Patents

Literature

224 results about "Fluorinated Polymers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A number of fluorinated polymers are manufactured and sold, but three of them -- polytetrafluoroethylene (PTFE), the copolymer (called FEP) of tetrafluoroethylene and hexafluoropropylene, and polyvinylidene fluoride (PVDF) -- have the largest market shares.

Fluorochemical composition comprising a fluorinated polymer and treatment of a fibrous substrate therewith

InactiveUS7094829B2Easy to oilGood water repellency propertyStain/soil resistant fibresLiquid repellent fibresFiberOrganic solvent

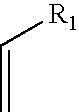

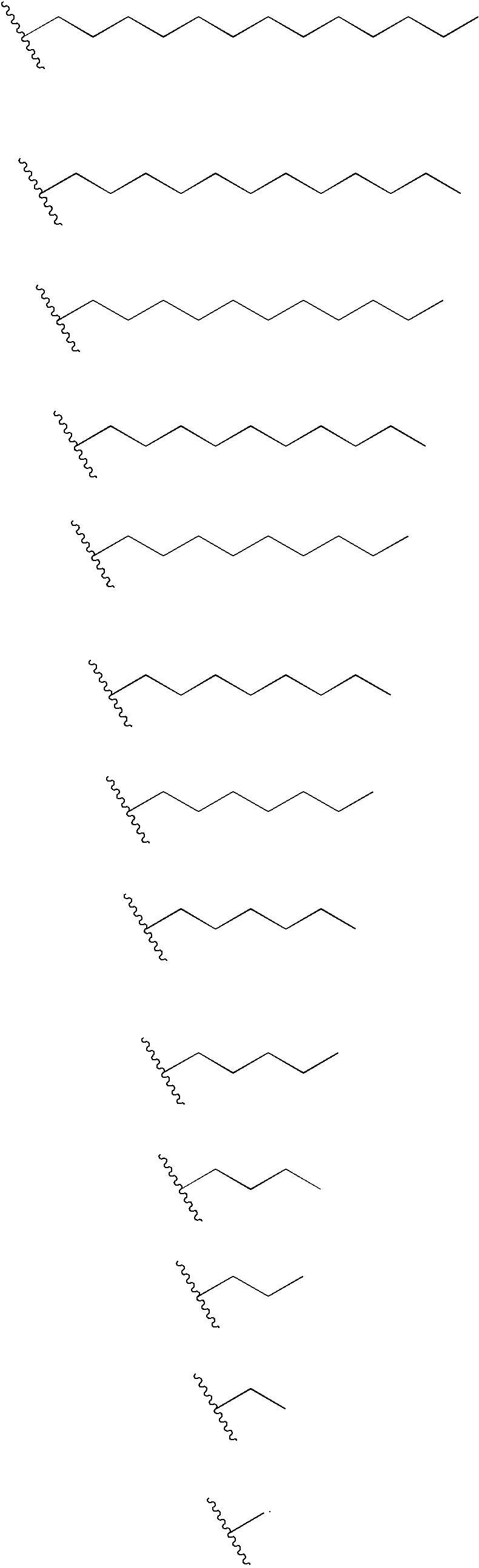

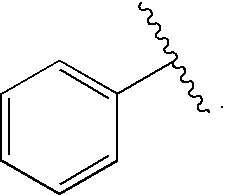

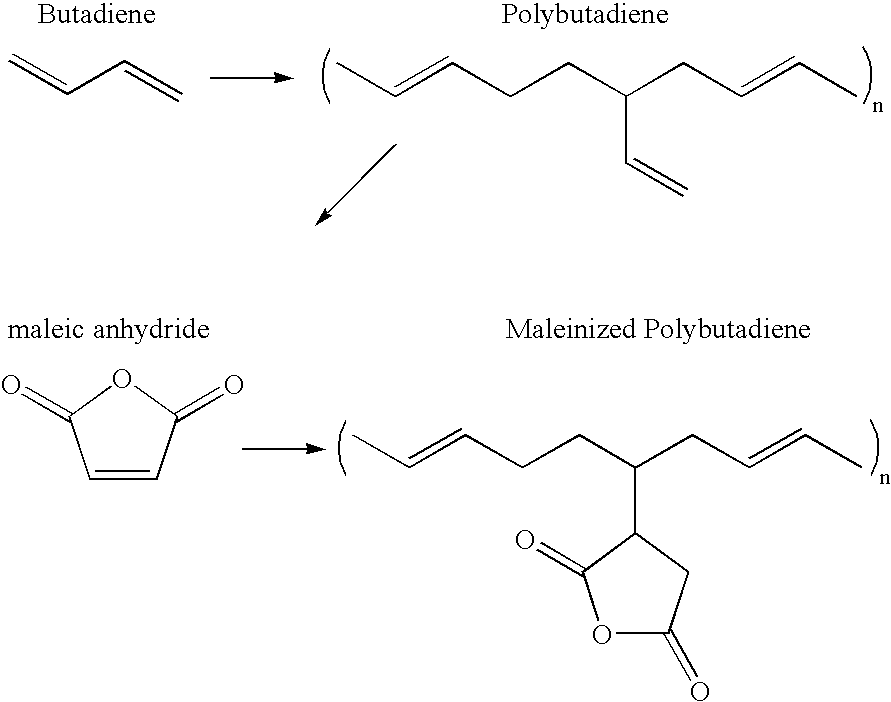

A fluorochemical composition for rendering fibrous substrates oil repellent, water repellent, and / or stain repellent and comprising a fluorinated polymer dispersed in water or dissolved or dispersed in an organic solvent, the fluorinated polymer comprising units derived from (i) a mixture of two or more fluorinated polyether monomers that differ in at least their molecular weight, the fluorinated polyether monomers having an ethylenically unsaturated group and a perfluorinated polyether group and wherein at least 90% by weight of the mixture consists of fluorinated polyether monomers that have a perfluorinated polyether group having a molecular weight of at least 750 g / mol and (ii) one or more units derived from one or more co-monomers other than a fluorinated polyether monomer and wherein the co-monomers comprise at least one non-fluorinated monomer. Also, method for treating fibrous substrate with such composition, fluorinated polyether monomers, and fluorinated polymers derived from such monomers.

Owner:3M INNOVATIVE PROPERTIES CO

Orthogonal Procesing of Organic Materials Used in Electronic and Electrical Devices

ActiveUS20110159252A1Avoid damageImprove throughputOrganic chemistryPhotosensitive materialsOrganic structureMethacrylate

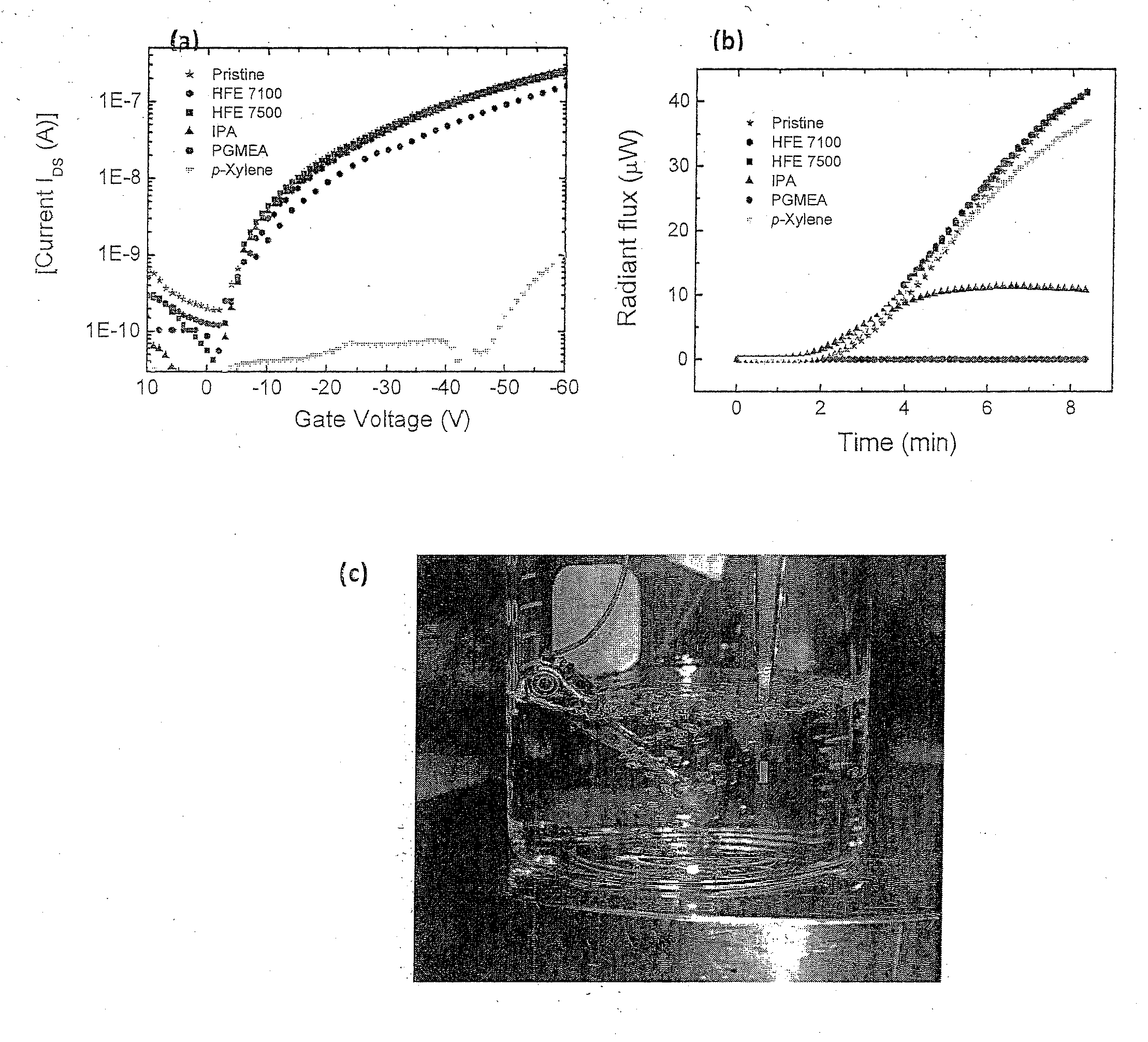

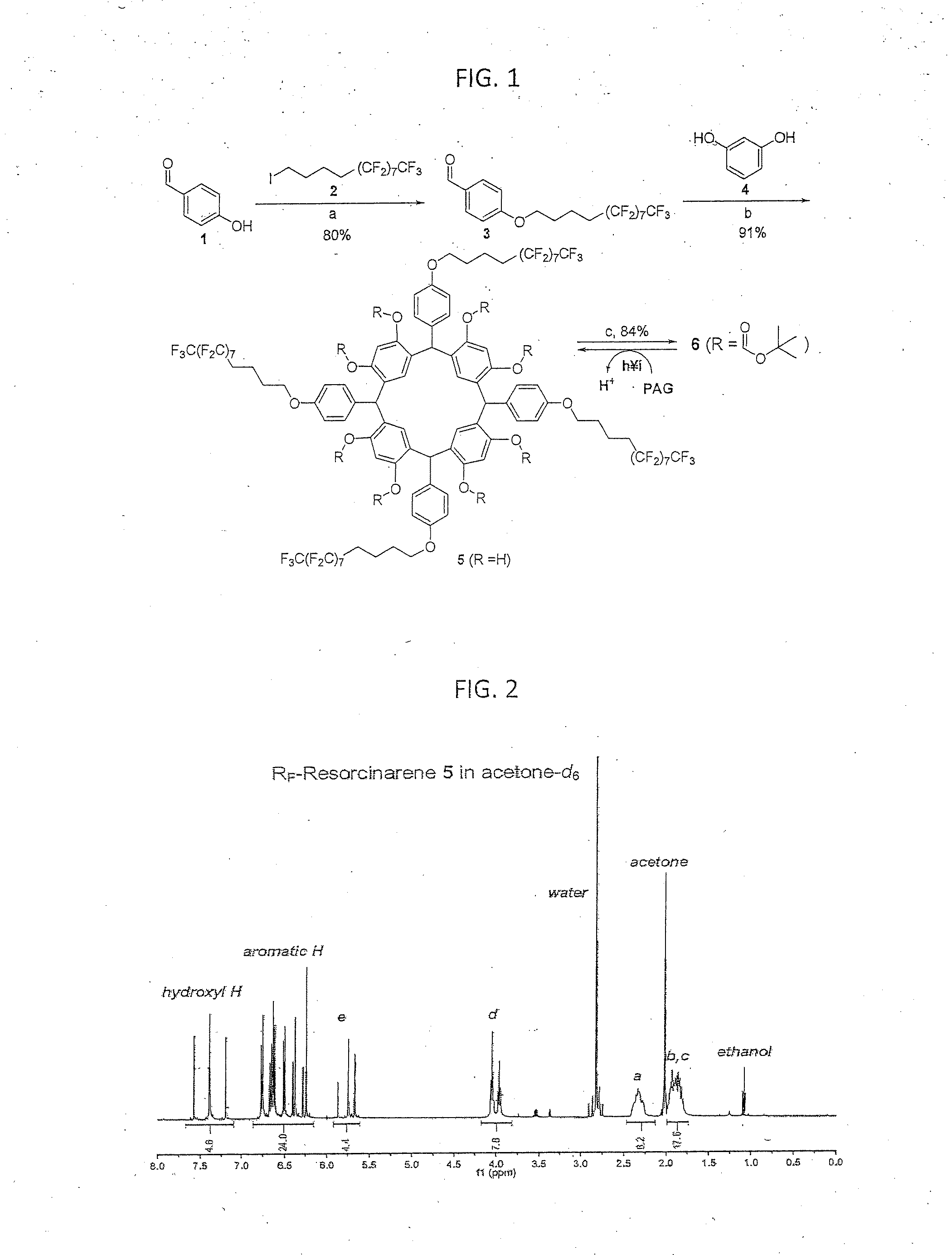

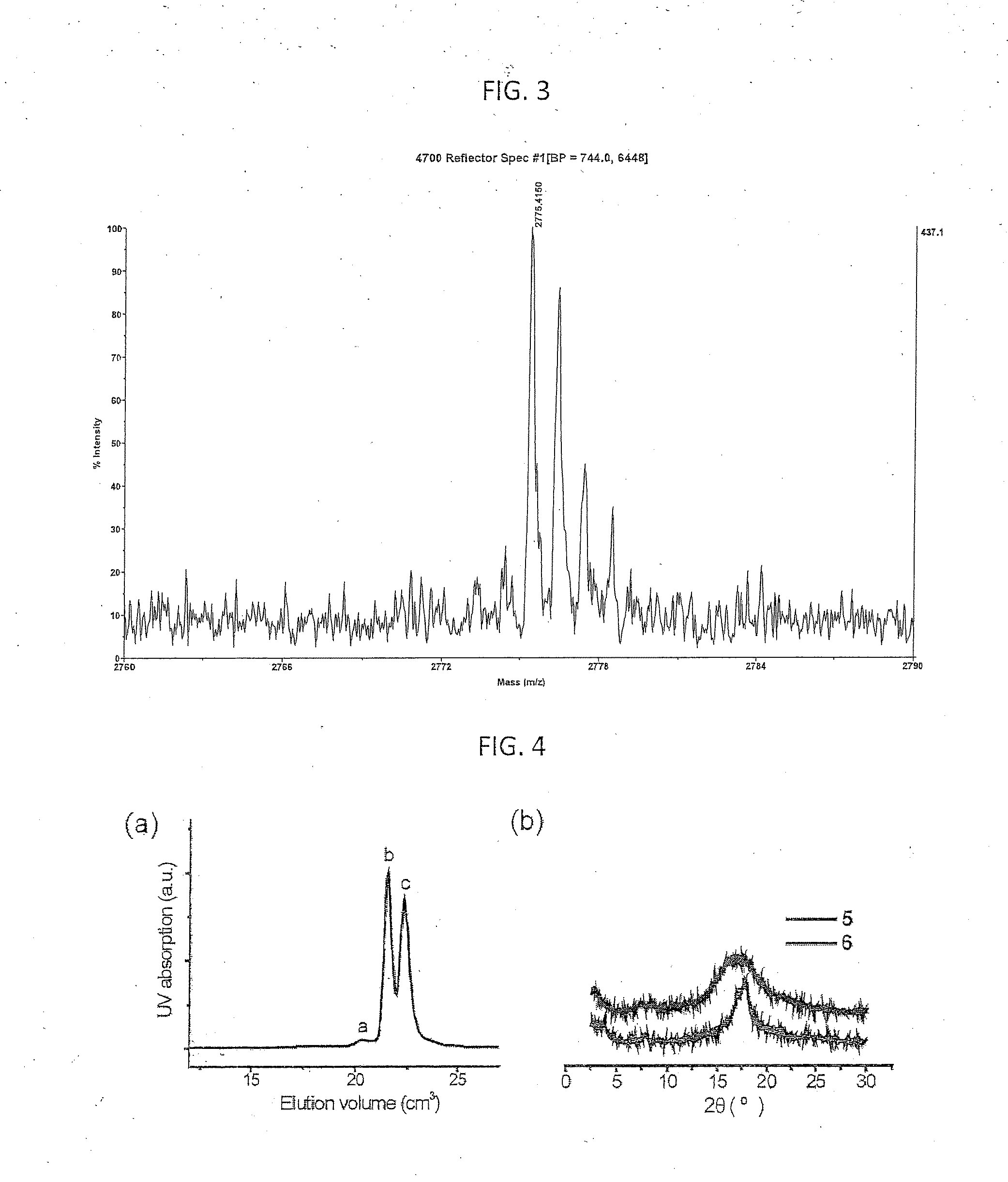

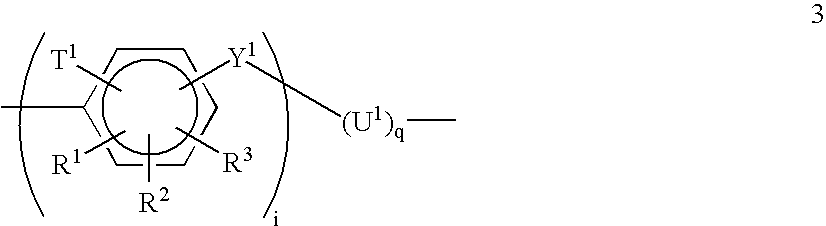

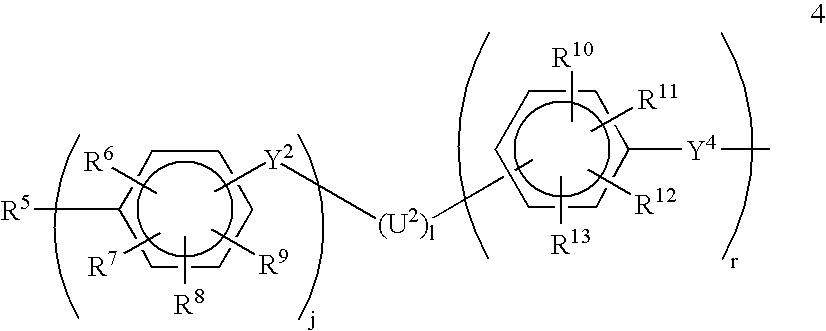

An orthogonal process for photolithographic patterning organic structures is disclosed. The disclosed process utilizes fluorinated solvents or supercritical CO2 as the solvent so that the performance of the organic conductors and semiconductors would not be adversely affected by other aggressive solvent. One disclosed method may also utilize a fluorinated photoresist together with the HFE solvent, but other fluorinated solvents can be used. In one embodiment, the fluorinated photoresist is a resorcinarene, but various fluorinated polymer photoresists and fluorinated molecular glass photoresists can be used as well. For example, a copolymer perfluorodecyl methacrylate (FDMA) and 2-nitrobenzyl methacrylate (NBMA) is a suitable orthogonal fluorinated photoresist for use with fluorinated solvents and supercritical carbon dioxide in a photolithography process. The combination of the fluorinated photoresist and the fluorinated solvent provides a robust, orthogonal process that is yet to be achieved by methods or devices known in the art.

