Patents

Literature

38results about How to "Save loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

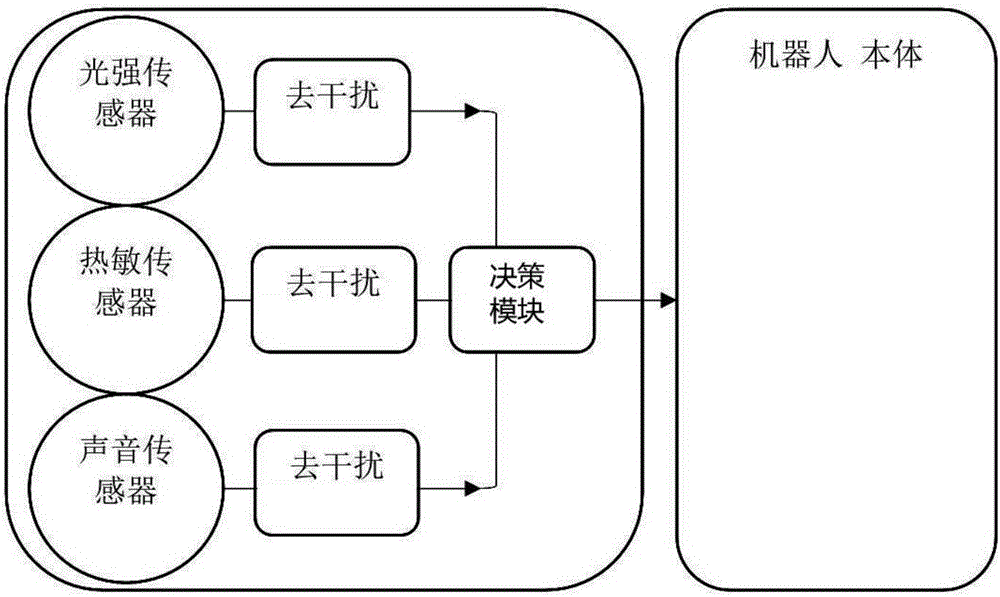

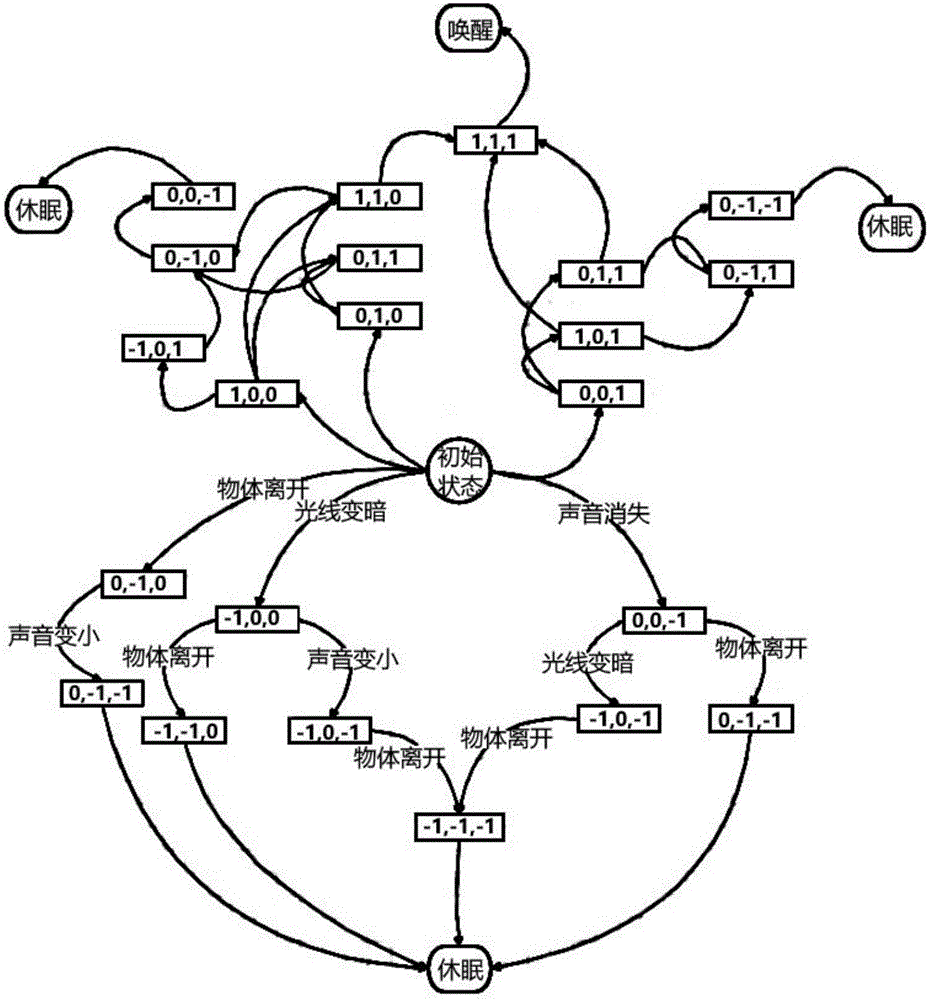

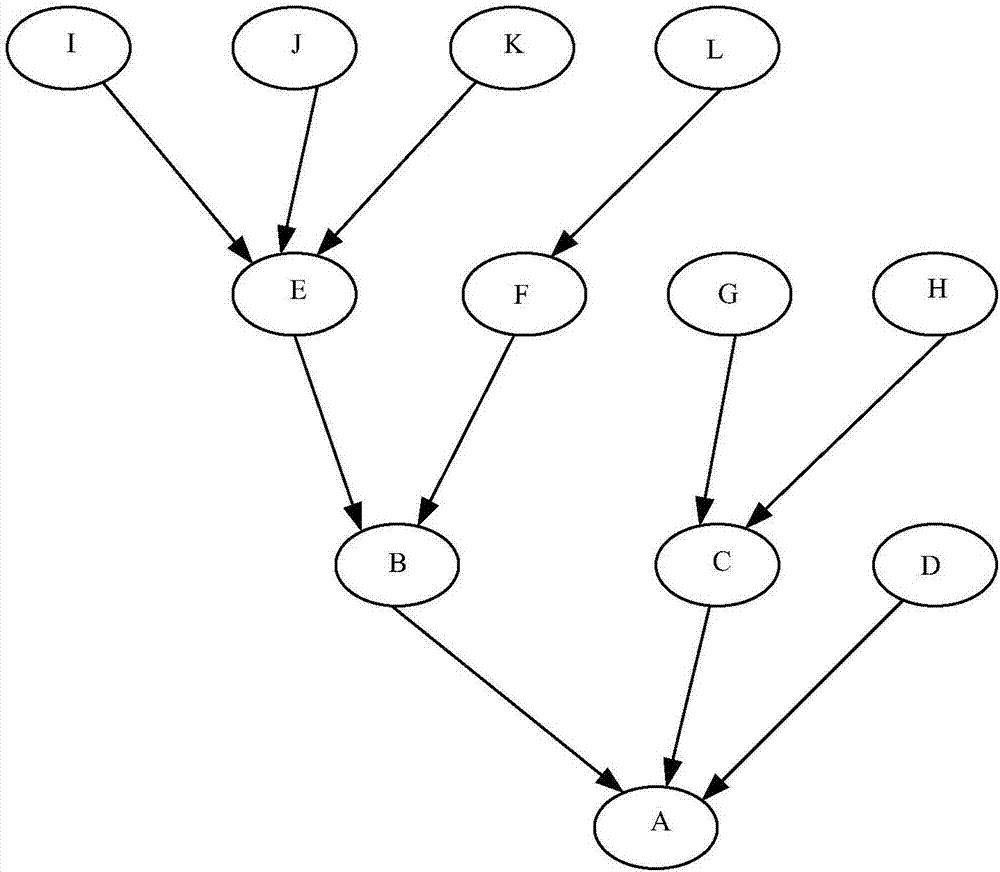

Arousing method and device for intelligent robot

The invention discloses an arousing method and device for an intelligent robot. The arousing method for the intelligent robot comprises the following steps that illumination intensity information, sound intensity information and object moving information in an environment where the robot is located are collected through an optical sensor, a sound sensor and a pyroelectric sensor correspondingly; the collected information is compared with preset values, and state information is obtained; when the added value of the sound intensity is higher than the arousing threshold value, and the object moving information reaches the first preset value, the robot is aroused; and when the weakened value of the sound intensity is higher than the dormancy threshold value, and the object moving information reaches the second preset value, the robot enters a dormancy state. By means of the arousing method and device for the intelligent robot, the robot can be intelligently aroused or made to enter the dormancy state, the intelligence degree is high, energy is saved, the working time of the robot is prolonged, and an interaction manner is simple; and meanwhile, a touch module or a key module does not need to be arranged, a user experience is improved, and the service life of the product is prolonged.

Owner:江苏小锶智能科技有限公司

Preparation method for foam model used for lost foam casting based on 3D printing

ActiveCN103934415ASave developmentSave lossAdditive manufacturing apparatusFoundry mouldsSteam pressurePolymer science

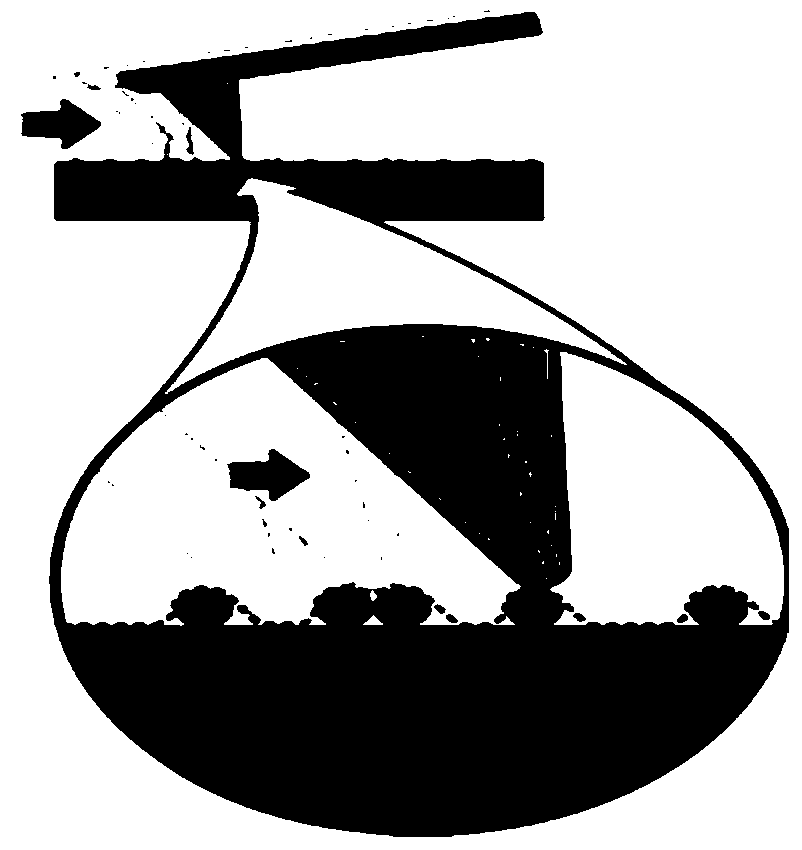

The invention discloses a preparation method for a foam model used for lost foam casting based on 3D printing. The method comprises the following steps: subjecting foam particles to steam pressure-maintained foaming so as to allow a foam particle raw material with bulk density of 500 to 600 g / L to become foamed foam particles with bulk density of 17 to 25 g / L through foaming; then filling the raw material box of a 3D printer with foam particles obtained through air blast cooling at 20 to 30 DEG C for printing; allowing every layer of foam particles sprayed on a heating model workbench to be fused and bonded under the action of heating temperature of the heating model workbench, wherein layers of foam particles are accumulated one by one and mutually bonded until a complete foam model is obtained; and completing printing with the 3D printer so as to obtain the foam model used for lost foam casting. The method provided by the invention has the advantages of small die loss, a short manufacturing period, low production cost and easy manufacturing.

