Instant krill paste and preparation method for instant krill paste

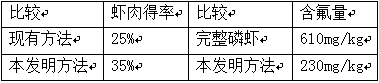

A krill and shrimp slip technology is applied in the field of ready-to-eat krill shrimp slip and its preparation to achieve the effect of reducing fluorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of ready-to-eat krill shrimp slip, which is composed of the following raw materials in parts by weight:

[0028] 75 parts of shrimp meat, 8 parts of water, 7 parts of trehalose,

[0029] 8 parts of potato starch, 1.6 parts of salt, 0.4 parts of monosodium glutamate.

[0030] Production Method:

[0031] (1) Fresh krill was first frozen at -20°C for 18 hours, in order to cause larger ice crystals in the krill tissue to cause greater damage to the cells; then thawed at 20°C for 4 hours, in order to make the phosphorus Some ice nuclei remain in the shrimp tissue, which induces the formation of larger ice crystals during the second freezing; then quickly freeze at -5°C for 6 hours, and then thaw at 20°C until completely melted;

[0032] (2) Centrifuge the frozen-thawed krill at a speed of 5,000 rpm for 10 minutes, put it on a filter cloth with a pore size of 3 mm, vacuumize it at a degree of 50 Pa, and vacuumize it for 1 hour. Collect Filtered shrimp meat;

[0033...

Embodiment 2

[0035] A kind of ready-to-eat krill shrimp slip, which is composed of the following raw materials in parts by weight:

[0036] 90 parts of shrimp meat, 3 parts of water, 3 parts of trehalose,

[0037] 3 parts of potato starch, 0.8 parts of salt, 0.2 parts of monosodium glutamate.

[0038] Production Method:

[0039] (1) Fresh krill was first frozen at -40°C for 24 hours, in order to form larger ice crystals in the krill tissue and cause greater damage to the cells; then thawed at 15°C for 5 hours, in order to make the phosphorus Some ice nuclei remain in the shrimp tissue, which induces the formation of larger ice crystals during secondary freezing; then quickly freeze at -10°C for 8 hours, and then thaw at 25°C until completely melted;

[0040] (2) Centrifuge the frozen-thawed krill at a speed of 5,000 rpm for 10 minutes, put it on a filter cloth with a pore size of 3 mm, vacuumize it at a degree of 50 Pa, and vacuumize it for 1 hour. Collect Filtered shrimp meat;

[0041...

Embodiment 3

[0043] 85 parts of shrimp meat, 5 parts of water, 4.5 parts of trehalose,

[0044] 4 parts of potato starch, 1 part of salt, 0.5 part of monosodium glutamate.

[0045] Production Method:

[0046] (1) Fresh krill was first frozen at -10°C for 20 hours, in order to form larger ice crystals in the krill tissue and cause greater damage to the cells; then thawed at 25°C for 6 hours, in order to make the phosphorus Some ice nuclei remain in the shrimp tissue, which induces the formation of larger ice crystals during secondary freezing; then quickly freeze at -8°C for 8 hours, and then thaw at 25°C until completely melted;

[0047] (2) Centrifuge the frozen-thawed krill at a speed of 5,000 rpm for 10 minutes, put it on a filter cloth with a pore size of 3 mm, vacuumize it at a degree of 50 Pa, and vacuumize it for 1 hour. Collect Filtered shrimp meat;

[0048] (3) Add salt to the obtained krill meat, put it into a blender and stir it at high speed to make it sticky, then add other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com