Owner:CORNELL UNIVERSITY

Biologically beneficial coatings for implantable devices containing fluorinated polymers and methods for fabricating the same

Coatings for an implantable medical device and a method of fabricating the coatings are disclosed. The coatings comprise a fluorinated polymer and a biologically beneficial polymer, an example of which includes poly(ethylene-glycol)-block poly(butylene terephthalate)-block poly(ethylene-glycol). A biologically active agent can be additionally conjugated to the biologically beneficial polymer.

Owner:ABBOTT CARDIOVASCULAR

Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups

InactiveUS20040242804A1Good optical performanceHigh glossTransportation and packagingMixingPolymeric surfacePolymer science

A fluorine containing polymer which acts as a wetting, flow or leveling agent, and has at least one polar group. The polymer has at least one pendant or ether side chain containing from about 1 to about 20 carbon atoms with at least 25% of the hydrogen atoms being replaced by fluorine atoms. The fluorinated polymers unexpectedly impart wetting, flow or leveling properties to a variety of coatings while producing little foam.

Owner:DEUT BANK AG NEW YORK BRANCH AS SUCCESSOR AGENT

Phosphor surface treatment method

A red phosphor in the form of a Mn-activated complex fluoride having the formula: A2MF6:Mn wherein M is one or more tetravalent elements selected from Si, Ti, Zr, Hf, Ge, and Sn, and A is one or more alkali metals selected from Li, Na, K, Rb, and Cs, and contains at least Na and / or K, is surface treated with a treating solution containing a surface treating agent selected from an organic amine, quaternary ammonium salt, alkyl betaine or fluorochemical surfactant, alkoxysilane, and fluorinated polymer.

Owner:SHIN ETSU CHEM IND CO LTD

Implantable medical devices with fluorinated polymer coatings, and methods of coating thereof

ActiveUS20050131527A1Reduce coefficient of frictionSurgeryPharmaceutical containersMedicineFluoropolymer

The present invention generally relates to implantable medical devices having a fluorinated coating, and methods of coating the same. More particularly, the present invention provides implantable metallic medical devices coated with a corrosion resistant coating comprising an amorphous fluoropolymer.

Owner:CR BARD INC

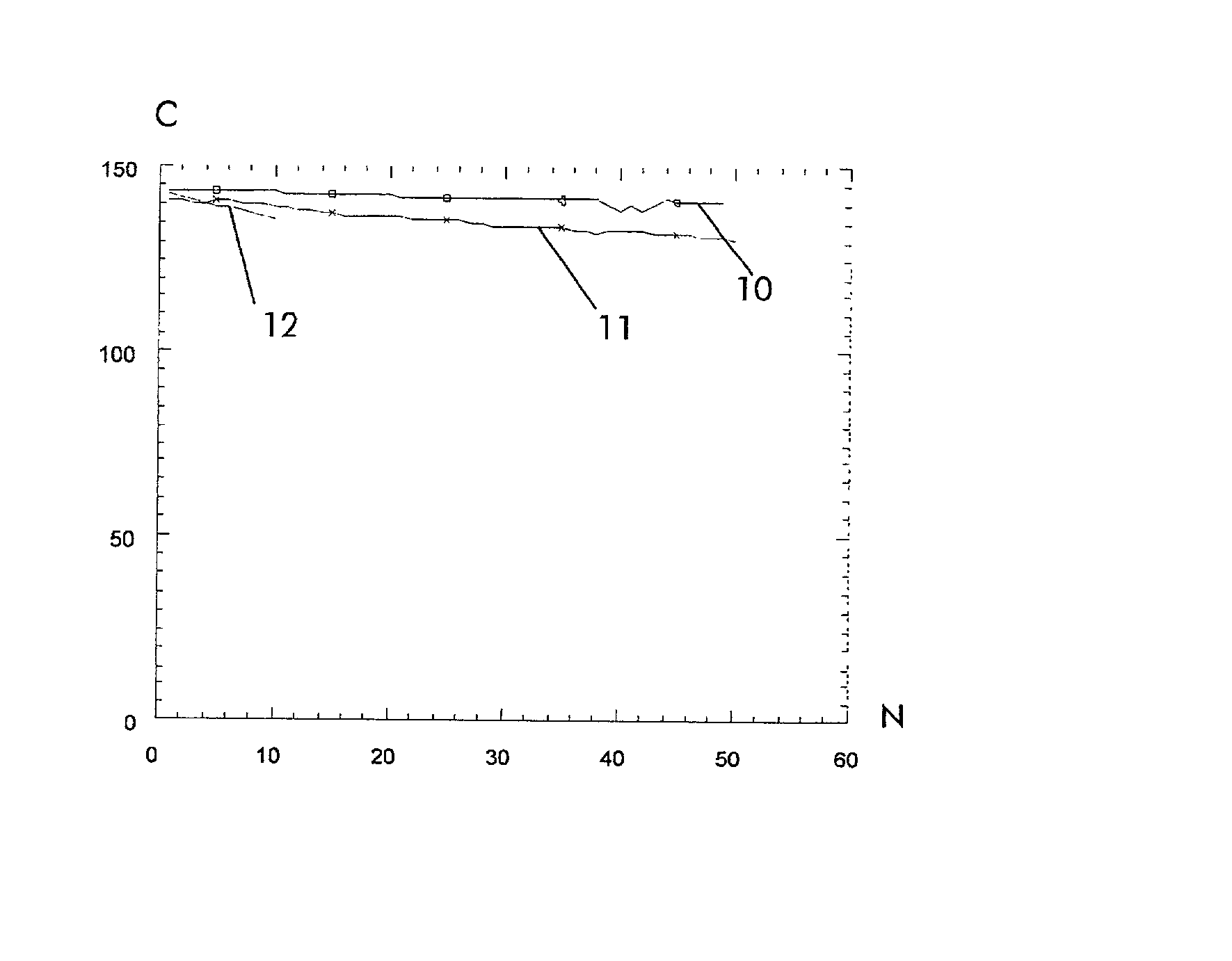

System in package

InactiveUS20050184376A1Improve cooling effectIncrease speedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsCopper conductorBand shape

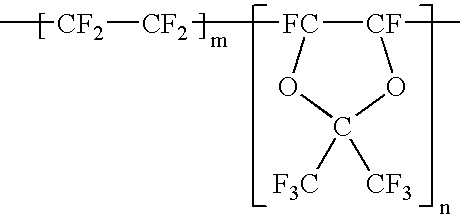

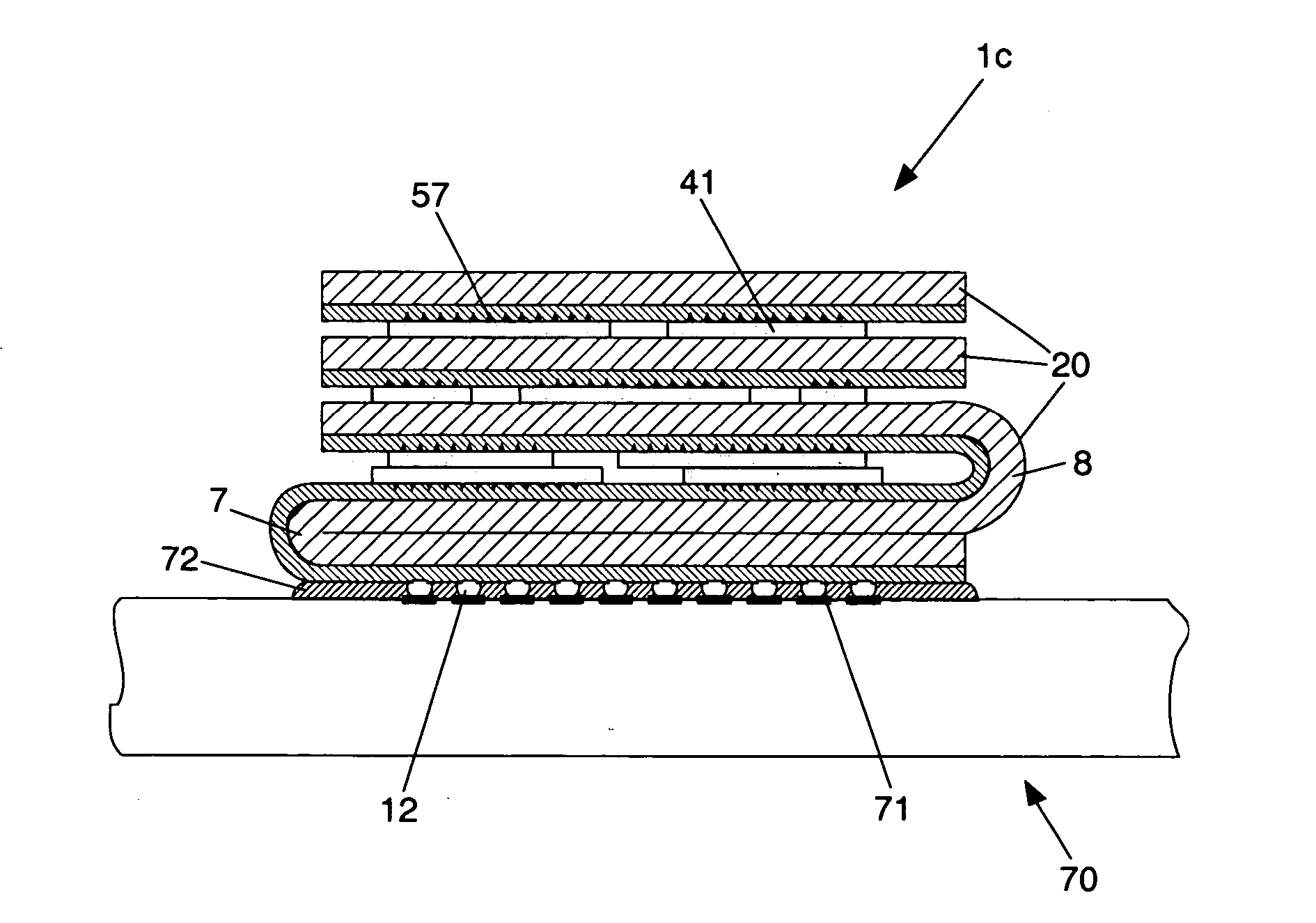

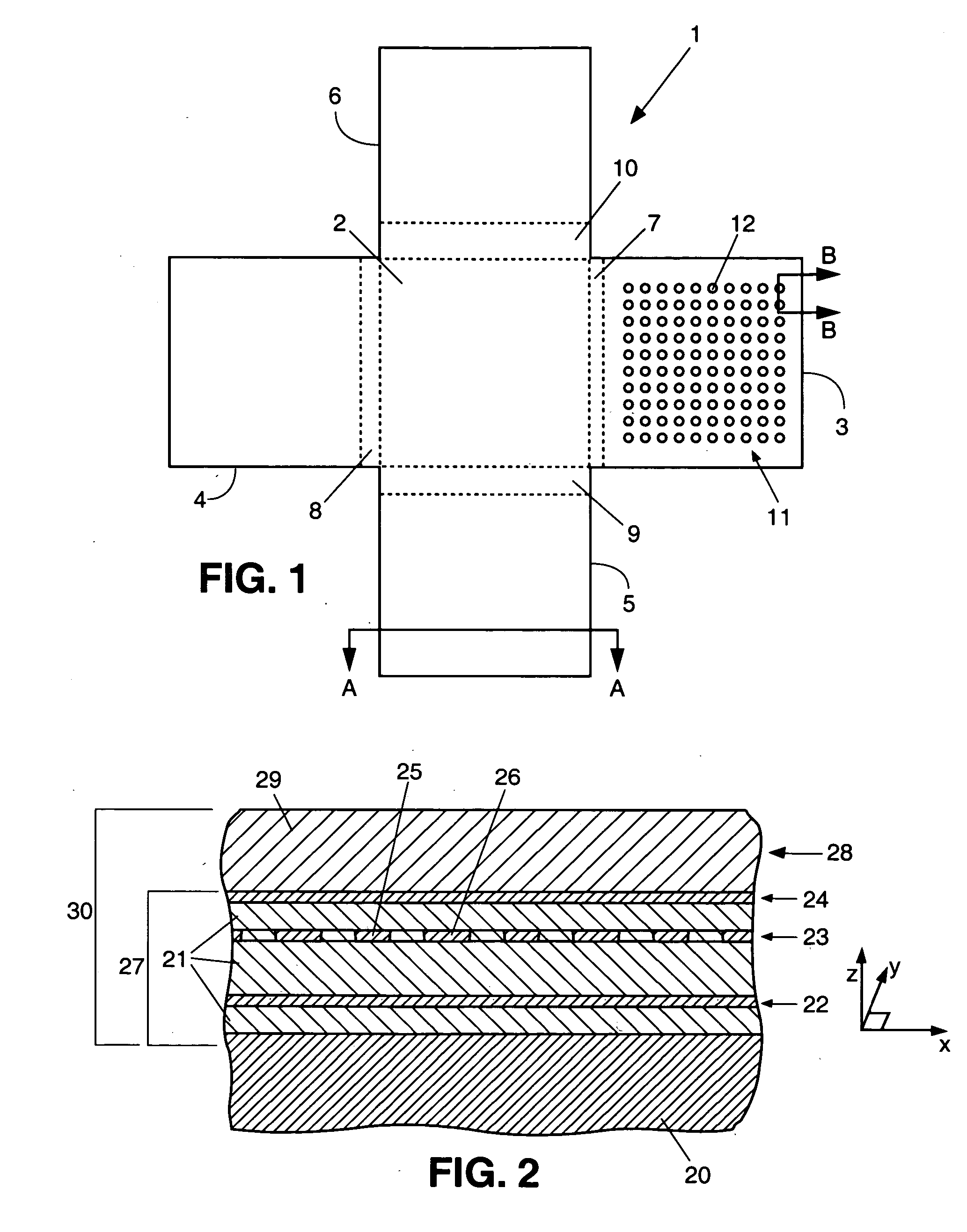

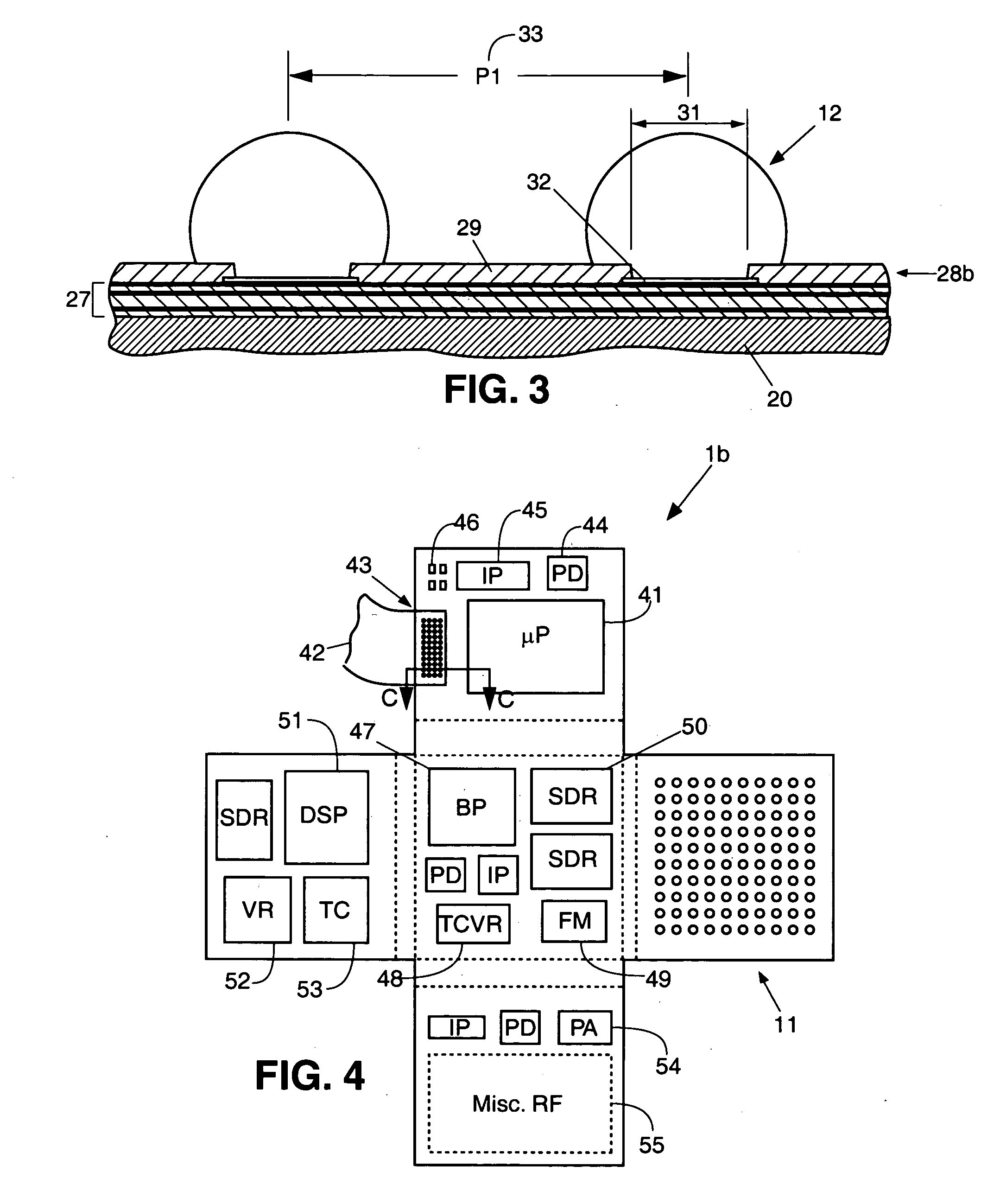

A system in package (SIP) is fabricated on a sheet of copper foil. An interconnection circuit is fabricated on the foil using copper conductors and a dual damascene structure for each conductive layer. The preferred dielectric material is an amorphous fluorinated polymer called Cytop. Input / output traces of the interconnection circuit terminate in wells filled with solder. Chips are bumped and direct attached by inserting the bumps into the wells. The preferred bumps are gold stud bumps, and the preferred wells contain solder paste to a depth of approximately 15 microns. Imprinting is the preferred method for patterning; it enables 6-micron wide traces, 6-micron diameter vias, and a cost per well of around 0.02 cents. Stripline structures are described for a 4-layer stackup that can support operating frequencies of at least 10 GHz. New methods are proposed for testing the completed assembly and for rework of any chips that prove defective. After the assembly is fully tested and reworked in sheet form the copper foil is folded to form a stacked die package or system in package. 5-high and 9-high stacks are illustrated. The copper foil provides a low impedance thermal path for cooling every chip in the SIP.

