Ceramic precursor slurry and 3D printing reaction forming method of porous ceramic part

A technology of ceramic precursors and precursor ceramics, applied in the field of 3D printing, can solve the problems of difficult to obtain lithium orthosilicate, complex process, low output, etc., and achieve improved tritium production efficiency and service life, uniform grain distribution, large The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

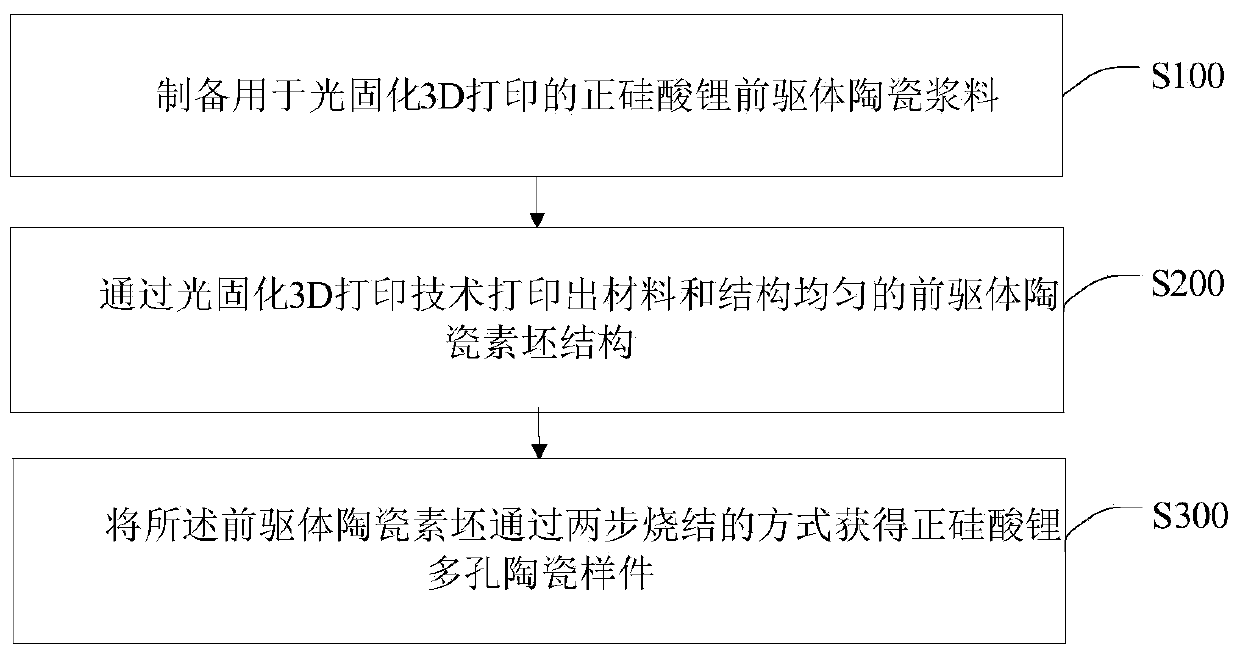

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of lithium orthosilicate precursor ceramic slurry for photocuring 3D printing

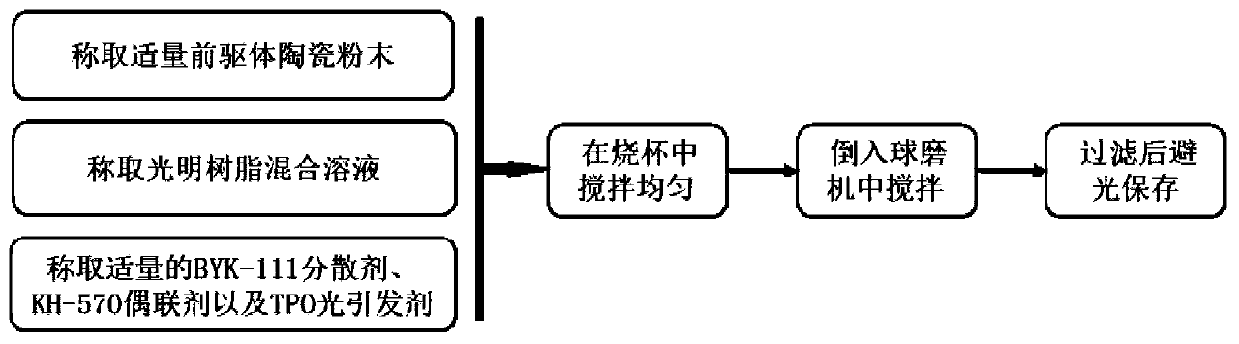

[0049] Specifically, a lithium orthosilicate precursor ceramic slurry with a solid phase content of 40% vol was prepared. Such as figure 2 As shown in , the specific method: weigh 100g of precursor ceramic powder (the molar ratio of lithium carbonate to silicon dioxide is 2:1) and pour it into a beaker; weigh 69.45ml of bright resin mixed solution (including trimethylolpropane The volume ratio of triacrylate to ethylene glycol diacrylate is 7.5:2.5) Pour it into a beaker and stir evenly; weigh 4g of BYK-111 dispersant, 2g of KH-570 coupling agent and 1g of TPO light Initiator, stir well. Finally, the slurry was poured into a ball mill and fully stirred for 12 hours, and filtered to obtain a lithium orthosilicate precursor ceramic slurry.

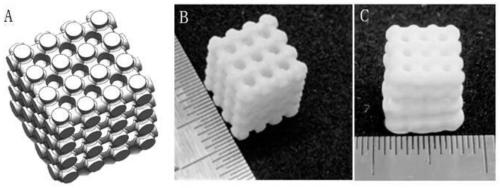

[0050] (2) Print out a porous ceramic sample with a uniform microstructure by a light-curing 3D printer

[0051] First, design a suit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com