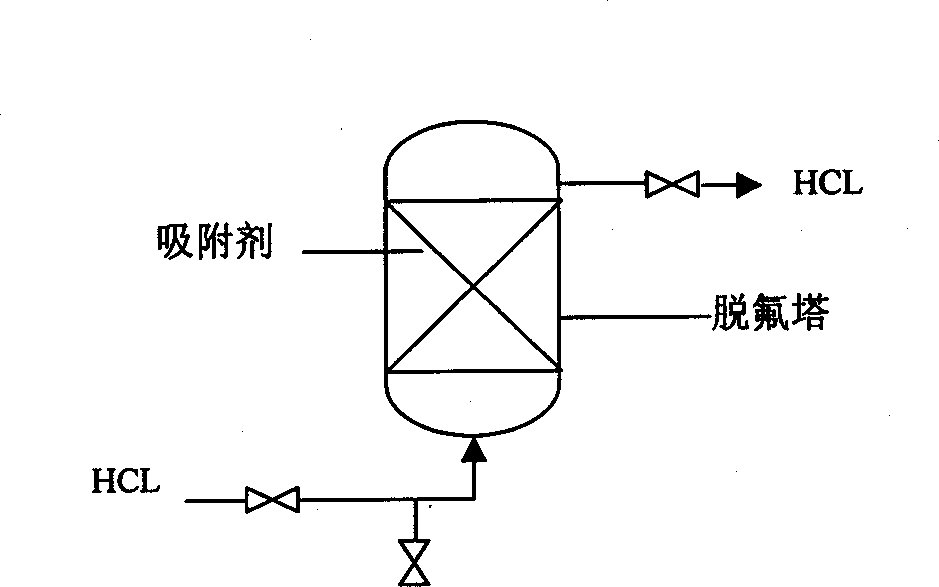

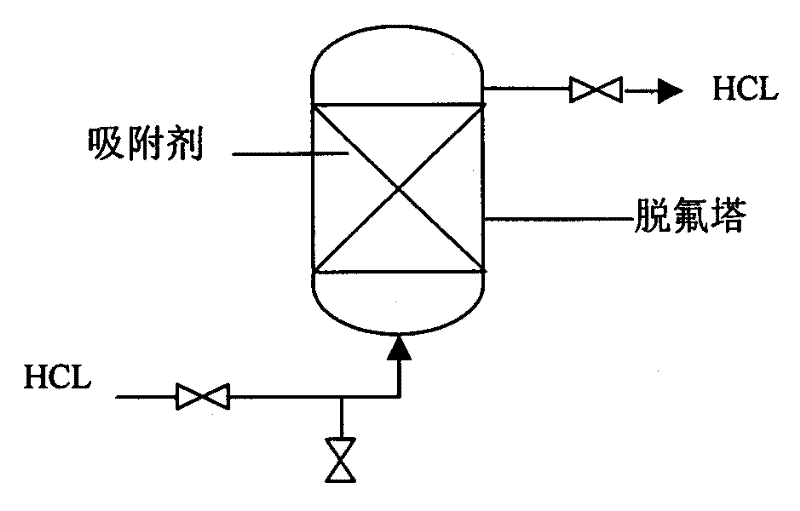

Process for defluorinating anhydrous hydrogen chloride

InactiveCN1363510AHigh purityLow fluorine contentChlorine/hydrogen-chlorideDispersed particle separationHydrogenSorbent

A process for defluorinating anhydrous hydrogen chloride as by-product in the technology for preparing hydrogen contained fluorchlorohydrocarbon features that the hydrogen chloride is pre-activated and then defluorinated in serially or parallelly connected defluorinating towers by adsorption at -10-80 deg.C and 0.1-20 MPa. The alumina is used as main component of defluorinating agent. Its advantage is high defluorinating effect (less than 10 ppm).

Owner:ZHEJIANG QUHUA FLUOR CHEM

Fluorine removing process and device for drinking water

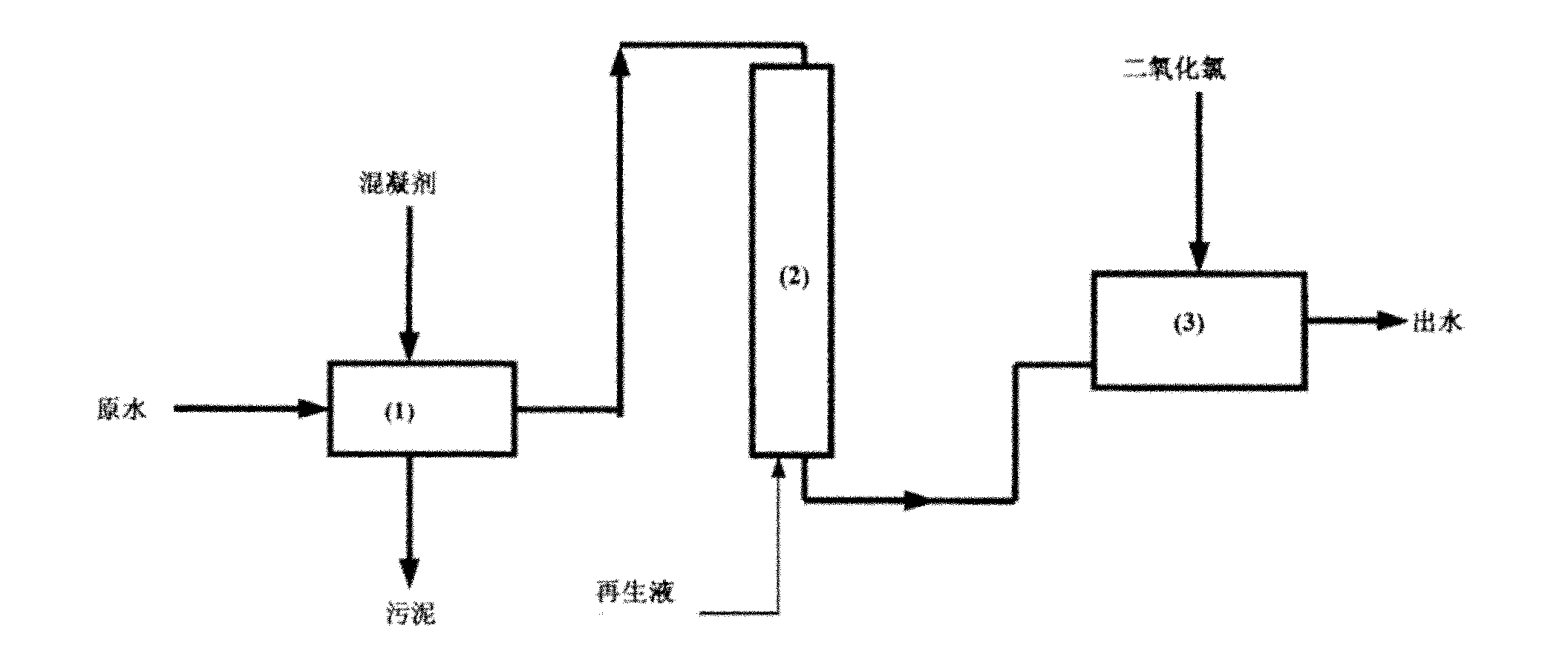

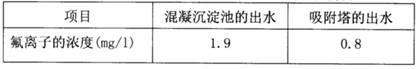

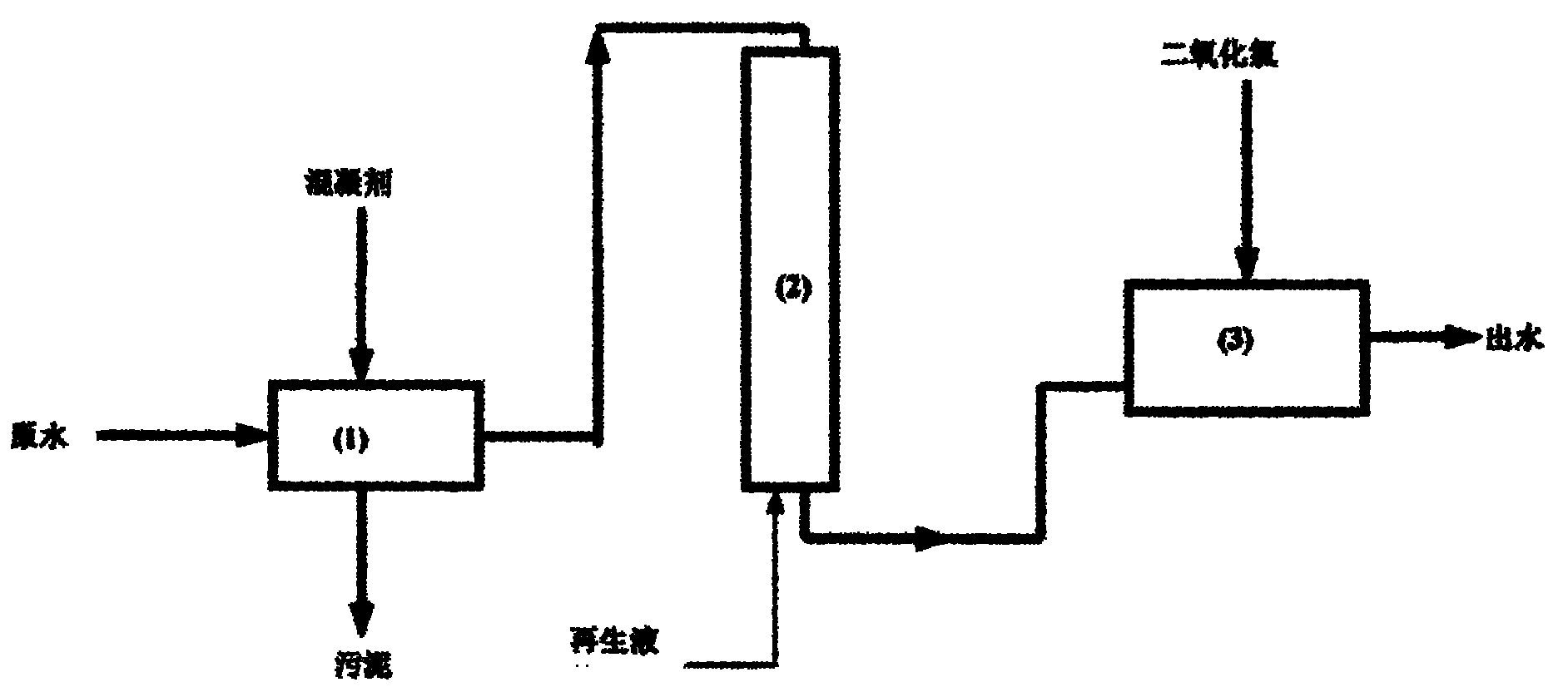

InactiveCN102120657ALow fluorine contentReduce processing costsWater contaminantsMultistage water/sewage treatmentHigh concentrationSorbent