Owner:SALMON TECH

Separators for electrochemical cells

InactiveUS20130171500A1Improve securityHybrid capacitor separatorsElectrolytic capacitorsElectrical batteryPyrrolidinones

Provided are separators for use in batteries and capacitors comprising (a) at least 50% by weight of an aluminum oxide and (b) an organic polymer, wherein the aluminum oxide is surface modified by treatment with an organic acid to form a modified aluminum oxide, and wherein the treatment provides dispersibility of the aluminum oxide in aprotic solvents such as N-methyl pyrrolidone. Preferably, the organic acid is a sulfonic acid, such as p-toluenesulfonic acid. Also preferably, the organic polymer is a fluorinated polymer, such as polyvinylidene fluoride. Also provided are electrochemical cells and capacitors comprising such separators.

Owner:OPTODOT CORP

Fluorinated Polymer Blocks For PEM Applications

InactiveUS20080027152A1Improve proton conductivityIn situ pavingsIon-exchanger regenerationHydrophilic polymersPolymer science

A fluorine-containing polymer segment includes at least one substituent for proton transfer that has one or more fluorine atoms. The fluorine-containing polymer segment is useful for forming hydrophilic polymer blocks that are used in block copolymers. Block copolymers useful for fuel cell applications incorporate the hydrophilic polymer blocks formed from the fluorine containing polymer segments.

Owner:GM GLOBAL TECH OPERATIONS LLC

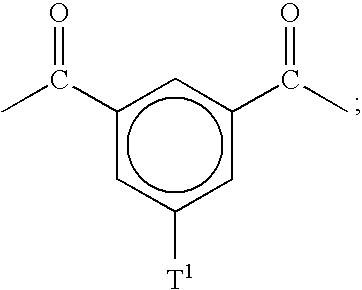

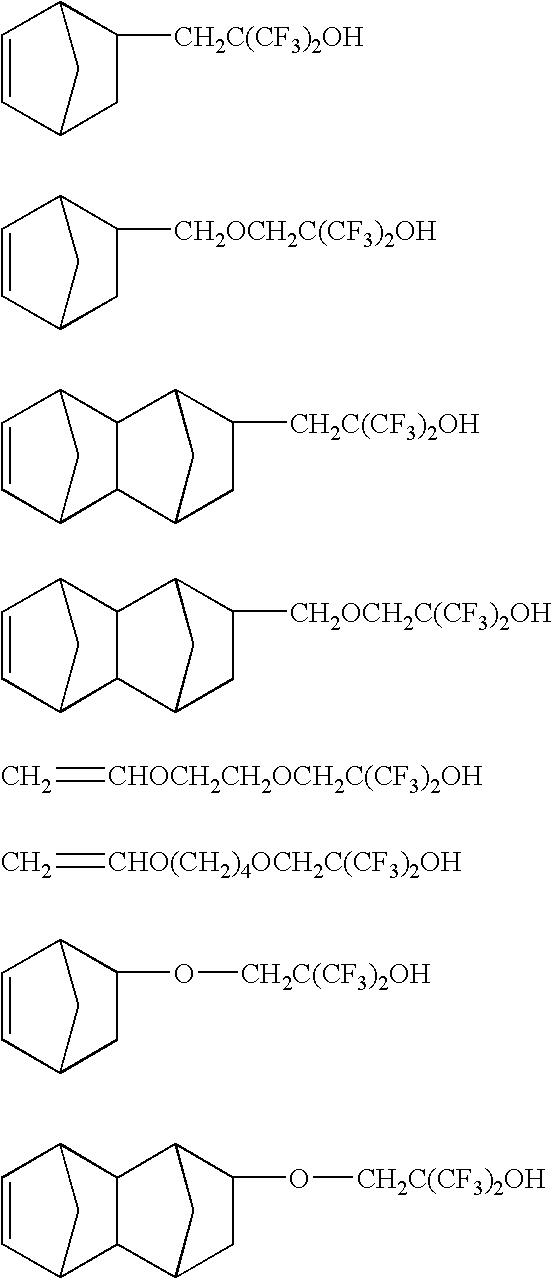

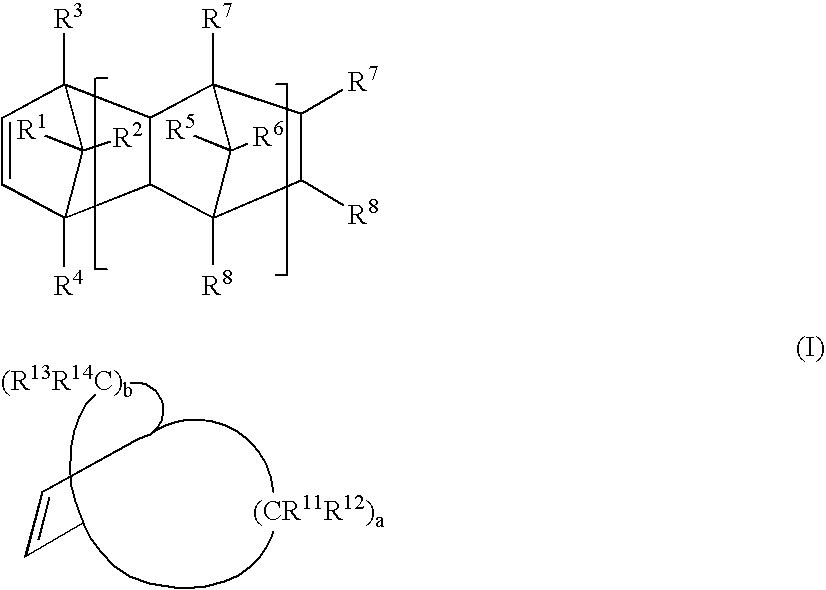

Fluorinated polymers, photoresists and processes for microlithography

InactiveUS20050203262A1Semiconductor/solid-state device manufacturingPhotosensitive material processingResistUltraviolet

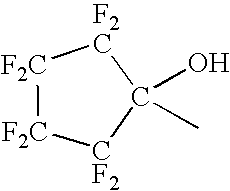

Fluorinated polymers useful in photoresist compositions and associated processes for microlithography are described. These polymers and photoresists have a fluoroalcohol functional group that simultaneously imparts high ultraviolet (UV) transparency and developability in basic media. The polymers also have a repeat unit derived from a C1-C25 alkyl hydroxymethylacrylate comonomer, e.g., tert-butyl hydroxymethylacrylate, or a C5-C50 polycyclic alkyl acrylate in which the polycyclic group contains a hydroxy group, e.g., hydroxyadamantyl acrylate. The materials of this invention have high UV tansparency, particularly at short wavelengths, e.g., 193 nm and 157 nm, which makes them highly useful for lithography at these short wavelengths.

