Water-repellent fabric and manufacturing method thereof

A fabric and polyester technology, applied in the field of fibers, can solve the problems of organic fluorine water- and oil-repellent finishing agents, such as difficulty in laminating, poor surface binding force of polyester fibers, and lack of high-polarity groups, etc., to improve the finishing effect and Washability, good compatibility, increase the effect of hydrogen bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A method for preparing a water-repellent fabric, comprising the steps of:

[0072] (1) Preparation of amino fatty acid ethylene glycol ester:

[0073] 1) Add dodecanedicarboxylic acid and methanol into the reactor at a molar ratio of 1:1.5, heat to 80°C under the catalysis of concentrated sulfuric acid, reflux for esterification, cool, separate and purify to obtain dodecanedicarboxylic acid Acid monomethyl ester; Described concentrated sulfuric acid refers to the sulfuric acid that mass concentration is 70%, and the concentrated sulfuric acid add-on is 3wt% of dodecane dicarboxylic acid;

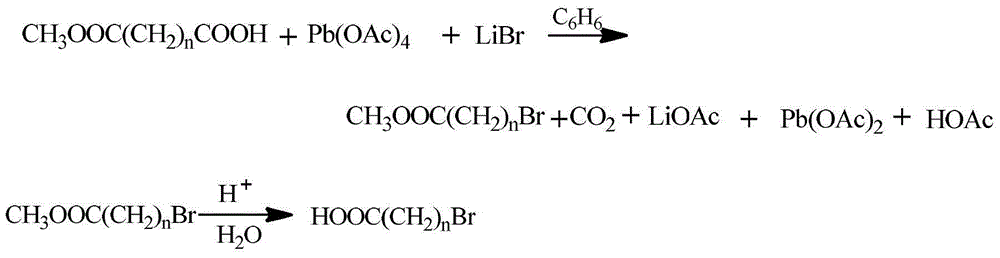

[0074] 2) Dissolve the monomethyl dodecanedicarboxylate, lead tetraacetate and lithium bromide in benzene (molar ratio 1:1:1), wherein the monomethyl dodecanedicarboxylate concentration is 0.05mol / L , under a nitrogen atmosphere, react at 80 ° C, reflux, when no more gas is produced, add a certain amount of dilute sulfuric acid to react for 2 hours, then wash, purify and dry to obtai...

Embodiment 2

[0102] A method for preparing a water-repellent fabric, comprising the steps of:

[0103] (1) Preparation of amino fatty acid ethylene glycol ester:

[0104] 1) Add pentacodecanedicarboxylic acid and methanol into the reactor in a molar ratio of 1:1.5, under the catalysis of concentrated sulfuric acid, heat to 110°C, reflux for esterification, cool, separate and purify to obtain pentacodecane Dicarboxylic acid monomethyl ester; Described concentrated sulfuric acid refers to the sulfuric acid that mass concentration is 70%, and the concentrated sulfuric acid add-on is 3wt% of pentacosane dicarboxylic acid;

[0105] 2) The monomethyl pentacodecanedicarboxylate, lead tetraacetate and lithium bromide are dissolved in benzene (molar ratio 1:1:1), wherein the concentration of monomethyl pentacodecanedicarboxylate is 0.07mol / L, under nitrogen atmosphere, react at 85°C, reflux, when no more gas is generated, add a certain amount of dilute sulfuric acid to react for 3 hours, then was...

Embodiment 3

[0133] A method for preparing a water-repellent fabric, comprising the steps of:

[0134] (1) Preparation of amino fatty acid ethylene glycol ester:

[0135] 1) Add pentadecanedicarboxylic acid and methanol into the reactor in a molar ratio of 1:1.5, under the catalysis of concentrated sulfuric acid, heat to 85°C, reflux for esterification, cool, separate and purify to obtain pentadecanedicarboxylic acid acid monomethyl ester; described concentrated sulfuric acid refers to the sulfuric acid that mass concentration is 70%, and the concentrated sulfuric acid add-on is 3wt% of pentadecanedicarboxylic acid;

[0136] 2) Dissolve the monomethyl pentadecanedicarboxylate, lead tetraacetate and lithium bromide in benzene (molar ratio 1:1:1), wherein the concentration of monomethyl pentadecanedicarboxylate is 0.08mol / L , under nitrogen atmosphere, react at 90°C, reflux, when no more gas is produced, add a certain amount of dilute sulfuric acid to react for 2.5 hours, then wash, purify ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com