The invention discloses a fluorine removing process and a fluorine removing device for drinking water, and relates to a water treatment process and a water treatment device. The process at least comprises two treatment steps of coagulating sedimentation and adsorption, wherein the coagulating sedimentation is that fluorinated water is subjected to coagulating sedimentation through an inorganic aluminum coagulant agent to make the fluorine content of the treated water less than 2mg / l; and the adsorption is that an adsorbent is adopted for adsorption treatment. The invention has the advantages that: the low cost of a coagulation process and the high efficiency of an adsorption method are integrated, and the low-cost and high-efficiency fluorine removal is realized. In the coagulating sedimentation process, a proper amount of proper coagulant is selected according to the fluorine content in raw water, and the fluorine content in the water can be reduced, so that the regeneration frequency of the adsorbent is greatly reduced, the service life of the adsorbent is prolonged, the water treatment cost is reduced, and the invention has good application prospect for treating high-concentration fluorine-containing drinking water.

Owner:姜雪

A supercritical carbon dioxide reverse-phase association fracturing fluid, and a preparing method and application thereof

ActiveCN108913116ALow fluorine contentSystem environmental protectionFluid removalDrilling compositionFracturing fluidSolvent

The invention relates to a supercritical carbon dioxide reverse-phase association fracturing fluid, and a preparing method and application thereof. The fracturing fluid has a reverse-phase associationstructure in which water is covered with supercritical carbon dioxide, and includes a carbon dioxide phase and a water phase, wherein the volume ratio of the carbon dioxide phase to the water phase is (7-9):(1-3), and the water phase comprises a fluorine-containing surfactant, a cosolvent or a cosurfactant and water. The viscosity of the supercritical carbon dioxide phase is improved, the fluorine content of the system is reduced, and the fracturing fluid is used for increasing the recovery efficiency of shale gas. The fracturing fluid is more environmentally friendly and higher in practicability, and can be effectively used for shale gas extraction through supercritical carbon dioxide displacement.

Owner:SHANDONG UNIV

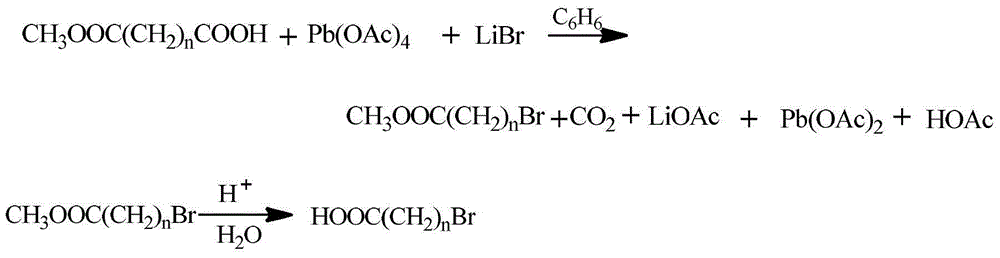

Method of leaching valuable metal from waste lithium ion battery and synchronously conducting defluorination

InactiveCN111961857ALow fluorine contentIncrease the aging defluorination stepProcess efficiency improvementMetal leachingProcess engineering

The invention provides a method of leaching valuable metal from a waste lithium ion battery and synchronously conducting defluorination. The method specifically comprises the steps that the waste lithium ion battery is pretreated, electrode powder materials are obtained, the electrode powder materials, water and concentrated sulfuric acid are evenly mixed, curing treatment is conducted, the temperature of the curing treatment is controlled to range from 50 DEG C to 200 DEG C, the time of the curing treatment is controlled to range from 1.0h to 24.0h, a leaching agent is added to a cured material to conduct leaching operation after the curing treatment is accomplished, filtering operation is conducted after leaching operation is accomplished, and low-fluorine-content valuable metal leachateis obtained. According to the method, removal of fluorine in the electrode powder and leaching operation of the valuable metal are organically combined, the curing defluorination step is added beforeacid pickling operation of the electrode powder is conducted, namely, part of concentrated sulfuric acid is added to the electrode powder to conduct curing defluorination, then part of concentrated sulfuric acid is supplemented and added to the defluorinated electrode powder to conduct leaching operation, and the two processes are closely connected. Compared with a conventional acid pickling technology, the method has the advantages that the acid consumption is not increased, the technological cost is low, the operability is high, the fluorine content of the obtained valuable metal leachate is low, and the industrial production is easily achieved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Technology and device for producing defluorinated phosphoric acid

PendingCN110980674AIncreased surface reaction areaIncreased fluorine release ratePhosphorus compoundsO-Phosphoric AcidPhysical chemistry

A technology for producing defluorinated phosphoric acid is characterized in that fluorine-containing phosphoric acid produced from wet-process phosphoric acid is divided into two parts, one part is used as a returned acid, and the other part is used as crude phosphoric acid; an injection pump A, a reaction kettle, an injection pump B, a gas-liquid separator and an absorption tower are sequentially connected through pipelines to form a circulating closed pipeline system which is in a micro-negative pressure state; the injection pump A and the injection pump B enable a gas in the system to circularly flow at a high speed, and the injection pump A sucks and mixes the returned acid and sulfuric acid, then sucks a reaction liquid and sulfuric acid in the reaction kettle, mixes the reaction liquid and sulfuric acid with gas flow and sprays the obtained mixture onto the liquid level of the reaction kettle; vacuum generated by the injection pump B makes the crude phosphoric acid and low-fluorine hot steam emitted from the reaction kettle be sucked and mixed and then enter the gas-liquid separator, a liquid led out from the gas-liquid separator is refined product defluorinated phosphoric acid, the gas is sent to the bottom of the absorption tower, and a defluorination tail gas led out from the top of the absorption tower enters the injection pump A and circularly flows; and a washing liquid is sprayed from the top of the absorption tower, and fluosilicic acid liquid is led out from the bottom of the absorption tower. The invention further discloses a device for producing defluorinated phosphoric acid.

Owner:HUANGGANG NORMAL UNIV +1

Low fluorine content material and synthesizing process thereof

ActiveCN1861680AImprove waterproof performanceGood oil resistanceFibre treatmentPaper coatingMethacrylateEmulsion

This invention relates to a low fluorine material used for fabric treatment or paper, leather, wood, rock and other materials surface treatment and protection. It is a O / W type emulsion, includes fluorolkyl methacrylate or fuoroalkyl acrylate or both, acrylic ester or metharylate active or both, substitute ethylene with active radicals, modified monomeric random copolymerization, and the use of monomer with fluorine is below 20%. The method is also opened. This material not only makes protected materials acquire good property such as water proof, oil proof, anti-fouling, gas permeation, but also has ability of solvent resistance, acid resistance, alkali stability, and resistance to aging.

Owner:GUANGZHOU BAIYUN CHEM IND +1

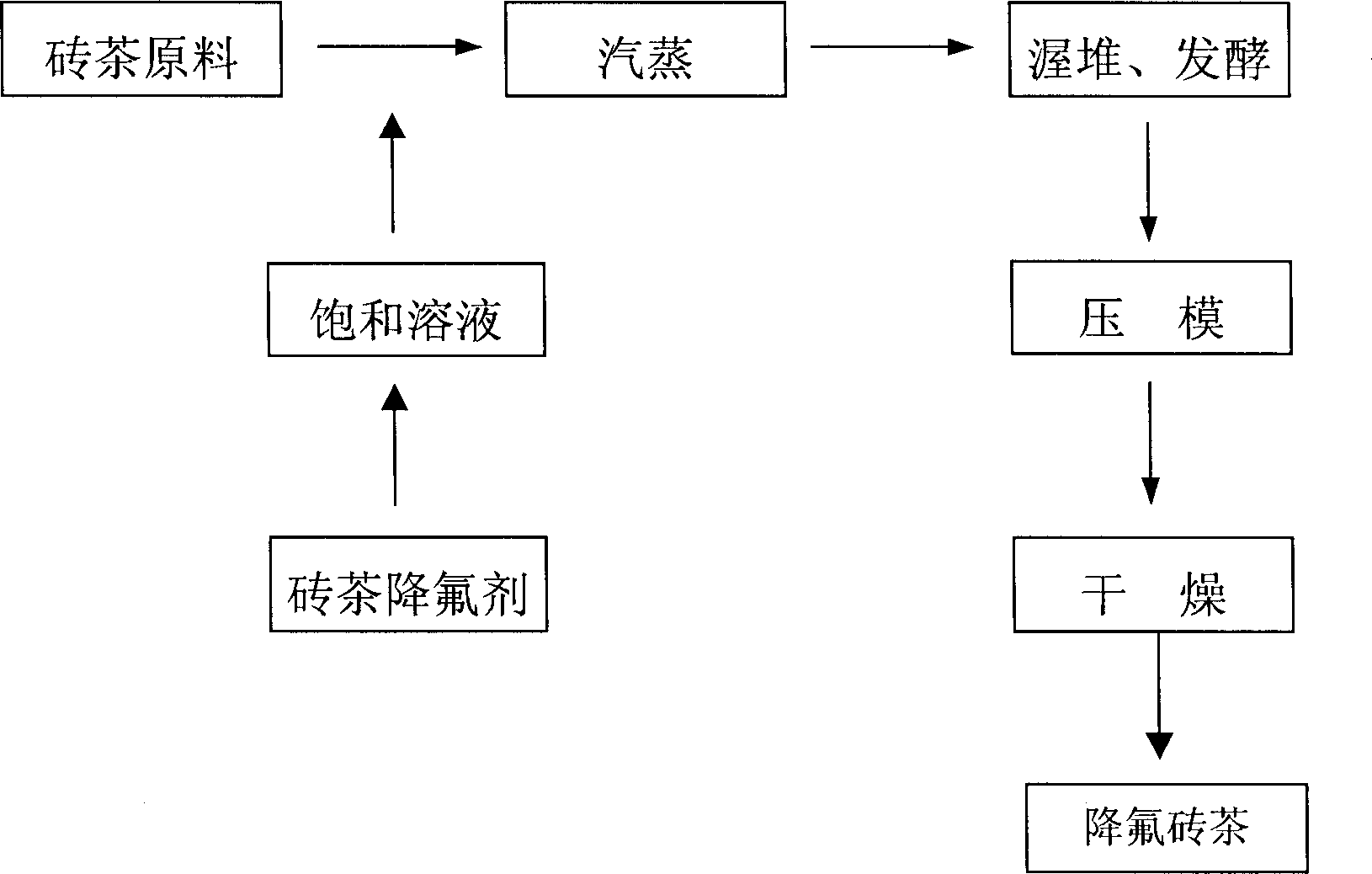

Method for processing reduced fluorine content brick tea

InactiveCN1435101AReduce water-soluble fluorine contentQuality is not affectedPre-extraction tea treatmentPolymer scienceBrick

