Triblock fluorinated polymer and preparation method thereof

A technology of fluorinated polymers and block polymers, which is applied in the field of fluorinated polymers and its preparation, can solve the problems of high fluorine content, high price, difficulty in fluorinated alkyl groups, etc., and achieve high stable hydrophobic surface, low content The effect of fluorine content and high technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

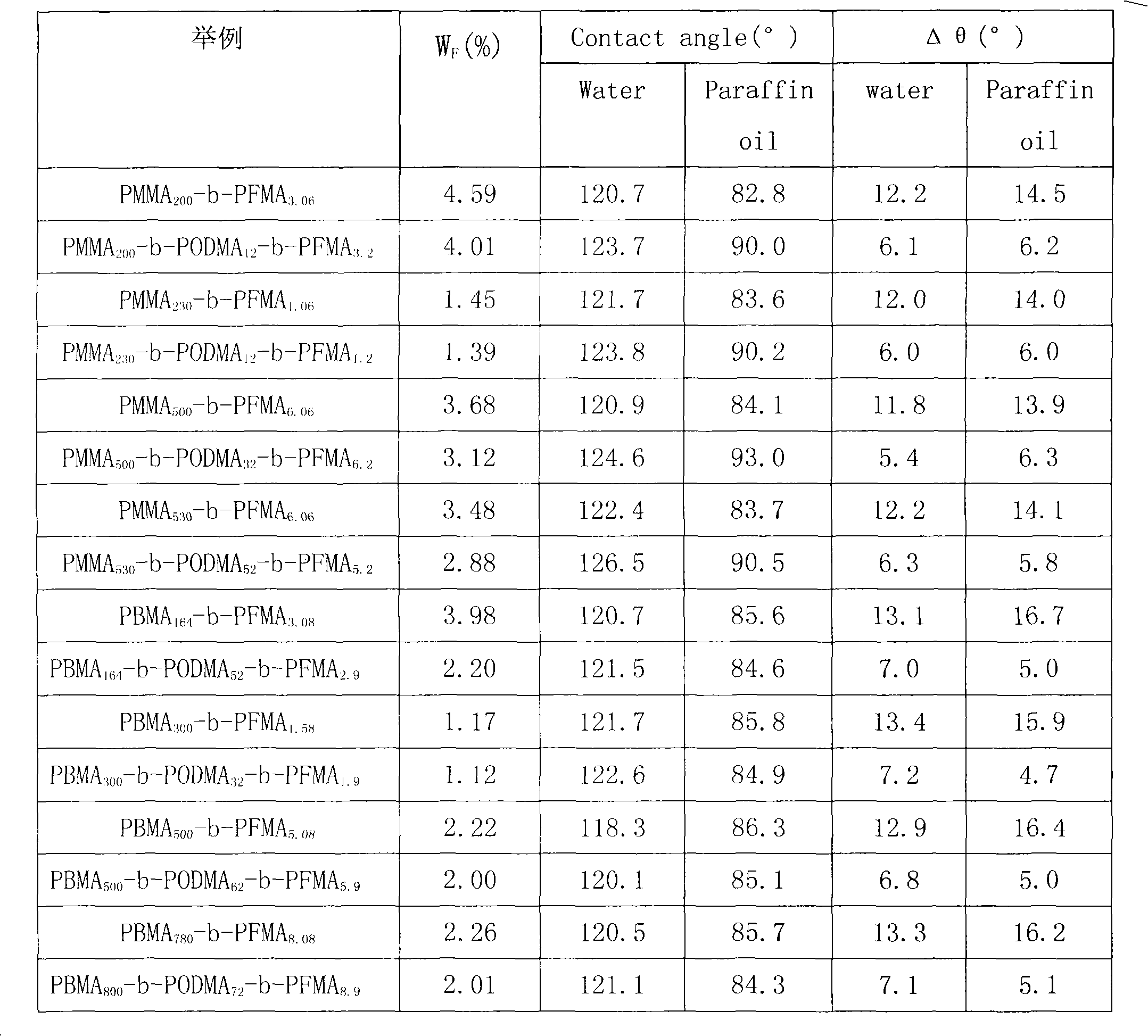

Examples

Embodiment 1

[0024] Polymethyl methacrylate-b-polyoctadecyl methacrylate-b-polyperfluorooctylethyl methacrylate triblock copolymer (PMMA 230 - Preparation of b-PODMAm-b-PFMAn). PMMA 230 The preparation of the -Br macromolecular initiator is as follows: the polymerization is carried out in a 500mL three-necked flask, and the baking bottle is ventilated three times to remove oxygen and moisture in the reaction device, and then in N 2Add metered catalytic CuBr or CuCl, monomer MMA, solvent toluene, complexing agent pentamethyldiethyltriamine (PMDETA), initiator 2-bromoethyl propionate (initiator / catalyst / coordination) successively under protection agent / monomer (1:1:2:120), stirred and heated to 70°C, and reacted in a constant temperature oil bath for 6h. After the reaction is finished, it is diluted with tetrahydrofuran, and the copper salt is separated through a column of neutral alumina. Dry in vacuum at 40°C to constant weight. PMMA 230 -b-PODMA m -The preparation of the Br macromol...

Embodiment 2

[0027] Polybutylmethacrylate-b-polyoctadecylmethacrylate-b-polyperfluorooctylethylmethacrylate triblock copolymer (PBMA 164 - Preparation of b-PODMAm-b-PFMAn). Polymerization was carried out in a 250mL three-neck flask, and the baking bottle was ventilated three times to remove oxygen and moisture in the reaction device, and then in N 2 Add metered catalyst CuCl and macromolecular initiator PBMA sequentially under protection 164 -Br, monomer ODMA, solvent toluene (feeding ratio ODMA / PBMA 164 - Br / catalyst / PMDETA: (10, 20, 50, 70) / 1 / 1 / 2). Waiting for PBMA 164 After the -Br is completely dissolved, the ligand is added last. Slowly raise the temperature to 85°C under stirring, and react in a constant temperature oil bath for 12 hours. After the reaction, use an ice-water cooling bath. After the temperature drops, dilute with tetrahydrofuran and separate through a column with neutral alumina to remove the catalyst CuCl. The obtained filtrate is removed by rotary evaporation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com