Owner:NINGBO TONGDA PRECISION CASTING

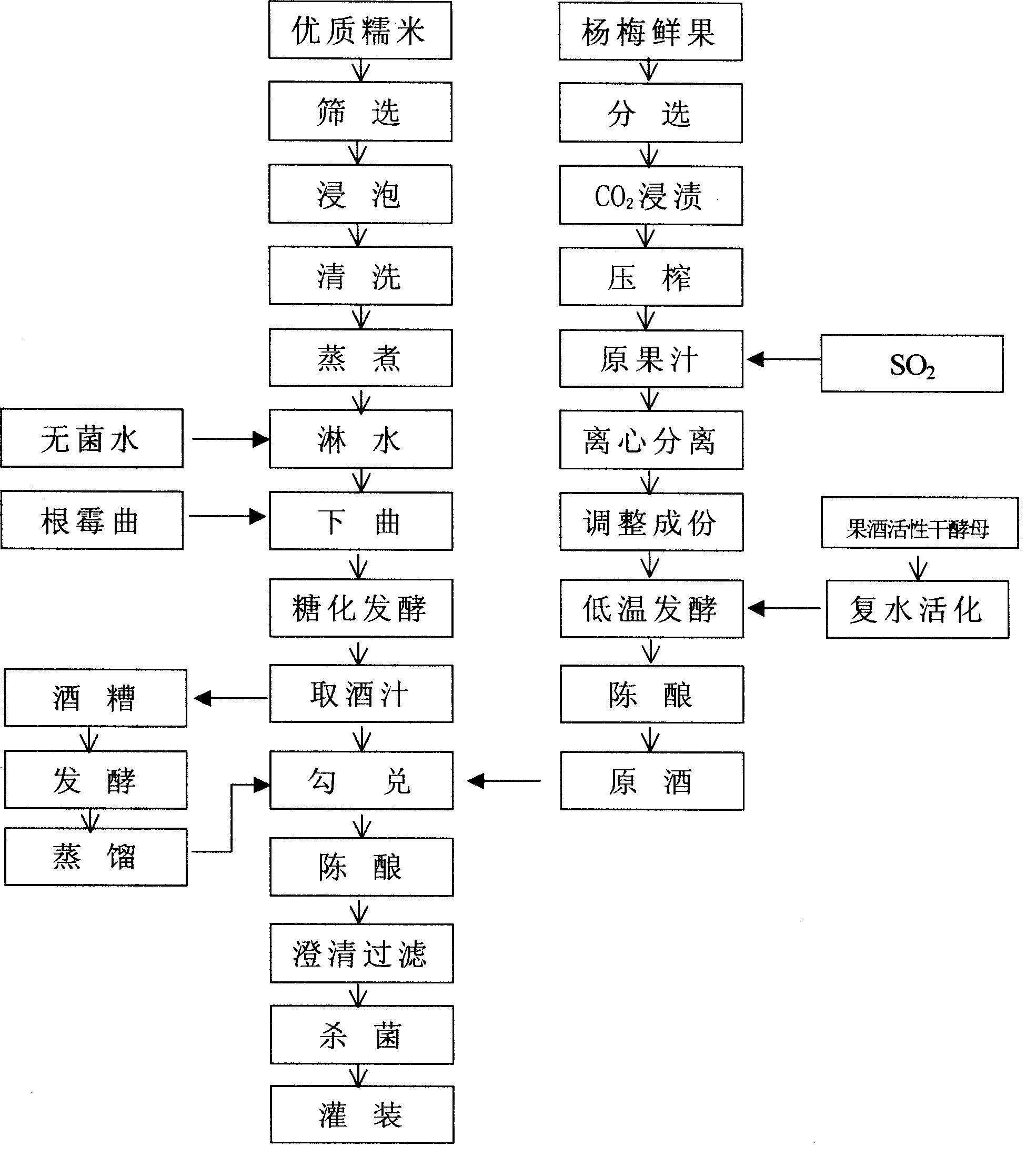

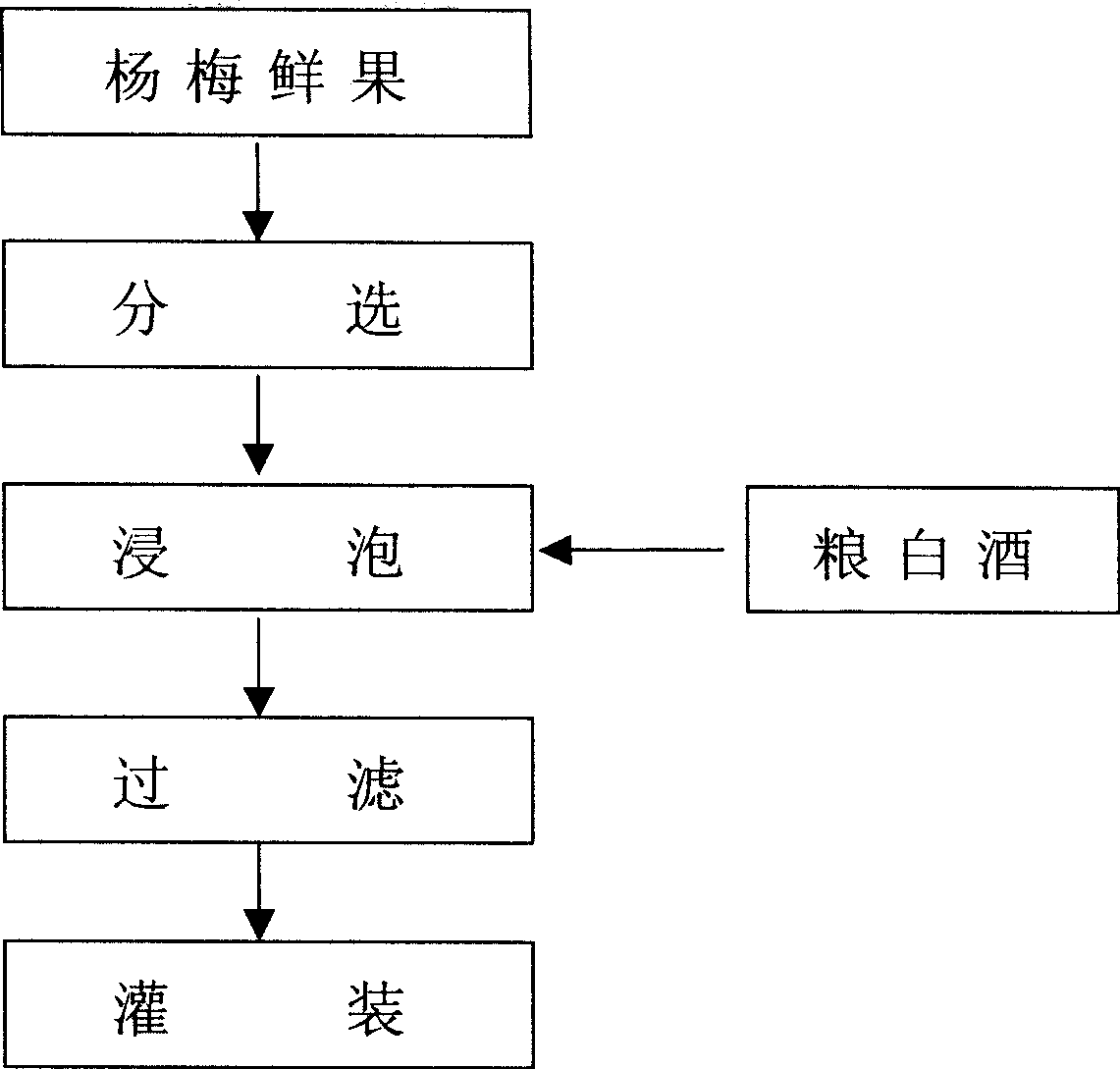

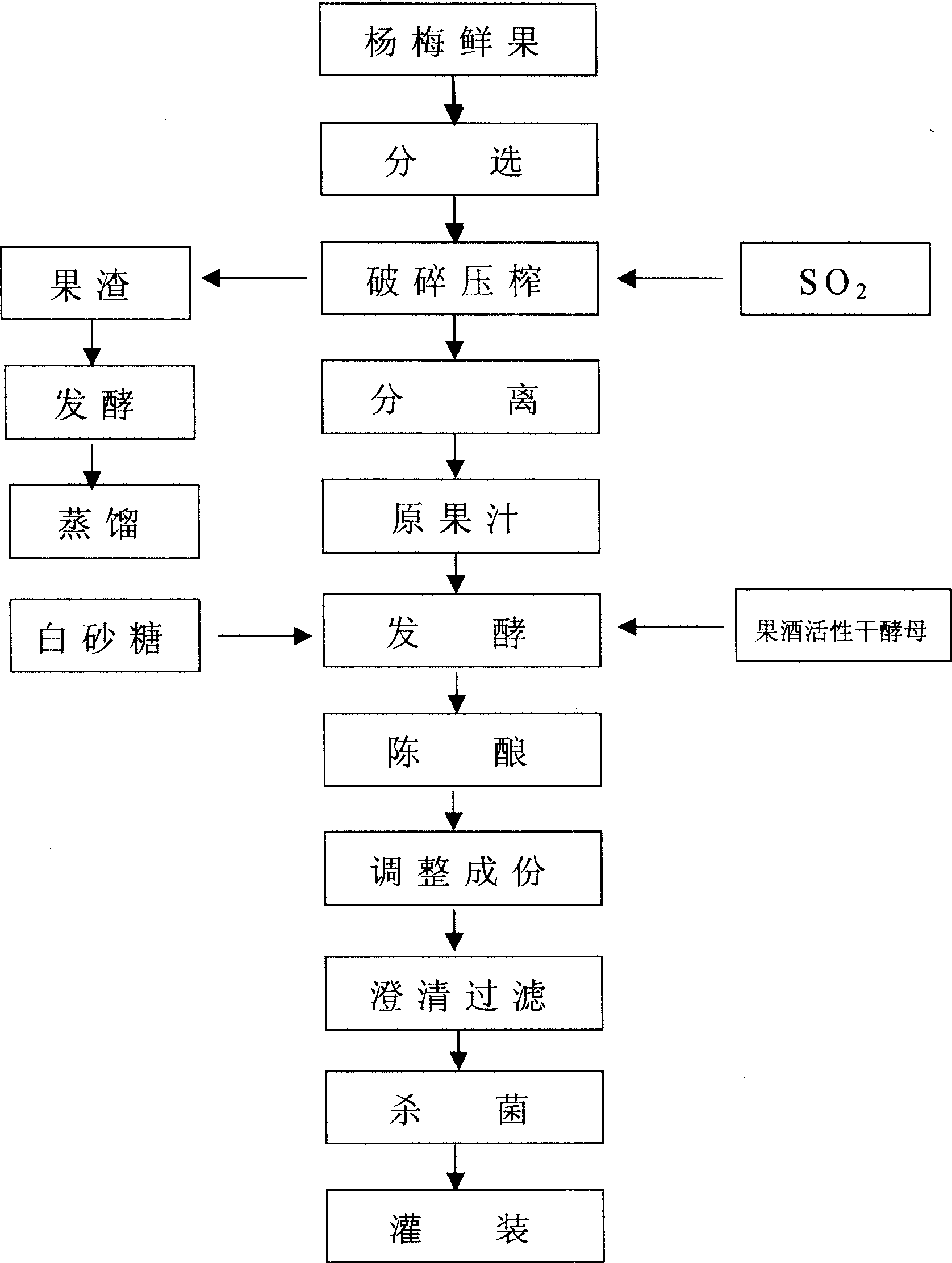

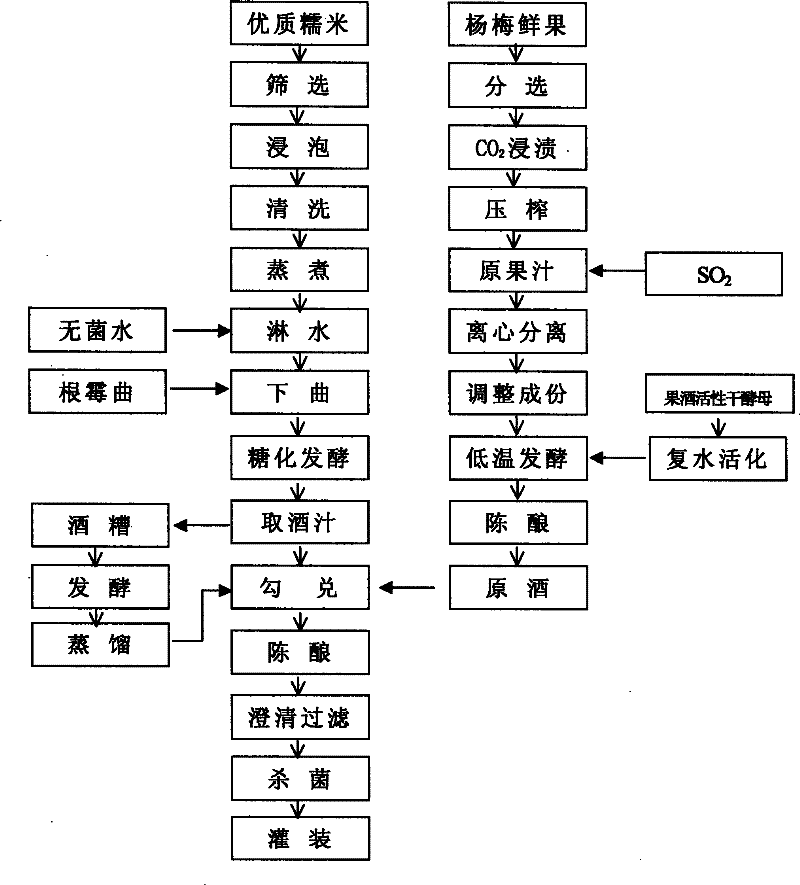

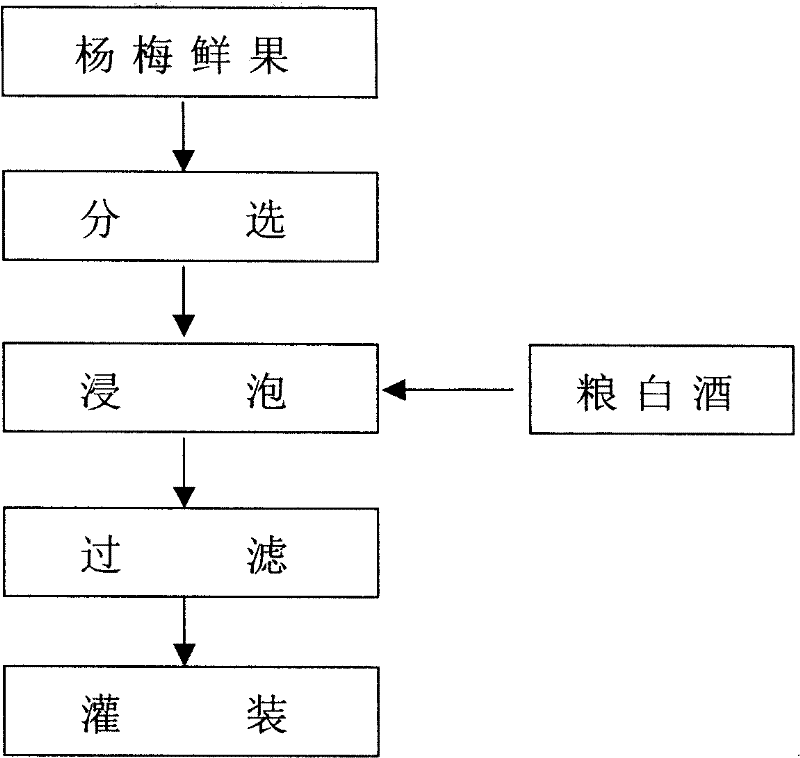

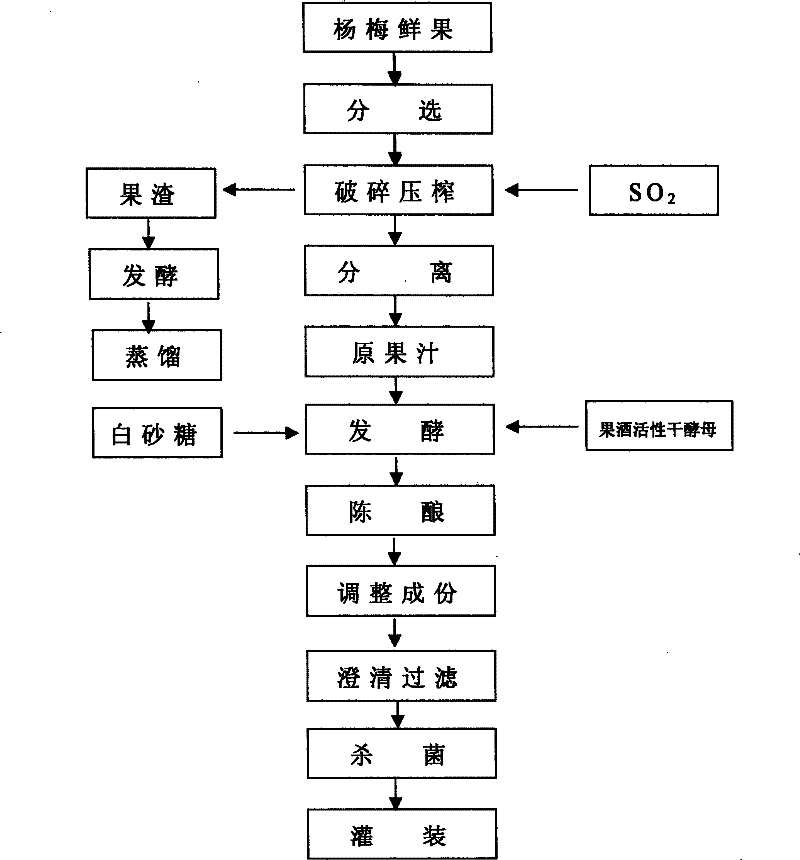

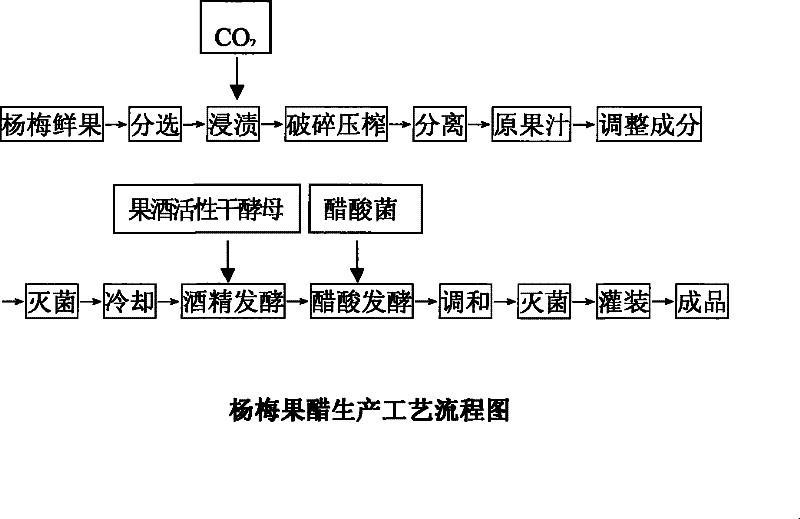

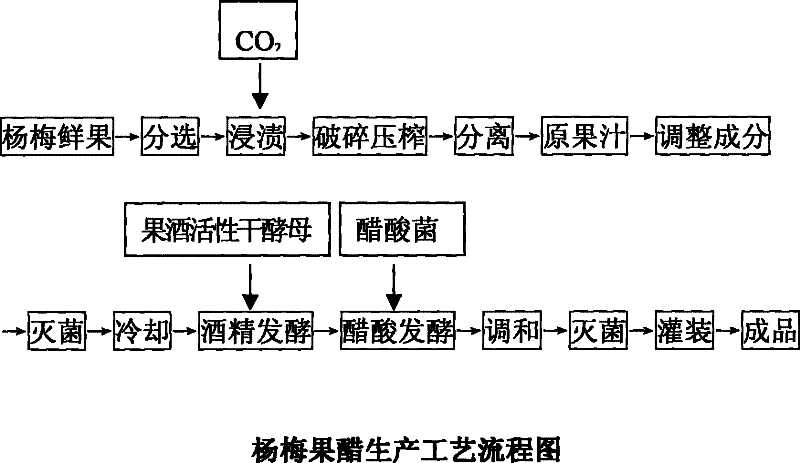

Waxberry wine and brewing method thereof

ActiveCN101544941ASave lossRaise the pHAlcoholic beverage preparationMicroorganism based processesFruit wineCurative effect

The invention discloses waxberry wine and a brewing method thereof. The wine comprises 50 to 60 percent of waxberry raw wine and 40 to 50 percent of glutinous rice wine juice, and is blended by the waxberry raw wine and the glutinous rice wine juice, wherein the waxberry raw wine is prepared by soaking waxberry fresh fruits into CO2 gas, then crushing and pressing the soaked waxberry fresh fruits, and extracting and fermenting juice. Because the waxberry wine prepared by the method has obviously different flavor and mouth feel compared with yellow wine and fruit wine, the product has unique novelty. The invention solves the technical problems that the waxberry wine is acerbic and has over-high acidity, the mouth feel is inharmonious, the nutrient components are easy to lose, and the like. The product is red, clear and transparent, has intense flavor of the waxberry fruit and mellowness of the glutinous rice wine, has sweet taste and harmonious acidity, is pure, fresh and satisfying, can be drunk as the fruit wine and the yellow wine, has the functions of supplementing substances such as vitamins, amino acid, trace elements and the like for human body, and has function of nourishing curative effect.

Owner:湖南佰诺酒业股份有限公司

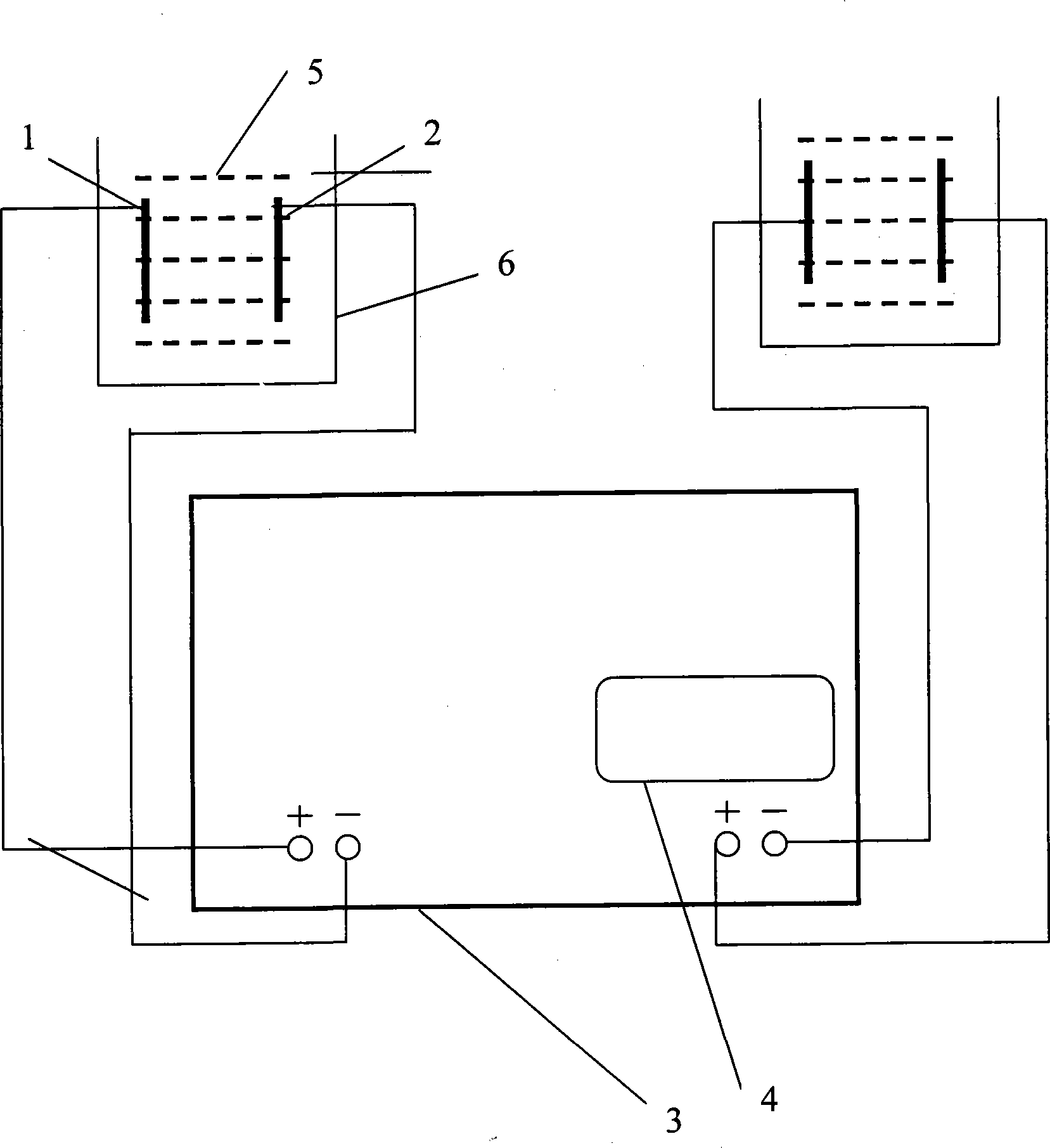

Maintenance free long life electrolysis anti-soil apparatus

InactiveCN101423267ARestoring Chlorine Electrolysis EfficiencyDoes not destroy activityWater/sewage treatmentElectrochemistryOxide coating

The invention belongs to the electrochemical electrolytic antifouling field and relates to a long-service-life maintenance-free electrolytic antifouling device which is suitable for being used in seawater; the main body of the device comprises a changeable direct current (DC) electrolytic power supply, an electrolytic anode, a nickel alloy cathode, a time relay, an electrolytic cell shell and a cable; the DC electrolytic power supply can output different directional current, and the time and size parameters thereof are set by a panel or a computer; the electrolysis anode is a metal platinum coating or a mixing metal oxide coating; when the electrolysis anode is electrolyzed over 30 days under various seawater environments, the current efficiency can not be reduced significantly; the cathode conducting the current uses a smooth flat nickel alloy material; the direction for the current leading to an electrolytic cell is switched once per 5 to 30 days; and the reverse current leading to the electrolytic cell every switch is 1 to 10 minutes and the current density is 10 to 100A / m<2>. The invention has the advantages of reliable principle, simple technology process, low cost, good antifouling effect, and long service life of equipment.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

1-deoxynojirimycin preparing method suitable for industrial production

ActiveCN103965096AEfficient separationImprove dissolution efficiencyOrganic chemistryDeoxynojirimycineUltrafiltration

A 1-deoxynojirimycin preparing method suitable for industrial production comprises the following steps: (1) raw material pre-treatment: crushing the dry mulberry leaf raw material; (2) enzymelysis: adding water into powder, raising the temperature, adding a combined enzyme for enzymelysis, and filtering; (3) continuous combined extraction: performing continuous combined extraction on filter residues by using 3-4 extracting devices, mixing extracting solutions, and filtering; (4) alcohol precipitation and centrifugation: performing pressure-reduction concentration to 1 / 3-1 / 2 of the original volume, cooling, adjusting pH, adding an alcohol solution, stirring, performing still standing, and centrifuging by using a tube centrifuge; (5) membrane filtration: at 25-35 bar pressure at room temperature, ultrafiltering by using an organic ultrafiltration membrane, and then at 0.5-1.5 MPa pressure at room temperature, nano-filtering by using a nanofiltration membrane; (6) concentrating; (7) drying. By using the 1-deoxynojirimycin preparing method, the loss of a solvent can be reduced to a large extent, the energy consumption can be reduced and the product yield can be increased; therefore, the 1-deoxynojirimycin preparing method is suitable for industrial production.

Owner:HUNAN HUACHENG BIOTECH

Efficient, anti-wear and energy-saving lubricating oil and preparation method thereof

InactiveCN105219495AExtend your lifeAnti-wear and energy-saving effect is obviousLubricant compositionEngineeringLubricant

The invention relates to automotive lubricating oil and industrial lubricating oil, and discloses efficient, anti-wear and energy-saving lubricating oil and a preparation method thereof. An efficient and energy-saving repairing agent is added to an engine lubricant, high-purity metal nanoparticles suspended in the efficient and energy-saving repairing agent form a micro rolling bearing on the friction surface of an engine, anti-wear, energy-saving and repairing functions are obvious, power can be improved, the service life of the engine can be prolonged, fuel and loss can be saved, and emission can be reduced.