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

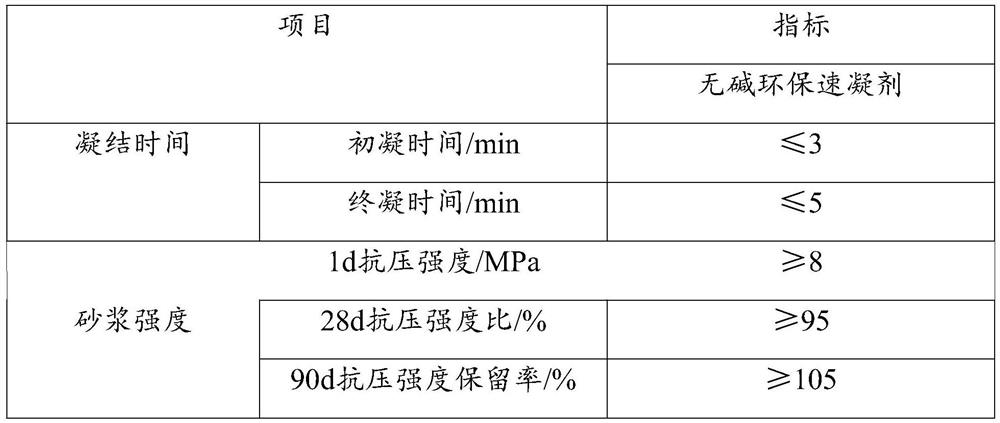

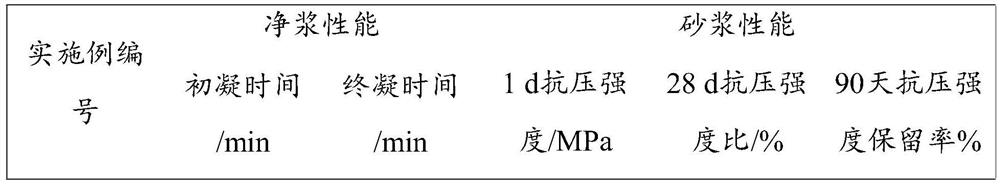

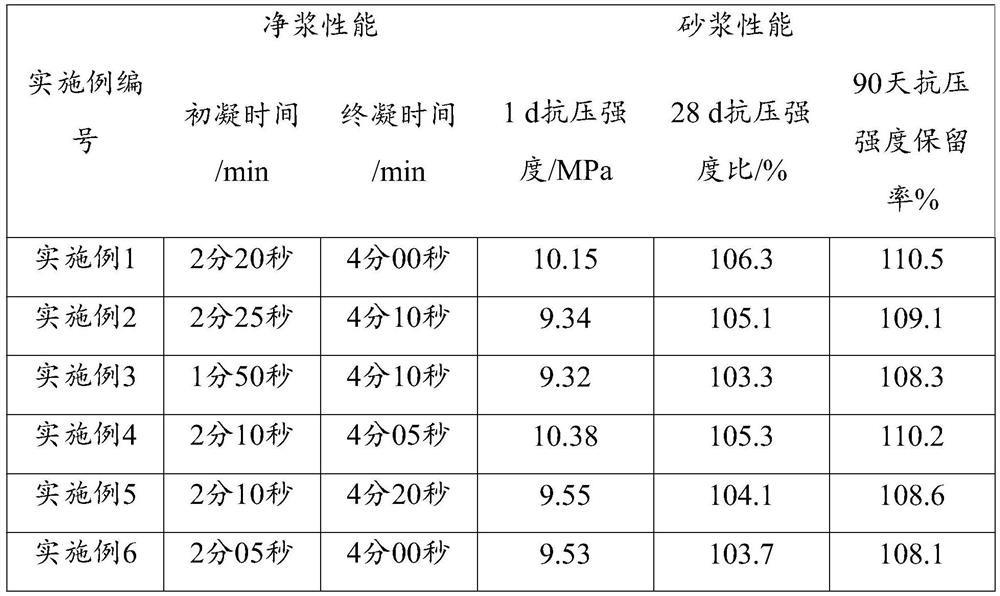

Alkali-free setting accelerator, preparation method and application thereof

The invention relates to the technical field of engineering materials, in particular to an alkali-free setting accelerator, a preparation method and application thereof. The alkali-free setting accelerator is prepared from, by mass, 40-55% of aluminum sulfate, 10-15% of aluminum nitrate, 5.2-10.8% of alkylol amine, 1-1.5% of magnesium fluosilicate, 1-5% of silicate, 0.5-1% of a stabilizer and thebalance water; wherein the stabilizer is a composition prepared by mixing any one or more of sepiolite, zeolite or diatomite according to any proportion. The alkali-free setting accelerator is mainlycomposed of aluminum sulfate, aluminum nitrate, alkylol amine, magnesium fluosilicate and silicate, is extremely low in fluorine content, does not contain other harmful substances, is green and environment-friendly, and does not cause harm to a human body; when the alkali-free setting accelerator is used for spraying concrete, the addition amount of the setting accelerator is small, the initial setting time, the final setting time, the mortar 1d compressive strength, the 28d compressive strength ratio, the 90day compressive strength retention rate and the like of neat paste of the alkali-freesetting accelerator can meet the construction requirements of different types of cement sprayed concrete, and the alkali-free setting accelerator has good cement adaptability.

