Utilization method of ferrovanadium slag and premelted refining slag

A technology for premelting and refining slag, which is applied in the field of utilization of premelting refining slag and ferrovanadium smelting slag, and achieves the effects of being beneficial to resource recycling, high-efficiency desulfurization, uniform and stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

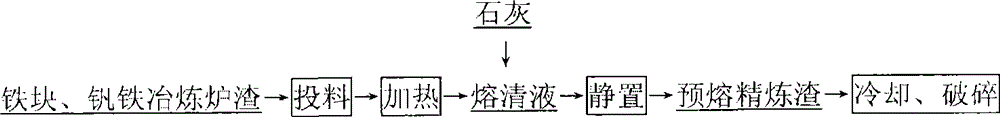

Method used

Image

Examples

example 1

[0033] Ferrovanadium smelting slag and lime as raw materials are weighed in a mass ratio of 30:70, totaling 15 tons.

[0034] The ferrovanadium smelting slag is melted in a high temperature furnace. After it is completely melted, add lime in three batches and stir with nitrogen gas. After stirring evenly, let it stand for 20 minutes. Stop heating the high-temperature furnace, pour the liquid slag into the mold, and the slag obtained after the slag is cooled is the pre-melted refining slag, which is broken into 6mm-12mm particles and packaged. The composition of pre-slag is by weight: Al 2 o 3 21.60%, CaO 70.15%, MgO4.7.55%, SiO 2 0.27%, TFe 0.43%, and the balance is impurities.

example 2

[0036] Ferrovanadium smelting slag and lime as raw materials are weighed in a mass ratio of 41:59, totaling 10t.

[0037] The ferrovanadium smelting slag is melted in a high temperature furnace. After it is completely melted, add lime in three batches and stir with nitrogen gas. After stirring evenly, let it stand for 15 minutes. Stop heating the high-temperature furnace, pour the liquid slag into the mold, and the slag obtained after the slag is cooled is the pre-melted refining slag, which is broken into 6mm-12mm particles and packaged. The composition of pre-slag is by weight: Al 2 o 3 35.78%, CaO 54.98%, MgO9.05%, SiO 2 0.19%, TFe 0.45%, and the balance is impurities.

example 3

[0039] The iron-vanadium smelting slag and lime used as raw materials are weighed in a mass ratio of 60:40, totaling 20 tons.

[0040] The ferrovanadium smelting slag is melted in a high temperature furnace. After it is completely melted, add lime in three batches and stir with nitrogen gas. After stirring evenly, let it stand for 30 minutes. The high-temperature furnace stops heating, and the liquid slag is poured into the mold. After the slag is cooled, the slag obtained is the pre-melted refining slag, which is broken into 6mm-12mm particles and packaged. The composition of pre-slag is by weight: Al 2 o 3 45.51%, CaO 44.03%, MgO10.22%, SiO 2 0.24%, TFe 0.48%, and the balance is impurities.

[0041] In summary, the present invention can effectively utilize the ferro-vanadium smelting slag to prepare pre-melted refining slag, which not only realizes the effective utilization of the ferrovanadium smelting slag as metallurgical waste, but also makes the pre-melted refinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com