Owner:EI DU PONT DE NEMOURS & CO

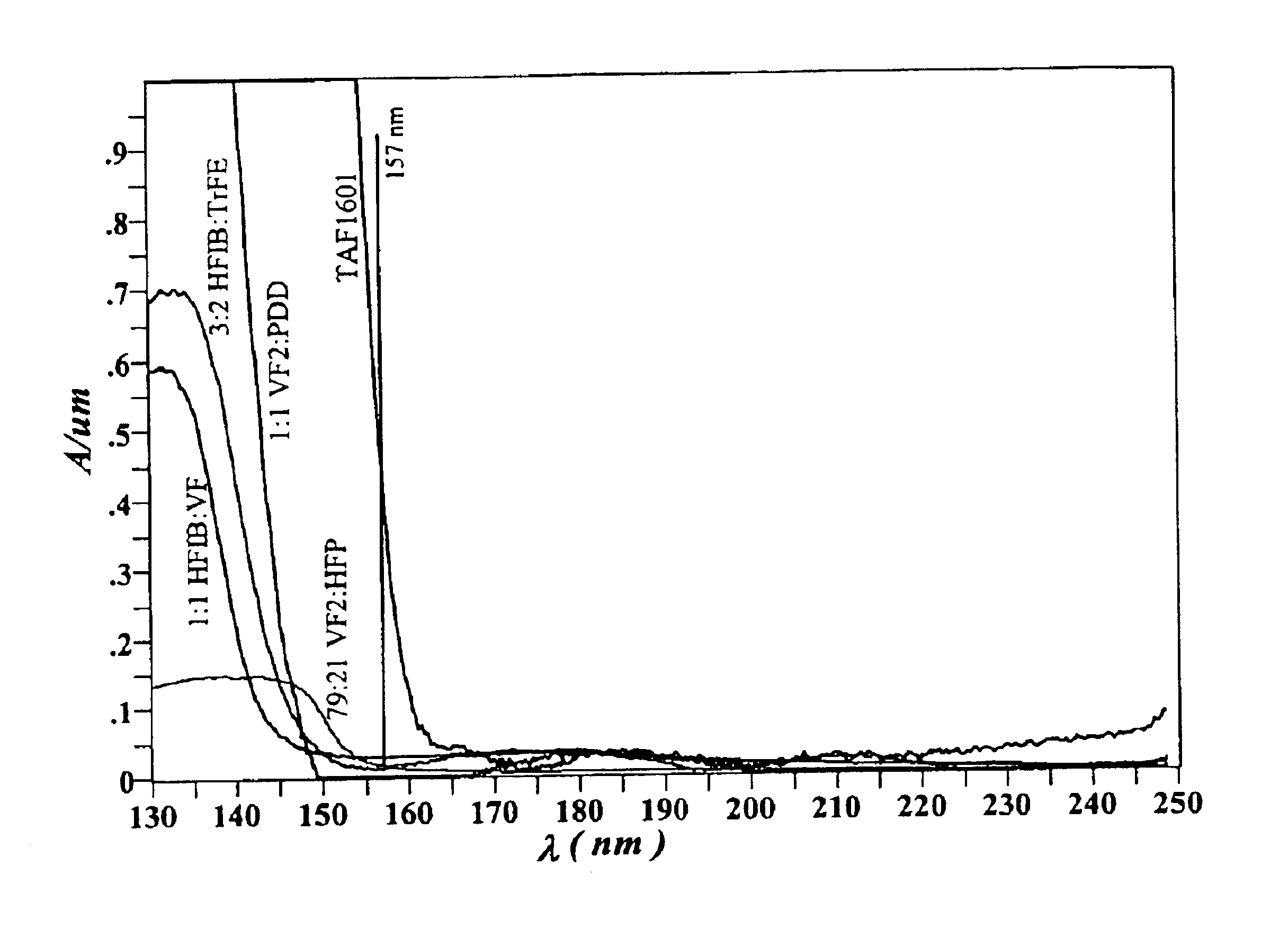

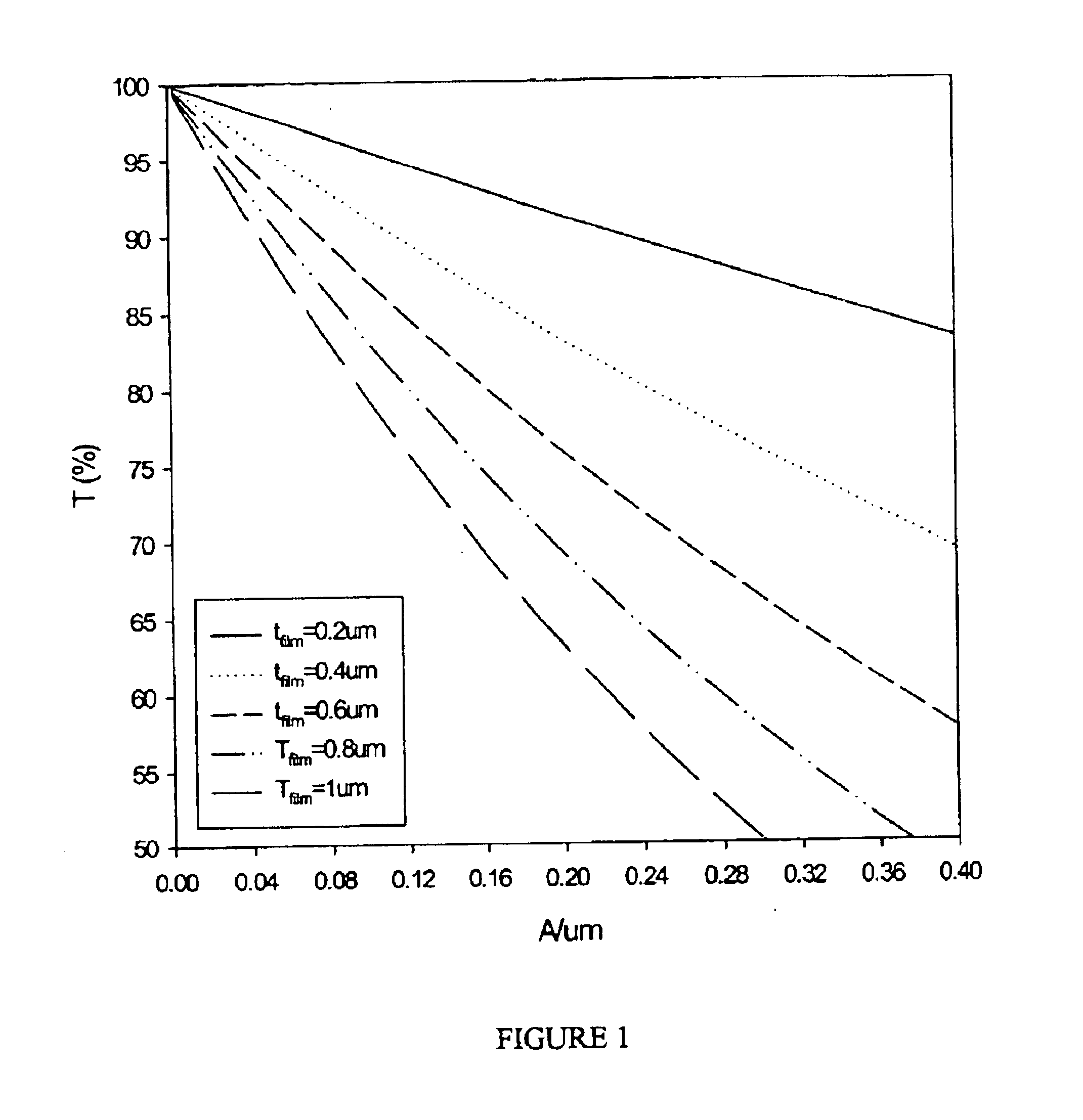

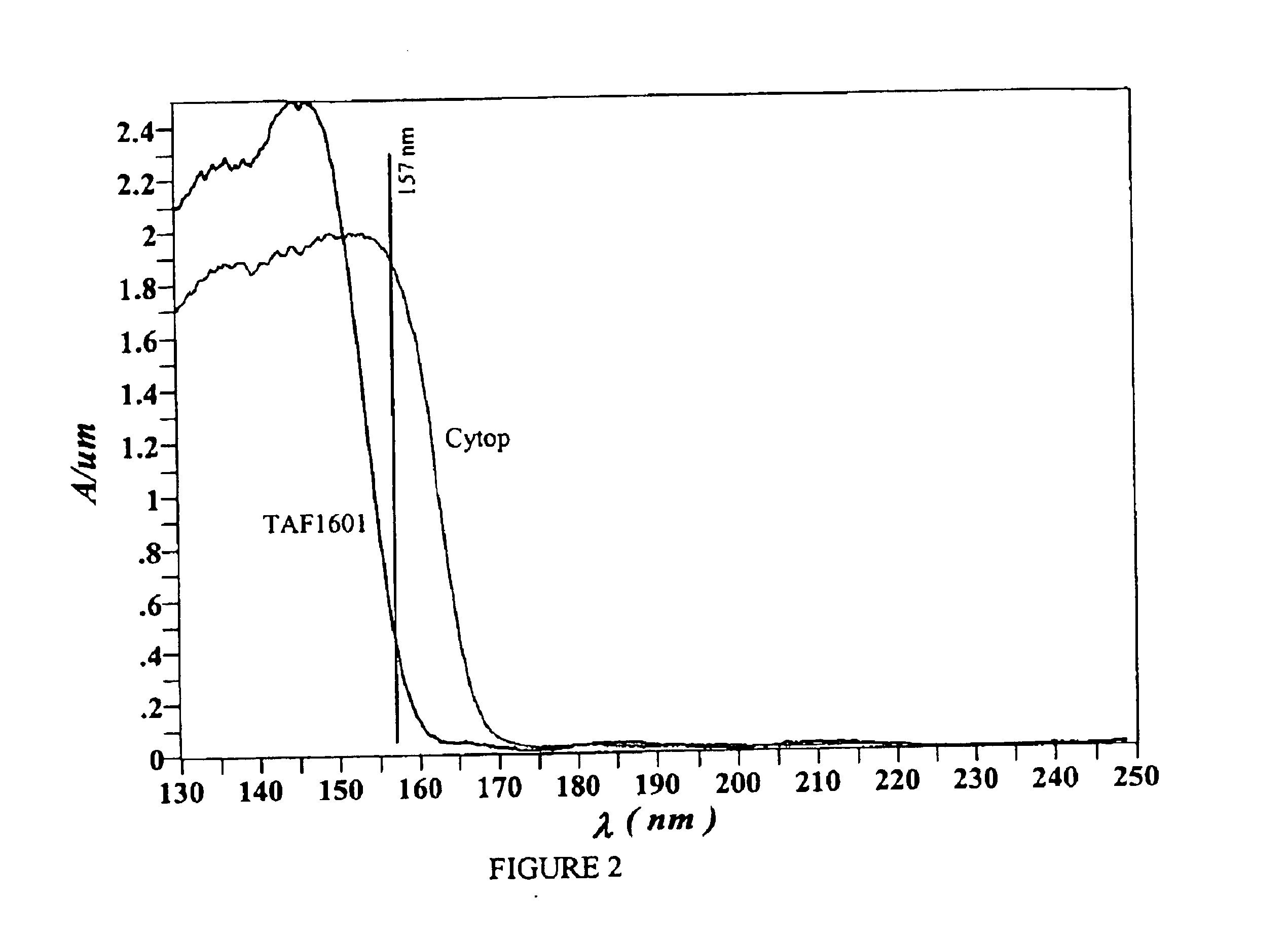

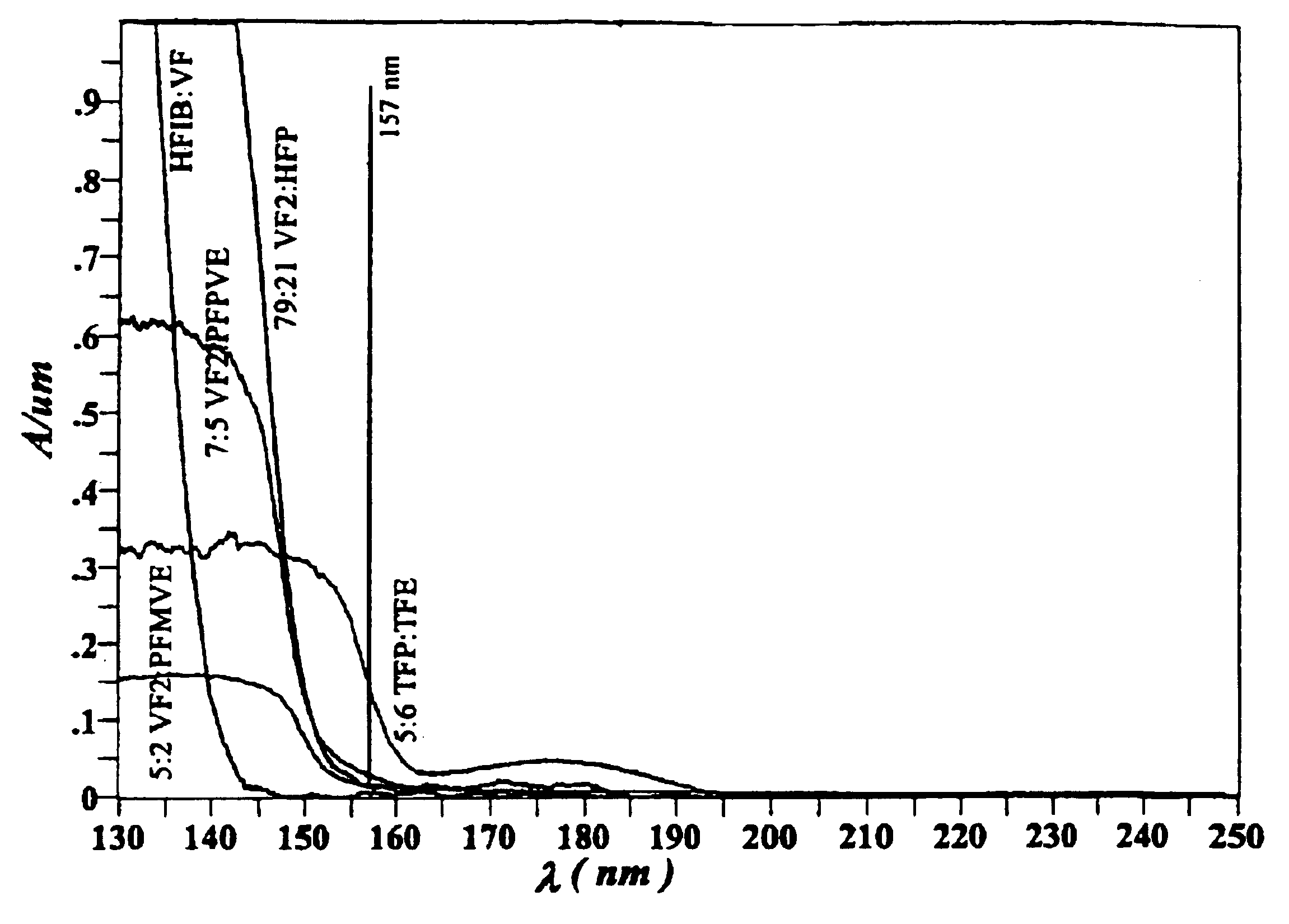

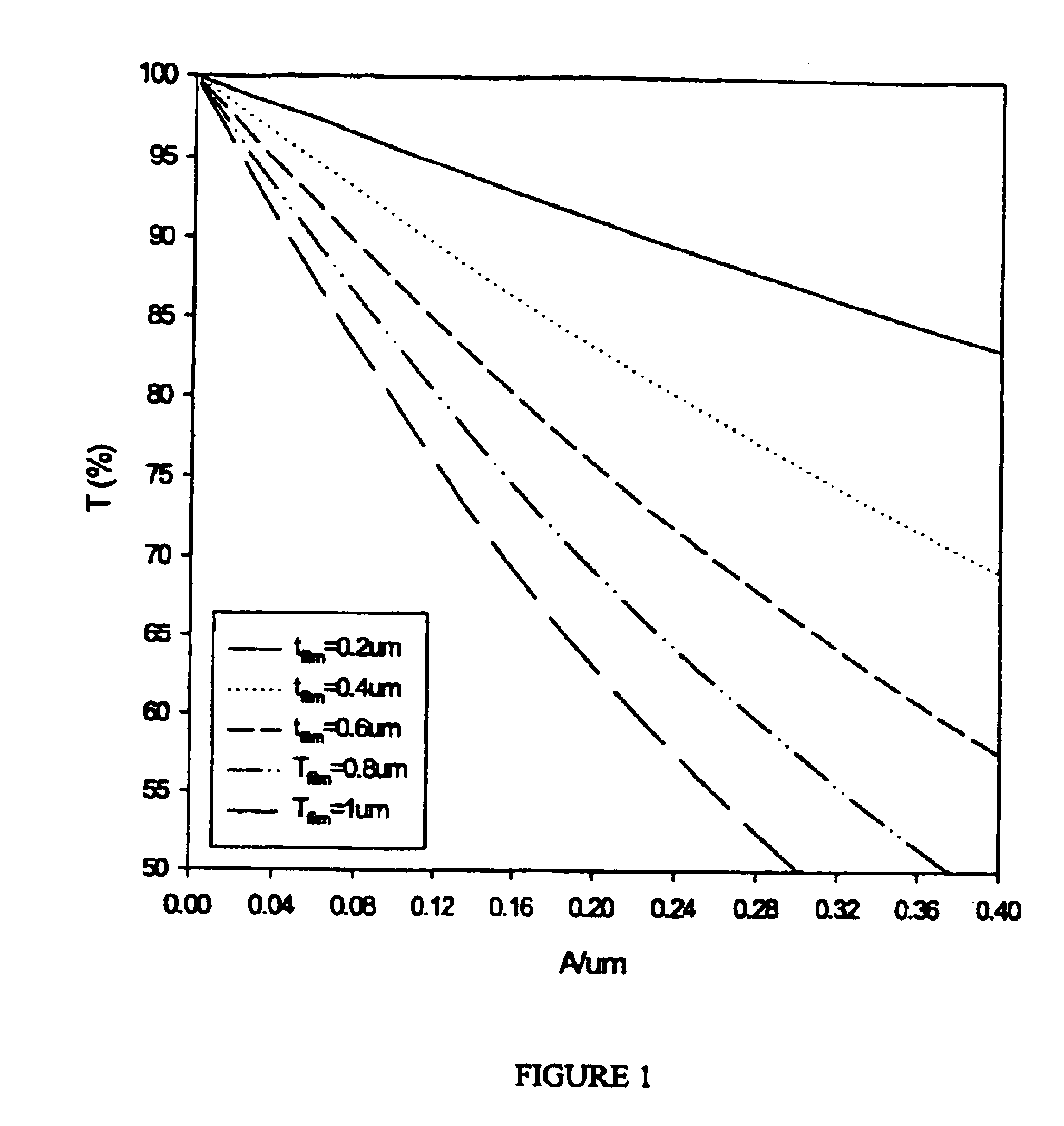

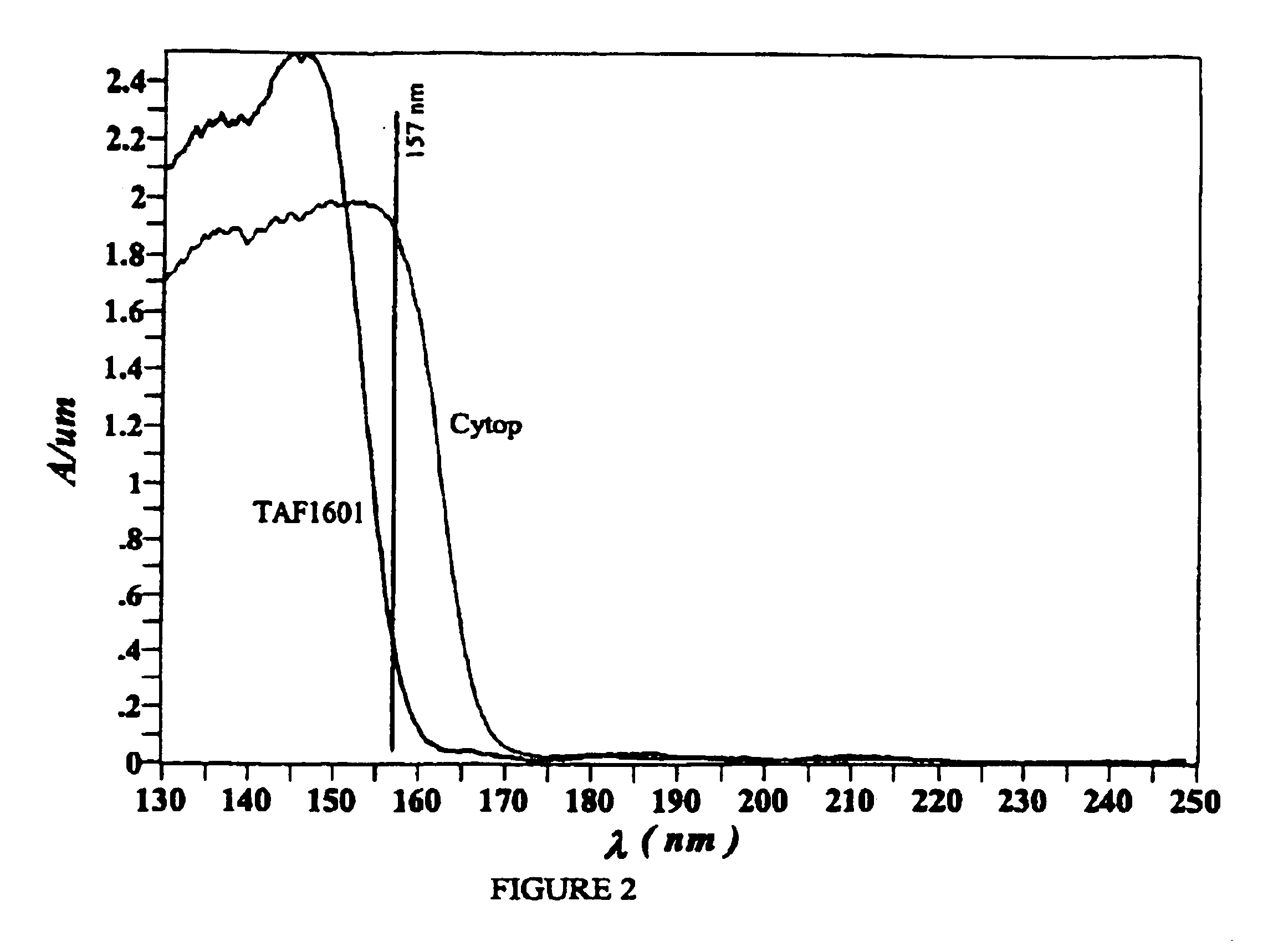

Ultraviolet and vacuum ultraviolet transparent polymer compositions and their uses

InactiveUS6824930B1Originals for photomechanical treatmentPhotosensitive materials for photomechanical apparatusLength waveVacuum ultraviolet

Disclosed are partially fluorinated and fully fluorinated polymers that are substantially transparent to ultraviolet radiation at wavelengths from 140 to 186 nanometers.