Owner:北京厚德交通科技股份有限公司

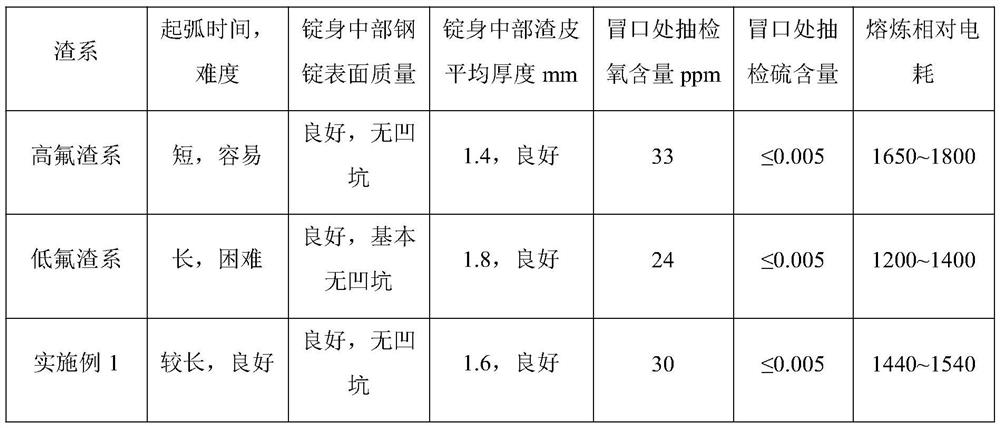

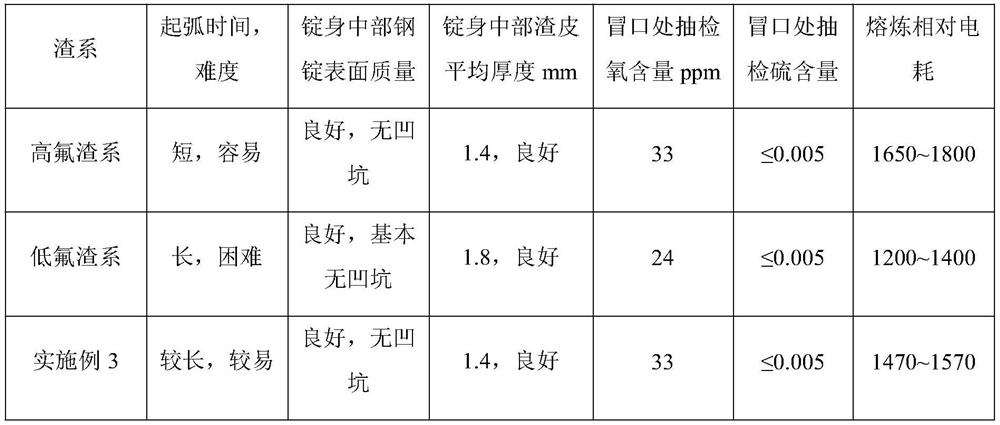

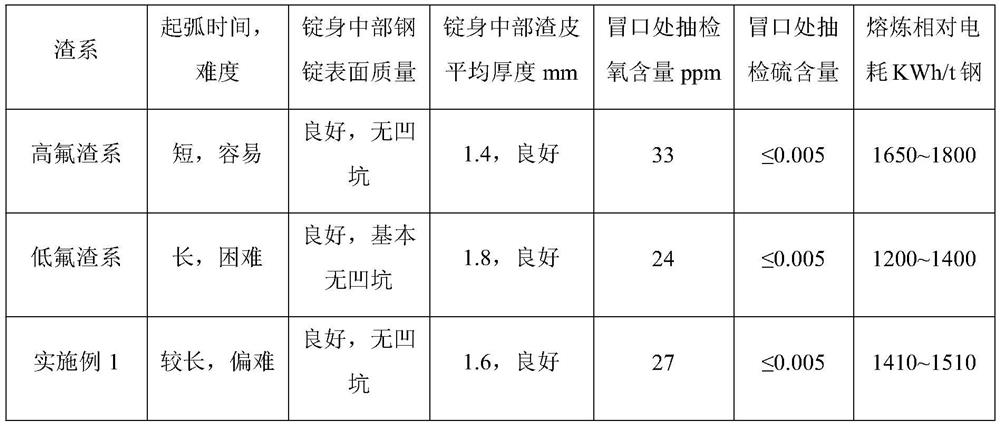

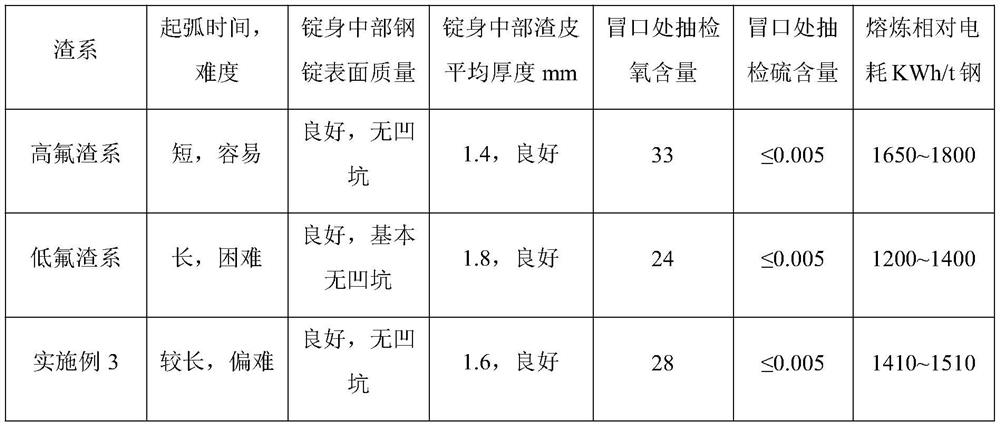

Medium-high fluorine slag system for electroslag remelting of B-containing rotor steel ingot and use method

The invention relates to a medium-high fluorine slag system for electroslag remelting of a B-containing rotor steel ingot and a use method, belongs to the technical field of electroslag special metallurgy, and is used for solving the problems of high energy consumption and high fluorine slag volatilization pollution of an existing B-containing electroslag remelting slag system. The medium-high fluorine slag system comprises the following components in percentage by mass: 40.26-46.79% of CaF2, 23.07-33.99% of Al2O3, 22.25-24.83% of CaO, 3-5% of MgO, 0.5-1.5% of B2O3 and the balance impurities, wherein SiO2 in the impurities is less than 0.5%. The medium-high fluorine slag system reduces the high fluorine slag volatilization pollution, and is low in power consumption and excellent in comprehensive metallurgical performance in use.

Owner:CENT IRON & STEEL RES INST

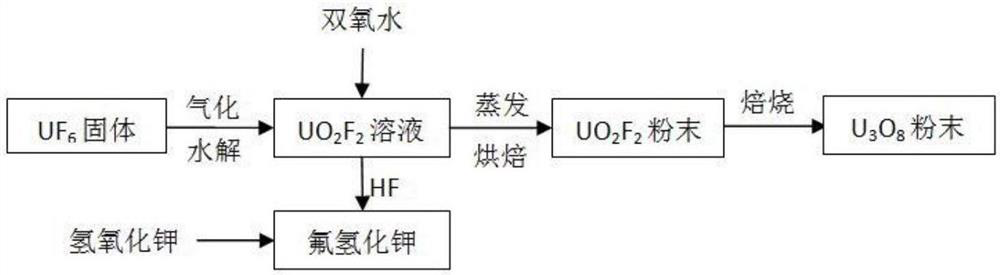

Method for preparing triuranium octaoxide from uranium hexafluoride

PendingCN112607780AAvoid joiningReduce generationAlkali metal fluoridesUranium oxides/hydroxidesHydrolysatePotassium hydroxide

The invention belonging to the technical field of nuclear fuel circulation, and particularly relates to a method for preparing triuranium octaoxide from uranium hexafluoride. The method comprises the following three steps: step 1, preparation of a UO2F2 hydrolysate; step 2, preparation of UO2F2 powder; step 3, roasting for preparation of U3O8. According to the method, the process of preparing U3O8 through conventional UF6 reduction is shortened, and the addition of ammonia water in the process is avoided, so ammonia nitrogen wastewater generated in the process is reduced, a preparation process is simple, cost is low, and industrialization is easy to realize. According to the method, a large amount of fluorine in UF6 is converted into HF acid through water, the HF acid reacts with potassium hydroxide to finally prepare a byproduct potassium hydrogen fluoride, and the byproduct potassium hydrogen fluoride can be returned to an electrolytic fluorine production unit in a uranium conversion system so as to realize recycling. The U3O8 prepared by the method is more uniform in granularity, good in powder flowability, low in radioactivity, low in fluorine content and convenient for long-term stable storage.

Owner:中核二七二铀业有限责任公司

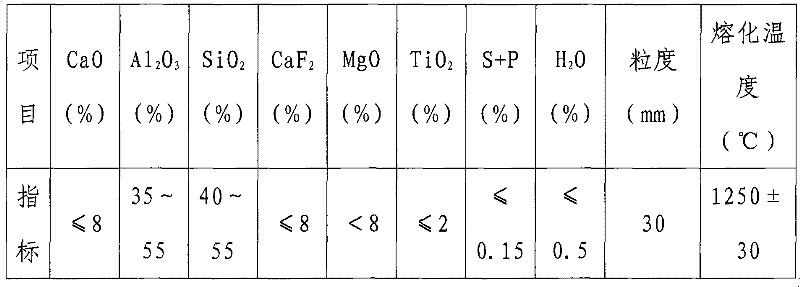

Aluminium-silica type refined pre-smelting slag

InactiveCN102344996AThe composition is uniform and stableLower melting temperatureProcess efficiency improvementBrickMetallic foreign material

The present invention discloses an aluminium-silica type refined pre-smelting slag, which is provided for solving the problems of prominent foreign material quality problem and the large fluctuation during a high-grade bearing steel producing process, low continuous casting success rate (only about 30%) during a middle (high) sulfur structure steel producing process, and high unqualified rate of the sulfide. The aluminium-silica type refined pre-smelting slag comprises the following components, by weight, 10.0-30.0% of waste glass, 25.0-45.0% of fly ash, 35.0-55.0% of 65% waste high alumina brick and 1.0-3.0% of a fluxing agent. The aluminium-silica type refined pre-smelting slag has the following advantages that: (1) the slag system is stable, and the slag adjusting process is not required; (2) the level for controling the non-metallic foreign material in the adsorption steel is high; (3) the slag does not agglomerate, the melting and slaggling time is short (less than or equal to 2 minutes); (4) the yield of the sulfur of the middle (high) sulfur structure steel during the later stage sulfur adjusting process is stable; (4) the product does not powder, and the shelf life is more than six months.

Owner:丹东泓辉科大高温材料有限公司

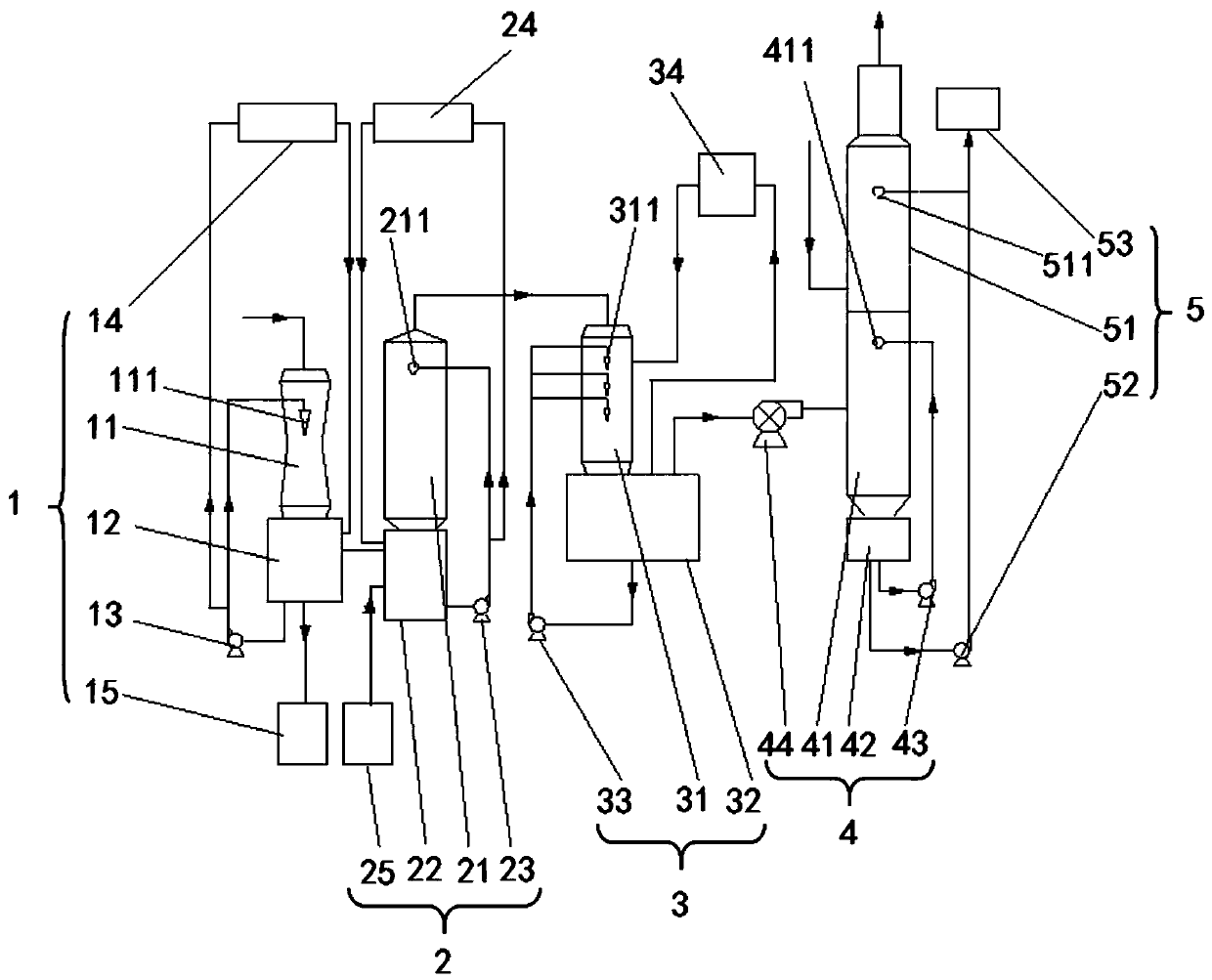

Fluorine absorption system used for wet-process phosphoric acid

ActiveCN109647137AReduce jam frequencyNo increase in total hydrationGas treatmentDispersed particle separationPhosphoric acidHexafluorosilicic acid

