Aluminium-silica type refined pre-smelting slag

A technology of pre-melting slag and refining slag, which is applied in the field of smelting, can solve the problems of outstanding quality of inclusions, high unqualified rate of sulfides, low success rate of continuous casting and continuous casting, etc., and achieve high level of adsorption of inclusions, stable yield The effect of low yield and fluorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

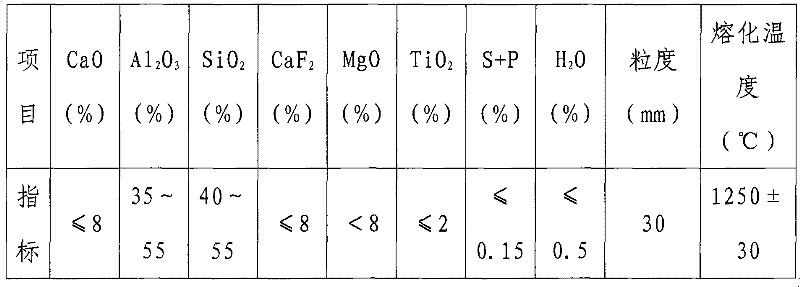

[0011] The three raw materials of waste glass, fly ash and 65% waste high-alumina bricks are respectively crushed by crushing equipment to the specified particle size (5mm-15mm) for melting in an electric furnace---weigh the raw materials according to the ratio in Table 1-- -The weighed raw material + borax (fluxing agent) is mixed by the mixing equipment---the mixed raw material is put into the electric furnace and melted to form the refined pre-melted slag---the melted refined pre-melted slag block is crushed to the particle size specified by the finished product (15mm-20mm) --- Product chemical composition testing --- Qualified products are put into storage.

[0012] Table 1

[0013] serial number

waste glass

fly ash

65% waste high alumina brick

1

10

33

55

2

2

25

25

47

3

3

19

45

35

1

4

30

28

40

2

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com