Owner:HUIZHOU CNISH OIL CO LTD

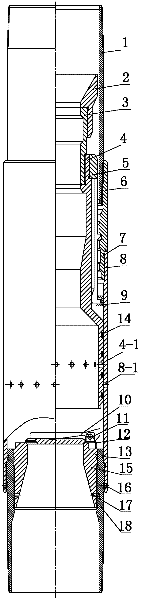

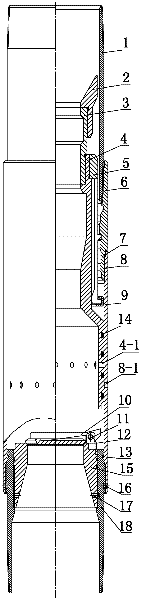

Pluggable oil-layer anti-leakage valve

ActiveCN102400662AFree from pollutionSave lossWell/borehole valve arrangementsSealing/packingUpper jointEngineering

The invention relates to a pluggable oil-layer anti-leakage valve, mainly comprising an upper joint, an outer sleeve, a plate valve and a lower joint and the like. The pluggable oil-layer anti-leakage valve is characterized in that the upper joint is internally provided with a guide head and an elastic claw seat connected with the guide head; the elastic claw seat is in threaded connection with a switch sleeve; a locking claw is connected with the switch sleeve; a locking ring is sheathed on the excircle at one end of the locking claw; the circumference of the outer sleeve is provided with pressure balance holes which have the same quantity with pressure balance holes of the switch sleeve; at least four sealing rings are arranged between the switch sleeve and the outer sleeve; a valve seat is connected in the lower joint under the switch sleeve, and is provided with a valve plate by a pin shaft; and the pin shaft is provided with a return spring. The pluggable oil-layer anti-leakage valve has the advantages that the leakage of completion fluid is reduced, the pollution of an oil layer is prevented, the operating procedure is simplified, the operating time is saved, the operating efficiency is improved and the operating cost is reduced; the anti-leakage valve is designed to be large diameter, so that the conventional pipe column can pass freely; and the plate valve can be opened repeatedly for multiple times by a special tool, and is made of drillable materials, so that when the plate valve can not be opened by the special tool, the valve plate can be fast drilled by a drill bit.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Steel rust inhibitor and preparation method thereof

The invention discloses a steel rust inhibitor and a preparation method thereof. The preparation method comprises the following steps: weighing phytate, barium petroleum sulfonate, aluminum naphthenate, sodium tripolyphosphate, diethanolamine, surfactant, zinc dialkyl dithiophosphate, sodium molybdate, amino trimethylene phosphonic acid, tolyl triazole, thickener, acetyl triethyl citrate and deionized water according to parts by weight, adding into a middle, and starting the reaction kettle to stir at 65-70 DEG C until the components are completely dissolved. The steel rust inhibitor is free of harmful components to the human body, has the advantages of favorable rust inhibition property, simple treatment technique, accessible raw materials and low production cost, and is convenient to use. Under the condition of satisfying the operating conditions, the viscosity of the rust inhibitor should be reduced to the lowest value. The steel rust inhibitor with low viscosity is easy for coating, can effectively lower the thickness, and achieves the goals of saving and loss reduction.

Owner:一站工材(常州)互联网科技有限公司

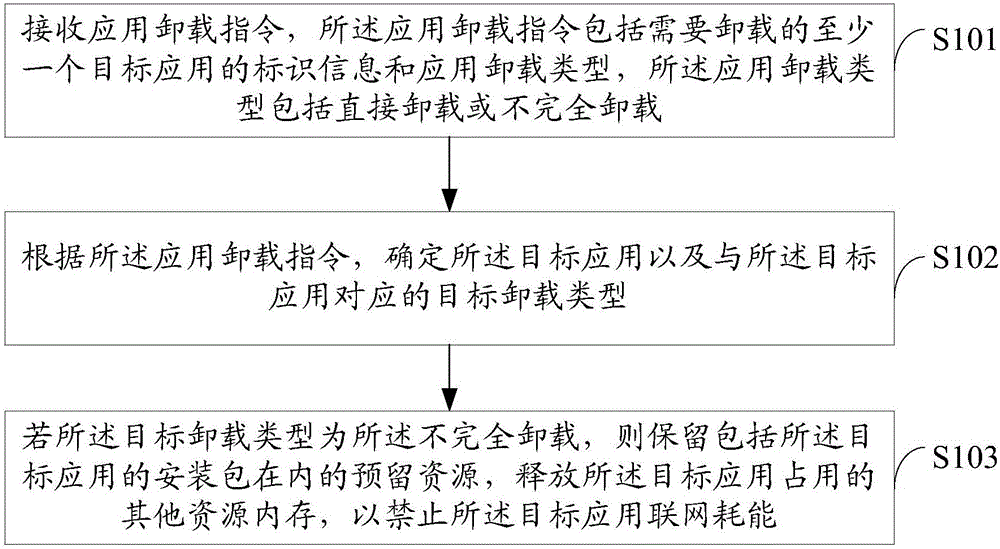

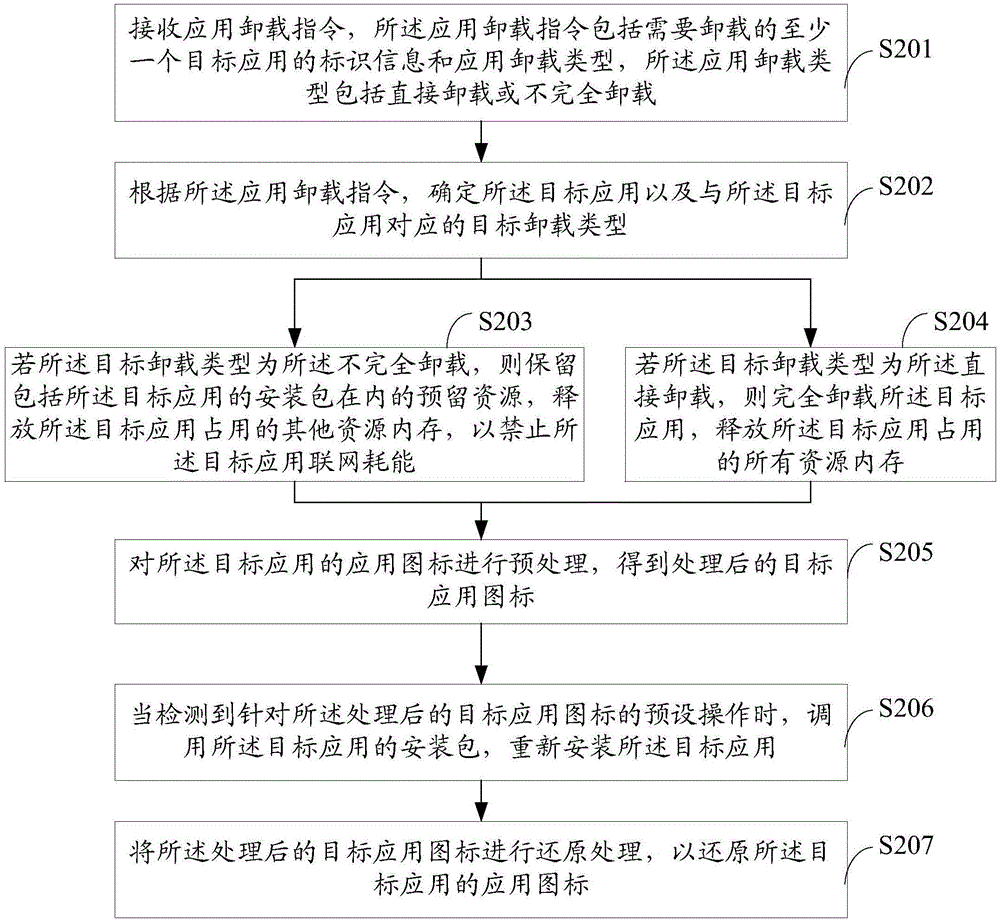

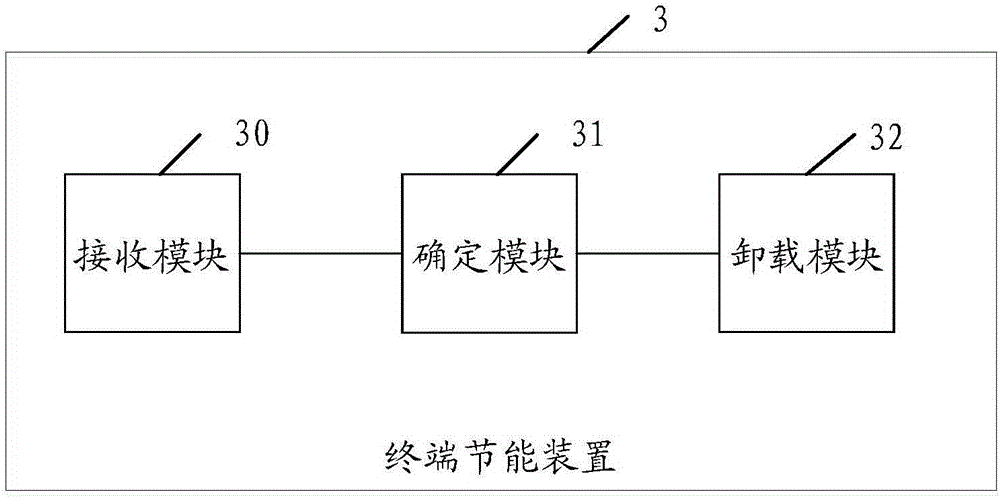

Terminal energy-saving method and device as well as terminal

InactiveCN106292999AImprove practicalityProhibition of energy consumptionPower supply for data processingProgram loading/initiatingSoftware engineeringPower consumption

The embodiment of the invention provides a terminal energy-saving method and device as well as a terminal. The method comprises: receiving an application uninstalling instruction, wherein the application uninstalling instruction comprises identification information of at least one target application needing to be uninstalled and an application uninstalling type and the application uninstalling type comprises direct uninstalling or incomplete uninstalling; according to the application uninstalling instruction, determining a target application and the target uninstalling type corresponding to the target application; if the application uninstalling type is the incomplete uninstalling, keeping reserved resource containing an installing package of the target application and releasing other resource memories occupied by the target application, so as to prohibit networking power consumption of the target application. By adopting the terminal energy-saving method and device as well as the terminal, memory resources and flow loss of the terminal can be saved; meanwhile, the practicability of application uninstalling is also improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Atomic force microscope probe device

ActiveCN103852600AAvoid misalignment, fallAvoid positionScanning probe microscopyCantileverMicroscope

The invention discloses an atomic force microscope probe device. The atomic force microscope probe device comprises a probe and a probe base, wherein the probe comprises a micro cantilever and a probe point; the probe point is arranged on one end of the micro cantilever; a slot is formed in the lateral surface of the other end, far from the probe point, of the cantilever; the probe base comprises an absorption part and a location part; the absorption part has an absorption surface; an air conduction slot is formed in the absorption surface and communicated with a vacuumizing part and used for enabling the probe to be absorbed on the absorption surface; the location part comprises a body and a slot patch which is arranged on the lower end of the body; the slot patch is matched with the slot in shape; the body is arranged on two sides of the absorption part in a sliding manner; and the body moves between a first position and a second position to enable the slot patch to be embedded into the slot or separated from the slot. Through the atomic force microscope probe device, the problems that the probe misplaces, falls off or is out of position in the process of replacing the probe can be avoided.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

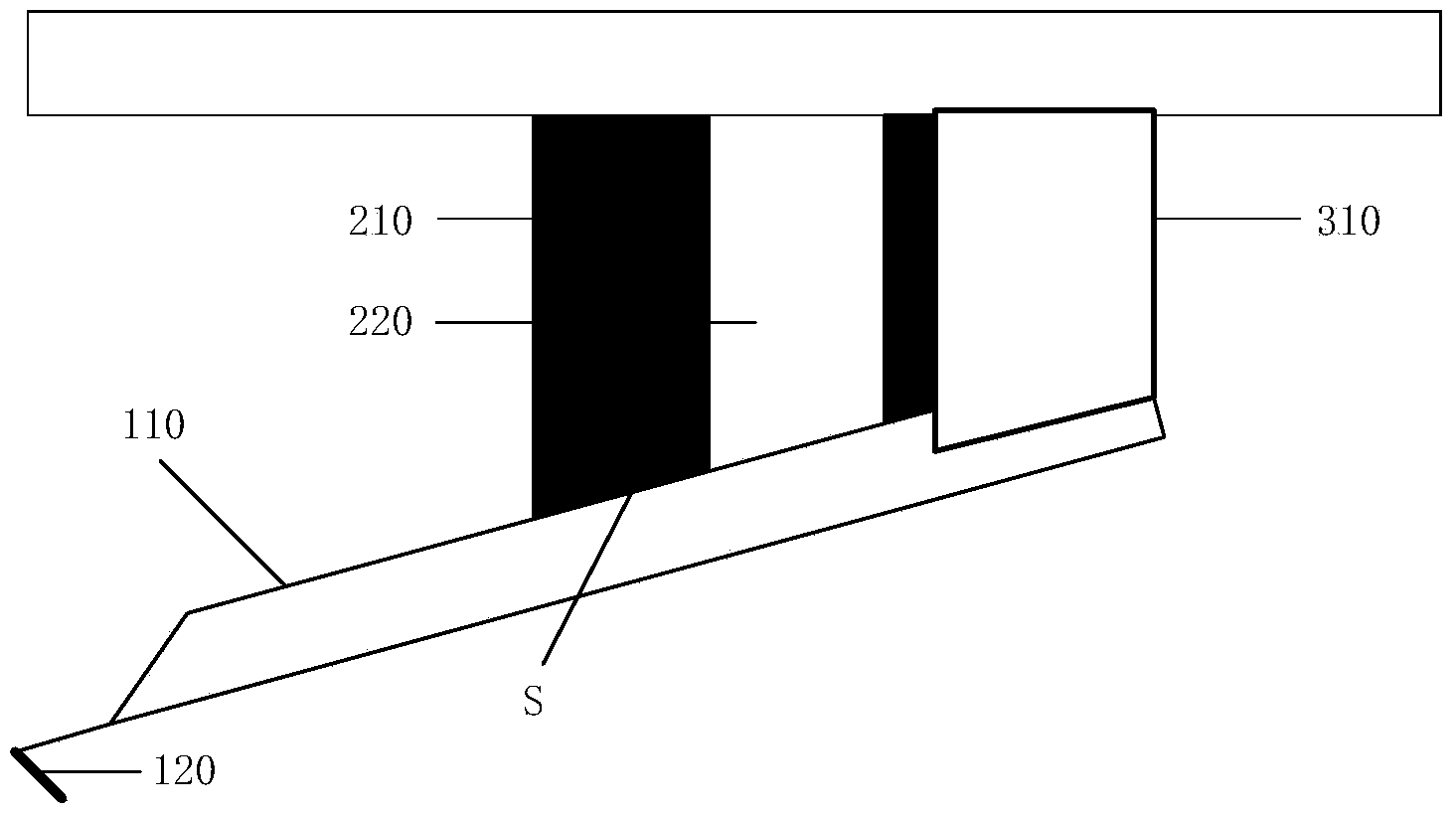

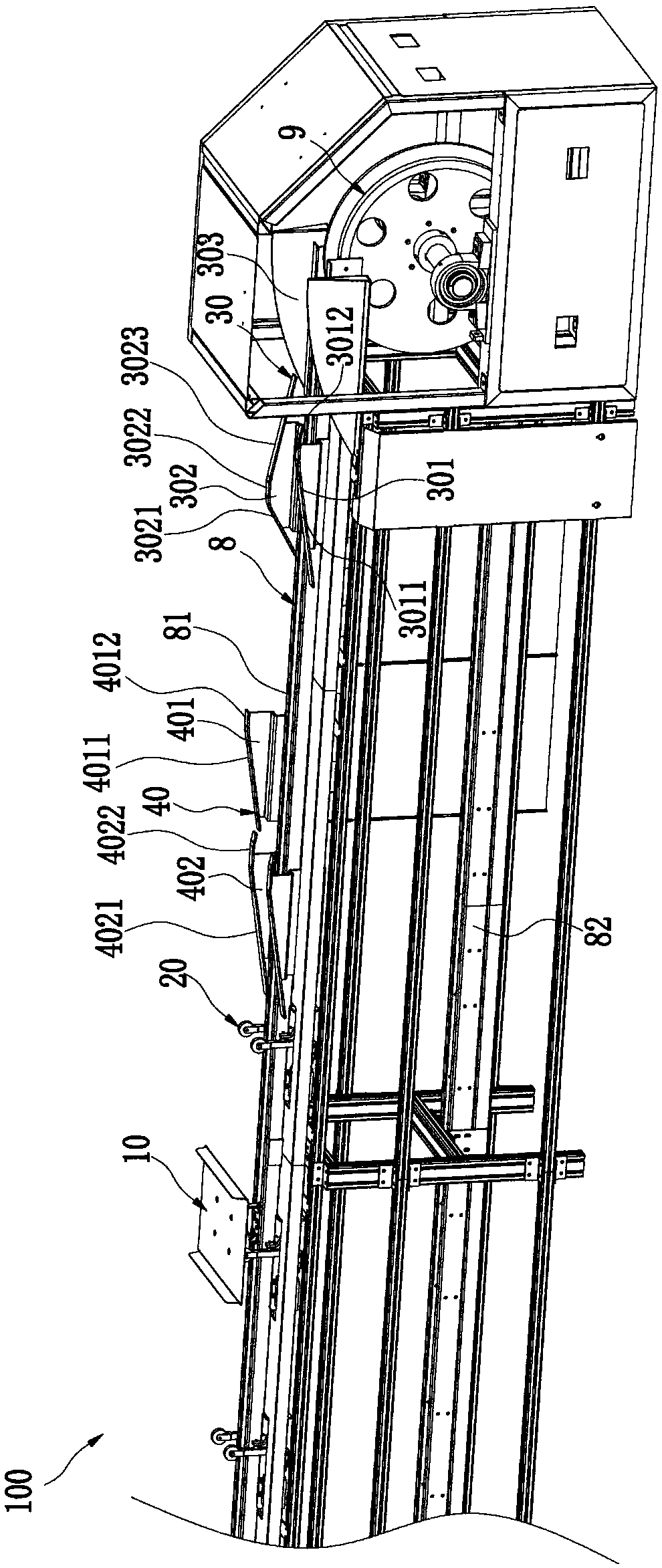

Turning-plate type sorting system

PendingCN108408314AResolve interferenceEffective combinationSortingStorage devicesEngineeringMulti path

The invention discloses a turning-plate type sorting system comprising a track and further comprising a feeding area located beside the track, detecting equipment located on the track and a grid opening area located beside the track. The track is slidably provided with at least one bidirectional turning-plate trolley with a turning plate capable of turning over towards two directions for unloading; and the bidirectional turning-plate trolleys are connected with driving devices driving the bidirectional turning-plate trolleys to slide along the track. In the turning-plate type sorting system, the bidirectional turning-plate trolleys can sort bidirectionally and can be combined with the track to realize synchronous work of multiple trolleys; by controlling the discharging position and discharging direction of each bidirectional sorting trolley, multi-path sorting can be effectively realized under the limited site condition, the problem of disturbance caused by travelling paths of a conventional trolley is avoided, and the requirement on the site is low; meanwhile, the multiple trolleys synchronously sort in multiple paths, and thus the sorting efficiency is greatly improved; and by combining feeding, detecting and sorting openings, automatic operation of the whole sorting process can further be achieved, and the turning-plate type sorting system is advantageously matched with other sorting equipment for being used through the design of discharging grid openings.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