Owner:EI DU PONT DE NEMOURS & CO

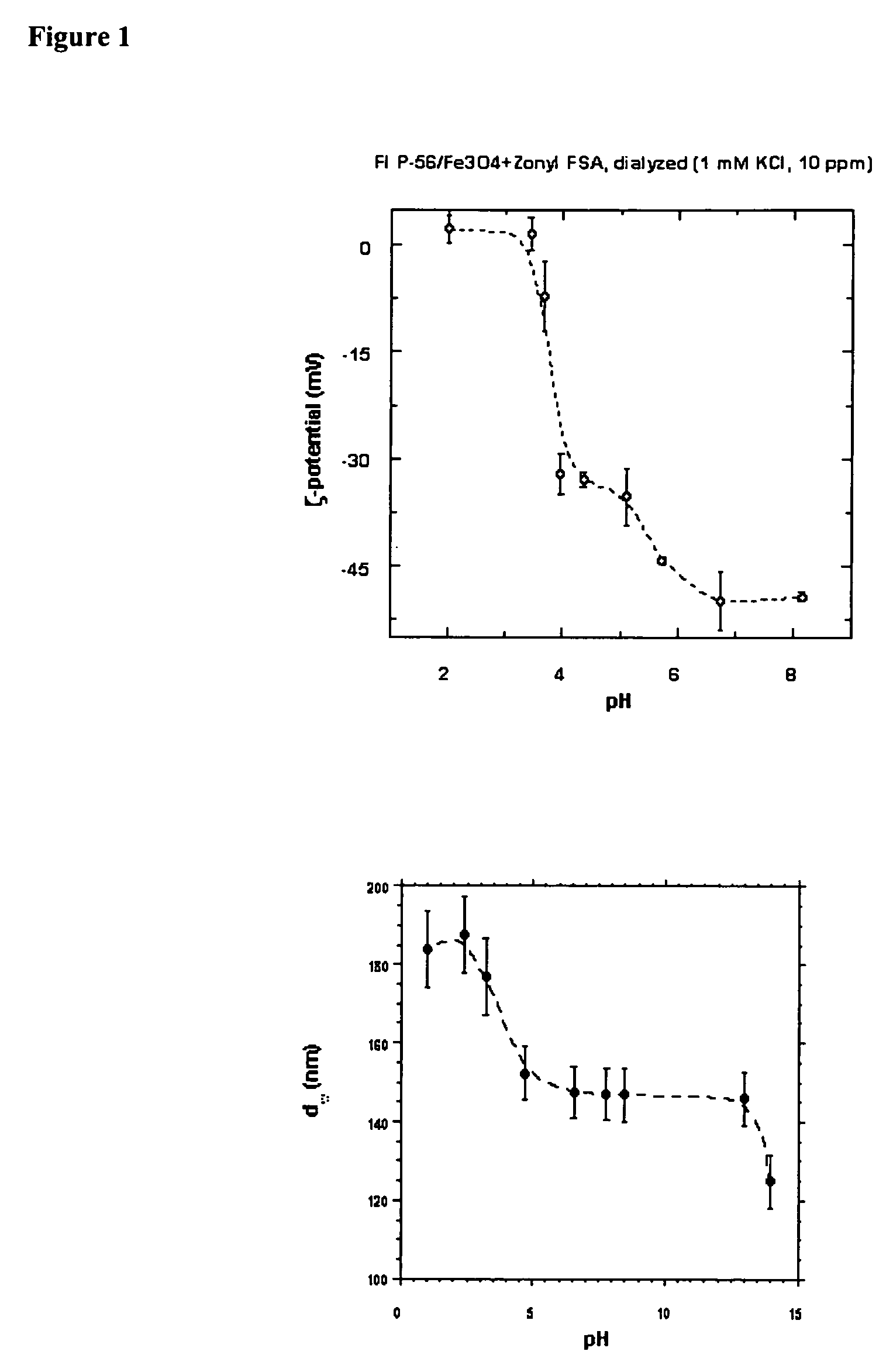

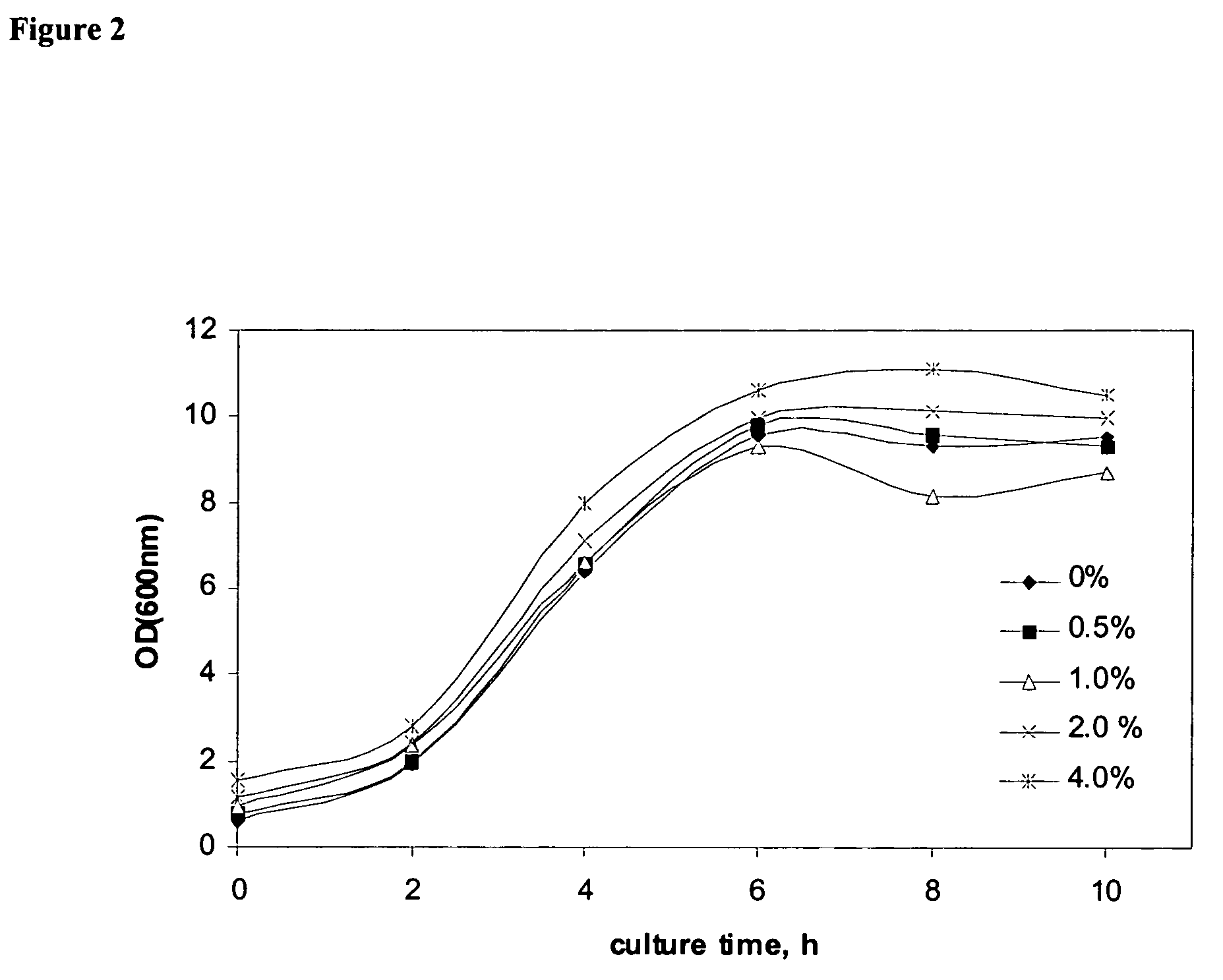

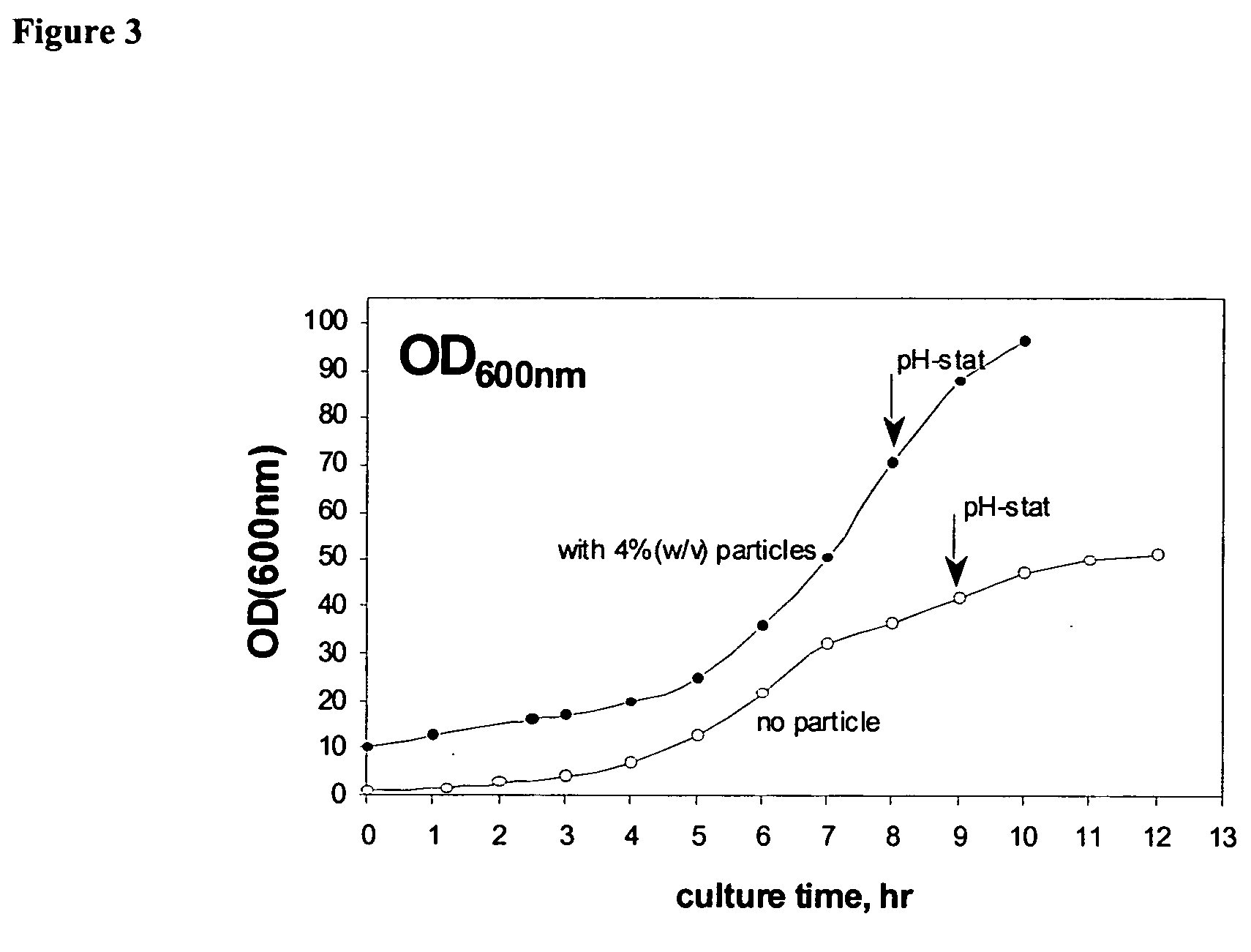

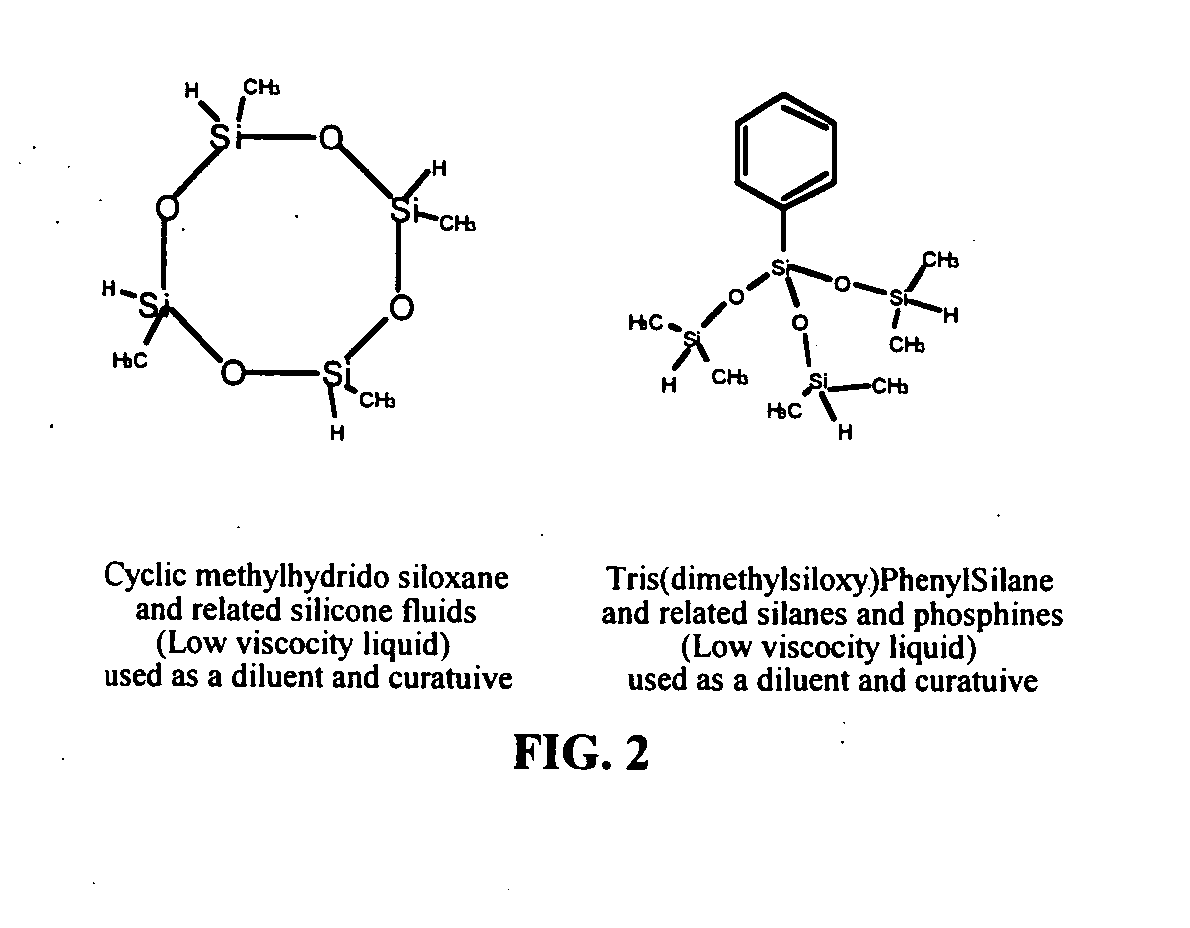

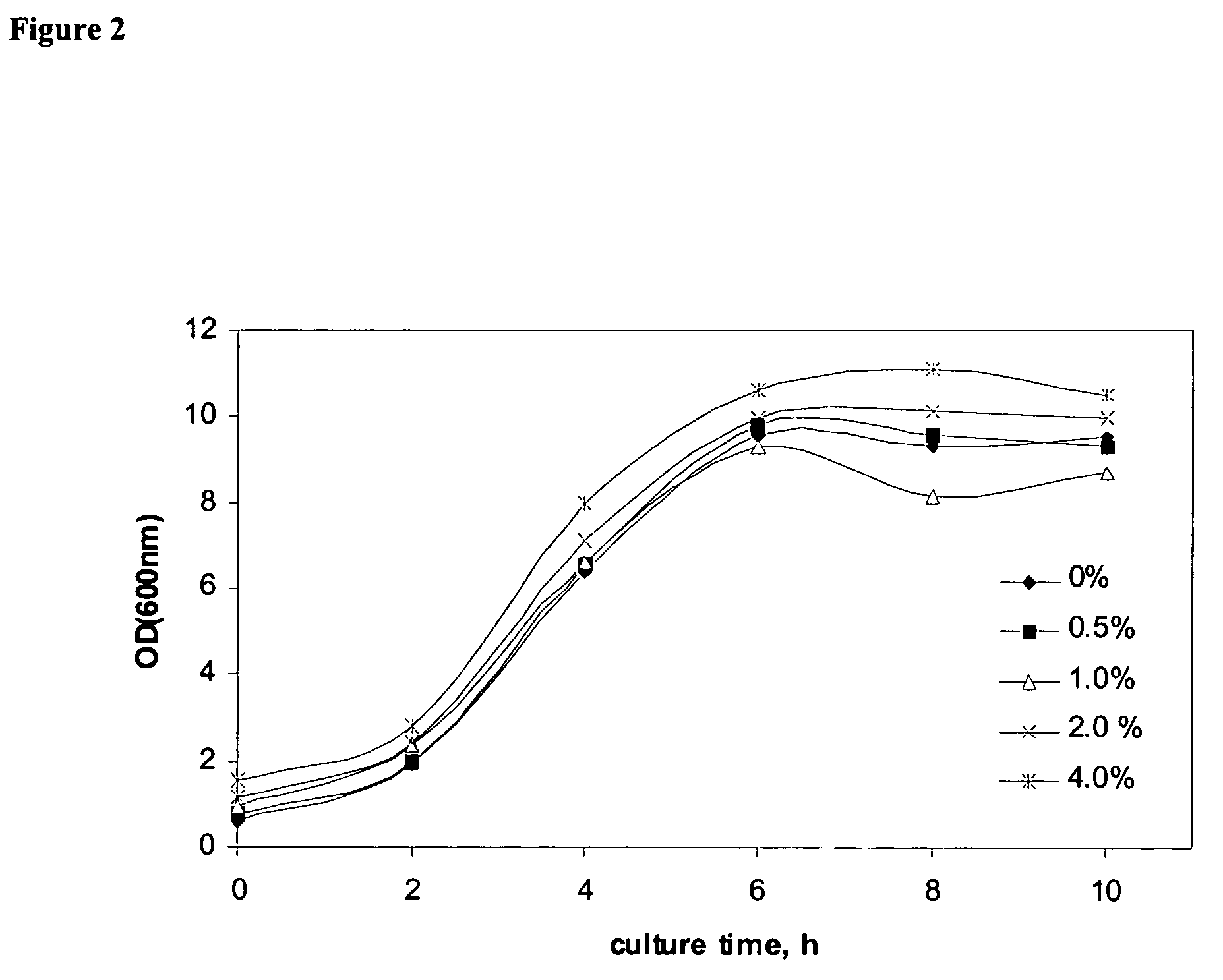

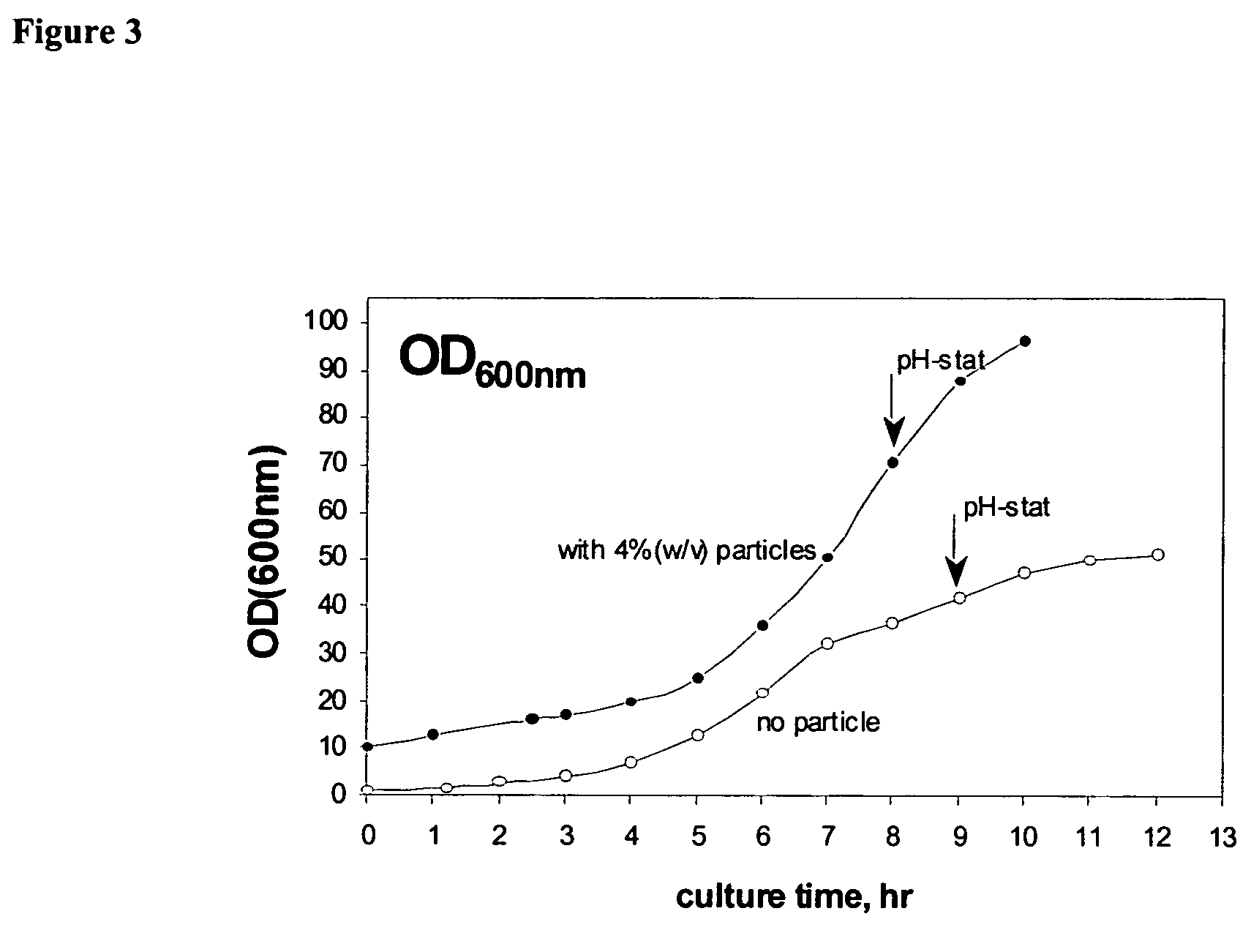

Bioprocesses enhanced by magnetic nanoparticles

InactiveUS20060040388A1Increase volumeEnhances gas transferMaterial nanotechnologyNanomagnetismMagnetite NanoparticlesOxygen

One aspect of the present invention relates to magnetic nanoparticles colloidally stabilized in aqueous milieu by association with an organic phase. The organic phase may be either a fluorinated polymer or an organic hydrocarbon bilayer, wherein the two layers are chemically bonded to each other. The stabilized particles are further non-toxic and provide useful enhancements in bioprocesses. Another aspect of the present invention relates to compositions comprising an oxygen-dissolving fluid vehicle and surface modified, nanometer-sized magnetic particles. The inventive compositions have utility in a wide range of applications, but are particularly suitable for use as recyclable oxygen carriers, separation and purification vehicles, and bioprocessing media, including fermentation processes.

Owner:MASSACHUSETTS INST OF TECH

Protective articles

InactiveUS7141303B2Good solvent resistanceDomestic sealsPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention provides protective articles comprising a backing that comprises a fluorinated polymer and a curable adhesive on at least one layer of the backing. The protective articles of the invention may be used to provide substrates or articles of the invention having a fluorinated surface. The invention also provides methods of preparing such articles, methods of repairing appliqués, and methods of edge sealing appliqués.

Owner:3M INNOVATIVE PROPERTIES CO

Water-repellent and soil-resistant finish for textiles

InactiveUS6855772B2Improve wear resistanceGood water solubilityPretreated surfacesOrganic dyesYarnEmulsion

The present invention is directed to polymeric treatment preparations for textiles and other fibrous substrates that impart water and oil repellency to fibers, yarns, textiles, or other fibrous substrates. More particularly, this invention comprises an aqueous solution, emulsion or suspension of (a) a fluorinated polymer that contains reactive groups that can complex with metal atoms that have a formal charge of 2 or greater, and (b) one or more metal atoms that have a formal charge of 2 or greater. The invention is further directed to the process for treating fibrous substrates with textile preparations in one step that provide water / soil repellency that is durable to repeated cleanings and to abrasion. This invention is further directed to the yarns, fibers, fabrics, textiles, webs, finished goods, or nonwovens (encompassed herein under the terms “textiles” and “fibrous substrates”) treated with the textile-reactive water- and soil-resistant preparation of the invention. Such fibrous substrates exhibit a greatly improved, durable water and soil repellency or resistance, even after multiple launderings.

Owner:NANO TEX

Protective articles

InactiveUS20070047099A1Good solvent resistanceDomestic sealsPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention provides protective articles comprising a backing that comprises a fluorinated polymer and a curable adhesive on at least one layer of the backing. The protective articles of the invention may be used to provide substrates or articles of the invention having a fluorinated surface. The invention also provides methods of preparing such articles, methods of repairing appliqués, and methods of edge sealing appliqués.

Owner:MICROSOFT CORP

Multi-layer compositions comprising a fluoropolymer

InactiveUS6156400ADecorative surface effectsDuplicating/marking methodsComposite constructionPolymer science

This invention provides a method of bonding substantially non-fluorinated polymeric material to dissimilar polymers, particularly fluoropolymer materials, utilizing a bonding composition comprising base-treated amide group-containing substantially non-fluorinated polymer. Multi-layer articles and composite constructions, including retroreflective sheeting, fuel line hoses, and adhesive articles made of a fluoropolymer layer and a substantially non-fluorinated layer are also provided.

Owner:3M INNOVATIVE PROPERTIES CO

Ultraviolet and vacuum ultraviolet transparent polymer compositions and their uses

InactiveUS6770404B1Originals for photomechanical treatmentPhotosensitive materials for photomechanical apparatusLength waveVacuum ultraviolet

Disclosed are partially fluorinated and fully fluorinated polymers that are substantially transparent to ultraviolet radiation at wavelengths from 187 to 260 nanometers.