The invention provides a fluorine absorption system used for wet-process phosphoric acid. The system comprises a Venturi scrubbing device, a primary washing device, a pipe washing device, a secondarywashing device and a tertiary washing device which are arranged in sequence. According to the fluorine absorption system used for the wet-process phosphoric acid, waste gas containing fluorine passesthrough the Venturi scrubbing device, the primary washing device, the pipe washing device, the secondary washing device and the tertiary washing device in sequence for multi-stage washing, the washingdevices are provided with circulating tanks respectively, circulating fluid in the Venturi circulating tank and the primary washing tower circulating tank is continuously pumped out to enter a firstplate-and-frame filter press and a second plate-and-frame filter press, silica gel precipitation in the fluorine absorption system is removed, and the blocking frequency is reduced. The recycled watersupplement path is changed, the temperature of exhaust and the concentration of the circulating fluid are reduced, and therefore, the fluosilicic acid absorbing efficiency is improved.

Owner:襄阳泽东化工集团股份有限公司

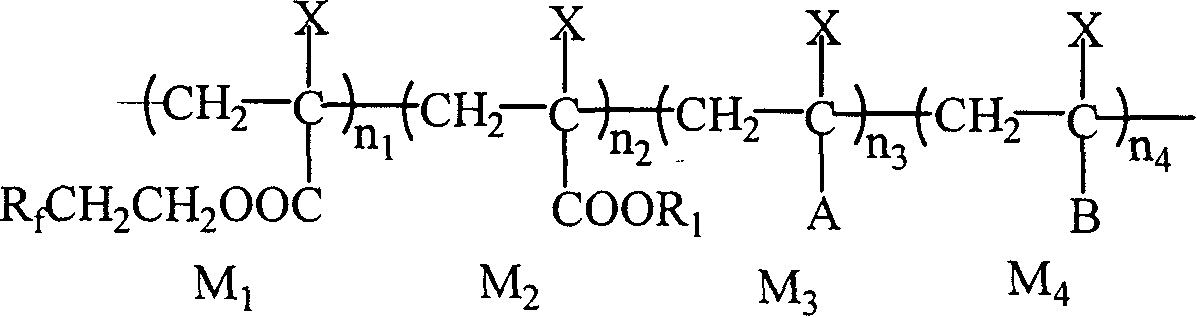

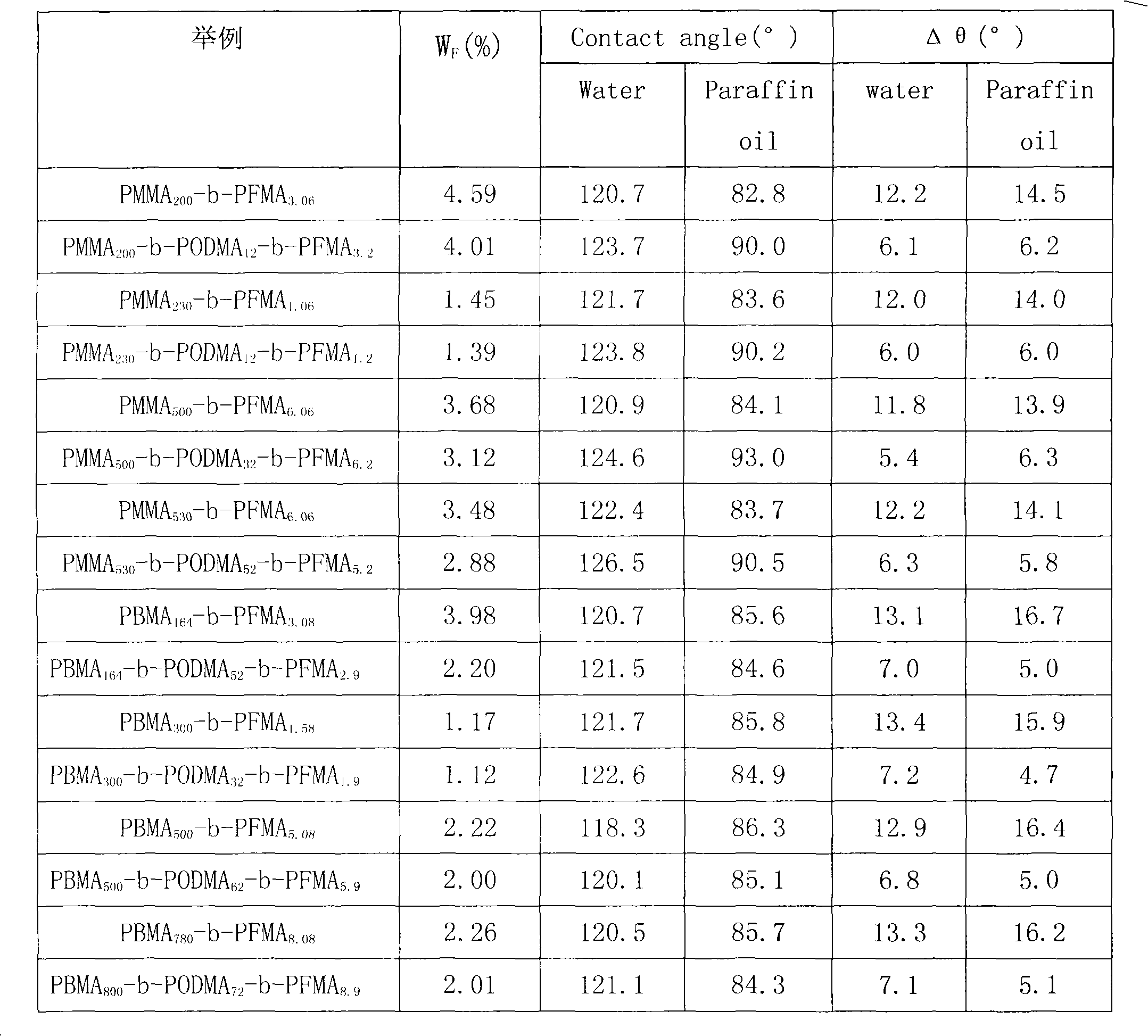

Triblock fluorinated polymer and preparation method thereof

InactiveCN102070755ALow fluorine contentHighly stable hydrophobic surfacePolymeric surfacePolymer science

The invention discloses a high-molecular compound and a preparation method thereof, particularly relates to a fluorinated polymer with extremely low fluorine content and a high-stability hydrophobic surface and a preparation method thereof. In the invention, crystalline long-chain alkyl methacrylate is introduced in the middle of a polymethylmethacrylate-b-polyperfluorooctylethyl methacrylate block polymer. The preparation method comprises the steps of preparing a PMMAk-Br macroinitiator and a PMMAk-b-PODMAm-Br macroinitiator stage by stage and then preparing a fluorinated block copolymer. The compound prepared by the invention can improve the surface hydrophobic and lipophobic properties, the surface fluorine-contained component enrichment and the environment surface stability of a polymer. The preparation method has mild reaction conditions, is easy to operate, moreover, the contents of all the components used in the method can be regulated and controlled. The invention has wide application value.

Owner:ZHEJIANG SCI-TECH UNIV

Processing technology of low-fluoro-content Tibetan tea

The invention relates to the technical field of low-fluoro-content Tibetan tea processing, and discloses a processing technology of low-fluoro-content Tibetan tea. The processing technology of the low-fluoro-content Tibetan tea comprises the following steps: S1, picking tender tea leaves, namely selecting tea trees which are older than 25 years, picking tea leaves with one bud and four leaves or five leaves which are within a growth cycle of 20 days; S2, carrying out withering treatment, namely putting the picked tender leaves into a withering tank, and carrying out hot-air withering at 30-50DEG C for 2 hour; S3, carrying out high-temperature fixating, dewatering and stem-removing, namely putting the withered tea leaves into a special fixation machine so as to be subjected to continuous stir-frying at 280-320 DEG C for 450 minutes so as to control the water content at 25%, thereby separating leaves from stems; S4, removing thick stems, namely removing think stems separated from the leaves by using an air-selecting machine, and retaining 15% of thin stems; and S5, sequentially carrying out steaming and rolling, namely putting the tea leaves after the primary selection into a steamdrum at 130 DEG C, and carrying out steaming for 5-8 minutes. The processing technology of the low-fluoro-content Tibetan tea is capable of solving the problems of relatively high fluorine content oftraditional Tibetan tea and low quality of Tibetan tea prepared by conventional processing technologies.

Owner:洪雅县偏坡山茶叶专业合作社

Manufacture process of low-flourine mica tape

The present invention relates to the mica tape manufacturing field, and especially relates to a manufacture process of low-flourine mica tapes. The manufacture process comprises the steps of coating brushing, mixed layer manufacturing, drying, cooling and tape cutting, wherein mica paper used in mixed layer manufacturing is tested low-flourine mica paper. With adoption of the manufacturing process provided by the present invention, a fluorine content of the manufactured mica tape is greatly reduced, requirements for environment protection are met, harms to human bodies are reduced, and the amount of release of fluorine especially in high-voltage cable application is lowered.