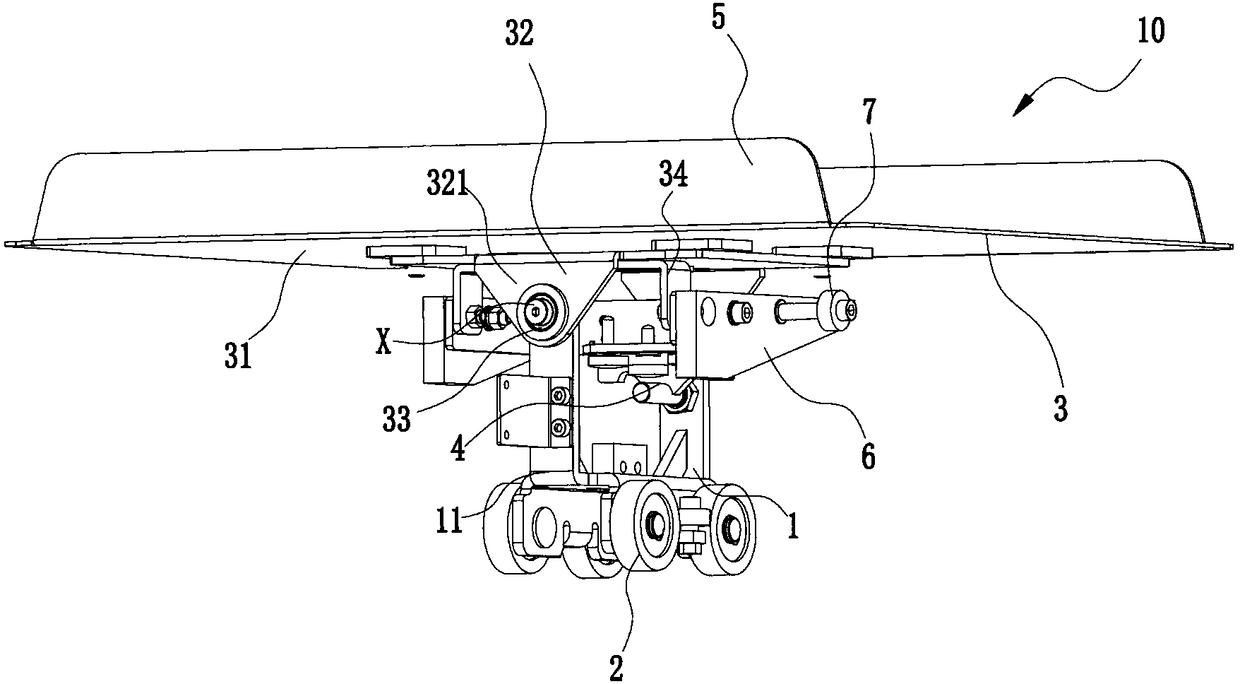

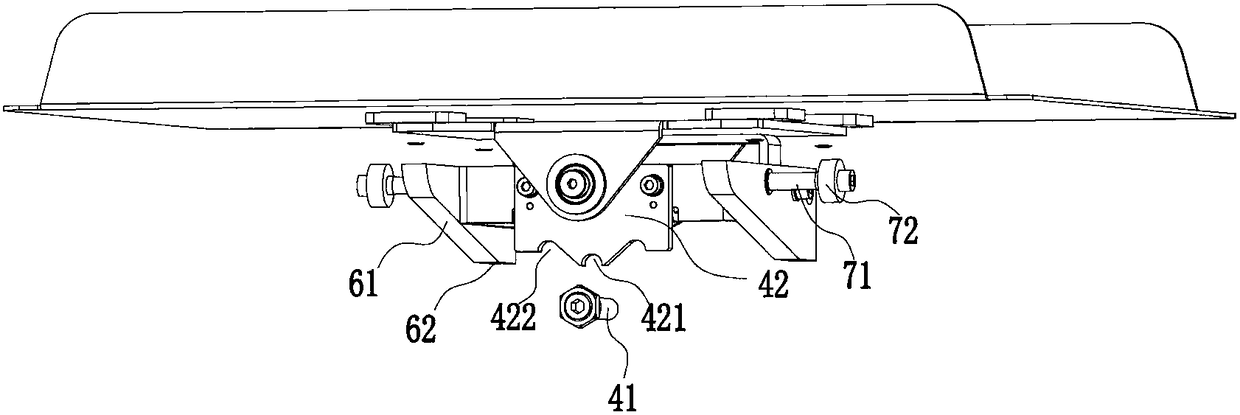

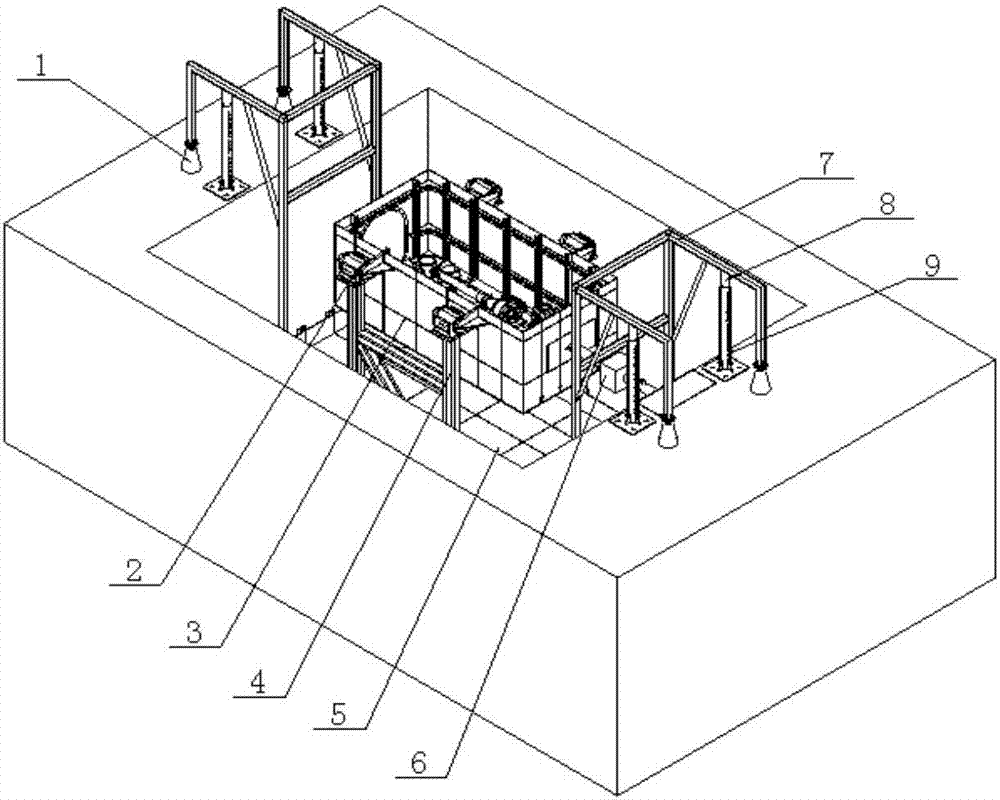

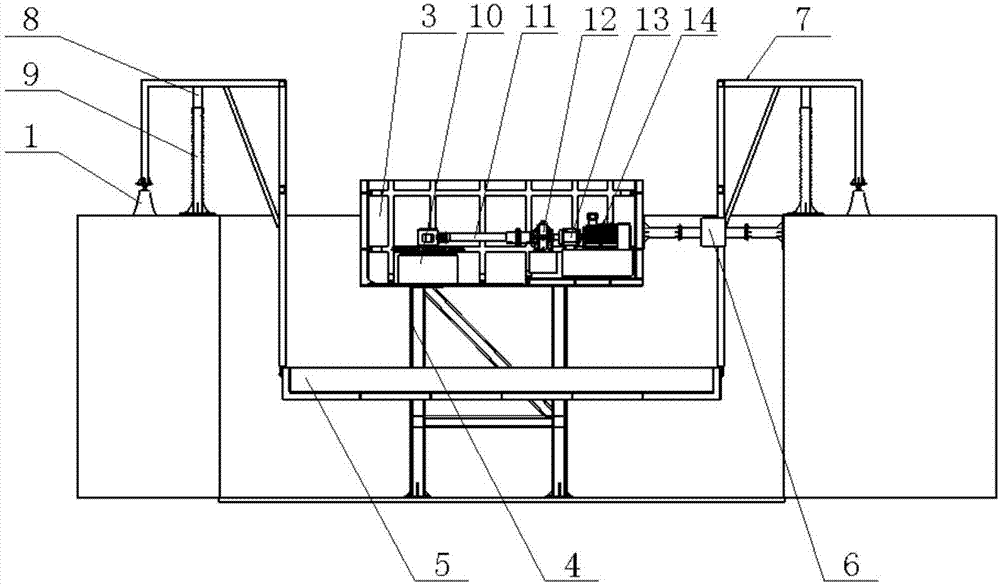

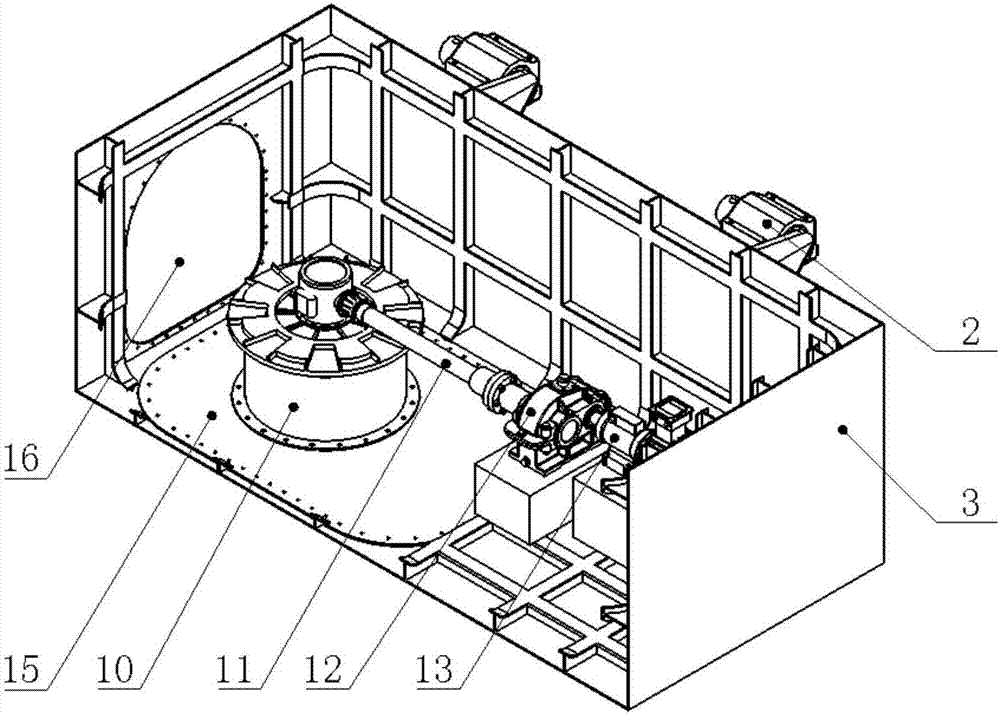

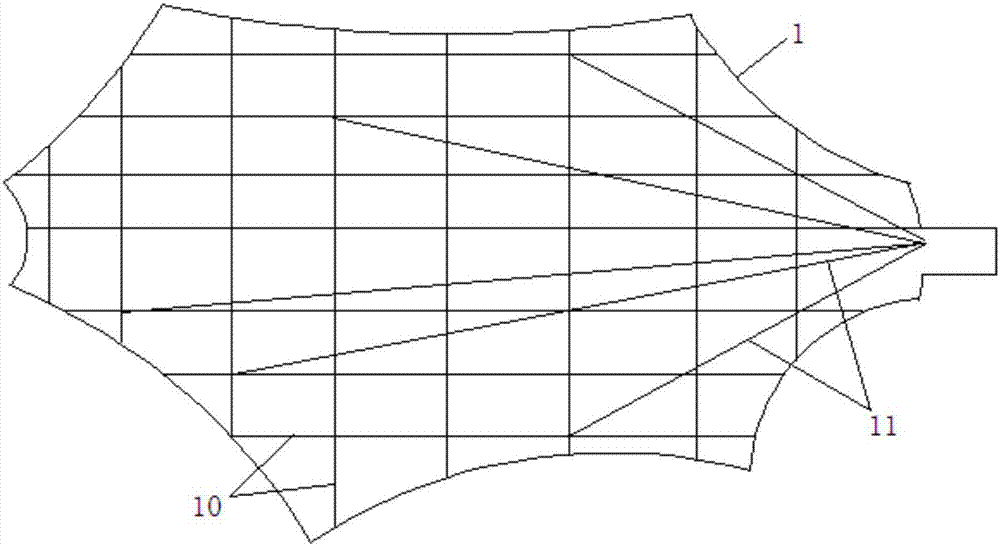

Test device capable of varying water depth to perform performance tests of multiple kinds of water jet propellers under mooring conditions

ActiveCN106872156AFast and convenient performance testShorten the timeMachine part testingElectricityPump-jet

The invention relates to a test device capable of varying water depth to perform performance tests of multiple kinds of water jet propellers under mooring conditions. The device comprises a buoyancy tank (3), a lifting platform (5), a thrust sensor (6) and an electric driving mechanism; the bottom surface of the buoyancy tank (3) is connected with the upper end of a buoyancy tank supporting frame (4); the lower end of the buoyancy tank supporting frame (4) is fixed to the bottom of a test pool; the lifting platform (5) is fixed through lifting platform connecting frames and lifting platform on-shore fixing rods at the left side and right side of the test pool; and one end of the thrust sensor (6) is connected with the electric driving mechanism, and the other end of the thrust sensor (6) is connected with a side wall of the test pool. With one such test device of the invention adopted, the performance tests of different kinds of water jet propellers under water depth varied working conditions can be realized, and time and cost required by the tests can be substantially decreased.

Owner:WUHAN UNIV OF TECH

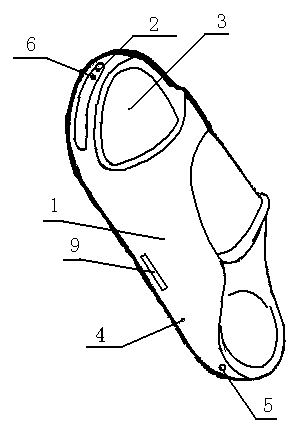

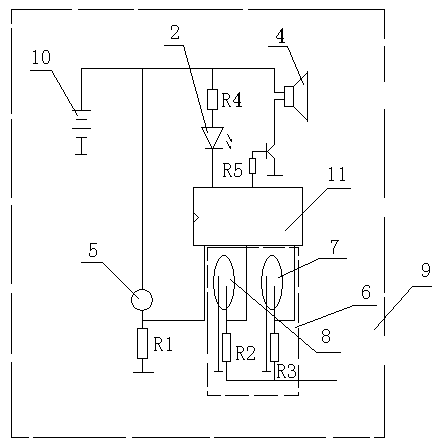

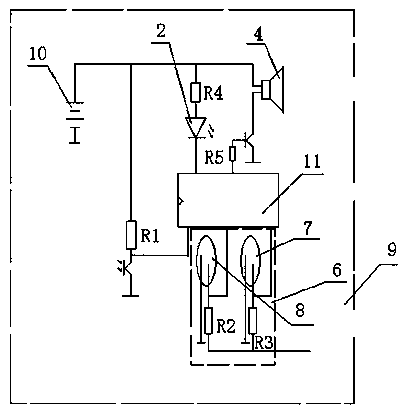

Illuminating slippers

InactiveCN104352010AAdd rollover signal detectionSave lossPoint-like light sourceElectric circuit arrangementsPower flowControl circuit

The invention relates to a pair of slippers, particularly to a pair of illuminating slippers. The pair of illuminating slippers at least includes slipper bodies, LEDs and control circuits, wherein for each of the pair of the slippers, the LED is embedded at the front end of the slipper sole, and illuminates forwards; a first sensor and a second sensor are arranged on each of the pair of illuminating slippers, the first sensor is used for detecting the light intensity, and the second sensor is used for detecting whether foot enters the slipper body or not; the control circuit controls the LED to illuminate only when the light intensity of night is detected and the second sensor detects that the foot enters the slipper body. The pair of illuminating slippers has the advantages that the aged can find the slippers in darkness conveniently and put the feet inside the slippers to move, and at the time, the LEDs illuminate instantly to enable the floor and the surroundings to be clear and visible, and the LEDs illuminate within 10-20 seconds for each triggering and only illuminate at night, so that current loss is greatly reduced and long-term use is guaranteed; slipper side turning signal detection is added to guarantee that family members arrive timely when the aged fall over carelessly, and delay for a too long time is avoided.

Owner:赵汤臣

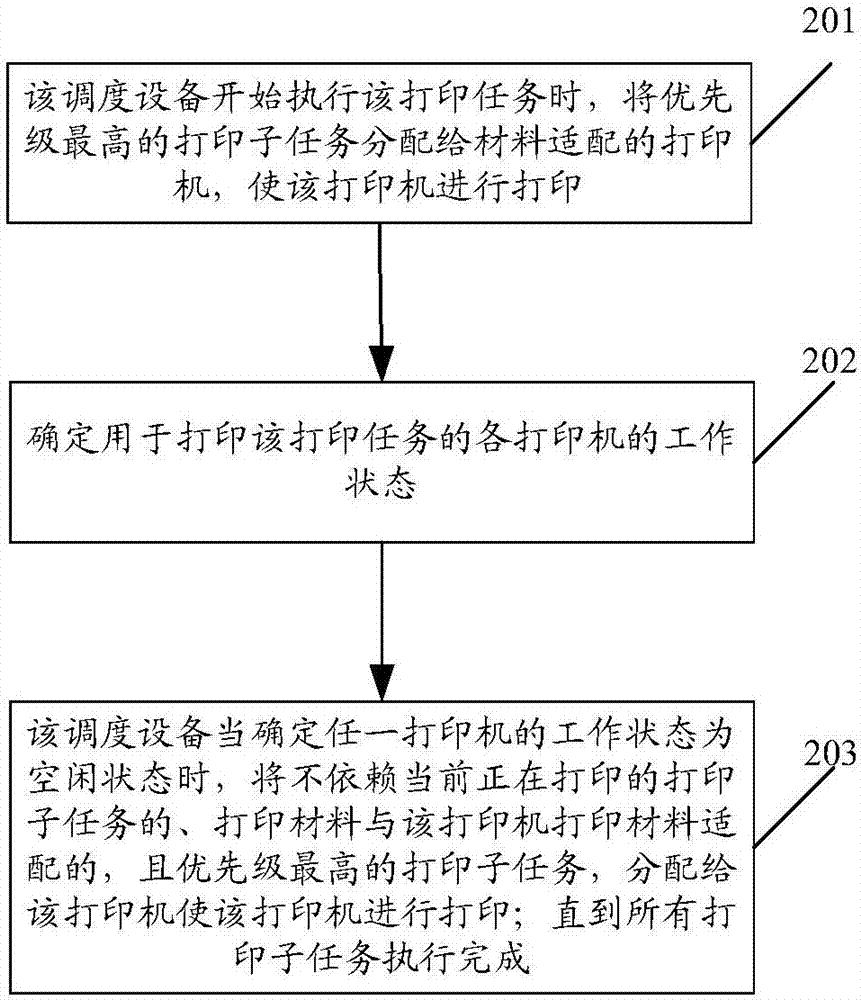

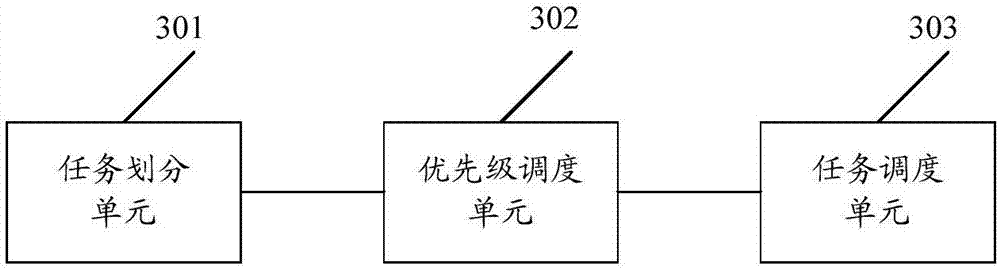

3D (Three-Dimensional) printing subtask scheduling method and device

InactiveCN107168781ASave lossShorten the timeProgram initiation/switchingDigital output to print unitsWork statusComputer engineering

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

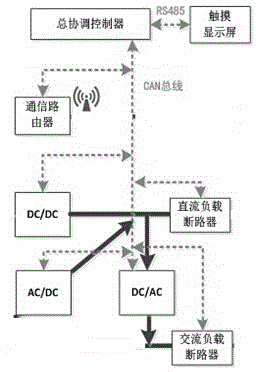

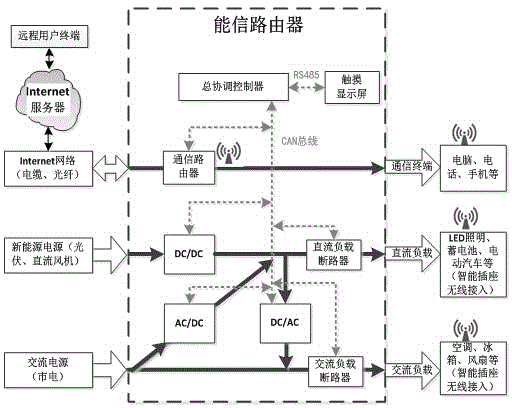

Energy-information router and application system for managing electric energy network and information network

ActiveCN104539050AImprove utilization efficiencyAchieving real-time complementarityCircuit arrangementsInformation technology support systemCurrent loadNew energy

The invention discloses an energy-information router which comprises an overall coordinating controller, a touch displaying screen, a communication router, an AC / DC module, a DC / DC module, a DC / AC module, a direct-current load breaker and an alternating-current load breaker. The overall coordinating controller is connected with the touch displaying screen through a serial RS485. The overall coordinating controller is connected with the communication router, the AC / DC module, the DC / DC module, the DC / AC module, the direct-current load breaker and the alternating-current load breaker respectively through a CAN bus. The energy-information router can achieve the functions of alternating current power supply, new-energy power supply and information network managing at the same time, an application system for managing an electric energy network and an information network is further provided, the application system can achieve real-time complementation of an alternating current power supply and a new-energy power supply, and connecting and full using of the new-energy power supply can be well achieved.

