Preparation method of low-fluorine high-purity tantalum pentoxide optical coating material

A technology of tantalum pentoxide and optical coating, applied in chemical instruments and methods, preparation of tantalum compounds, inorganic chemistry, etc., can solve problems such as unsatisfactory fluorine removal effect and unsatisfactory crystallinity of tantalum pentoxide, and achieve removal The effect is ideal and sufficient, the crystal structure is ideal, and the grain distribution is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

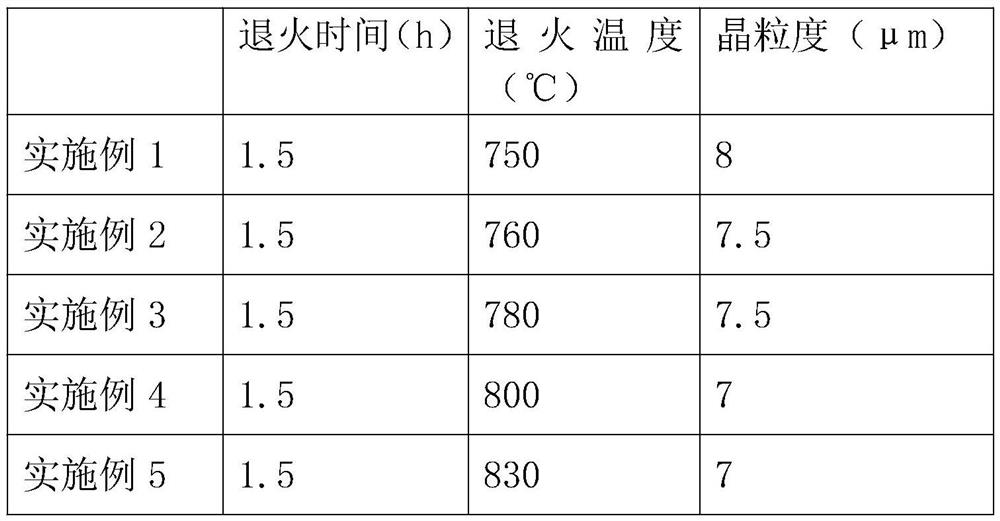

Embodiment 1

[0017] Embodiment 1: A kind of low-fluorine high-purity tantalum pentoxide optical coating material preparation method, comprises the following steps:

[0018] Step 1, first dissolve metal tantalum into the mixed acid of hydrofluoric acid and nitric acid, then extract and purify to obtain high-purity tantalum liquid, pass the high-purity tantalum liquid into the neutralization precipitation tank, and add liquid to the high-purity tantalum liquid at the same time Ammonia, after the precipitation of tantalum hydroxide, pass the solution containing the precipitation of tantalum hydroxide into the filter press, and add hot pure water containing ammonia at the same time, then obtain tantalum hydroxide, and then repeat the process of adding tantalum hydroxide into the filtration process , adjust the fluorine content in the solution to be less than or equal to 0.01g / L, then obtain high-purity tantalum hydroxide, put it into hydrofluoric acid and sulfuric acid mixed acid to dissolve, c...

Embodiment 2

[0023] Embodiment 2: A kind of low-fluorine high-purity tantalum pentoxide optical coating material preparation method, comprises the following steps:

[0024] Step 1, first dissolve metal tantalum into the mixed acid of hydrofluoric acid and nitric acid, then extract and purify to obtain high-purity tantalum liquid, pass the high-purity tantalum liquid into the neutralization precipitation tank, and add liquid to the high-purity tantalum liquid at the same time Ammonia, after the precipitation of tantalum hydroxide, pass the solution containing the precipitation of tantalum hydroxide into the filter press, and add hot pure water containing ammonia at the same time, then obtain tantalum hydroxide, and then repeat the process of adding tantalum hydroxide into the filtration process , adjust the fluorine content in the solution to be less than or equal to 0.01g / L, then obtain high-purity tantalum hydroxide, put it into hydrofluoric acid and sulfuric acid mixed acid to dissolve, c...

Embodiment 3

[0029] Embodiment 3, a method for preparing a low-fluorine and high-purity tantalum pentoxide optical coating material, comprising the following steps:

[0030] A method for preparing a low-fluorine and high-purity tantalum pentoxide optical coating material, comprising the following steps:

[0031] Step 1, first dissolve metal tantalum into the mixed acid of hydrofluoric acid and nitric acid, then extract and purify to obtain high-purity tantalum liquid, pass the high-purity tantalum liquid into the neutralization precipitation tank, and add liquid to the high-purity tantalum liquid at the same time Ammonia, after the precipitation of tantalum hydroxide, pass the solution containing the precipitation of tantalum hydroxide into the filter press, and add hot pure water containing ammonia at the same time, then obtain tantalum hydroxide, and then repeat the process of adding tantalum hydroxide into the filtration process , adjust the fluorine content in the solution to be less t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com