Owner:PINGJIANG XINGKE MICA PRODS

Method for preparing lanthanum-enriched rare earth chloride from bastnaesite

The invention relates to a method for producing lanthanum-enriched rare earth chloride by using bastnaesite as a raw material. The method comprises the following steps of: mixing the bastnaesite and sodium hydroxide and then roasting, carrying out sodium hydroxide alkali conversion on the bastnaesite to remove fluorine, washing the bastnaesite subjected to alkali conversion with water, and carrying out hydrochloric acid optimum solution to obtain lanthanum-enriched rare earth chloride liquid. In the alkali conversion process, the ratio of NaOH to REO (Rare Earth Oxide) in the bastnaesite is (0.10-0.40):1, the alkali conversion is carried out at 300-600 DEG C, and then the bastnaesite subjected to the alkali conversion is washed with water 3-8 times of the bastnaesite by weight proportion.In the optimum solution process, the weight ratio of 31% of industrial hydrochloric acid by weight to the REO in the bastnaesite is (1-1.5):1. In the alkali conversion process, the fluorine in the enriched lanthanum is preferentially subjected to the alkali conversion to obtain lanthanum-enriched hydroxide which is dissolved with acid, acid-soluble lanthanum-enriched rare earth is dissolved in a solution, and cerium is reserved in slag with large amount of fluorine, therefore, the purpose of separating the cerium and non-cerium can be achieved easily. In the whole process, the step of solid-liquid separation is reduced, the consumption of auxiliary materials is lowered, the yield per unit of equipment and the yield of rare earth are improved, and the production process has less pollution.

Owner:CHINA MINMETALS BEIJING RES INST OF RE

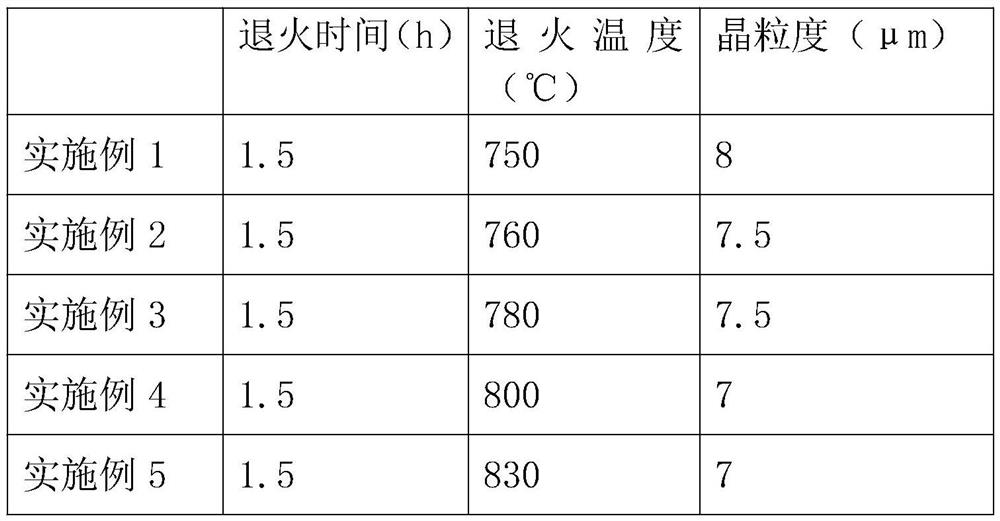

Preparation method of low-fluorine high-purity tantalum pentoxide optical coating material

InactiveCN112592180AThe removal effect is ideal and sufficientUniform grain distributionTantalum compounds preparationCrystal systemElectron bunches

The invention discloses a preparation method of a low-fluorine high-purity tantalum pentoxide optical coating material, and particularly relates to the technical field of tantalum metal oxide preparation, which comprises the following steps: dissolving metal tantalum in a mixed acid of hydrofluoric acid and nitric acid, extracting and purifying to obtain a high-purity tantalum liquid, introducingthe high-purity tantalum liquid into a neutralization precipitation tank, adding liquid ammonia into the high-purity tantalum liquid at the same time, introducing a solution containing tantalum hydroxide precipitate into a filter press after the tantalum hydroxide precipitate appears, adding ammonia-containing hot pure water at the same time, then obtaining tantalum hydroxide, and then repeatedlyadding tantalum hydroxide into the filtering process for multiple times. According to the method, tantalum pentoxide is heated through electron beams, the purpose of heating calcination can be achieved without high temperature, grain distribution is uniform, the crystal system structure is more ideal, meanwhile, ammonia-containing hot pure water is repeatedly used for assisting the filtering process, it is guaranteed that the effect of removing fluorine in the tantalum hydroxide solution is more ideal and sufficient, and the fluorine content in the product is greatly reduced.

Owner:海宁拓材科技有限公司

Method for extracting germanium from fluorine-containing germanium concentrate through distillation

ActiveCN110453097AHigh recovery rateAvoid generatingProcess efficiency improvementDistillationWater vapor

The invention provides a method for extracting germanium from fluorine-containing germanium concentrate through distillation. The method includes the following steps that a fluorine fixing agent is added into a hydrochloric acid solution to be evenly dispersed, and a mixed system A is obtained, wherein the fluorine fixing agent is an aluminum compound; the fluorine-containing germanium concentrateis added into the mixed system A, stirring is carried out for 0.8 h-1.2 h, and a reaction system B is obtained; after it is confirmed that the concentration of hydrogen chloride in the reaction system B is 6.0 mol / L-8.0 mol / L, chlorine and water vapor are used for carrying out chlorination distillation on the reaction system B; and a gas-state germanium tetrachloride obtained through chlorinationdistillation is condensed. The process method is simple, short in flow path, low in cost and high in recovery rate, the germanium is extracted from the fluorine-containing germanium concentrate safely and environmentally friendly, and the recovery rate of the germanium directly extracted from the fluorine-containing germanium concentrate can reach 99.9%.

Owner:FIRST RARE MATERIALS CO LTD

Water-repellent fabric and manufacturing method thereof

ActiveCN104532389AIncreased free volumeEnhanced interface bindingFibre typesMonocomponent polyesters artificial filamentBreaking strengthYarn

The invention relates to water-repellent fabric and a manufacturing method of the water-repellent fabric. The water-repellent fabric is formed by weaving polyester industrial yarn used for the water-repellent fabric, the polyester industrial yarn used for the water-repellant fabric is made of modified polyester, and the water-repellant fabric is formed by arranging after water repellency. The modified polyester is composed of polyester and amino fatty acid glycol ester dispersed among molecular chains of the polyester, a hydrogen-bond interaction is achieved between the amino fatty acid glycol ester and the molecular chains of the polyester, and therefore the relative positions of the amino fatty acid glycol ester and the molecular chains of the polyester are fixed. According to the water-repellent fabric, at the temperature of 70 DEG C-130 DEG C, the free volume space between the molecular chains inside fibers is enlarged by 10 v / v%-30 v / v%, the breaking strength of the polyester industrial yarn used for the water-repellant fabric is larger than or equal to 7.2 cN / dtex, and the elongation at break is 20.0+ / -2.0%. The washable performance of the water-repellant fabric is good. The water-repellant fabric can be used for industries such as tents and drapes.

Owner:JIANGSU HENGLI CHEM FIBER

Process for optimizing phosphoric acid reaction and separation by using active silicon dioxide

InactiveCN111943156AGuaranteed qualityUniform particlesCalcium/strontium/barium sulfatesPhosphorus compoundsO-Phosphoric AcidPhosphogypsum

The invention discloses a process for optimizing phosphoric acid reaction and separation by using active silicon dioxide. The process comprises the following steps: adding active silicon dioxide, which is a byproduct of an enterprise for producing anhydrous hydrogen fluoride by a fluosilicic acid method, into a phosphoric acid digestion tank, mixing phosphogypsum with the active silicon dioxide and an extremely small amount of flocculant at 80 DEG C, and aging to form a co-crystal, so that the phosphogypsum crystallization rate of the digestion tank is improved, filtering by a phosphoric acidvacuum drum filter, so that the filter cake is uniformly distributed, the formed filter pore size is uniform and fine, the filtering speed is greatly improved, and the total phosphorus and fluorine content of the phosphogypsum are both at a lower level, and carrying out dilute phosphoric acid concentration, separation and water washing to prepare fluosilicic acid for fluorine hydride production. According to the invention, the process achieves harmless treatment of fluorine-containing silicon dioxide, and the recovery rate of fluosilicic acid in phosphorite is increased, and after the auxiliary agent is mixed into the phosphoric acid digestion tank, efficient separation of phosphogypsum and dilute phosphoric acid is achieved, so that the process is a new process of resource recycling, byproduct comprehensive treatment and efficient phosphoric acid separation and purification.

Owner:福建瓮福蓝天氟化工有限公司

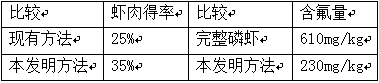

Instant krill paste and preparation method for instant krill paste

PendingCN111084350AGuaranteed tasteLow fluorine contentFood freezingFood ingredientsPotato starchFishery

The invention discloses an instant krill paste and a preparation method for the instant krill paste. The instant shrimp paste consists of 75-90 parts of krill flesh, 3-8 parts of water, 3-8 parts of mycose, 3-8 parts of potato starch, 0.8-1.6 parts of table salt and 0.2-0.6 parts of aginomoto. According to the instant krill paste, by taking the shelled krill flesh as a raw material, not only is the crisp mouth feeling of the krill paste guaranteed, but also the fluorine content of krill products is reduced by removing parts including krill shells with relatively high fluorine content, so thatthe fluorine content of the product is reduced by about 62%; and the type of the krill products is broadened, and a new way is opened to developing commercial value of krill.