Owner:SOUTHEAST UNIV

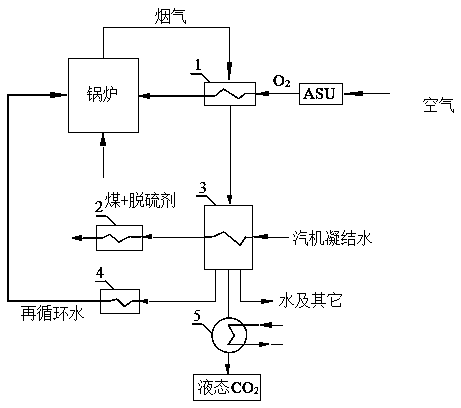

Bubbling fluidized bed type O2/H20 pressurized oxygen-enriched combustion system

InactiveCN105509038ASave energySave lossFluidized bed combustionIndirect carbon-dioxide mitigationWater vaporEngineering

The invention discloses a bubbling fluidized bed type O2 / H20 pressurized oxygen-enriched combustion system. According to the integral system, the entire process from air separation for oxygen, boiler combustion and heat exchange to CO2 capture is carried out with the high pressure maintained at 6 to 8 MPa, and compared with a traditional oxygen-enriched combustion technology, the system has the advantage that the compression energy consumption and depressurization loss are greatly reduced; a steam regulating system is utilized for replacing a gas recirculation system, a lot of vaporization latent heat is absorbed during water vaporization, and the temperature regulation ability is relatively strong, so that under the same condition, the flue gas amount is lower, and compared with O2 / CO2 circulation, the system has the advantage that the energy consumption and waste heat loss of a fan can be greatly reduced; besides, the combustion temperature of a bubbling fluidized bed is relatively low, so that the generation amount of NOx can be effectively decreased; and a pressurized O2 / H20 oxygen-enriched combustion technology is adopted, so that the vaporization latent heat of vapor can be utilized, the energy consumption and waste heat loss of the fan can be greatly reduced, and compared with a normal pressure O2 / H20 oxygen-enriched combustion technology, the pressurized O2 / H20 oxygen-enriched combustion technology has the advantage that the gross generation power is increased by about 7% and is quite considerable.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

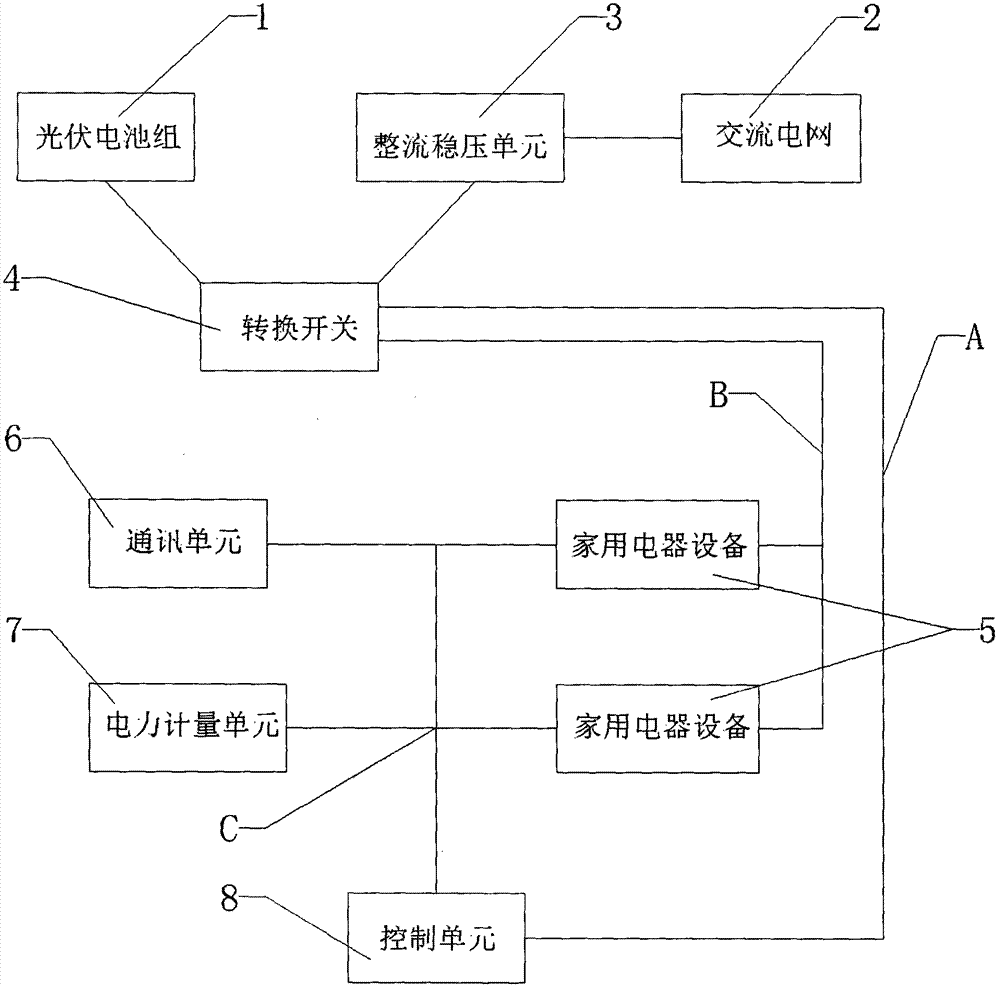

Intelligent power supply system with solar energy as main power supply

InactiveCN104852680ASave electricitySave lossBatteries circuit arrangementsPower network operation systems integrationCommunication unitControl line

The present invention relates to an intelligent power supply system with solar energy as a main power supply. The power supply system comprises a photovoltaic battery group, an AC power grid, a rectifying and voltage stabilizing unit which is connected to the AC power grid, a transfer switch which is connected to the photovoltaic battery group and the rectifying and voltage stabilizing unit, home appliance equipment which is connected to the transfer switch through at least one power line, a control unit which is connected to the transfer switch through a switch control line, a communication unit which is connected to the control unit through a data bus and a power metering unit. According to the power supply system, large amount of electrical energy of the AC power grid can be saved, basic data is provided for the implementation of carbon emission metering and transaction, a basis is provided for contract energy management, and a unified communication infrastructure can be created for a real smart home.

Owner:谢明

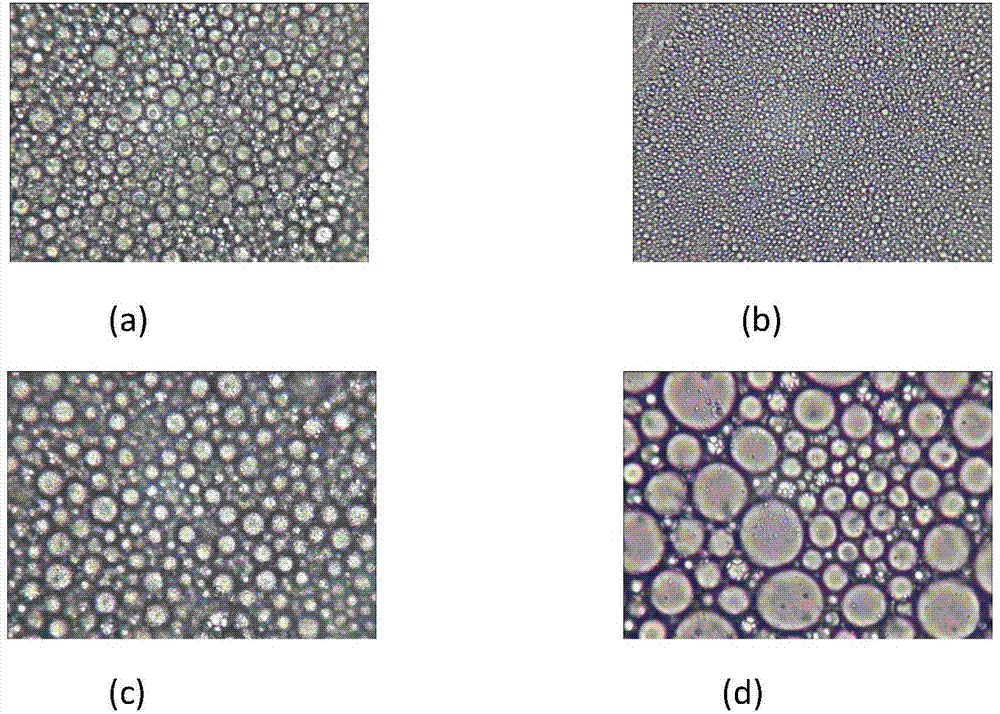

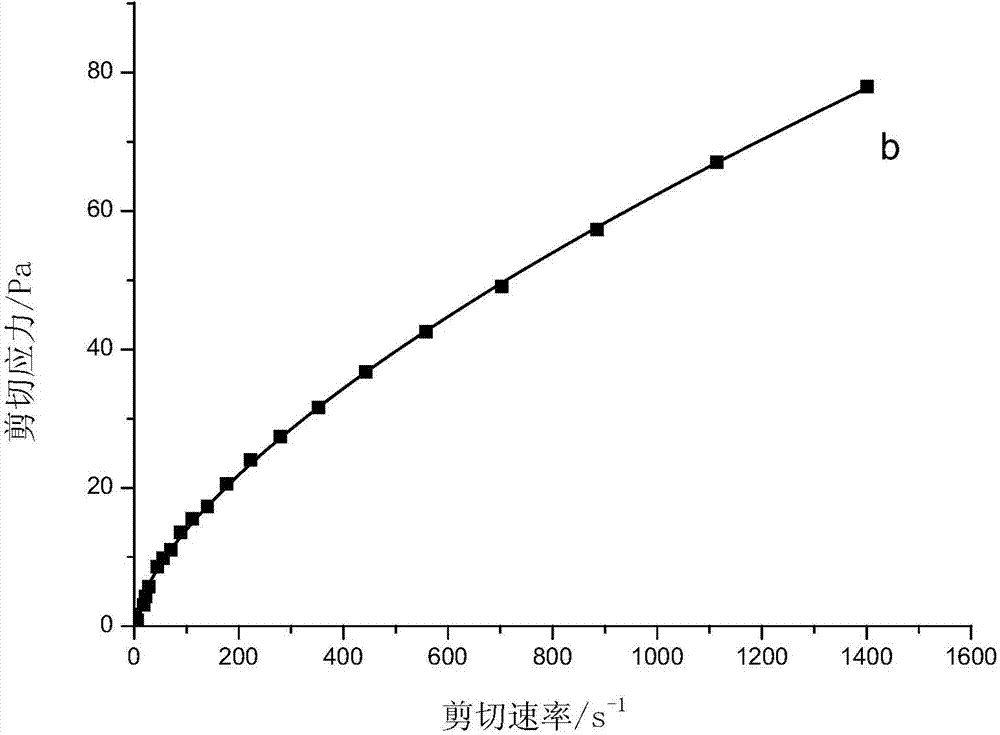

Cold-rolling emulsion and preparation method thereof

ActiveCN103773583AIncrease frictionGood annealing and cleaning propertiesLubricant compositionMass ratioOil phase

The invention provides a cold-rolling emulsion and a preparation method thereof. The cold-rolling emulsion comprises an oil phase and a water phase which are sufficiently mixed, wherein the oil phase comprises reclaimed lubricating oil and an emulsifying agent accounting for 4-8% of the mass percentage of the cold-rolling emulsion, and the hydrophilic-lipophilic balance value of the emulsifying agent is 3.5-5; the water phase comprises water and a bactericide accounting for 0.3-1% of the mass percentage of the cold-rolling emulsion; the mass ratio of the oil phase to the water phase is X: (100-X), wherein X ranges from 48 to 60. According to the invention, the reclaimed lubricating oil is used as a raw material which is mixed according to a proper oil-to-water ratio, and proper surfactants such as the emulsifying agent, the bactericide and the like are added, so that the cold-rolling emulsion with favorable stability, friction performance, annealing detergency and rheological property is obtained, the quality of the cold-rolling emulsion is ensured, meanwhile, the production cost is greatly reduced, the energy is saved, and the loss is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

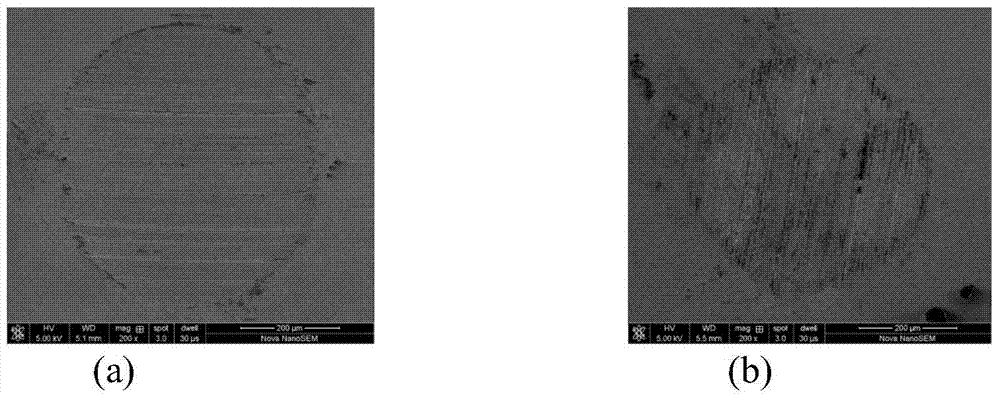

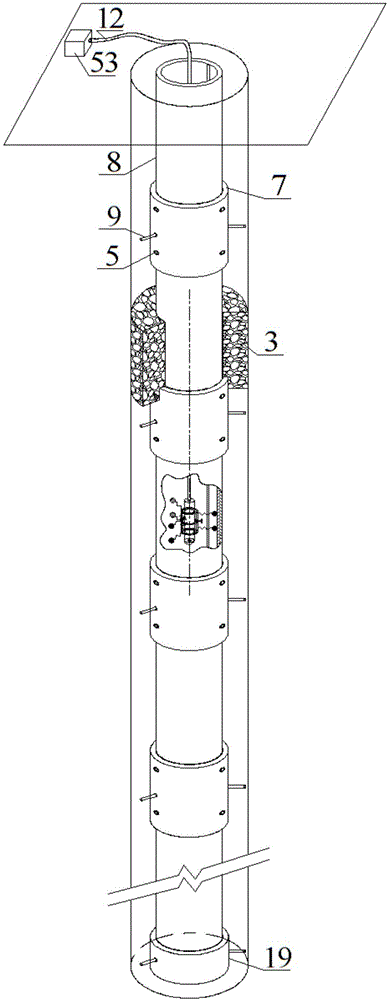

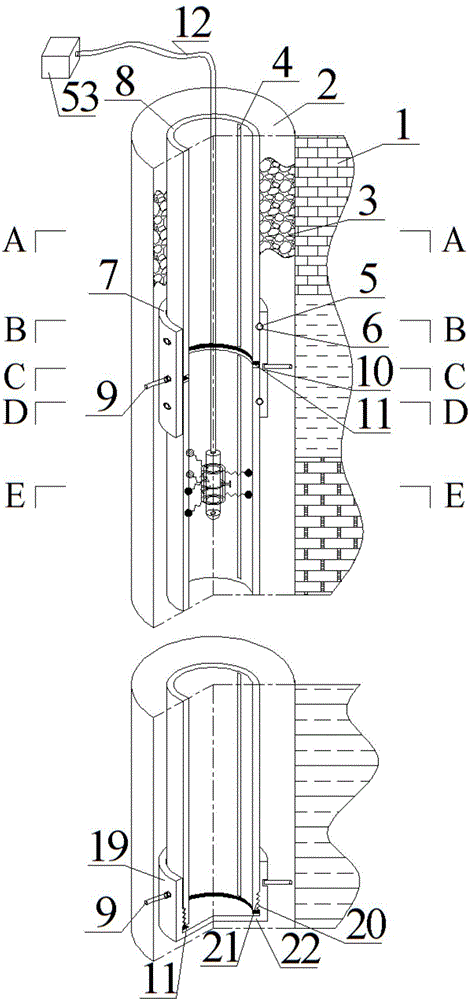

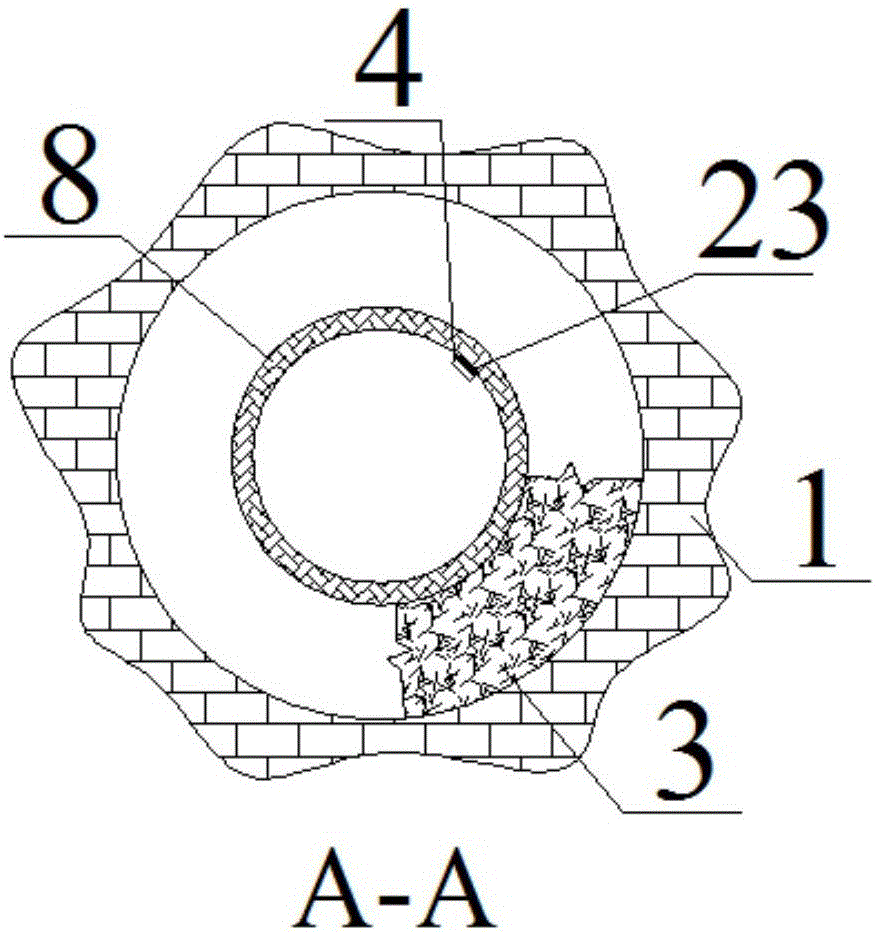

Drill hole anchoring structure for monitoring floor surrounding rock fractures and construction method thereof

ActiveCN106321001ASafe and stable drillingAvoid Drilling and Patching SituationsConstructionsBorehole/well accessoriesFailure rateButt joint

The invention discloses a drill hole anchoring structure for monitoring floor surrounding rock fractures and a construction method thereof. Transparent hollow pipes are connected in a butt joint mode section by section through butt joint sealing assemblies and a bottom sealing assembly and then fed into a drill hole; after a gap between the drill hole and the transparent hollow pipes is subjected to grouting anchoring, drill hole surrounding rock fractures at different scale positions on a measuring ruler are recorded through a detecting and positioning assembly. The rock stratum development condition in the drill hole is directly read, and the drill hole anchoring structure has the advantages of being reasonable in integral structural design, easy to construct, safe, stable, low in drilling failure rate, capable of providing clear images, capable of meeting the requirement for repeated observation and the like; the fracture positions and forms on a drill hole grouting body are directly read through the transparent hollow pipes and directly reflect the positions of floor surrounding rock fractures in the drill hole, and compared with traditional distance position data acquired indirectly, errors are greatly reduced; the drill hole in the same position is used for observing the progress of fracture development at different stages, data is real and reliable, and the position and development condition of rock stratum change can be rapidly and precisely obtained.

