Process for defluorinating anhydrous hydrogen chloride

A technology of hydrochlorofluorocarbons and hydrogen chloride, which is applied in the direction of chlorine/hydrogen chloride, chemical instruments and methods, and separation methods, and can solve the problems of not using dry methods to separate hydrogen chloride

Inactive Publication Date: 2002-08-14

ZHEJIANG QUHUA FLUOR CHEM

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, in China, manufacturers producing hydrochlorofluorocarbons all use wet methods to separate hydrogen chloride, and none of them use dry methods to separate hydrogen chloride.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0014] The selected adsorbent

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Login to View More

Abstract

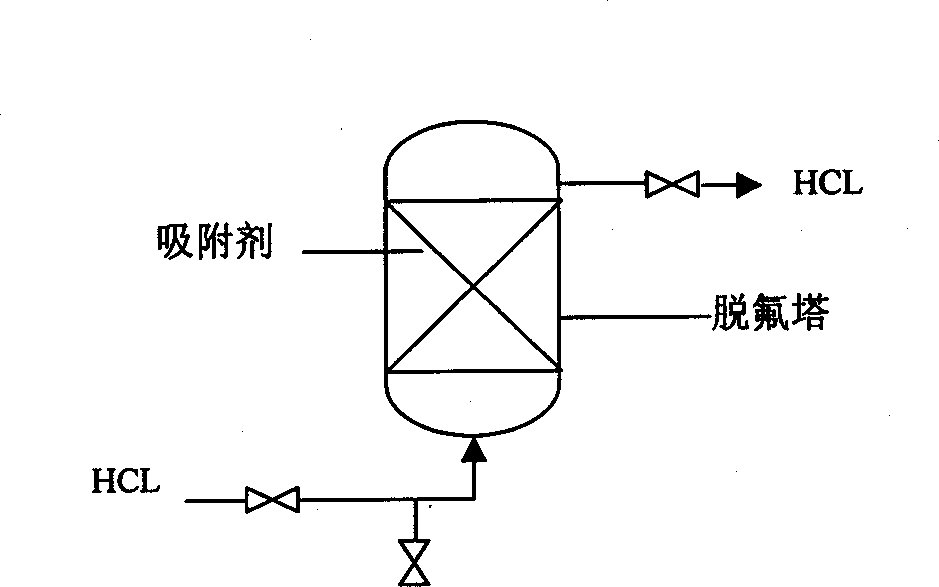

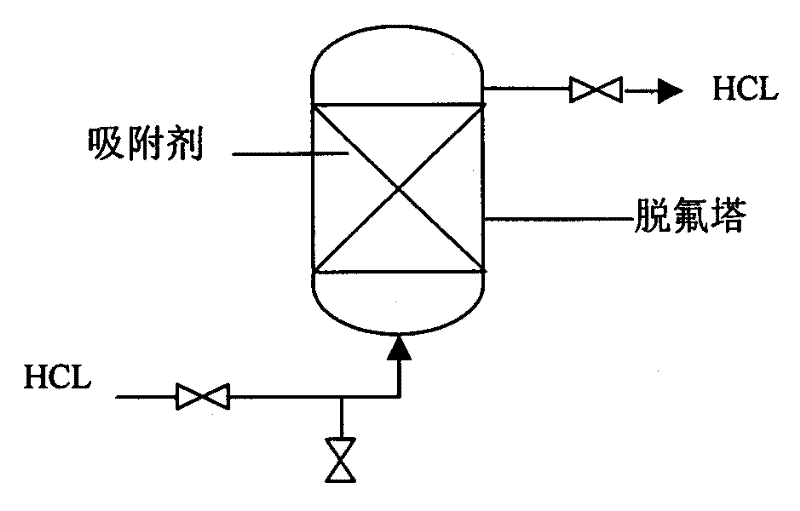

A process for defluorinating anhydrous hydrogen chloride as by-product in the technology for preparing hydrogen contained fluorchlorohydrocarbon features that the hydrogen chloride is pre-activated and then defluorinated in serially or parallelly connected defluorinating towers by adsorption at -10-80 deg.C and 0.1-20 MPa. The alumina is used as main component of defluorinating agent. Its advantage is high defluorinating effect (less than 10 ppm).

Description

technical field [0001] The invention relates to a method for defluorinating anhydrous hydrogen chloride in a hydrofluorochlorocarbon process. Background technique [0002] Internationally, in the production process of hydrochlorofluorocarbons, the by-product hydrogen chloride separated from the crude product is generally treated and utilized in two ways, that is, wet separation of hydrogen chloride and dry separation of hydrogen chloride. At present, in China, manufacturers that produce hydrochlorofluorocarbons all use wet methods to separate hydrogen chloride, and none of them use dry methods to separate hydrogen chloride. [0003] In the production process of hydrochlorofluorocarbons, the raw material undergoes a liquid-liquid catalytic fluorination reaction, and the product from the reactor undergoes rectification, and the separated hydrogen chloride is directly absorbed into industrial hydrochloric acid, which is wet separation of hydrogen chlor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/02B01D53/68B01D53/83C01B7/01

Inventor 汤月明陈科峰王小呈

Owner ZHEJIANG QUHUA FLUOR CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com