Owner:RONGCHENG HONGYE IND

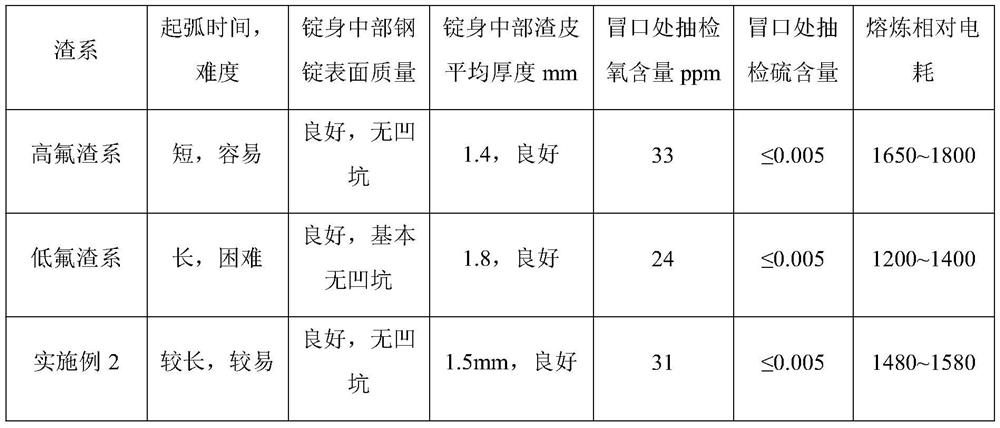

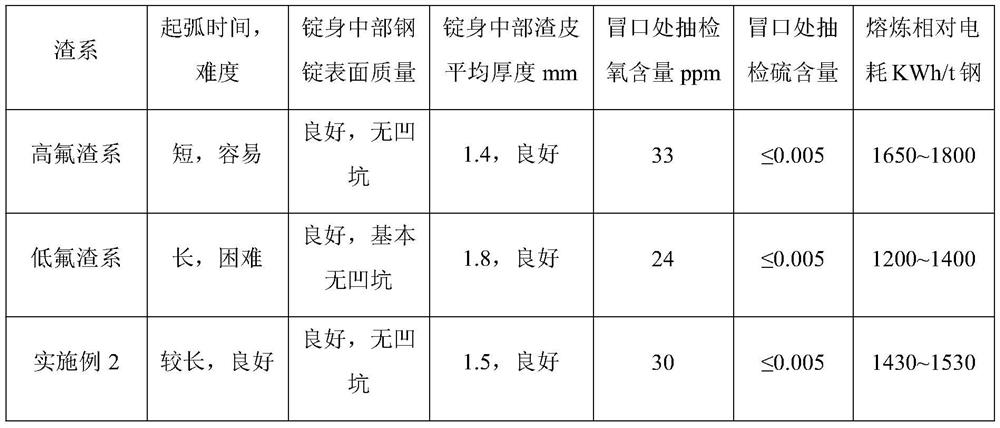

Medium-low fluorine slag system for electroslag remelting B-containing rotor steel ingot and use method

The invention relates to a medium-low fluorine slag system for electroslag remelting of a B-containing rotor steel ingot and a using method, belongs to the technical field of electroslag special metallurgy, and aims to solve the problems that an existing B-containing electroslag melting slag system is high in energy consumption and high-fluorine slag volatilizes to cause pollution. The medium-low fluorine slag system comprises the components in percentage by mass: 30.06%-39.30% of CaF2, 34.02%-43.79% of Al2O3, 18.31%-22.72% of CaO, 3%-5% of MgO, 0.10%-3.50% of B2O3 and the balance impurities, wherein the content of SiO2 in the impurities is less than 0.5%, and the range of CaO / (SiO2 + 0.5 * Al2O3) is from 0.7 to 1.4. The medium-low fluorine slag system reduces volatilization pollution of high-fluorine slag, and is low in power consumption during use and good in comprehensive metallurgical performance.

Owner:CENT IRON & STEEL RES INST

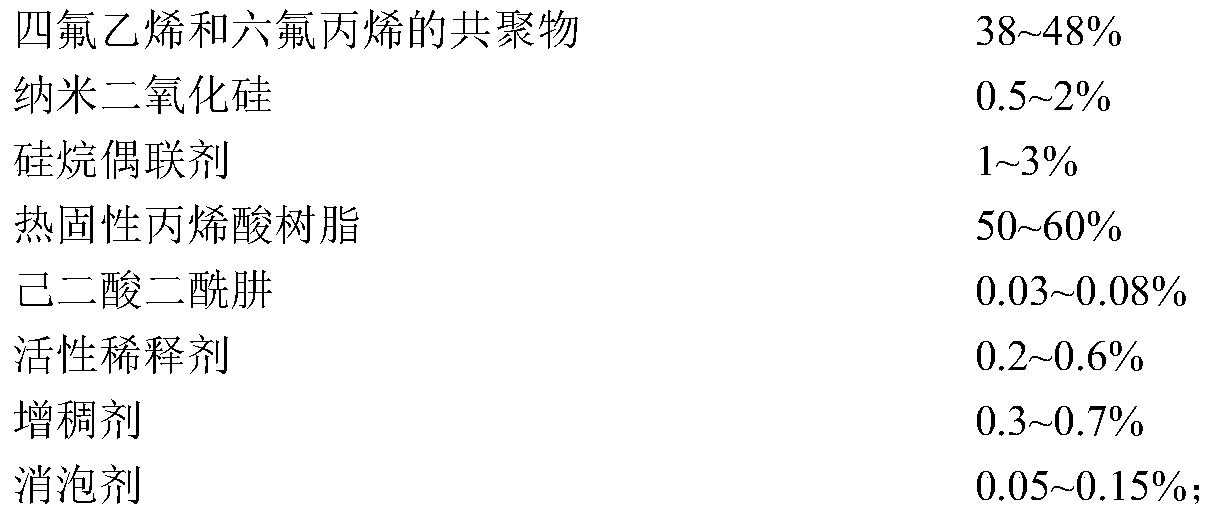

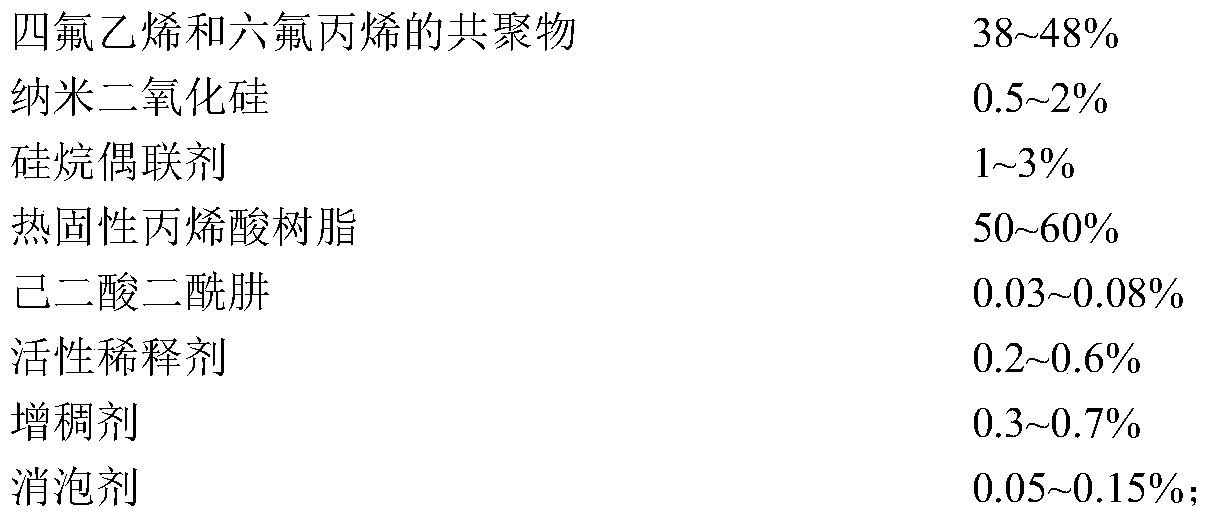

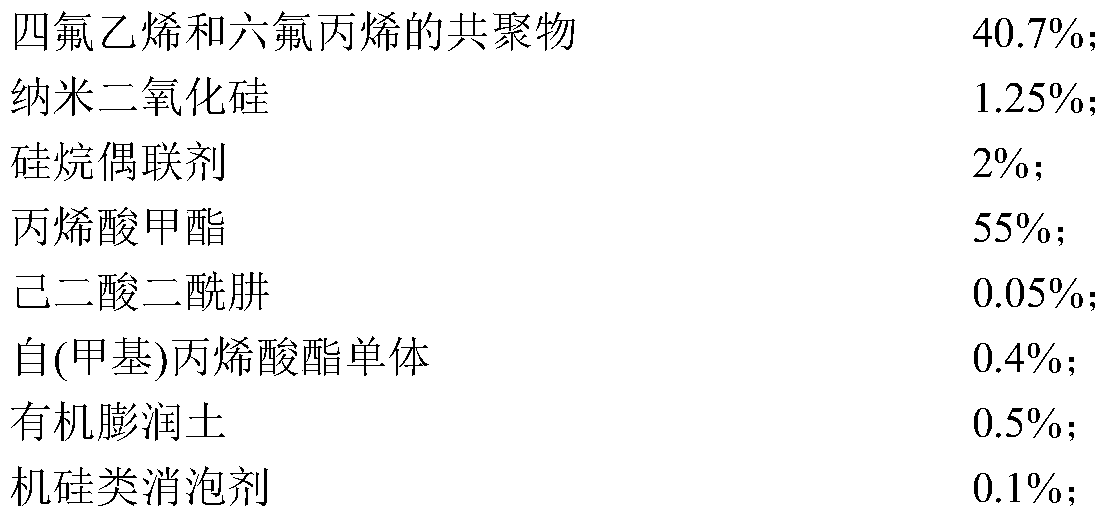

Super-hydrophobic paint applicable to diagnostic glass slides and preparation method thereof

ActiveCN110628254AImprove thermal stabilityGood chemical stabilityFireproof paintsAntifouling/underwater paintsWater bathsHexafluoropropylene

The invention relates to a super-hydrophobic paint applicable to diagnostic glass slides and a preparation method thereof. The method includes: by mass fraction, mixing 38-38% 48% of a copolymer of tetrafluoroethylene and hexafluoropropylene, 0.5-2% of thermosetting acrylic resin, 0.03-0.08% of adipic dihydrazide, 0.2-0.6% of an active diluent, 0.3-0.7% of a thickening agent and 0.05-0.15% of a defoaming agent in proportion evenly, then performing dispersing with a dispersant at a speed of 2000-2500r / min for 30-60min, then subjecting the mixed paint to ultrasonic dispersion for 40-60min, and then subjecting the dispersed paint to water bath heating at 60-80DEG C for 30-60min to obtain a mixed material, adding 0.5-2% by mass of nano silicon dioxide and 1-3% by mass of a silane coupling agent in proportion, and employing a three-roller machine to performing grinding 10 times so as to obtain the super-hydrophobic paint. The preparation process of the super-hydrophobic paint is simple andeasy to operate, and the paint can be subjected to enzyme and microwave treatment, and the paint has advantages of long storage time, acid resistance, good glass adhesion and the like.