Owner:EI DU PONT DE NEMOURS & CO

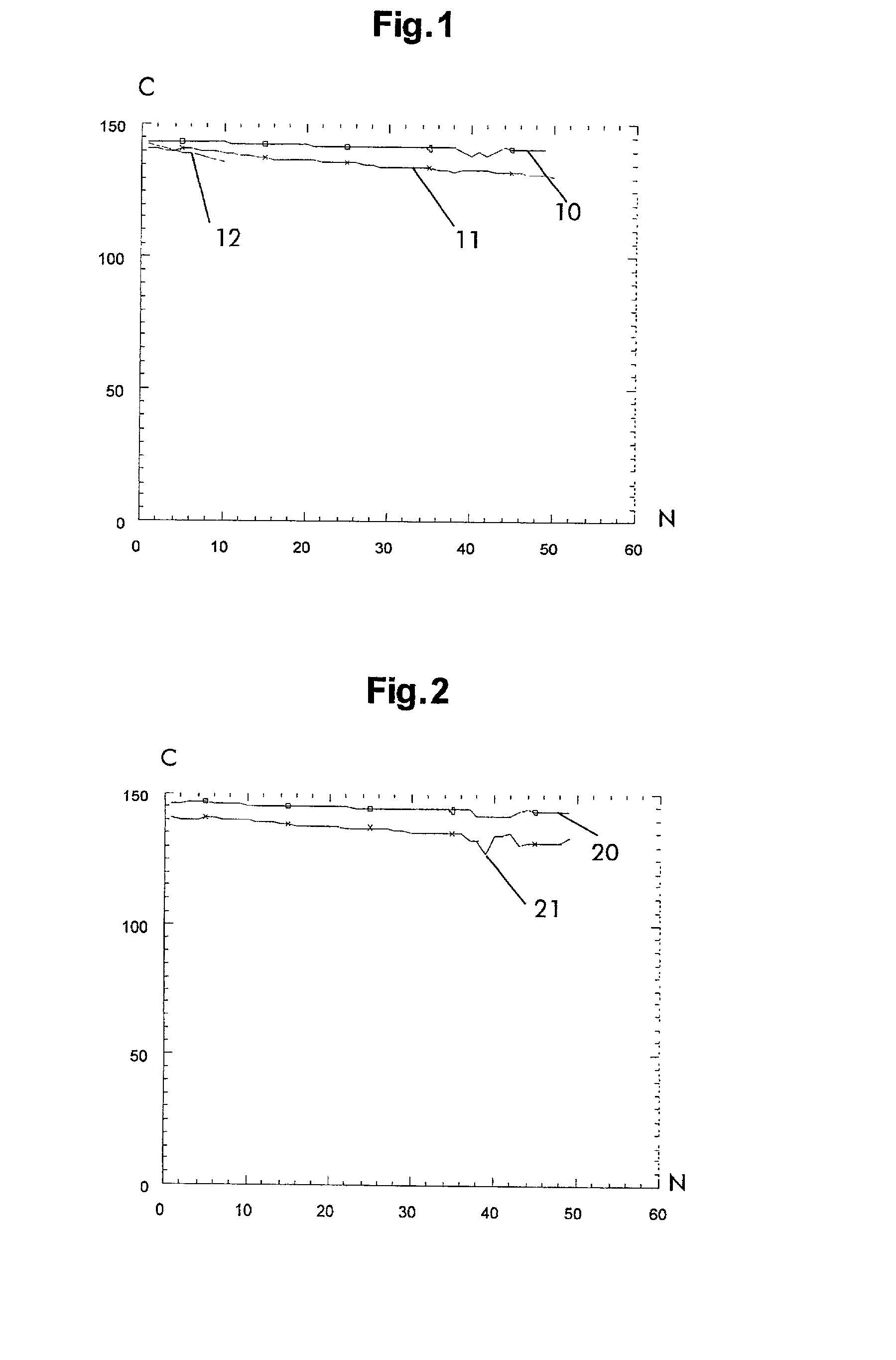

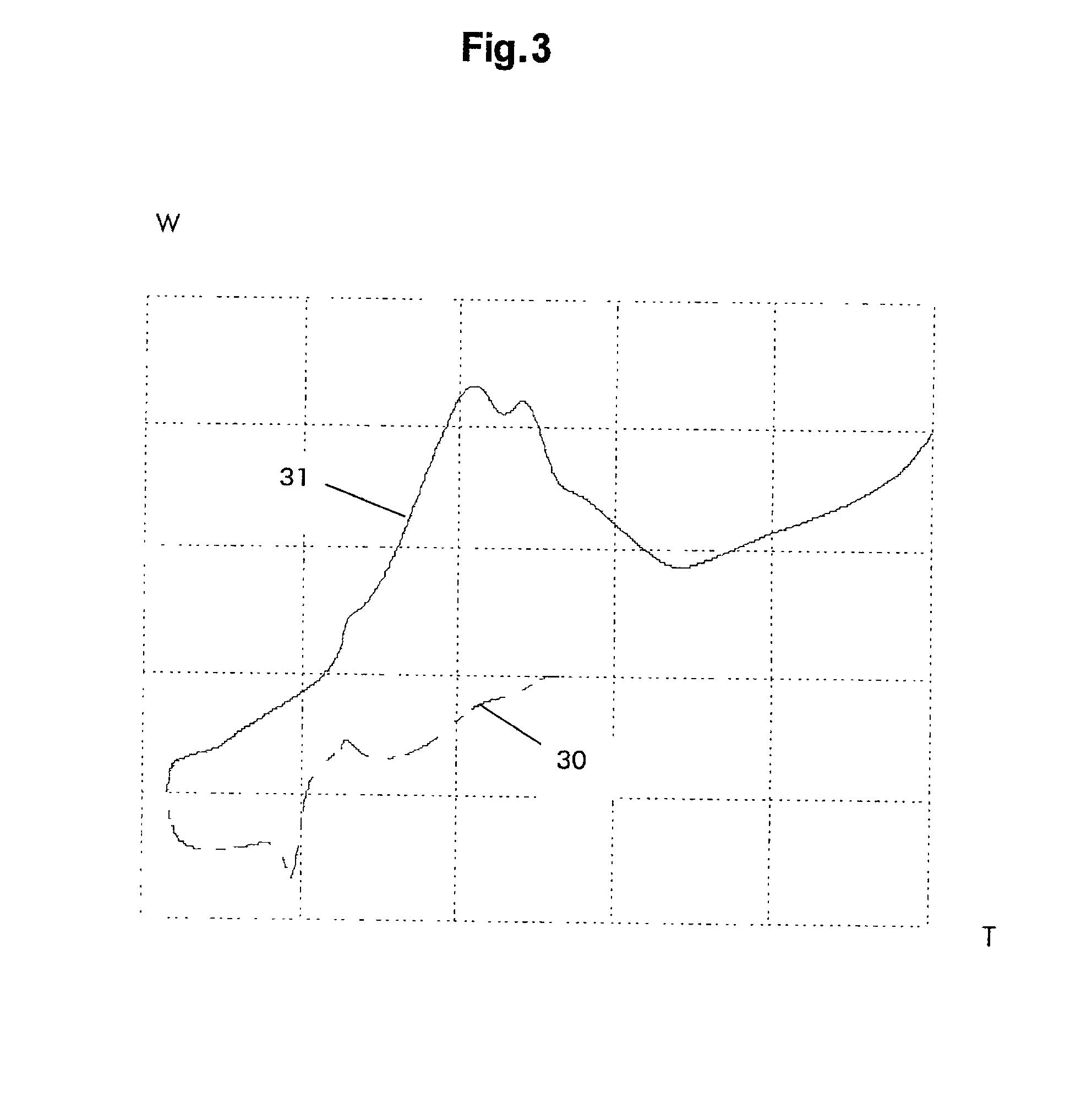

Rechargeable lithium storage cell

A rechargeable lithium storage cell includes a positive electrode, whose electrochemically active material includes one or more oxides of a transition metal, and a negative electrode, consisting of a conductive support and an active layer containing a binder and an electrochemically active material. The binder is a polymer containing no fluorine. The electrochemically active material is a mixed oxide of lithium and titanium with the general formula Li.sub.xTi.sub.yO.sub.4 in which 0.8.ltoreq.x.ltoreq.1.4 and 1.6.ltoreq.y.ltoreq.2.2. The non-fluorinated polymer is preferably soluble in water or capable of forming a stable emulsion in suspension in water. The binder preferably contains an elastomer, especially an acrylonitrile / butadiene copolymer and / or a cellulose compound such as carboxymethylcellulose.

Owner:SAFT FINANCE S AR L

Fluorinated carbon composite cathode for a high-energy lithium battery

InactiveUS20120126182A1Reduce voltage dropNon-metal conductorsElectric discharge heatingCarbon compositesCarbon monofluoride

A lithium / fluorinated carbon (Li / CFx) battery having a composite cathode including an electroactive cathode material, a non-electroactive additive, a conductive agent, and a binder. The electroactive cathode material is a single fluorinated carbon having a general formula of CFx, whereby x is an averaged value ranging from about 0.5 to about 1.2. The non-electroactive additive is at least one or a mixture of two or more oxides selected from the group comprising Mg, B, Al, Si, Cu, Zn, Y, Ti, Zr, Fe, Co, or Ni. The conductive agent is selected from the group comprising carbon, metals, and mixtures thereof. Finally, the binder is an amorphous polymer selected from the group comprising fluorinated polymers, ethylene-propylene-diene (EPDM) rubbers, styrene butadiene rubbers (SBR), poly (acrylonitrile-methyl methacrylate), carboxymethyl celluloses (CMC), and polyvinyl alcohol (PVA). Also, a method of reducing the initial voltage drop of a lithium / fluorinated carbon (Li / CFx) battery by providing a composite cathode which includes an electroactive cathode material having a general formula of CFx, whereby x is an averaged value ranging from about 0.5 to about 1.2, a non-electroactive additive, a conductive agent, and a binder.

Owner:ARMY US SEC THE

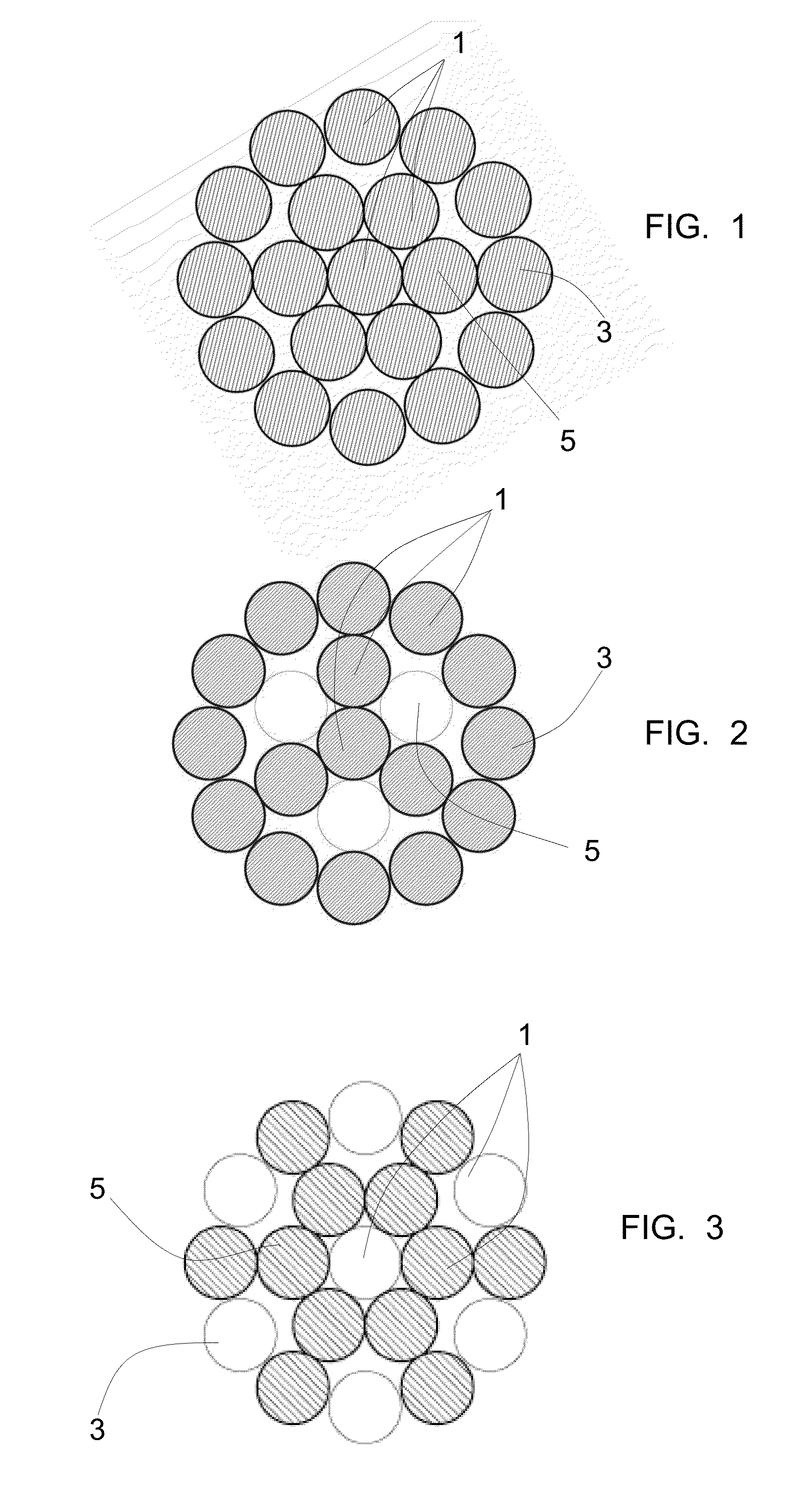

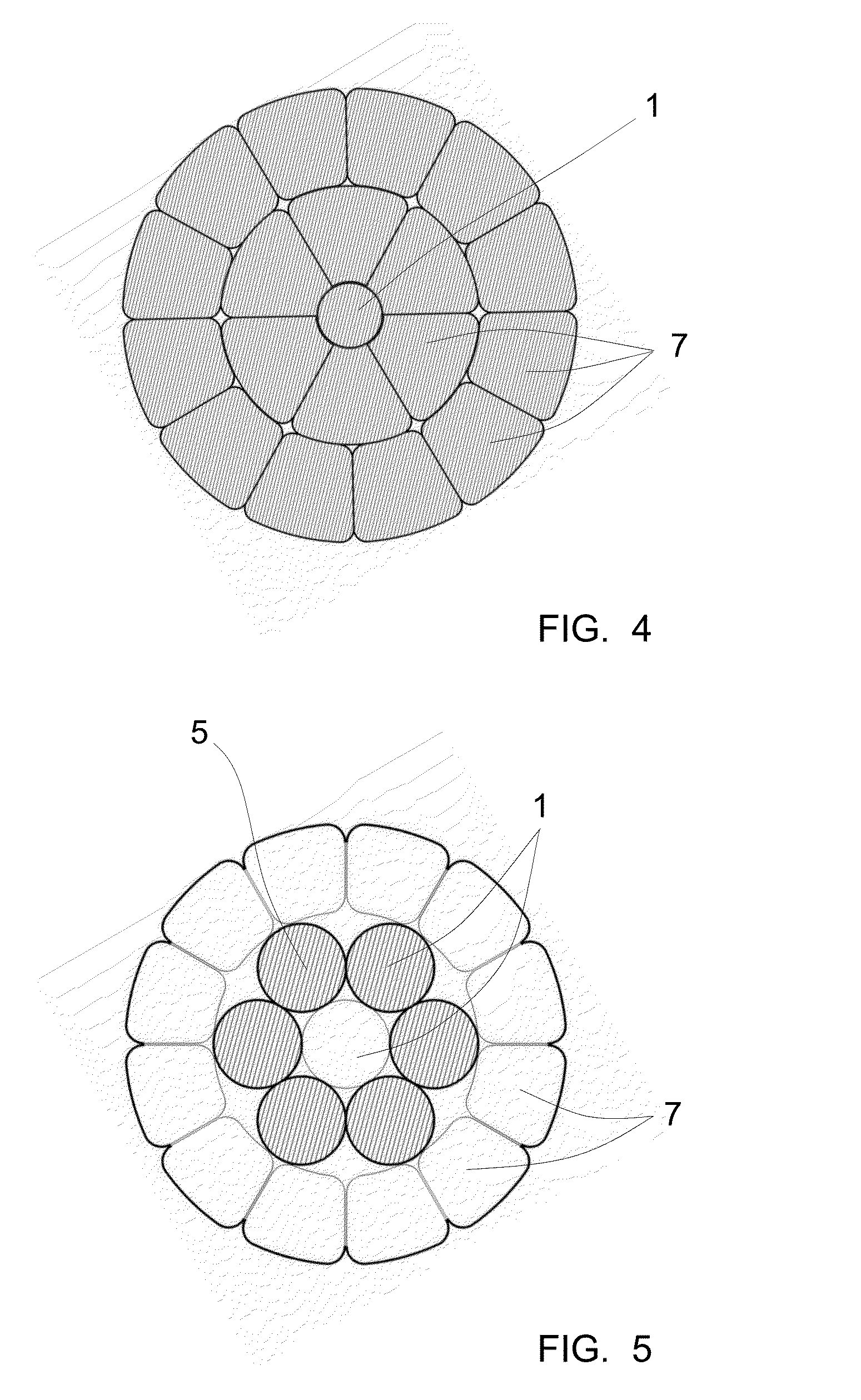

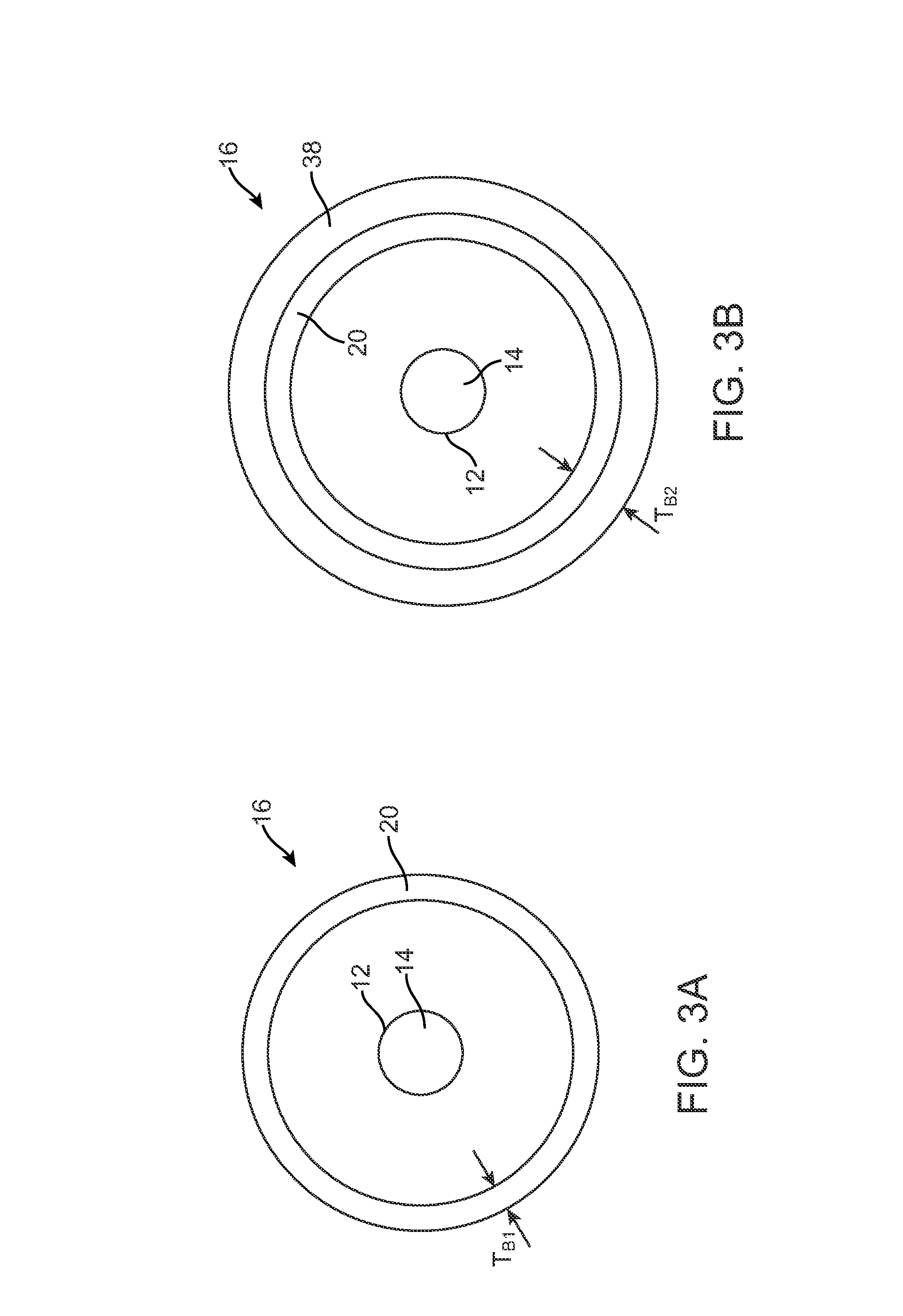

Electrical Conductor for Transporting Electrical Energy and Corresponding Production Method

InactiveUS20130264093A1Small catenary sagImprove electrical performanceNon-insulated conductorsConductive materialElectrical conductorSkin effect

An electrical conductor for transmission of electrical power, having a total cross-section equal to or above 10 mm2 and comprising a plurality of stranded filamentary members, where at least one of the filamentary members is made from microalloyed copper or microalloyed aluminium having annealing temperatures higher than 250° C., and has the side surface thereof totally coated with a fluorinated polymer. The conductor has a better behavior relative to the skin effect and allows operation at high temperatures. Furthermore, if the electrical conductor is suspended, it has a smaller sag and prevents or reduces the accumulation of ice and / or snow.