Owner:XIAN UNIV OF SCI & TECH

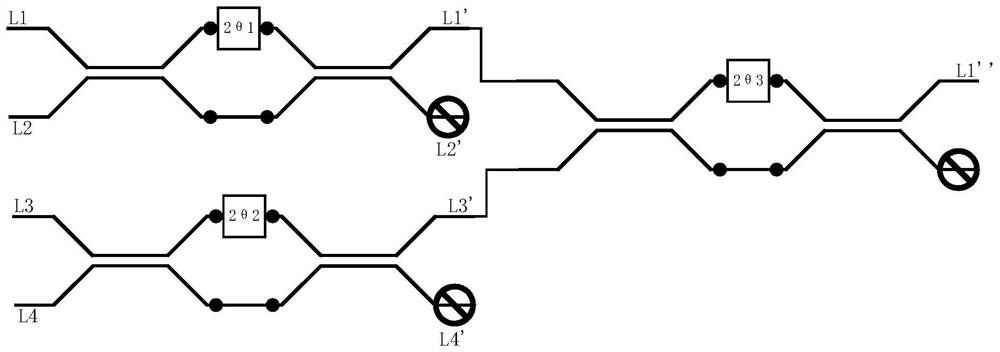

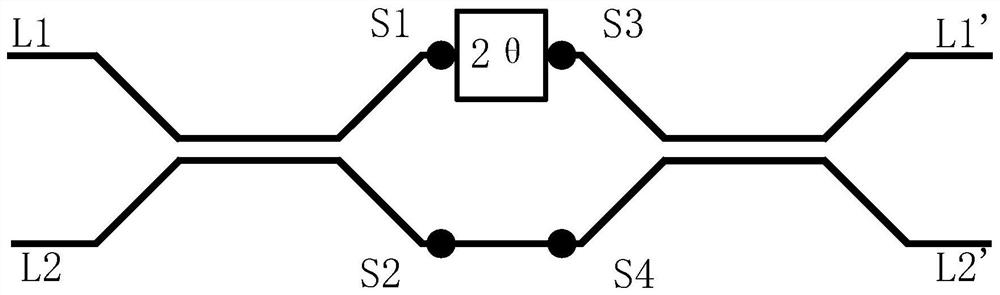

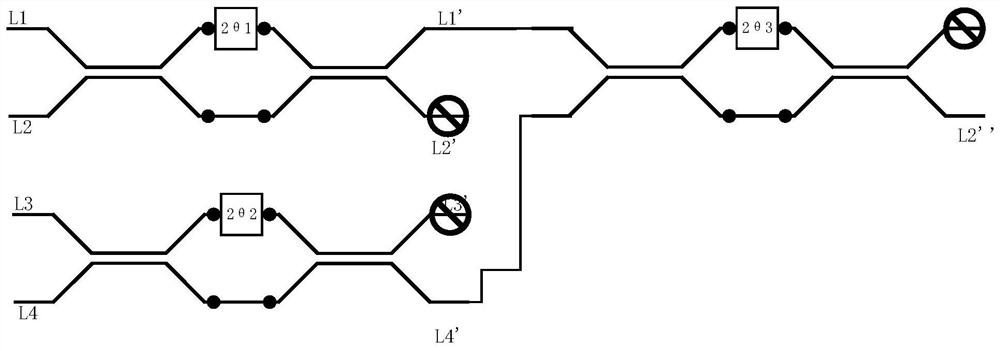

Optical circuit, optical signal processing method and device and readable storage medium

ActiveCN113325650AThe connection relationship is simpleReduce in quantityNon-linear opticsComplex mathematical operationsEngineeringSignal processing

The invention discloses an optical circuit, an optical signal processing method, an optical signal processing device, optical signal processing equipment and a readable storage medium. The optical circuit is characterized in that one optical output end of a first MZI is connected with one optical input end of a third MZI; one optical output end of the second MZI is connected with the other optical input end of the third MZI; two optical input ends of the first MZI and two optical input ends of the second MZI are respectively connected with optical signals corresponding to a 2*2 convolution sequence to be multiplied; the first MZI, the second MZI and the third MZI respectively carry out phase shift on input optical signals of the first MZI, the second MZI and the third MZI so as to realize convolution calculation; and one optical output end of the third MZI outputs a light signal carrying a convolution result. According to the optical circuit, the number of MZIs is smaller, and a structure is simpler; compared with 2*2 convolution operation achieved in a Gridnet mode, half of time loss and equipment loss can be saved, a convolution calculation speed can be increased, and the structure of an optical device can be simplified.

Owner:山东云海国创云计算装备产业创新中心有限公司

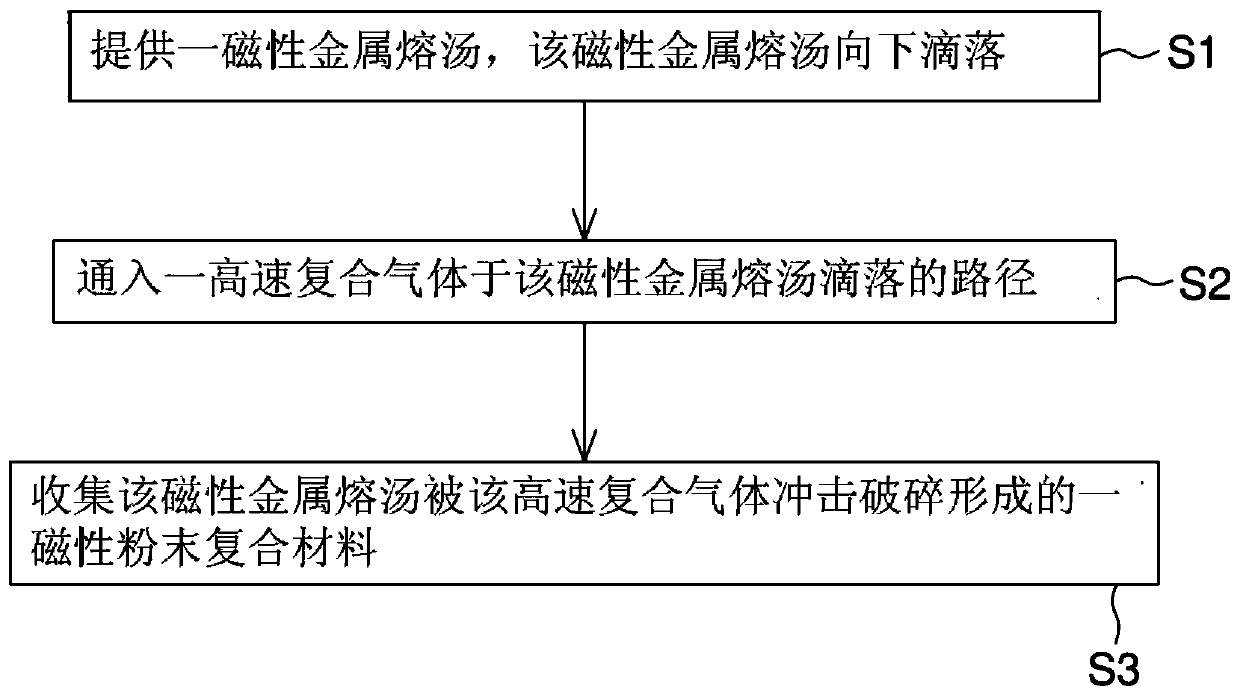

Magnetic powder composite material and preparation method thereof

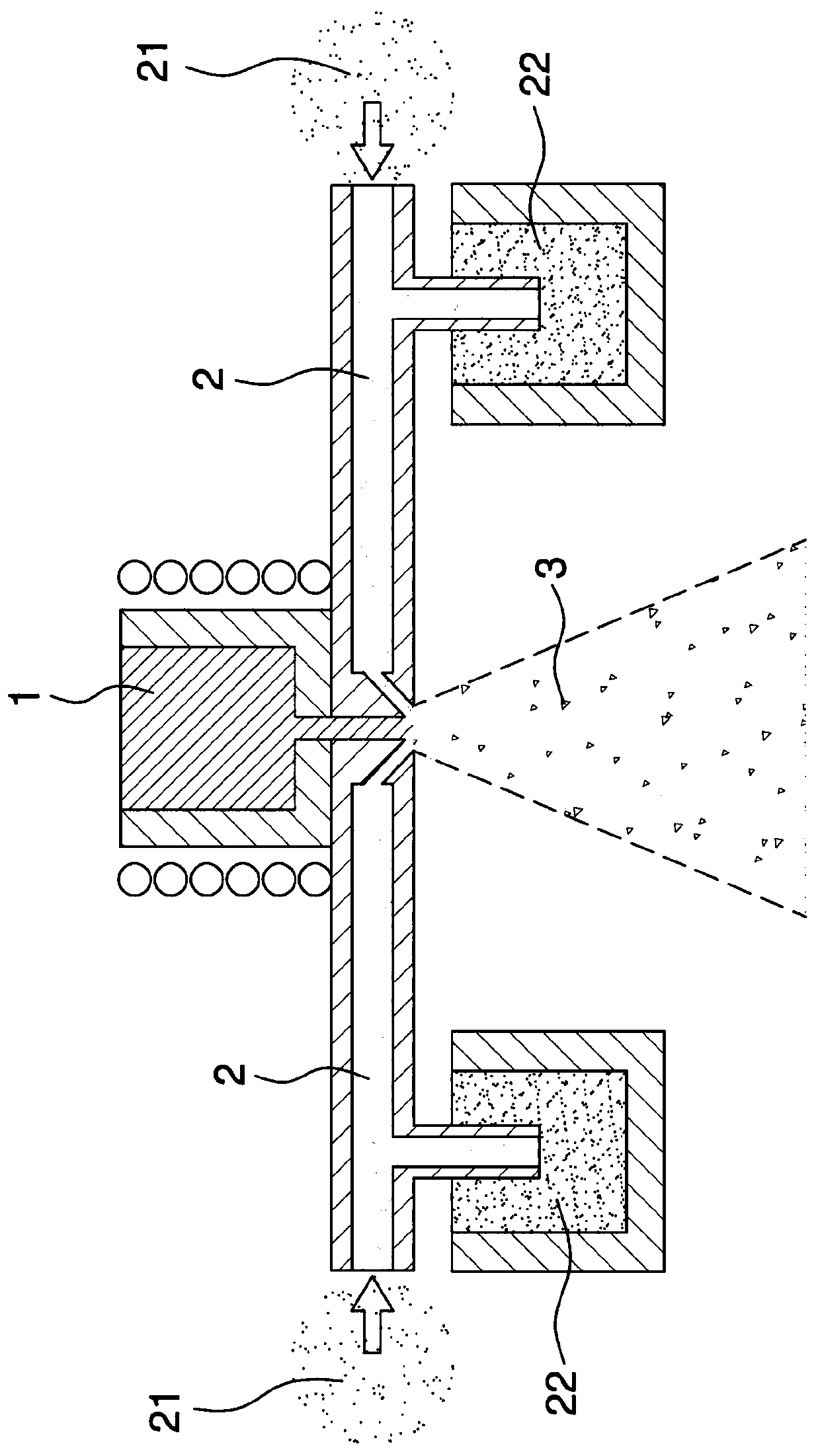

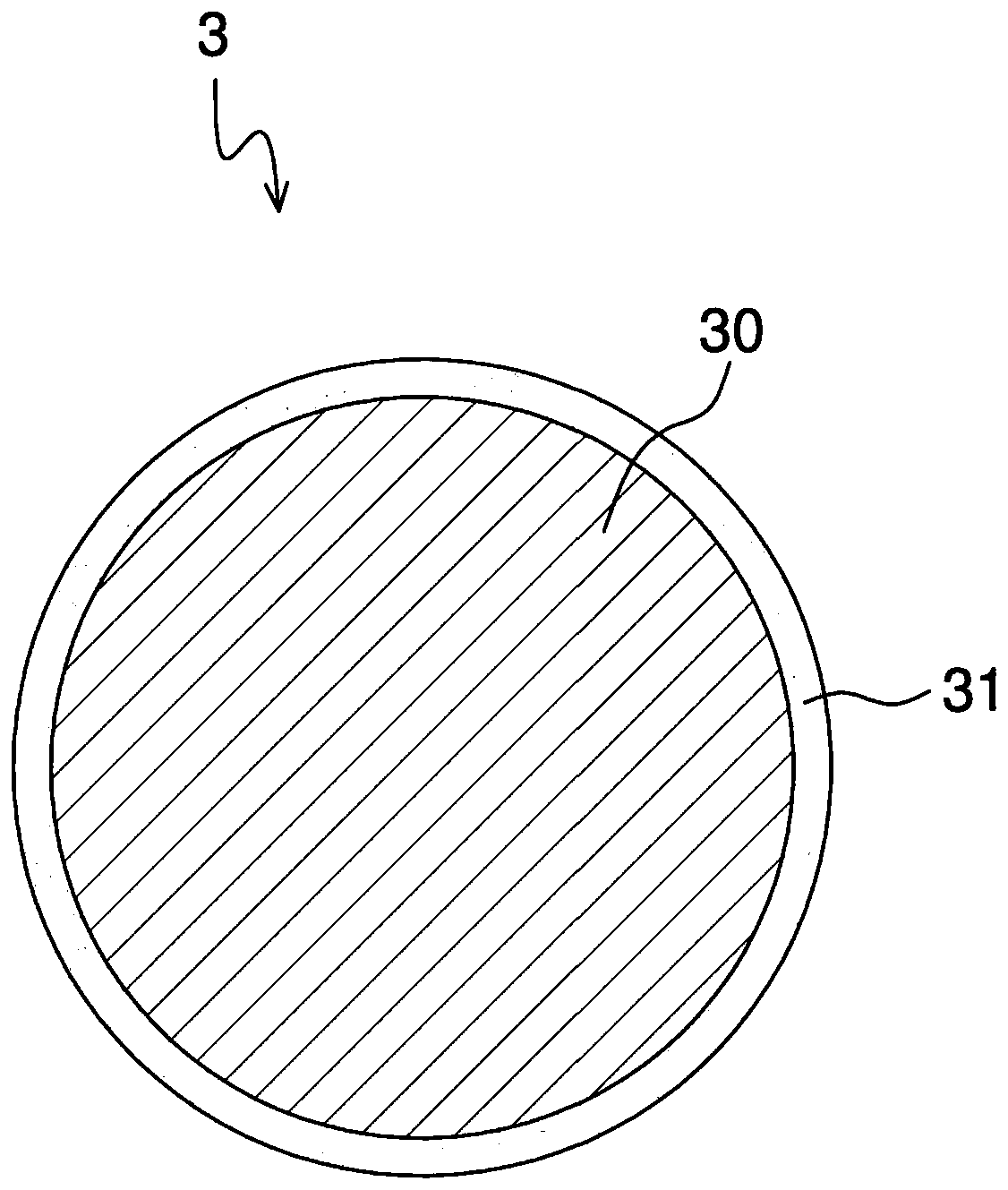

InactiveCN111347054AReduce usageDosage aidTransportation and packagingMetal-working apparatusSilicon oxideAluminum metal

The invention relates to a preparation method of a magnetic powder composite material. The method comprises the following steps that magnetic molten metal is provided, and the magnetic molten metal drips downwards; a high-speed composite gas is introduced into a dripping path of the magnetic molten metal; and the magnetic powder composite material is collected, wherein the magnetic molten metal isimpacted and crushed by the high-speed atomizing gas to form the magnetic powder composite material. The magnetic powder composite material prepared through the preparation method of the magnetic powder composite material structurally comprises magnetic metal powder and an insulating layer coating film; the magnetic metal powder is made of iron-silicon-aluminum metal material; the insulating layer coating film is made of silicon oxide material; and the surface of the magnetic metal powder is coated with the insulating layer coating film. According to the preparation method, the post-treatmentprocedures, pollution and loss are omitted; and the magnetic metal composite material prepared through the method can be directly pressed into a finished product or prepared into the finished productthrough 3D printing without powder post-treatment.

Owner:METAL INDS RES & DEV CENT

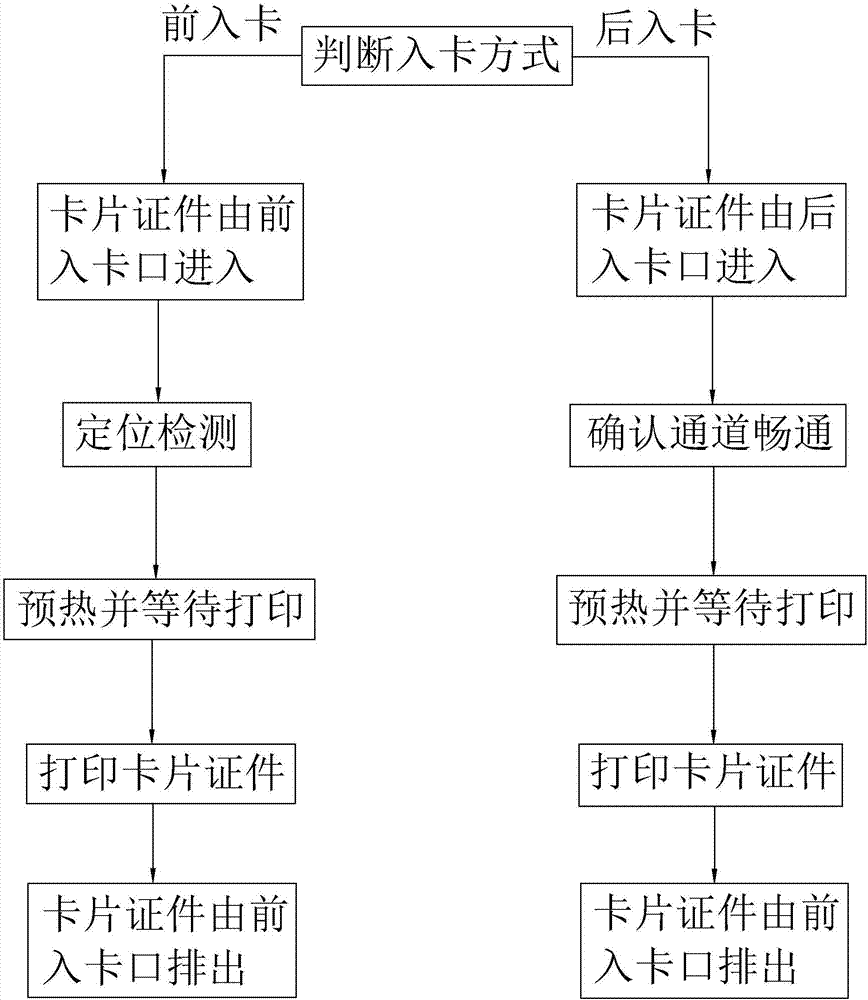

Hot-erase printer and working control method thereof

ActiveCN107571632AEasy to printRealize repeated erasing and writing operationsOther printing apparatusEnergy efficient computingTime efficientEngineering

The invention discloses a hot-erase printer and a working control method thereof. The hot-erase printer comprises a printer main body. The printer main body comprises a control processing module, a front card entry port, a back card entry port, a positioning area, a printing area, an area to be printed and a card feeding channel. The positioning area is provided with a card entry positioning sensor. The printing area is provided with a card detection sensor and a printing device. The area to be printed is provided with a tail card sensing device. The card entry positioning sensor, the card detection sensor, the printing area and the tail card sensing device are connected with the control processing module. By means of the hot-erase printer, repeated erasure for card documents can be achieved, so that surface information of the card documents can be changed along with change of cardholder information in time, the card-making time of people and document-making time of the document-makingdepartment are greatly reduced, time and financial loss are saved, growing convenience needs of people are met, and high convenience is brought to the majority of people needing document-making.

