Device and method for homogenizing oil shale powder

A technology of oil shale powder and homogenization device, which is applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve problems affecting oil grade, oil production rate and operating cost, difficulty in roasting operation, and fluctuation of composition Larger and other problems, to achieve the effect of uniform and stable material composition, significant economic benefits, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

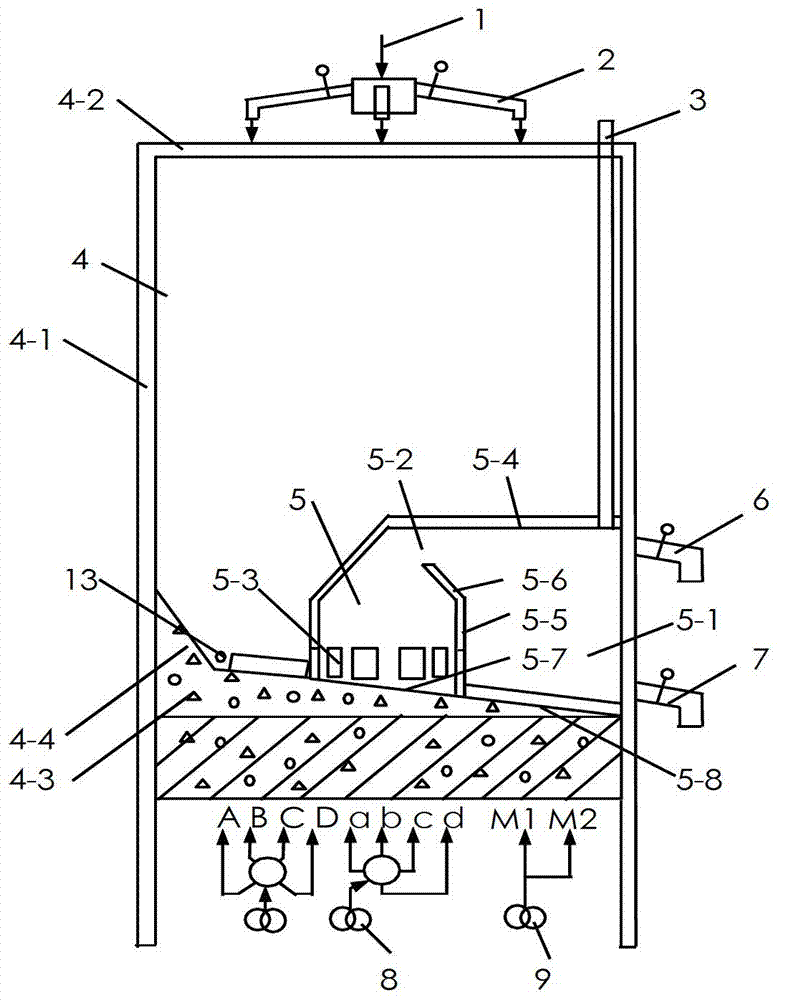

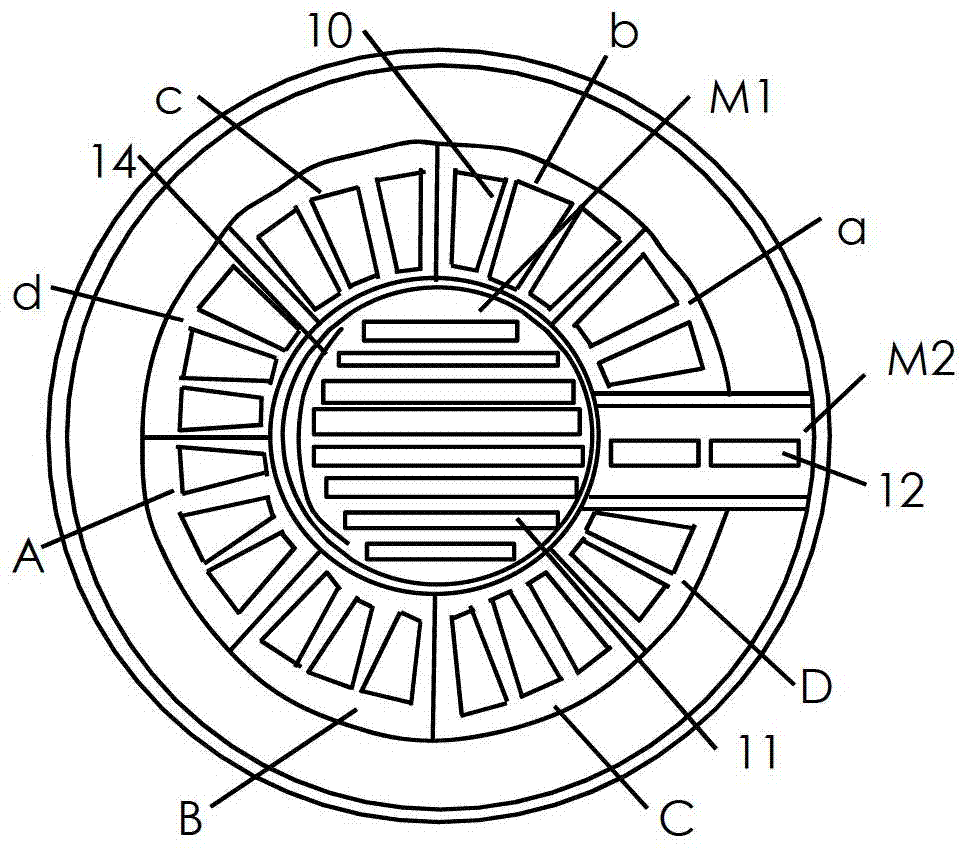

[0031] Schematic diagram of the homogenization device for oil shale powder figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes incoming material system (1), distributor (2), exhaust pipe (3), round warehouse (4), homogenization chamber (5), discharge chamber (5-1), homogenization chamber outlet Feed port (5-2), homogenization chamber feed port (5-3), discharge chamber top plate (5-4), homogenization chamber lower cylinder (5-5), homogenization chamber upper cone ( 5-6), homogenization chamber bottom plate (5-7), discharge chamber bottom plate (5-8), high unloader (6), low unloader (7), weak inflation system (8), strong inflation System (9), wedge-shaped open-type inflatable box (10), the first cuboid open-type inflatable box group (11), the second cuboid open-type inflatable box group (12), inflatable connecting pipes (13) in the round storehouse, Inflation connection pipe (14) in the chemical chamber.

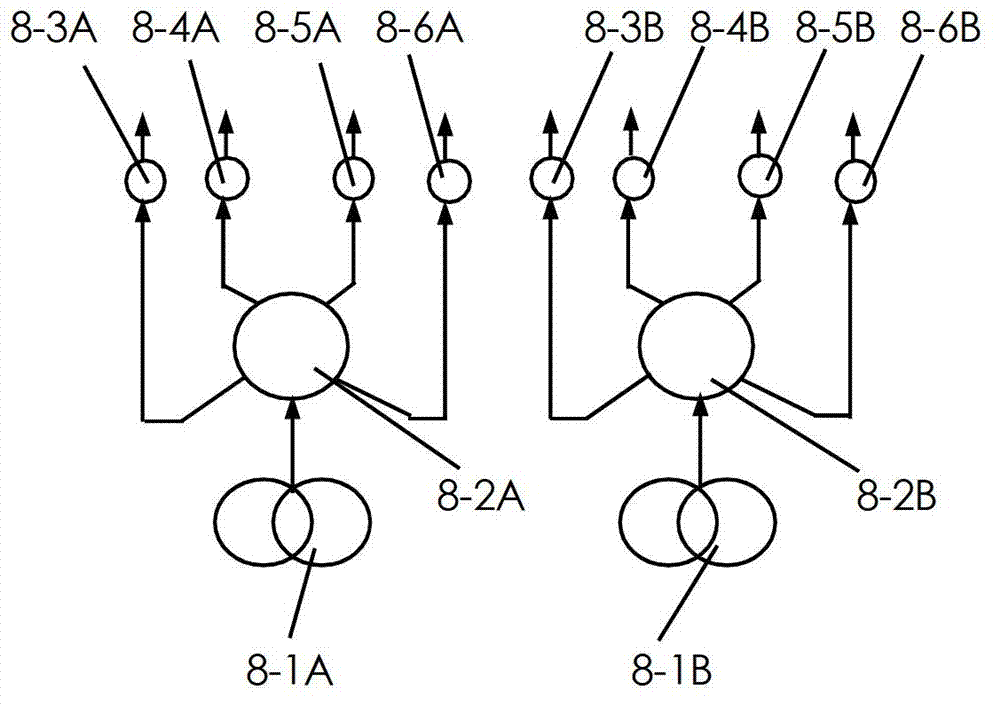

[0032] The weak inflation system (8) in the above de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com