Owner:LA FARGA LACAMBRA

In situ polymerization for skin treatment

InactiveUS20090220436A1Long lastingResist of effectivenessCosmetic preparationsBiocideSkin treatmentsIn situ polymerization

Cosmetics represent a world-wide multi-billion dollar industry. The present invention provides technology for polymerizing monomers on skin in situ to produce desired skin characteristics. For example, the inventive system may be used to reduce the signs of aging or to protect the treated skin from UV light. The polymerization of monomers on skin is typically initiated using a thermal or photoinitiatied free radical initiator. In certain embodiments, the monomers are fluorinated thereby producing a fluorinated polymer on the skin upon polymerization. The invention provides monomers, initiators, methods, and kits for use in treating skin with polymers.

Owner:LIVING PROOF INC

Durable finishes for textiles

InactiveUS6872424B2Improve stabilityGood water solubilitySynthetic resin layered productsPretreated surfacesTextile fiberAlcohol

The present invention relates to textile treatment compositions for imparting desirable characteristics durably to textile fibers and fabrics, including softness, hydrophobicity, oleophobicity, surface lubricity, abrasion resistance, tear resistance, improved drape, and pilling resistance. More particularly, in one embodiment, the invention is directed to preparations that comprise a carboxylate-functionalized fluorinated polymer and a catalyst that is capable of forming reactive anhydride rings between carboxyl groups on the polymer. In another embodiment, the invention is directed to preparations comprising a polymeric softener having at least one anhydride functional group or at least one reactive group capable of forming an anhydride functional group, together with a catalyst for forming anhydrides from the reactive group or groups. In either embodiment, the resulting reactive anhydride rings bind to substrates, such as textiles and other webs, having free sulfhydryl, alcohol, or amine groups. The invention is further directed to the process for treating textiles and other webs with desirable finishes durable to repeated cleanings. This invention is further directed to the yarns, fibers, fabrics, textiles, finished goods, or nonwovens (encompassed herein under the terms “textiles” and “webs”) treated with the textile-reactive preparations of the invention. Such textiles and webs exhibit a greatly improved, durable characteristics, such as softness and / or hydrophobicity, even after multiple launderings.

Owner:NANO TEX

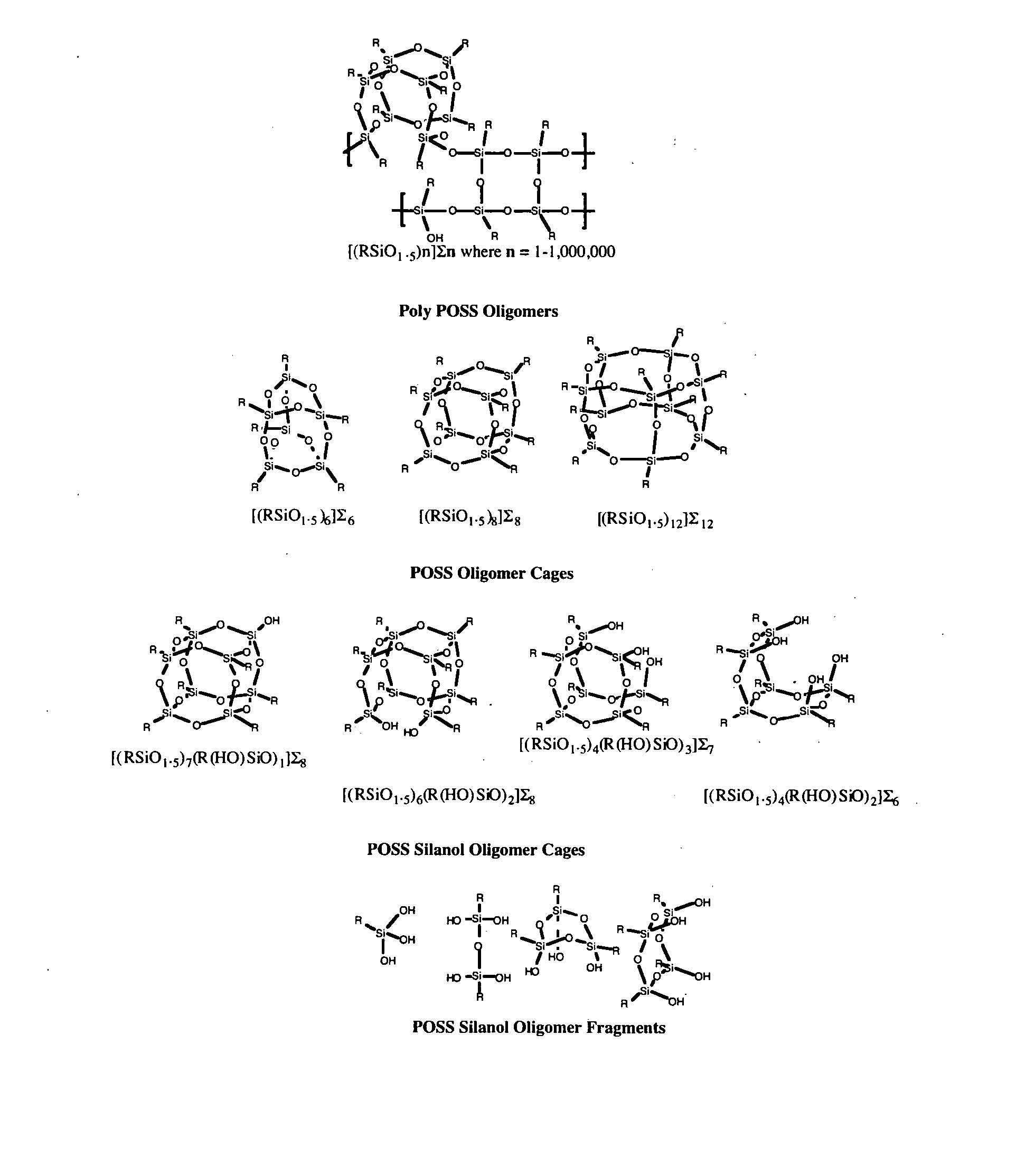

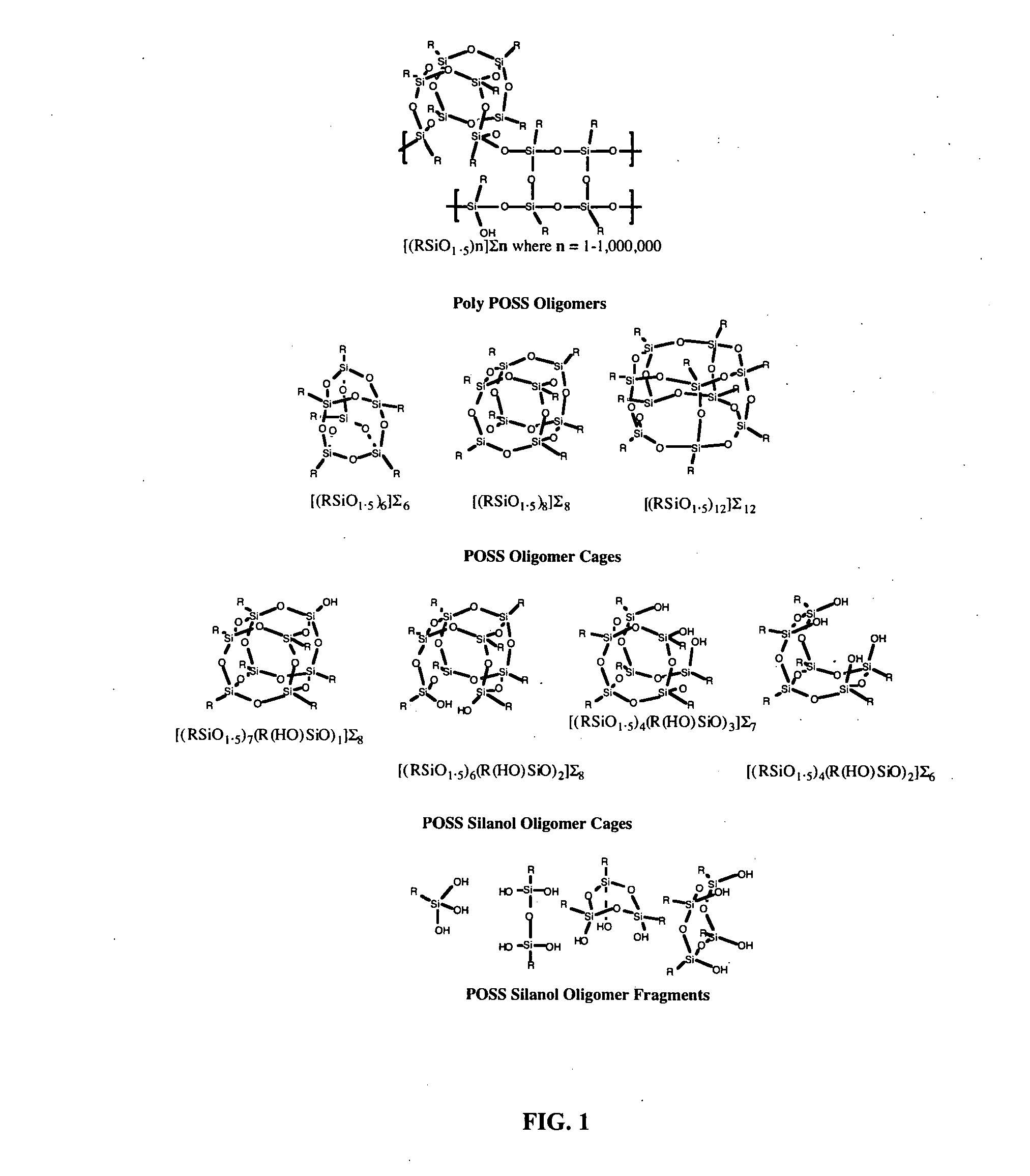

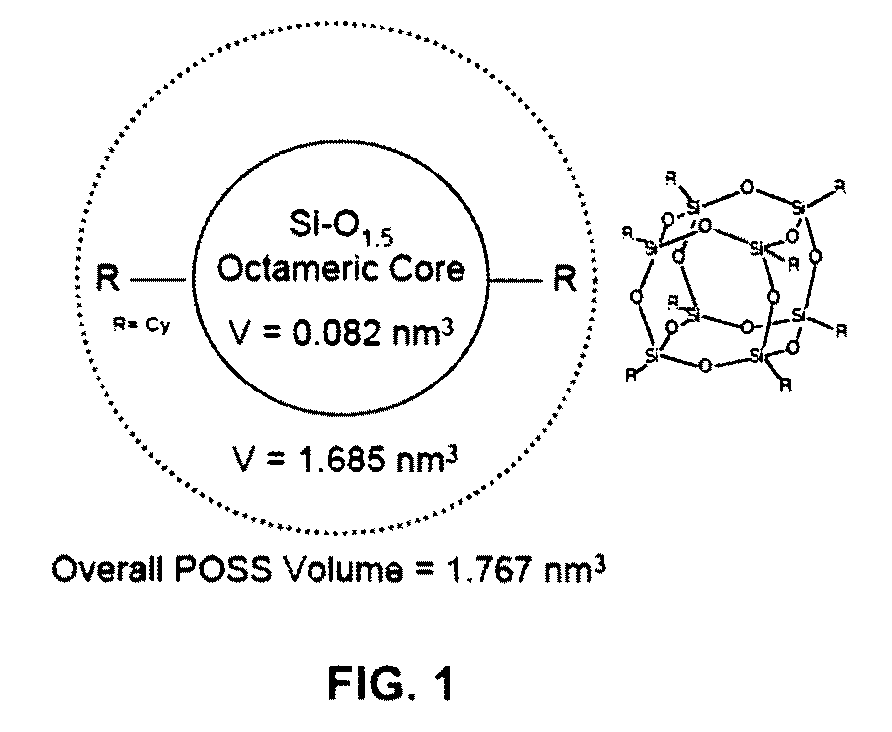

High use temperature nanocomposite resins

InactiveUS20080020213A1Reduce resistanceLow viscosityLayered productsThin material handlingMolecular levelCompression set

A method of using olefin containing nanostructured chemicals and silanol containing nanostructured chemicals as high temperature resins is described. Vinyl containing nanostructured chemicals are particularity effective in thermosets as they control the motions of polymer chains, and segments, at the molecular level. Silanol containing nanostructured chemicals are particularity effective in thermosets containing polar groups as the silanol can enhance the reactivity of these groups. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending and polymerization processes. The incorporation of a nanostructured chemical into a polymer favorably impacts a multitude of polymer physical properties. Properties most favorably improved are heat distortion and flammability characteristics, permeability, optical properties, texture, feel and durability. Other properties improved include time dependent mechanical and thermal properties such as creep, compression set, shrinkage, modulus, and hardness. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, and gas oxygen permeability. These improved properties may be useful in a number of applications, including composite materials, foams, cosmetics, and durable coatings.

Owner:HYBRID PLASTICS INC

Bioprocesses enhanced by magnetic nanoparticles

One aspect of the present invention relates to magnetic nanoparticles colloidally stabilized in aqueous milieu by association with an organic phase. The organic phase may be either a fluorinated polymer or an organic hydrocarbon bilayer, wherein the two layers are chemically bonded to each other. The stabilized particles are further non-toxic and provide useful enhancements in bioprocesses. Another aspect of the present invention relates to compositions comprising an oxygen-dissolving fluid vehicle and surface modified, nanometer-sized magnetic particles. The inventive compositions have utility in a wide range of applications, but are particularly suitable for use as recyclable oxygen carriers, separation and purification vehicles, and bioprocessing media, including fermentation processes.

Owner:MASSACHUSETTS INST OF TECH

Implantable medical devices with fluorinated polymer coatings, and methods of coating thereof

The present invention generally relates to implantable medical devices having a fluorinated coating, and methods of coating the same. More particularly, the present invention provides implantable metallic medical devices coated with a corrosion resistant coating comprising an amorphous fluoropolymer.

Owner:CR BARD INC

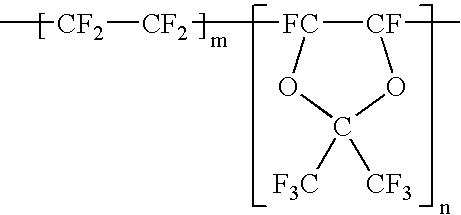

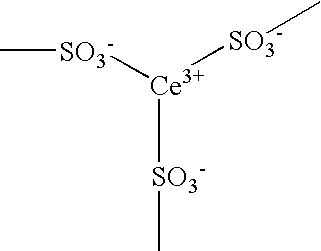

Electrolyte membrane for polymer electrolyte fuel cell, process for its production and membrane-electrode assembly for polymer electrolyte fuel cell

InactiveUS20080118808A1Improve the immunityIncreased durabilitySolid electrolytesIon-exchanger regenerationHigh energyIon exchange

To provide an electrolyte membrane for a polymer electrolyte fuel cell, capable of generating power in high energy efficiency, having high power generation performance regardless of the dew point of the feed gas and capable of generating stable power over a long period of time. A membrane used as an electrolyte membrane for a polymer electrolyte fuel cell, which comprises a cation exchange membrane made of a fluorinated polymer having cation exchange groups and having an ion exchange capacity of from 1.0 to 2.5 meq / g dry polymer, wherein some of the cation exchange groups are ion-exchanged with at least one type of ions selected from the group consisting of cerium ions and manganese ions.