Owner:AEROSPACE INFORMATION +1

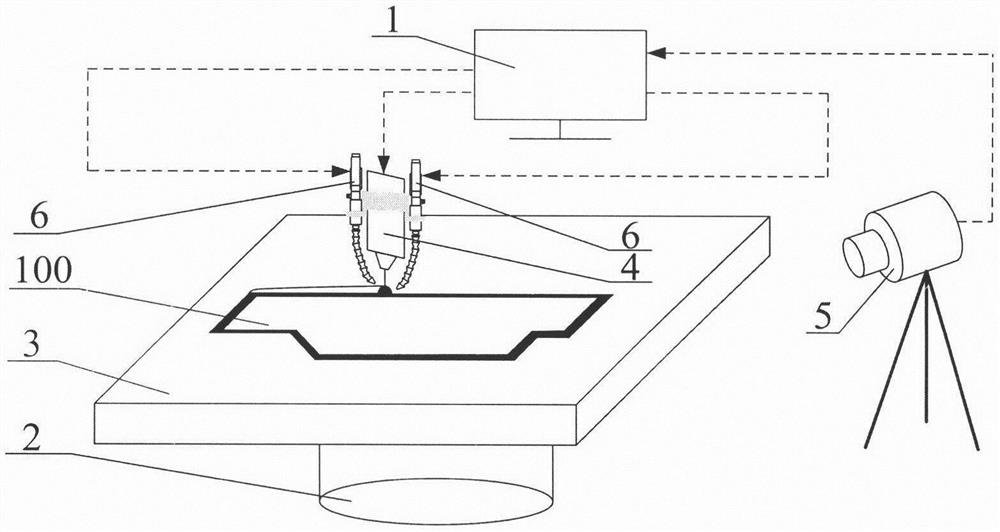

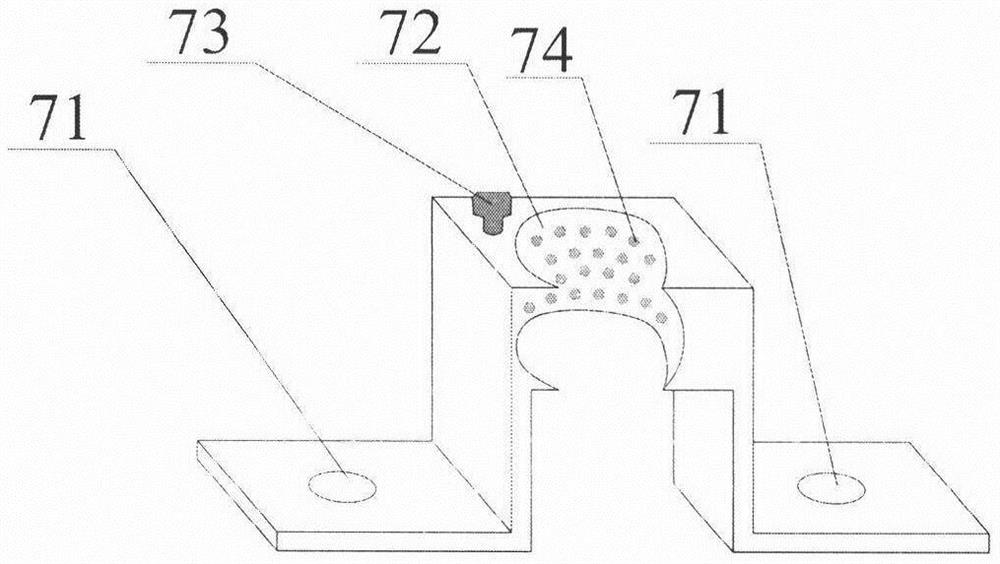

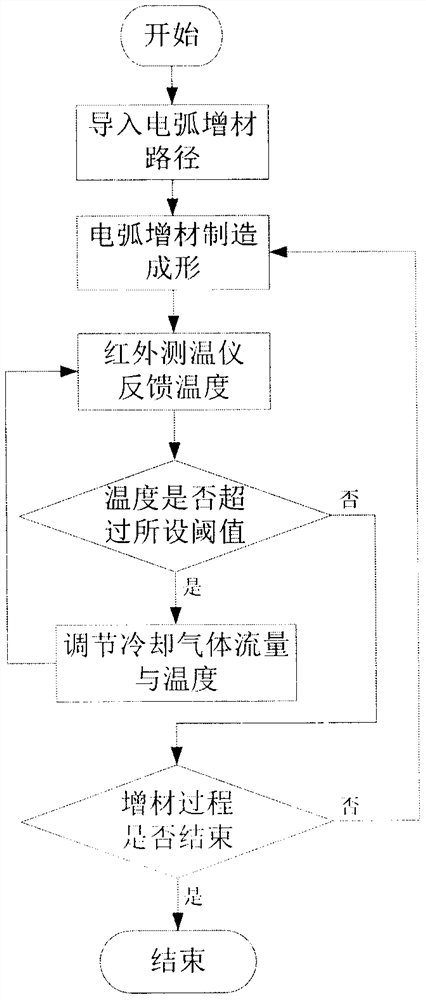

Cooling device and method for variable cross-section structure in electric arc additive manufacturing process

PendingCN113263242AHigh densityIncrease profitAdditive manufacturing apparatusWelding accessoriesComputer control systemCold air

The invention provides a cooling device and method for a variable cross-section structure in an electric arc additive manufacturing process. The cooling device comprises a computer control system, a workbench, a bottom plate, an MIG welding gun, an infrared thermometer, a cold air gun and a clamping assembly, wherein the bottom plate is clamped on the surface of the workbench, the infrared thermometer is arranged on the side of the workbench in a close range, the MIG welding gun is connected with the cold air gun through the clamping assembly, the infrared thermometer monitors and feeds back temperature information in the additive manufacturing process to the computer control system in real time, and the cold air gun adaptively adjusts the flow and temperature of the cooling gas according to the fed-back temperature information so as to eliminate heat accumulation generated in the additive process and improve the additive precision. According to the cooling device and method, the problems of serious heat accumulation and poor forming precision in the electric arc additive manufacturing process are solved, meanwhile, the additive efficiency is guaranteed, and effective control over the forming precision and quality in the electric arc additive manufacturing process of the variable cross-section structural part can be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

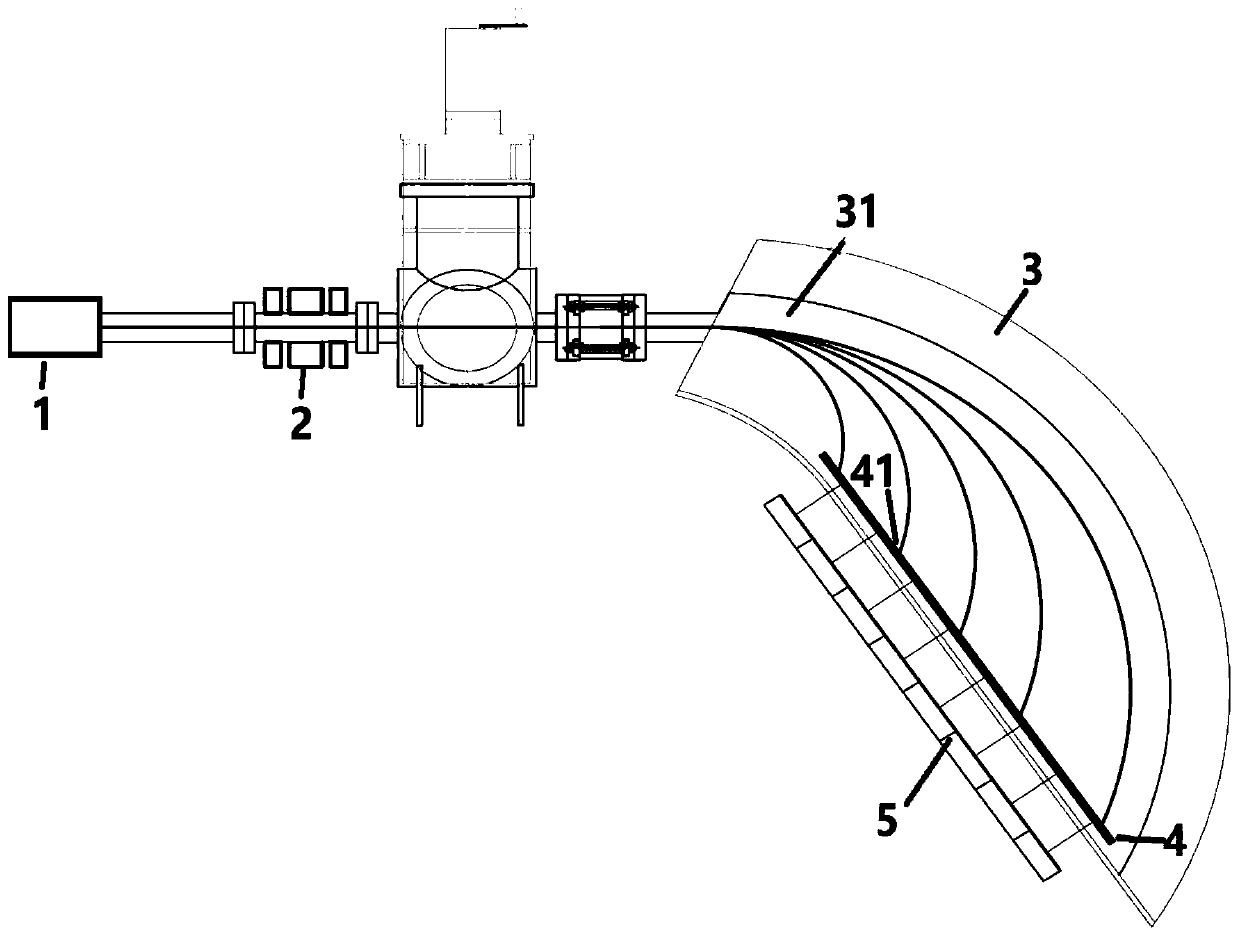

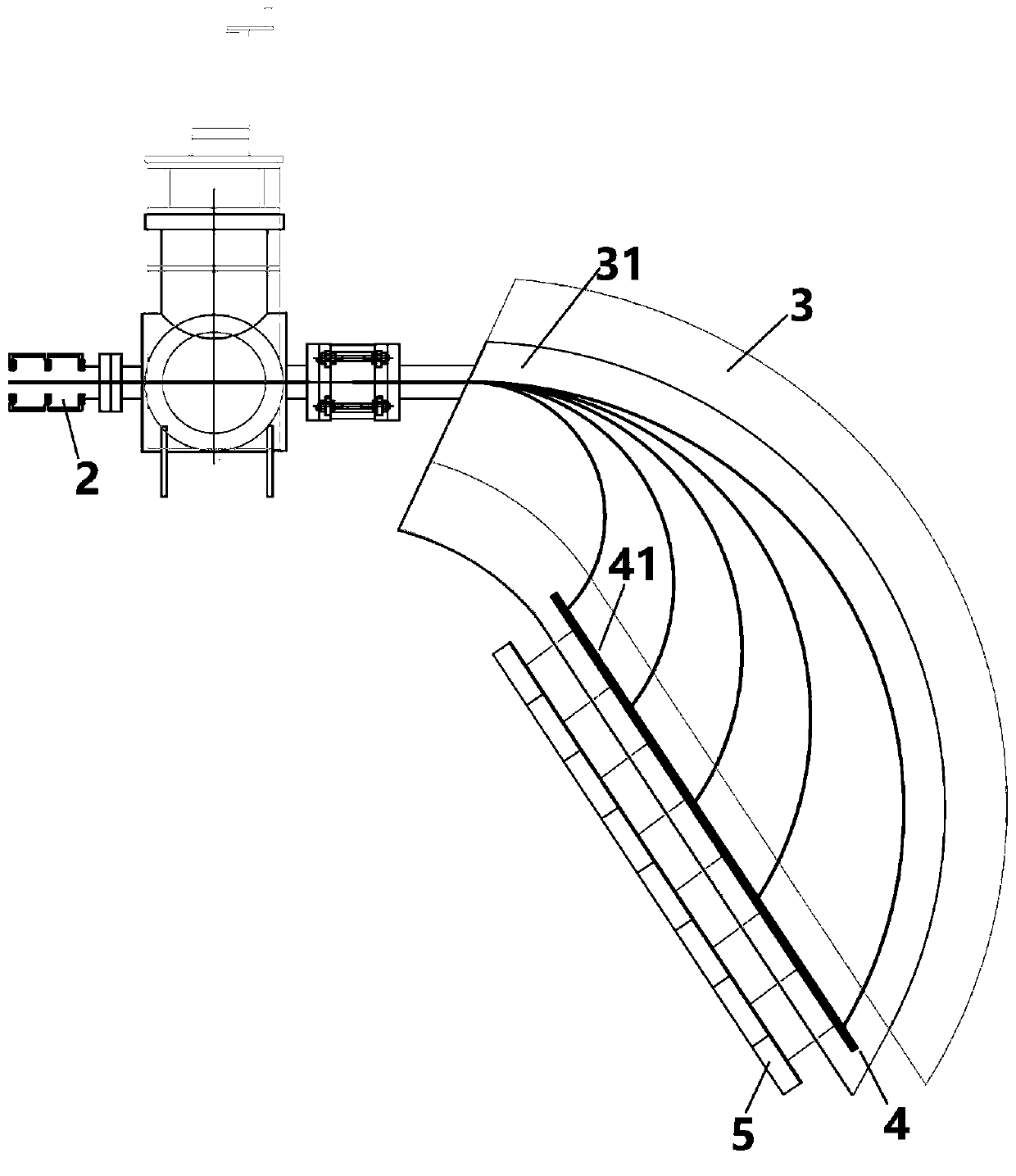

Multi-mass-to-charge-ratio ion beam mass spectrometry device and method

ActiveCN111293031AResolution timeSolution areaStatic spectrometersAccelarator mass spectrometersMass Spectrometry-Mass SpectrometryIon beam

The invention relates to a multi-mass-to-charge-ratio ion beam mass spectrometry device and method. The multi-mass-to-charge-ratio ion beam mass spectrometry device comprises an ion source, a focusingmodule, a magnetic separation module, an acquisition module and a data processing module. The ion source is used for emitting an ion beam comprising ions with multiple mass-to-charge ratios; the focusing module is used for focusing the ion beam; the magnetic separation module is used for separating ions with different mass-to-charge ratios in the focused ion beam along different curvature radiuses according to the magnetic stiffness; the acquisition module is arranged at the ion beam imaging end of the magnetic separation module and is used for receiving the ions with different mass-to-chargeratios corresponding to the curvature radiuses and generating corresponding electric signals; and the data processing module is connected with the acquisition module, and is used for determining thetypes and proportions of ions with different mass-to-charge ratios according to the curvature radius and the electric signals generated by the acquisition module. The device solves the problems that in the prior art, the device is long in distinguishing time, and the application range is narrow due to the fact that the sample component proportion distinguishing capacity is insufficient.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Waxberry wine and brewing method thereof

ActiveCN101544941BEffective preservationEffectively preserve the loss of nutrients such as VC in fruit juiceAlcoholic beverage preparationMicroorganism based processesFruit wineCurative effect

The invention discloses waxberry wine and a brewing method thereof. The wine comprises 50 to 60 percent of waxberry raw wine and 40 to 50 percent of glutinous rice wine juice, and is blended by the waxberry raw wine and the glutinous rice wine juice, wherein the waxberry raw wine is prepared by soaking waxberry fresh fruits into CO2 gas, then crushing and pressing the soaked waxberry fresh fruits, and extracting and fermenting juice. Because the waxberry wine prepared by the method has obviously different flavor and mouth feel compared with yellow wine and fruit wine, the product has unique novelty. The invention solves the technical problems that the waxberry wine is acerbic and has over-high acidity, the mouth feel is inharmonious, the nutrient components are easy to lose, and the like.The product is red, clear and transparent, has intense flavor of the waxberry fruit and mellowness of the glutinous rice wine, has sweet taste and harmonious acidity, is pure, fresh and satisfying, can be drunk as the fruit wine and the yellow wine, has the functions of supplementing substances such as vitamins, amino acid, trace elements and the like for human body, and has function of nourishing curative effect.

Owner:湖南佰诺酒业股份有限公司

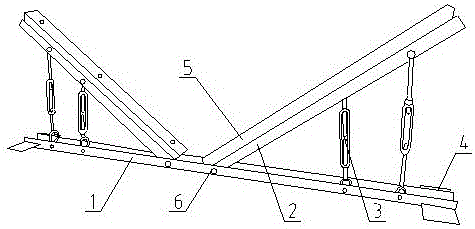

Adjustable lifeboat shelf

InactiveCN105035288AAdjustable widthAdjustable heightWaterborne vesselsExternal framesEngineeringBilateral symmetry

The invention relates to an adjustable lifeboat shelf and belongs to the technical field of ship repairing and manufacturing. The adjustable lifeboat shelf comprises bottom steel channel (1). The bottom steel channel (1) is provided with two inclined steel channels (2) in a bilateral symmetry mode. The lower ends of the inclined steel channels (2) are hinged to the bottom steel channel (1) through pin shafts (6), two cable lock catches (3) are arranged between the back sides of the inclined steel channels (2) and the bottom steel channel (1). Rubber strips (5) are arranged on the front sides of the inclined steel channels (2). The left side and the right side of the end of the bottom steel channel (1) are provided with supporting plates (4). According to the adjustable lifeboat shelf, the width and the height of the shelf can be adjusted. The adjustable lifeboat shelf is suitable for containing lifeboats in various specifications and models, consumption and loss of raw materials are reduced, cost is reduced, and oil paint damage traces of the contact portions of the lifeboats and the shelf are eliminated.

