Manufacture process of low-flourine mica tape

A manufacturing process, mica tape technology, applied in the direction of mica, cable/conductor manufacturing, conductors, etc., can solve the problems of low tensile strength, gluing penetration time, unstable air permeability, low compressive strength, etc., to prevent electrical conduction , reduce the probability of being burned out, and reduce the effect of calcination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

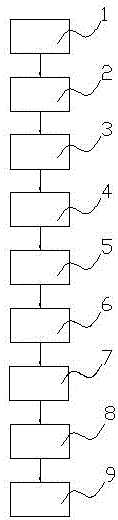

Image

Examples

Embodiment 1

[0049] 1) The selection of raw materials, select natural mica flakes with flat flakes and large diameters from the mica raw material pile;

[0050] 2) Medium-temperature calcination, the selected natural mica is sent to a medium-temperature flow converter at 600°C for calcination for 5 minutes to preheat;

[0051] 3) Defluorination process, sending the preheated mica to a high-temperature flow furnace at 900°C for calcination for 25 minutes to remove fluoride;

[0052] 4) Low-temperature calcination, the defluoridated mica is then calcined at 400°C for 10 minutes to cool down;

[0053] 5) Cooling, washing and foaming, put the cooled mica in the equipment for cooling, washing and foaming;

[0054] 6) pulping, the mica obtained in step 5) is mechanically pulped by pulping equipment;

[0055] 7) Copying, making mica pulp into low-fluorine mica paper;

[0056] 8) Inspection, test the fluorine content of the mica paper that has been made, and the qualified standard of the inspecti...

Embodiment 2

[0064] 1) The selection of raw materials, select natural mica flakes with flat flakes and large diameters from the mica raw material pile;

[0065] 2) Medium-temperature calcination, the selected natural mica is sent to a medium-temperature flow converter at 750°C for calcination for 10 minutes to preheat;

[0066] 3) In the defluorination process, the preheated mica is sent to a high-temperature flow furnace at 810°C for calcination for 15 minutes to defluoride;

[0067] 4) Low-temperature calcination, the defluoridated mica is then calcined at 600°C for 5 minutes to cool down;

[0068] 5) Cooling, washing and foaming, put the cooled mica in the equipment for cooling, washing and foaming;

[0069] 6) pulping, the mica obtained in step 5) is mechanically pulped by pulping equipment;

[0070] 7) Copying, making mica pulp into low-fluorine mica paper;

[0071] 8) Inspection, test the fluorine content of the mica paper that has been made, and the qualified standard of the insp...

Embodiment 3

[0079] 1) The selection of raw materials, select natural mica flakes with flat flakes and large diameters from the mica raw material pile;

[0080] 2) Medium-temperature calcination, the selected natural mica is sent to a medium-temperature flow converter at 700°C for 8 minutes of preheating;

[0081] 3) In the process of defluoridation, the preheated mica is sent to a high-temperature flow furnace at 840°C for calcination for 20 minutes to remove fluoride;

[0082] 4) Calcining at low temperature, the defluoridated mica is then calcined at 500°C for 7 minutes to cool down;

[0083] 5) Cooling, washing and foaming, put the cooled mica in the equipment for cooling, washing and foaming;

[0084] 6) pulping, the mica obtained in step 5) is mechanically pulped by pulping equipment;

[0085] 7) Copying, making mica pulp into low-fluorine mica paper;

[0086] 8) Inspection, test the fluorine content of the mica paper that has been made, and the qualified standard of the inspectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com