Owner:南通大学技术转移中心有限公司

Carbon dioxide based fluoric series coolant

InactiveCN101161758ANon-destructiveReduce the greenhouse effectHeat-exchange elementsOctafluorocyclobutaneFreon

The invention discloses a carbon dioxide-based fluoric series freezing medium to replace all kinds of freon freezing media. The freezing medium of the invention is based on carbon dioxide and is mixed with one or more than one of R134a (1, 1, 1, 2-tetrafluoro thane), R152a (1, 1-difluoroethane), RC318 (octafluorocyclobutane), wherein, the mass percentage of carbon dioxide in the mixture is between 5 to 20 percent. The invention is characterized by innocuity, non-pollution, non-corrosion, no public nuisance and uninflammability.

Owner:HUNAN UNIV

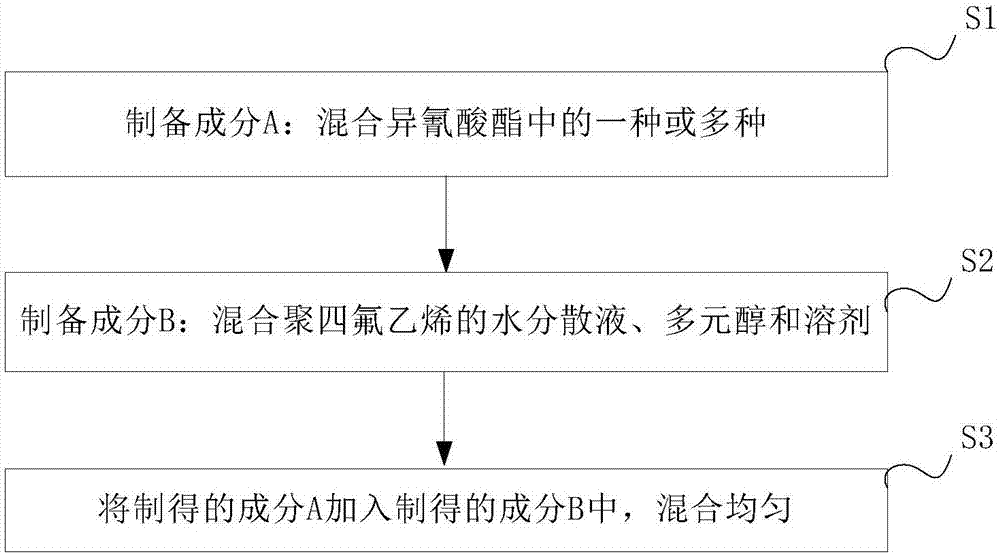

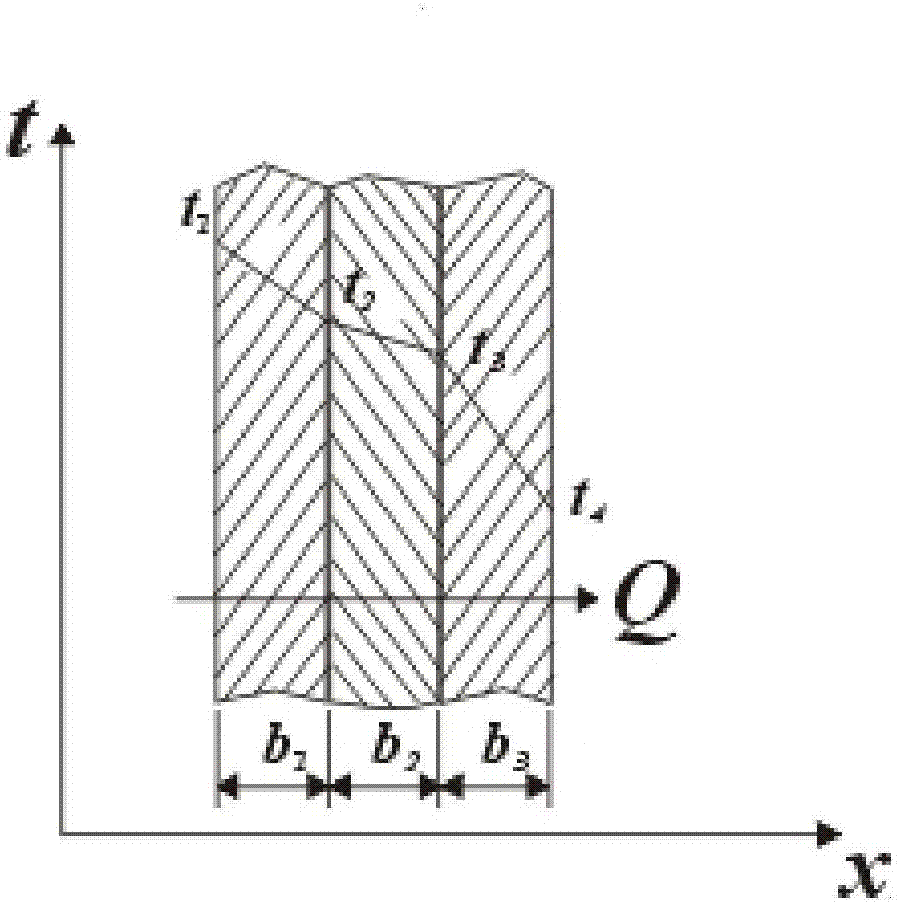

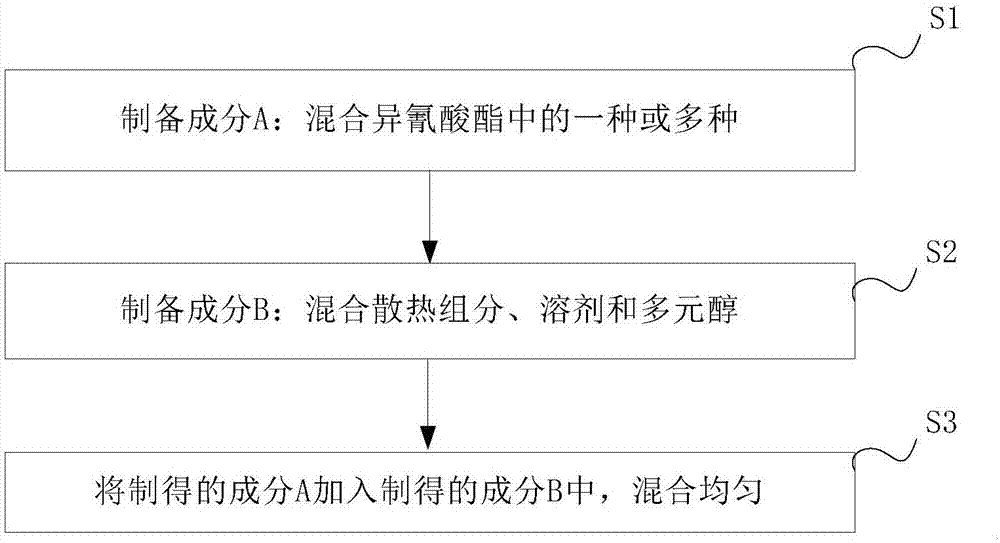

Polyurethane heat-dissipating dustproof coating and preparation method and application thereof

InactiveCN107254246AImprove bindingImprove heat resistanceLiquid surface applicatorsAntifouling/underwater paintsSolventPolytetrafluoroethylene

The invention discloses a polyurethane heat-dissipating dustproof coating and a preparation method and application thereof. Raw materials of the polyurethane heat-dissipating dustproof coating include a component A and a component B. The component A comprises the following ingredient in parts by weight: 16-75 parts of isocyanate; the component B comprises the following ingredients in parts by weight: 1-3 parts of polytetrafluoroethylene, 40-100 parts of polyhydric alcohols and 300-600 parts of a solvent; the total parts by weight of the isocyanate and the polyhydric alcohols is 90-150; the average particle size of the polytetrafluoroethylene is 120-800 nm; the polyhydric alcohols comprise fluorine-containing dihydric alcohols; and on the basis of the total weight of the polyhydric alcohols, the weight percentage of the fluorine-containing dihydric alcohols is 15-30wt%. By the polyurethane heat-dissipating dustproof coating and the preparation method and application thereof, dust accumulation is reduced, and the problems that the surface heat resistance of a heat sink and the like is increased, the heat conduction coefficient is reduced and the heat transfer efficiency is reduced due to dust blockage are solved.

Owner:HISENSE VISUAL TECH CO LTD

Dustproof polyurethane coating as well as preparation method and application thereof

InactiveCN107325700AImprove bindingImprove hydrophobicityProjectorsPolyurea/polyurethane coatingsHexagonal boron nitrideSolvent

The invention discloses a dustproof polyurethane coating as well as a preparation method and an application thereof. The dustproof polyurethane coating is prepared from an ingredient A and an ingredient B, wherein the ingredient A is prepared from components in parts by weight as follows: 14.5-75 parts of isocyanate; the ingredient B is prepared from components in parts by weight as follows: 2-5 parts of heat-dissipating components, 500-800 parts of a solvent and 40-100 parts of polyols, and polyols and isocyanate account for 90-150 parts by weight totally; the heat-dissipating components comprise nano hexagonal boron nitride and nano tri-titanium tetranitride and have the average particle size ranging from 30 nm to 800 nm; polyols comprise fluorine-containing dihydric alcohol which accounts for 15wt%-30wt% of the total weight of polyols. According to the dustproof polyurethane coating as well as the preparation method and the application thereof, accumulation of dust is reduced, and the problems that the surface thermal resistance of a radiator and the like is larger, the heat conductivity coefficient is reduced and the heat transfer efficiency is reduced as a result of dust blocking are solved.

Owner:HISENSE VISUAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com