Owner:ASAHI GLASS CO LTD

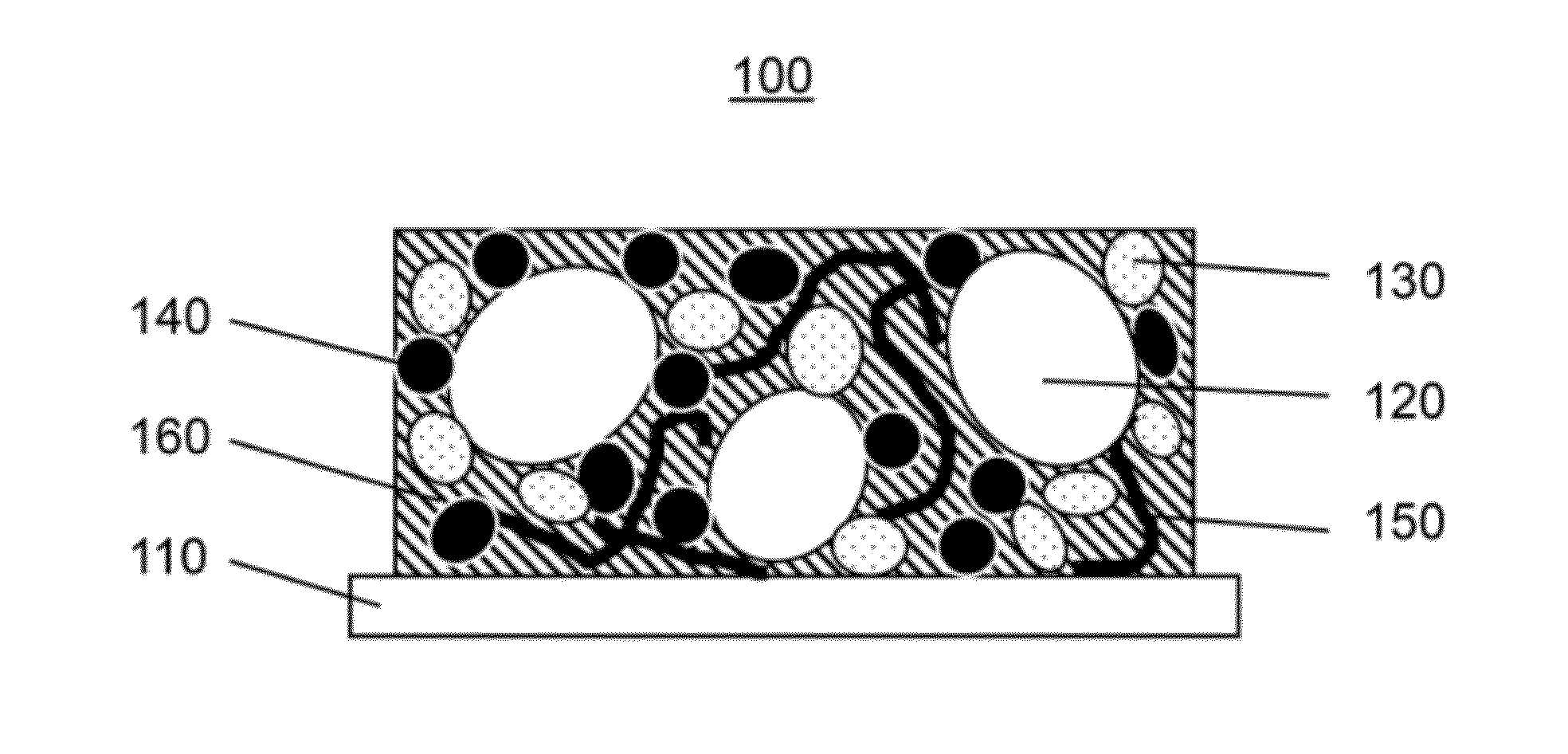

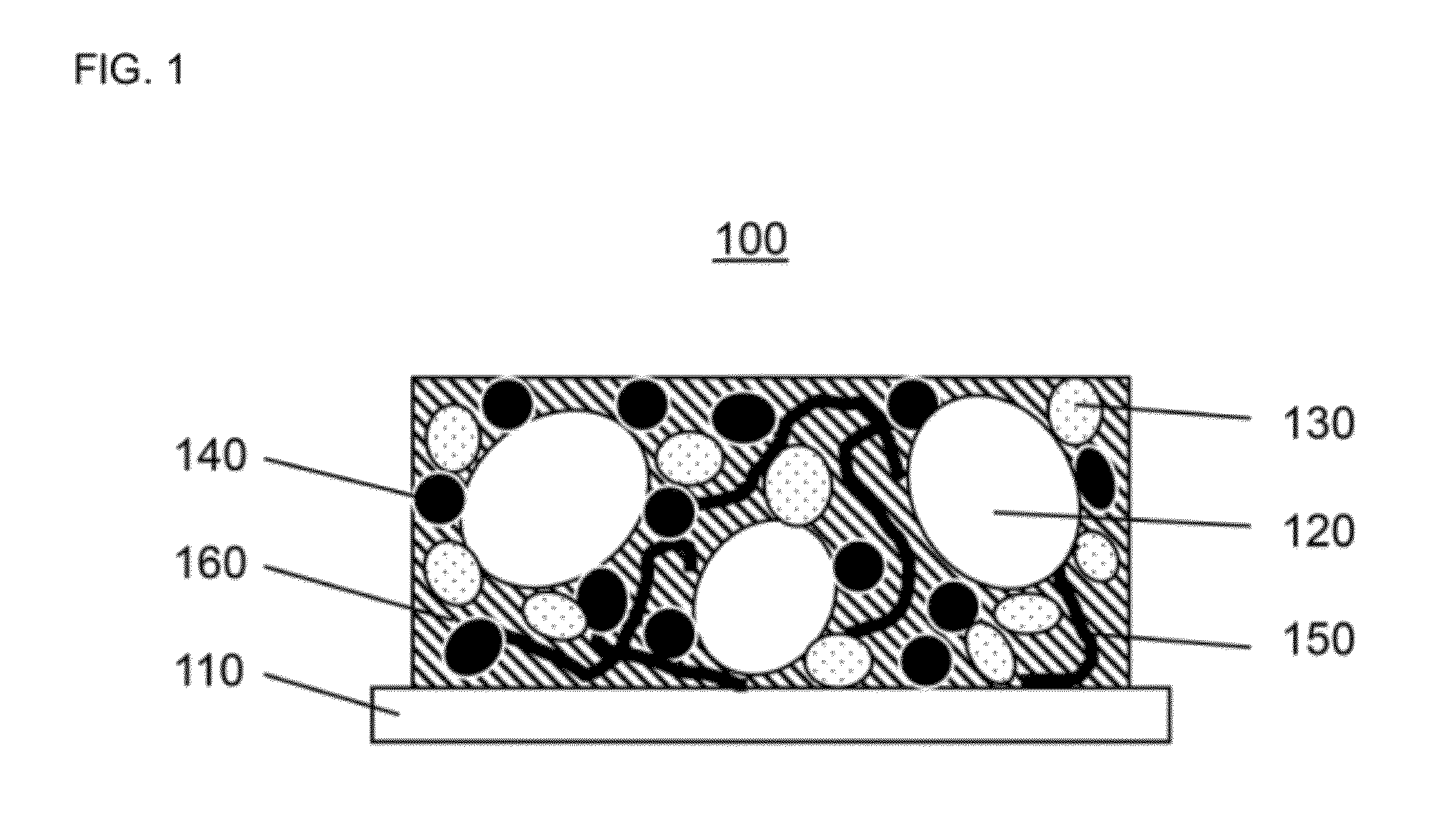

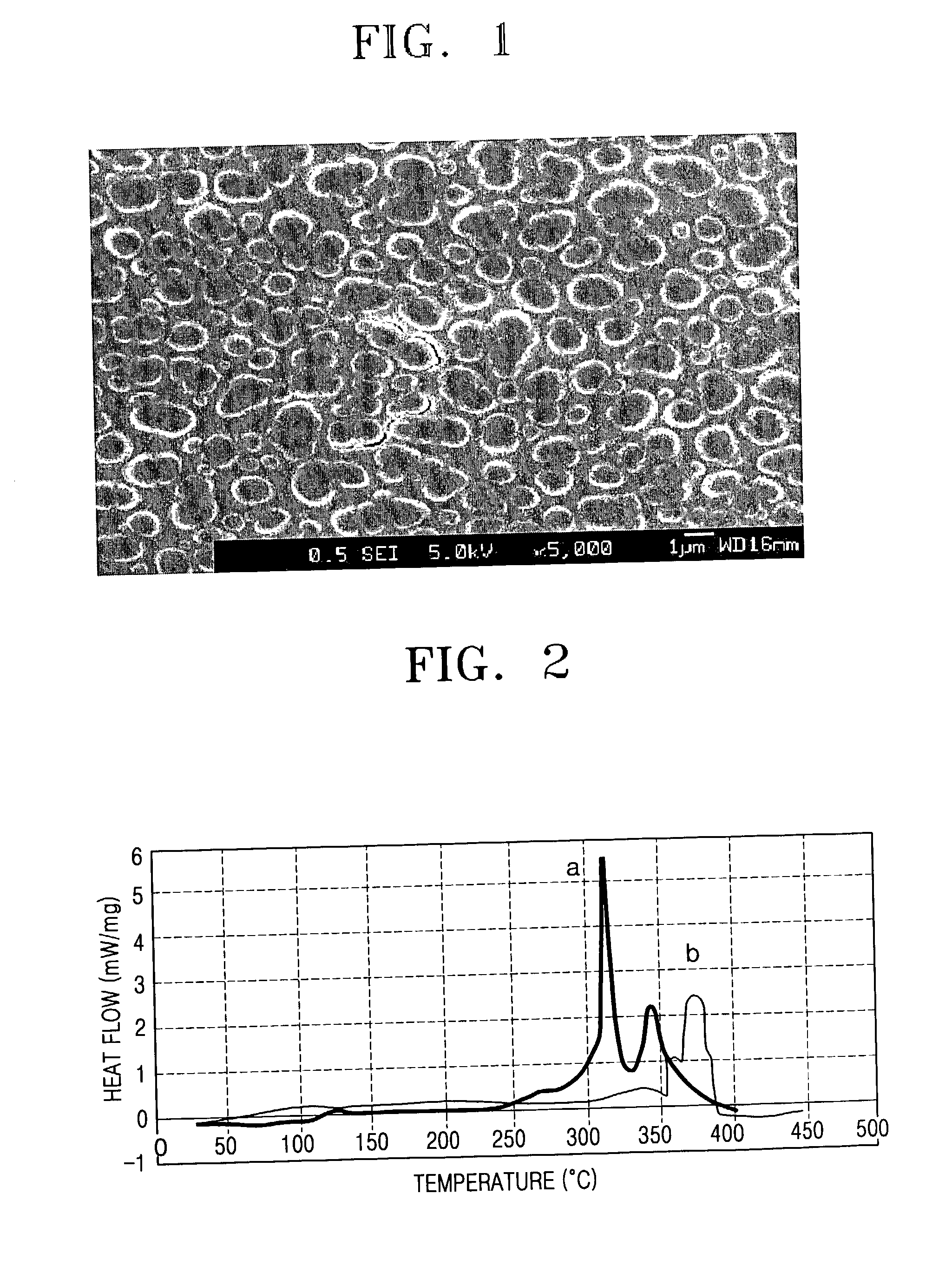

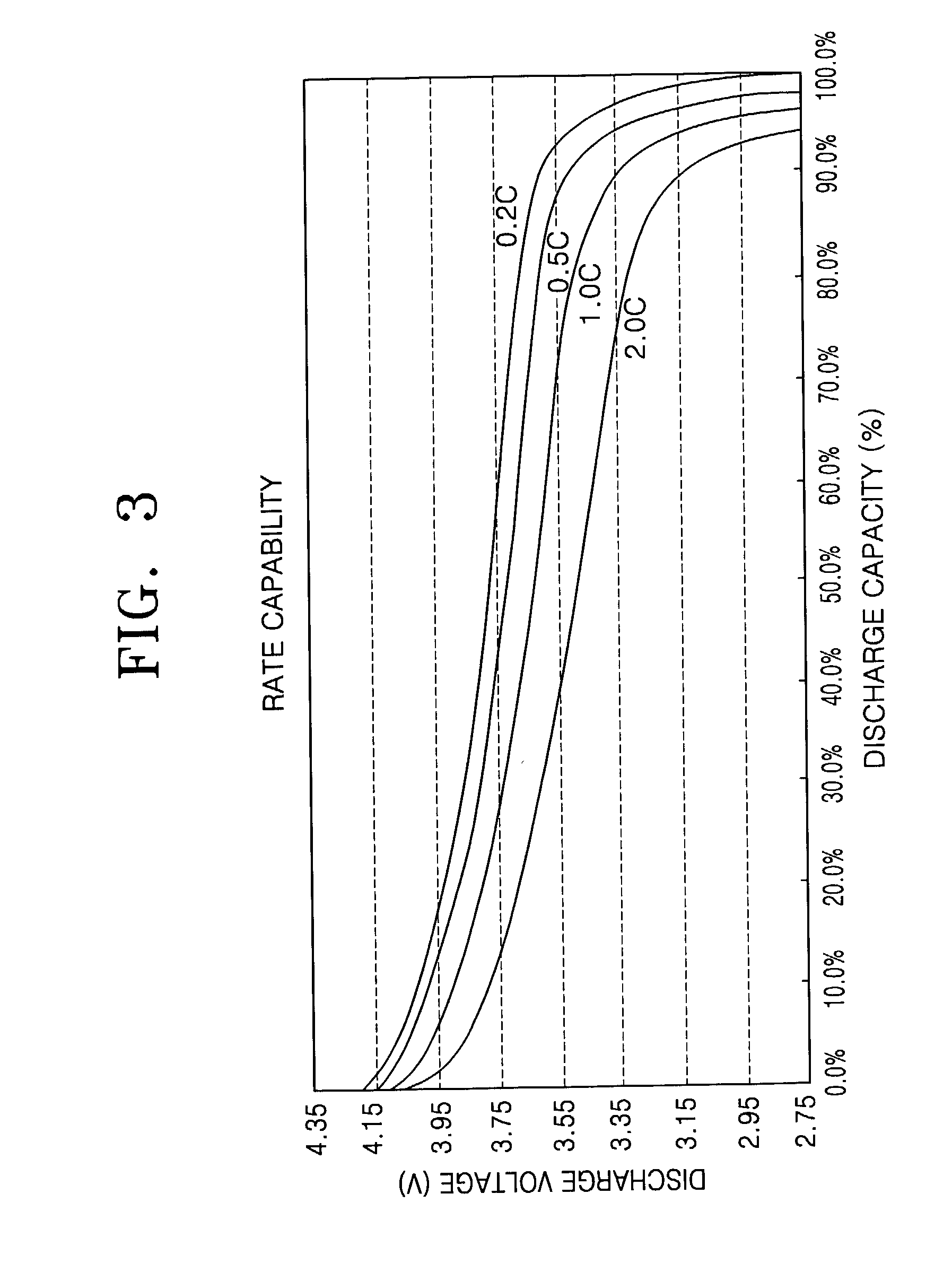

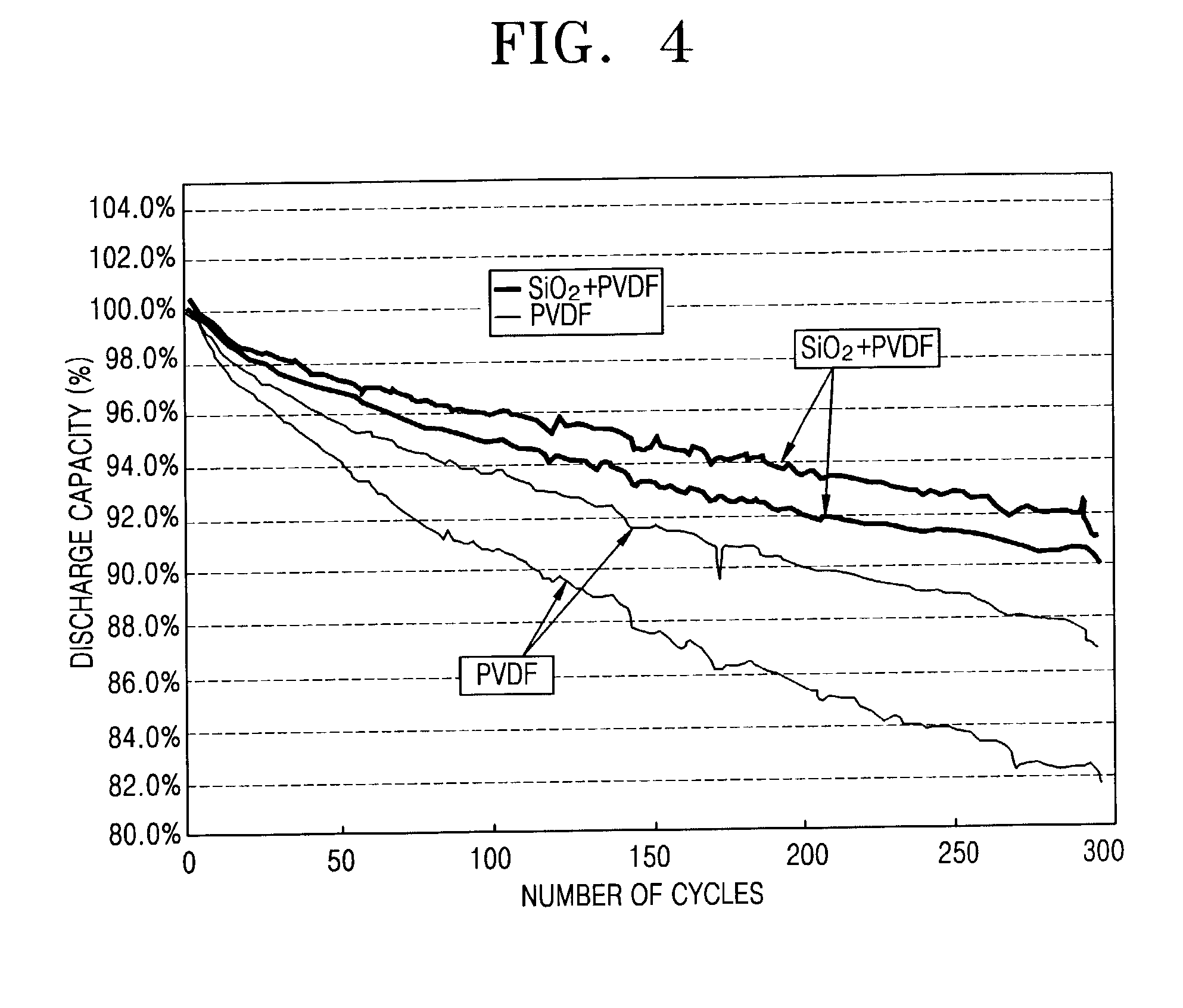

Electrode, lithium battery having the electrode, and method of manufacturing the same

ActiveUS20030113625A1Excellent cycle characteristicsImprove thermal stabilityNon-aqueous electrolyte accumulatorsFinal product manufactureEngineeringMesophase

An electrode including a current collector and active material layers stacked on the current collector, and a lithium battery using the electrode. In the electrode, the active material layers include a complex binder having a fluorinated polymer and mesophase SiO2 particles homogenously combined therein.

Owner:SAMSUNG SDI CO LTD

Polyolefin polymer and catalyst blend for bonding fluoropolymers

InactiveUS6869682B2Improve adhesionReduce manufacturing costNon-fibrous pulp additionNon-macromolecular adhesive additivesPolymer sciencePolyolefin

The invention relates to compositions useful for bonding fluoropolymer to substantially non-fluorinated polymer. The compositions of the invention comprise a substantially non-fluorinated polymer or a mixture of said polymers, a base, and a crown ether catalyst. Another aspect of the invention is an article comprising the above composition adhered to a fluoropolymer and methods of making said article.

Owner:3M INNOVATIVE PROPERTIES CO

Fluorinated POSS as alloying agents in nonfluorinated polymers

InactiveUS7897667B2Reduce contactWeaken energyMaterial nanotechnologyPlastic/resin/waxes insulatorsPersonal careMolecular level

Owner:HYBRID PLASTICS INC +1

Drug diffusion barriers for a catheter assembly

Materials having barrier characteristics are used with a balloon of a catheter assembly and a sheath for covering the balloon. The barrier materials prevent significant absorption of therapeutic substances used in association with the balloon, for example via a medicated prosthesis, into the balloon wall or the sheath. Accordingly the quantity and concentration of the therapeutic substances are preserved. Materials which can serve as a barrier include barrier polymers, polymers with additive fillers, polymers with a metallic coating, metallic films, polymers with a main group element oxide coating, and sulfonated or fluorinated polymers. For the sheath, materials such as glass and metals also function effectively.

Owner:ABBOTT CARDIOVASCULAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com