Cooling device and method for variable cross-section structure in electric arc additive manufacturing process

A technology of additive manufacturing and cooling device, applied in manufacturing tools, additive processing, arc welding equipment, etc., to achieve the effect of reduced production time, simple structure and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

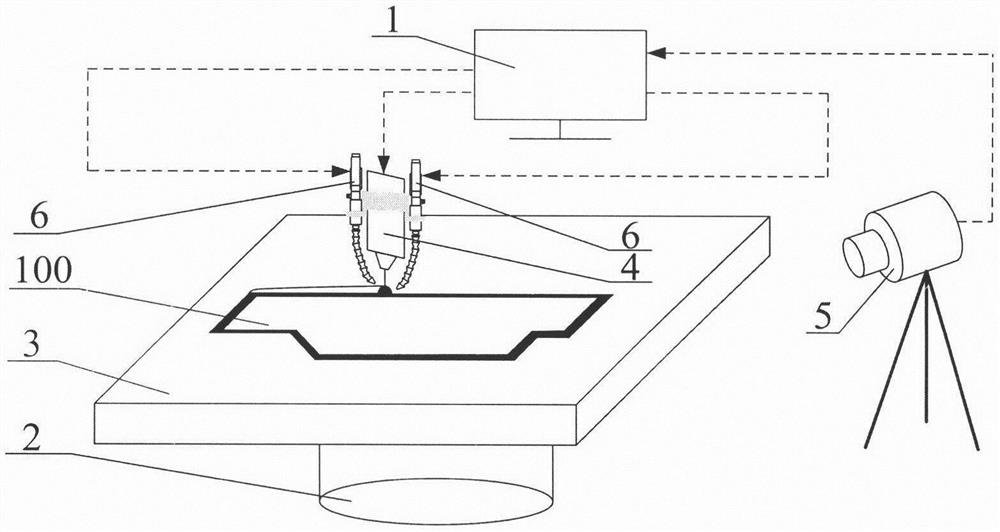

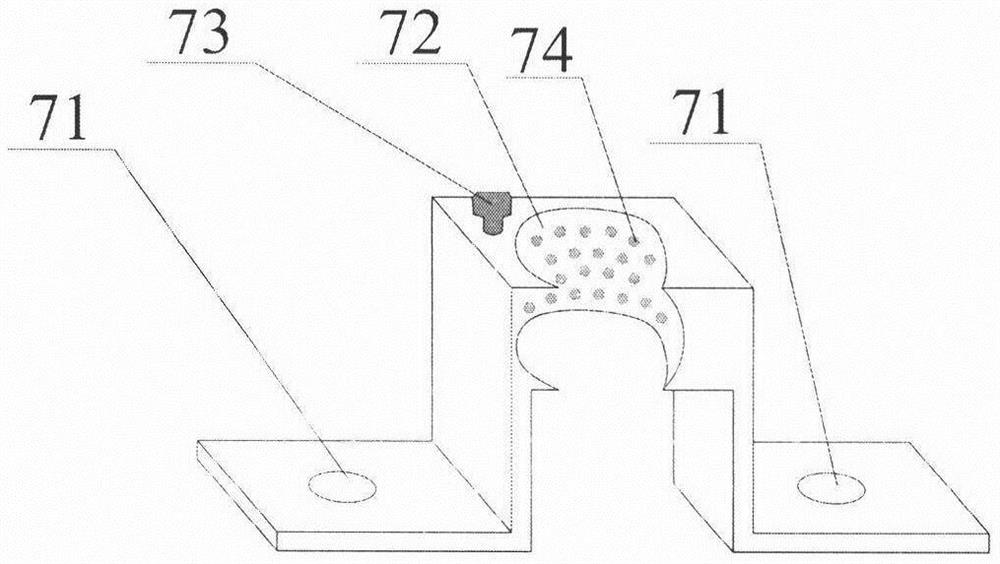

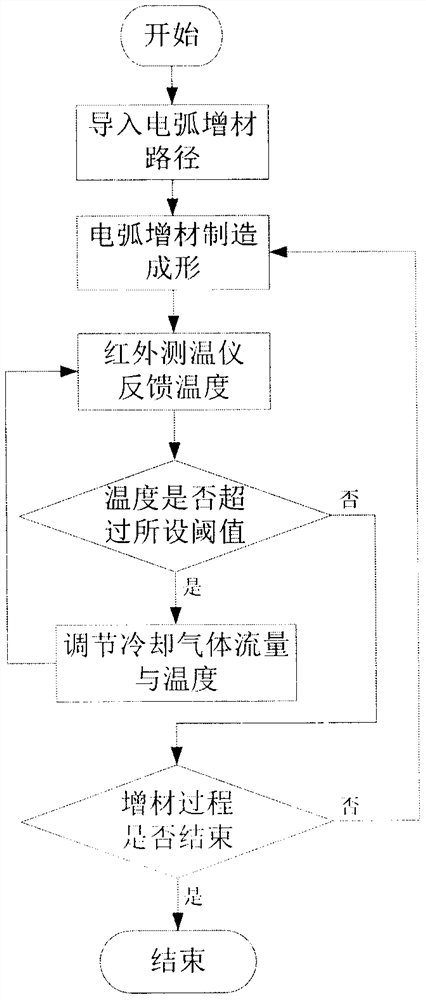

[0039] Please refer to figure 1 , figure 2 and image 3 shown. A cooling device and method in the process of arc additive manufacturing with variable cross-section structure according to the present invention includes a workbench 2; a bottom plate 3, which is clamped on the workbench 2 to support the variable cross-section structure 100 in the arc additive manufacturing process; MIG welding torch 4 The infrared thermometer 5 is placed close to the side of the workbench 2 to detect and collect temperature information during the arc additive manufacturing process and feed it back to the computer control system 1; two cold air guns 6 are used to blow out cooling gas; The computer control system 1, the computer control system 1 is electrically connected with the cold air gun 6, the infrared thermometer 5 and the MIG welding torch 4 and is used to receive the temperature fed back by the infrared thermometer 5, and adaptively regulate the temperature and flow rate of the gas blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com