Polyurethane heat-dissipating dustproof coating and preparation method and application thereof

A technology of dust-proof paint and polyurethane, applied in the field of paint, can solve the problems such as the pores of the dust cover being easily blocked, unfavorable for the popularization and use of the radiator, hindering the heat dissipation of the radiator, etc., so as to achieve enhanced heat dissipation, good heat conduction and heat dissipation, Enhance water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

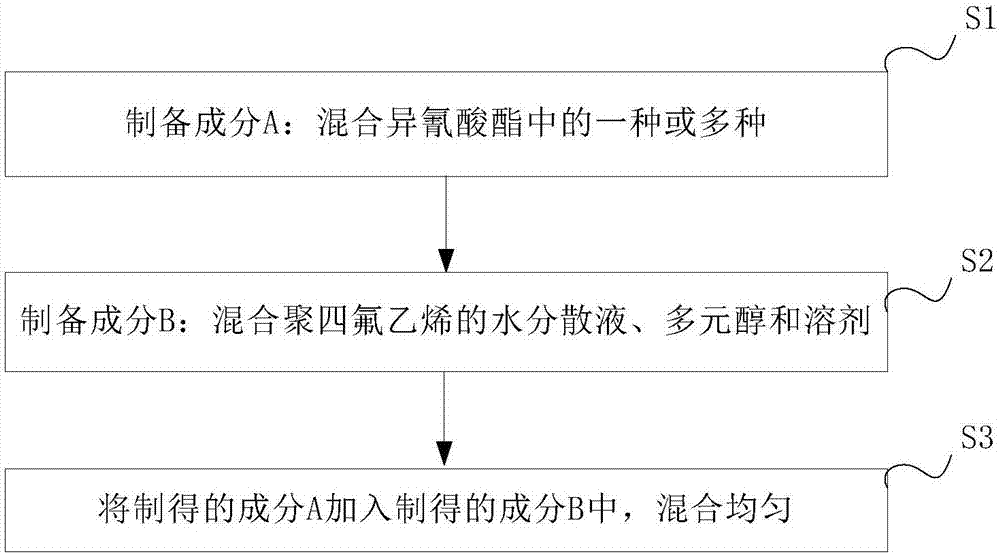

Method used

Image

Examples

preparation example Construction

[0048] In order to improve and speed up the preparation of the coating in the examples of the present application and improve the dustproof performance of the coating, the raw materials of the coating in the examples of the present application also include a catalyst, and the weight fraction of the catalyst is 1-4wt% of the total weight fraction of isocyanate and polyol . The catalyst can be selected from one or more of carbamate catalysts, organotin catalysts and bismuth carboxylate catalysts. Wherein, the carbamate catalyst is selected from triethylamine, 1,4-diazobicyclo[2.2.2.]octane (DABCO), N-methylmorpholine, N-ethylmorpholine, N,N, One or more mixtures of N',N'-tetramethylhexamethylenediamine and 1,2-dimethylimidazole. The organotin catalyst is selected from one of tin(II) acetate, tin(II) octoate, tin(II) laurate, dibutyltin dilaurate, dibutyltin dimaleate, dioctyltin diacetate and dibutyltin dichloride species or a mixture of several species. The bismuth carboxyla...

Embodiment 1

[0065] A polyurethane heat-dissipating and dust-proof coating, comprising component A and component B, component A is a mixture of MDI and XDI, the weight of component A is 30.5g, wherein, the -NCO equivalent of component A is 110; component B is 6g and the concentration is 50 % polytetrafluoroethylene aqueous dispersion, the mixture of 100g polyhydric alcohol and 600g solvent, wherein, the particle diameter of polytetrafluoroethylene is 120nm, and solvent is the mixture of 100g ethyl acetate, 200g butyl acetate and 300g ethylene glycol ethyl ether acetate The mixture, the hydroxyl value of the polyol is 170mgKOH / g, and the polyol is composed of the following components: 85g of PPG and 15gC n f 2n+1 -A-CH 2 OCH 2 -C(CH 2 Oh) 2 -R, n=8, A is -CH=HC-, R is -CH3.

[0066] Components A and B were mixed and sprayed on the surface of the laser radiator, dried at 100°C for 30 minutes to form a 30-micron coating, and the sprayed surface of the laser radiator was tested for dust p...

Embodiment 2

[0068] A polyurethane heat-dissipating and dust-proof coating, comprising component A and component B, component A is a mixture of MDI and XDI, the weight of component A is 40g, wherein, the -NCO equivalent of component A is 90; component B is 4g and the concentration is 50% The mixture of polytetrafluoroethylene water dispersion liquid, 50g polyhydric alcohol and 300g solvent, wherein, the particle diameter of polytetrafluoroethylene is 120nm, and solvent is the mixture of 100g ethyl acetate, 100g butyl acetate and 100g ethylene glycol ethyl ether acetate , the hydroxyl value of the polyol is 500mgKOH / g, and the polyol is composed of the following components: 35g of PPG and 15gCn f 2n+1 -A-CH 2 OCH 2 -C(CH 2 Oh) 2 -R, n=20, A is -CH 2 -CH 2 -, R is -CH 2 CH 3 .

[0069] Components A and B were mixed and sprayed on the surface of the heat sink of the driver board. After drying at 90°C for 60 minutes, a 15-micron coating was formed. The dustproof and heat dissipation pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com