Owner:CHENGXI SHIPYARD

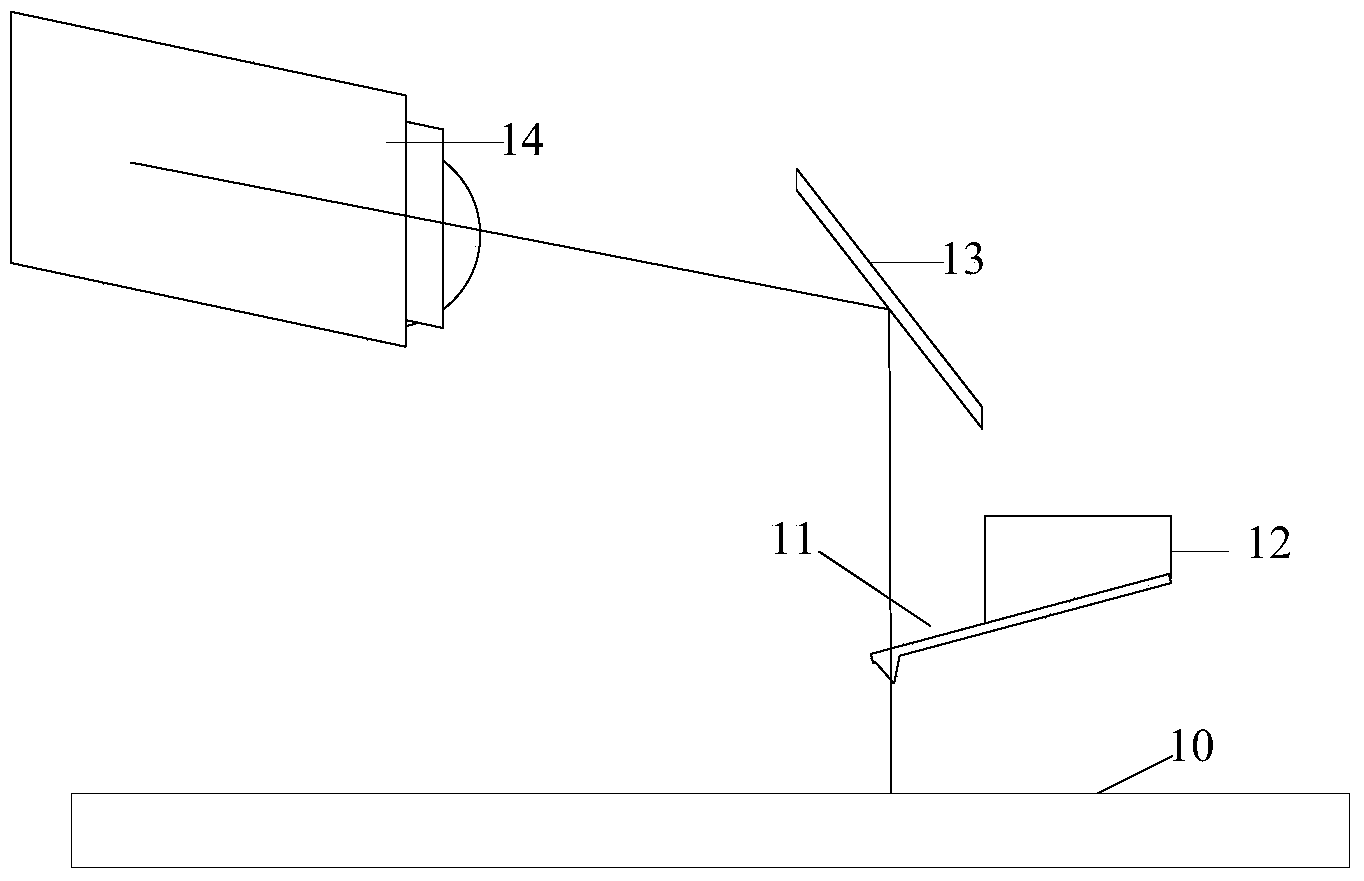

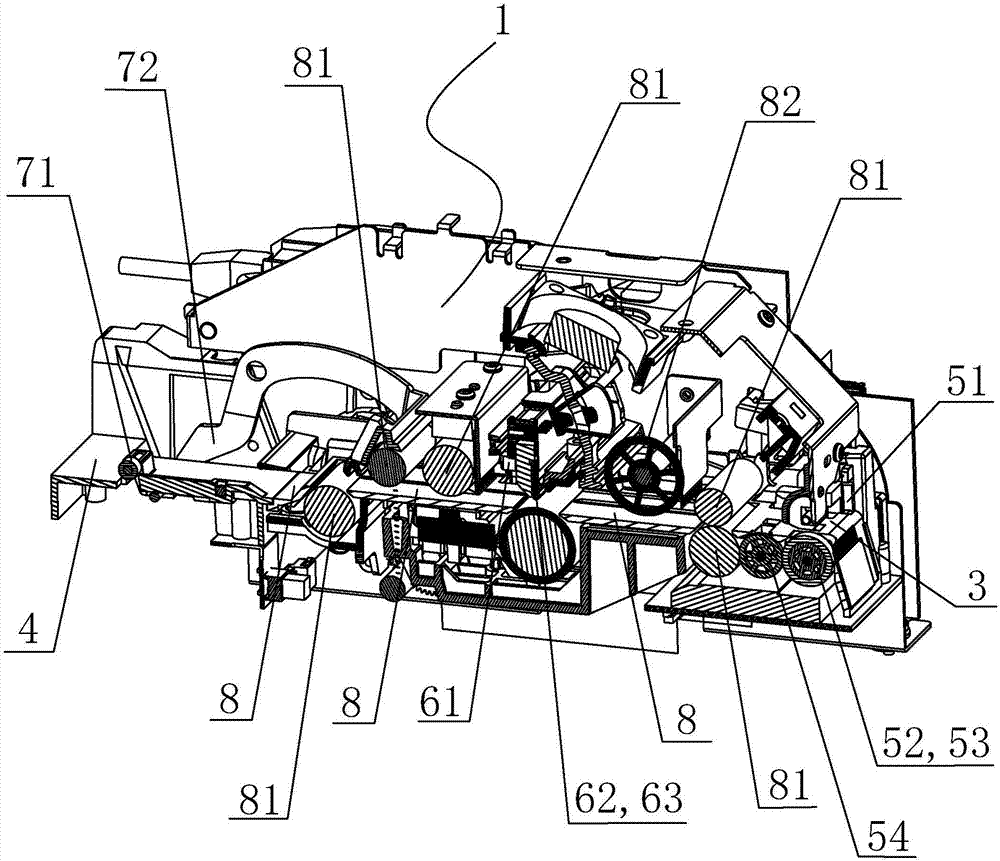

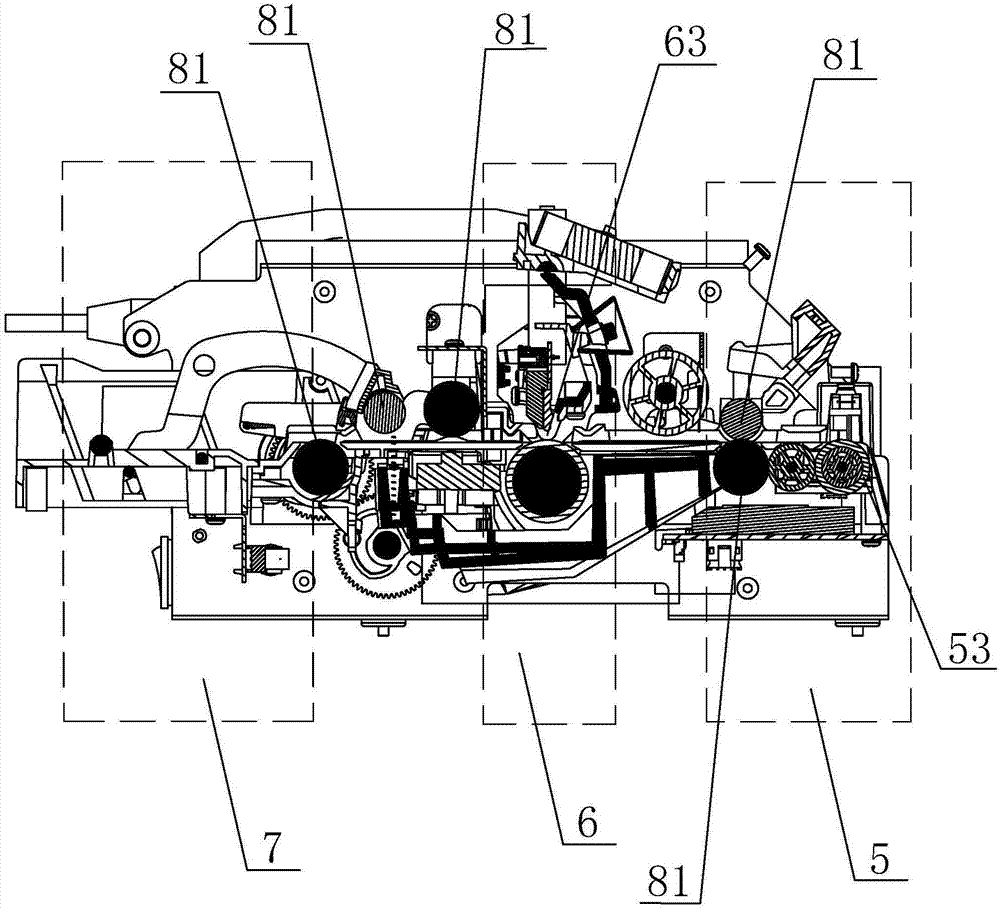

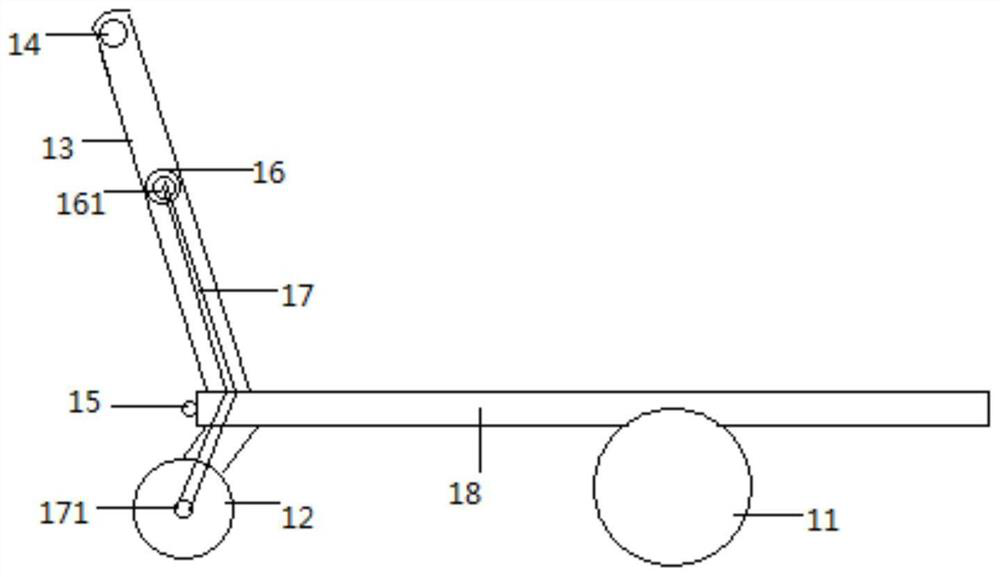

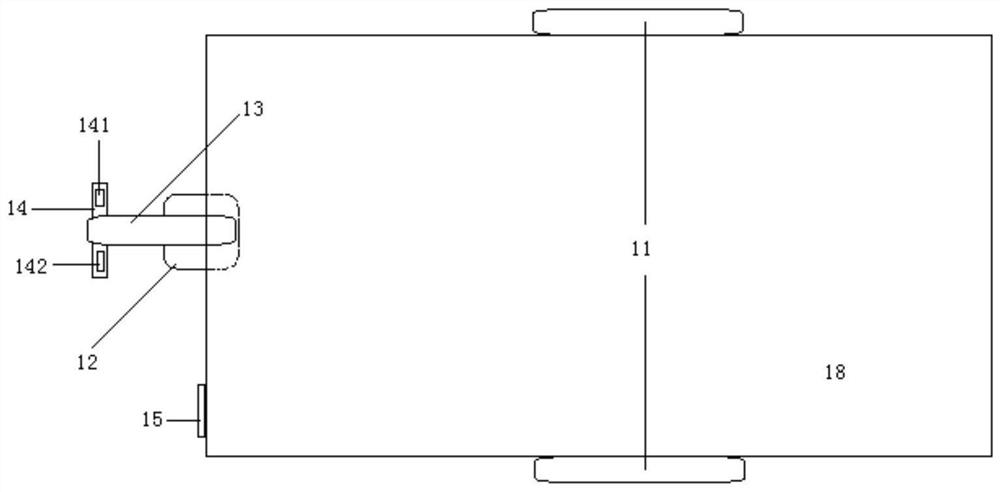

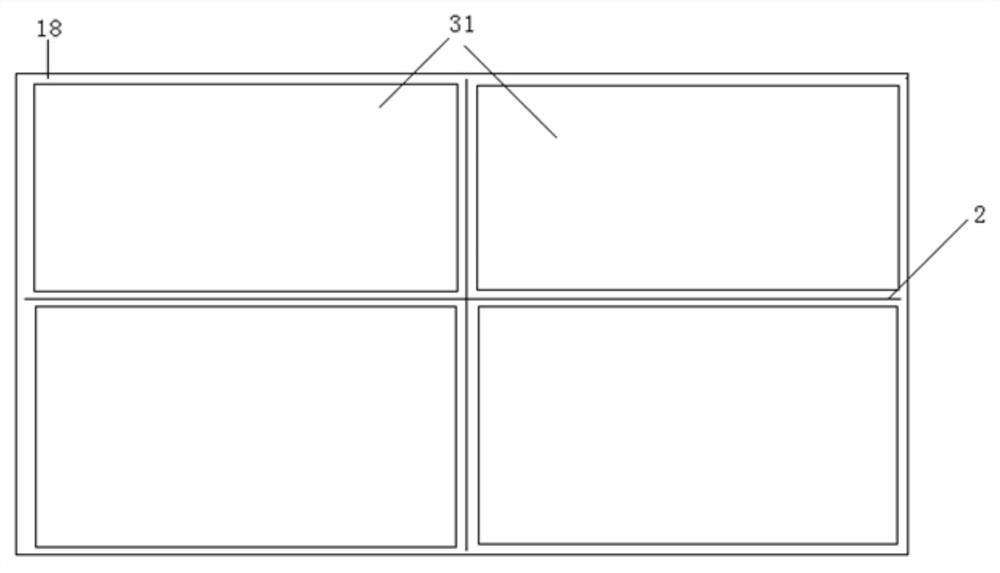

Order picking system and method for electronic commerce

InactiveCN114308682AReduced memorization burdenEase of workSortingElectric machineryStructural engineering

A goods picking system for e-commerce is characterized by comprising a goods picking trolley (1), goods picking partition plates (2), goods picking basket sets (3), an own RF (radio frequency) (4) and a server (5). The picking vehicle comprises rear wheels (11), front wheels (12), a front rod (13), a handle (14), a fixer (15), a motor (16), a toothed chain (17) and a vehicle plate (18); the picking partition plate is composed of two overlapped vertical plates, the picking basket set is composed of a plurality of picking baskets (31), and the RF (4) of the picking basket set is carried by picking personnel. The server (5) is provided with a processor (51), a personnel information memory (52), a commodity information memory (53) and a picking order memory (54). The invention further provides a goods picking method for electronic commerce, and the goods picking method is implemented through the system.

Owner:BINZHOU UNIV

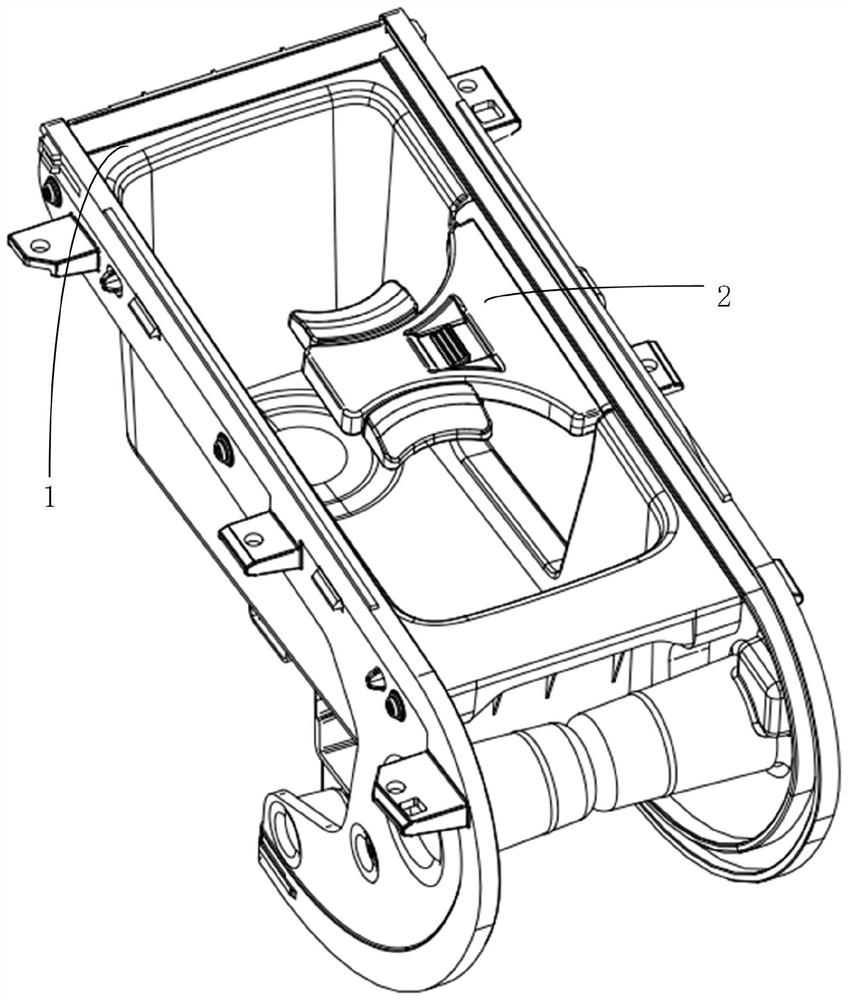

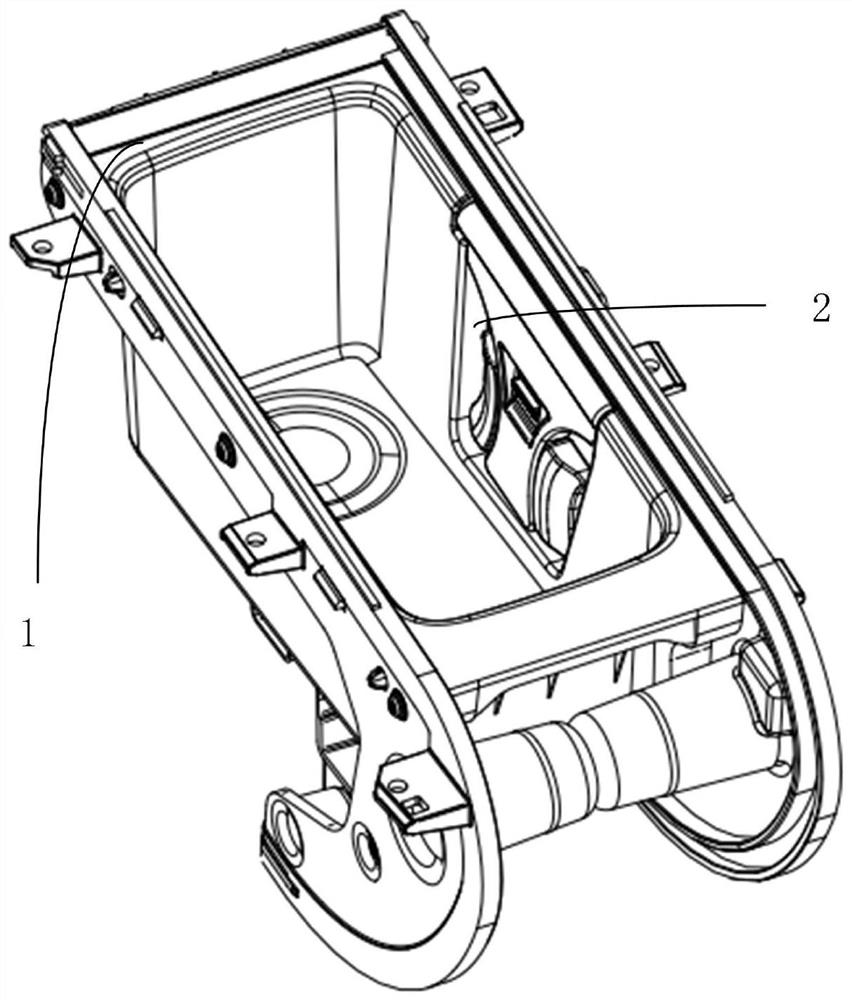

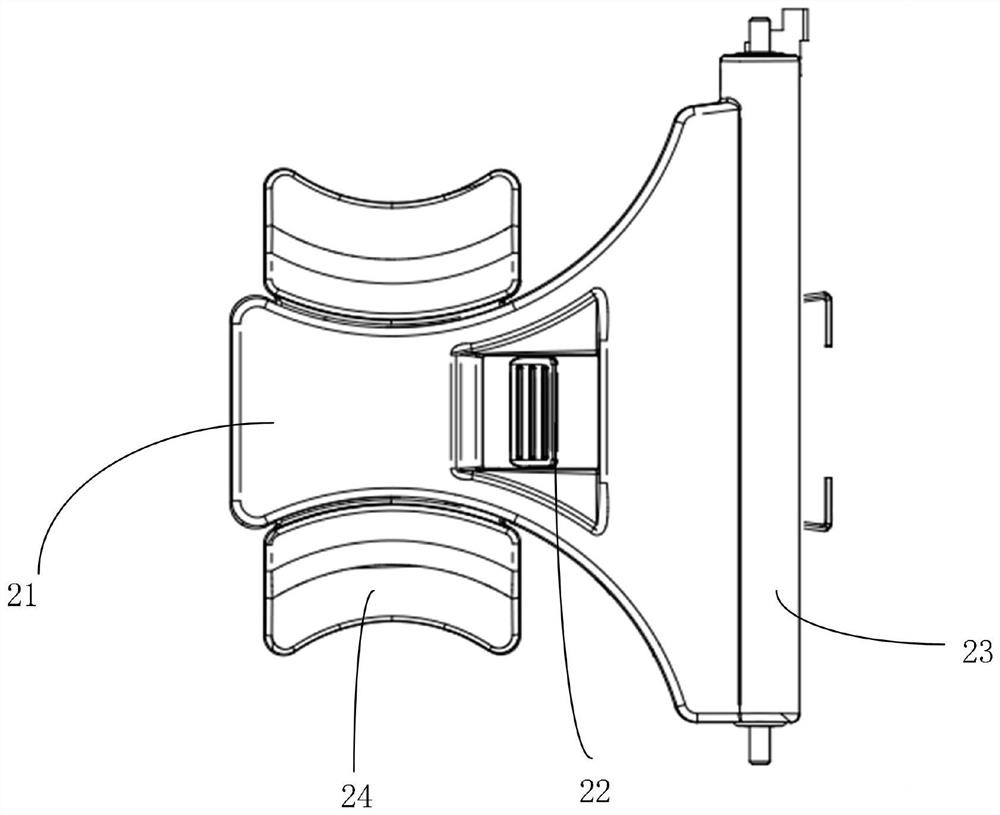

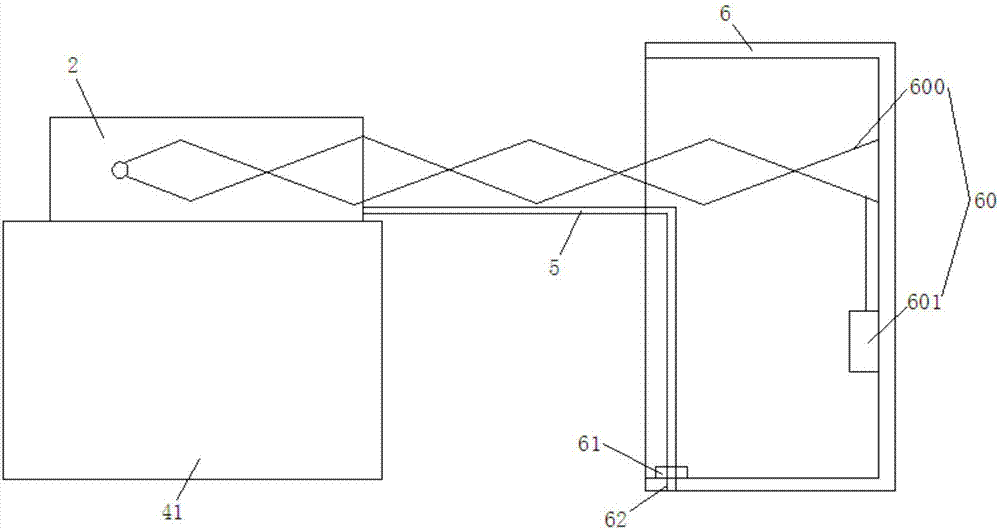

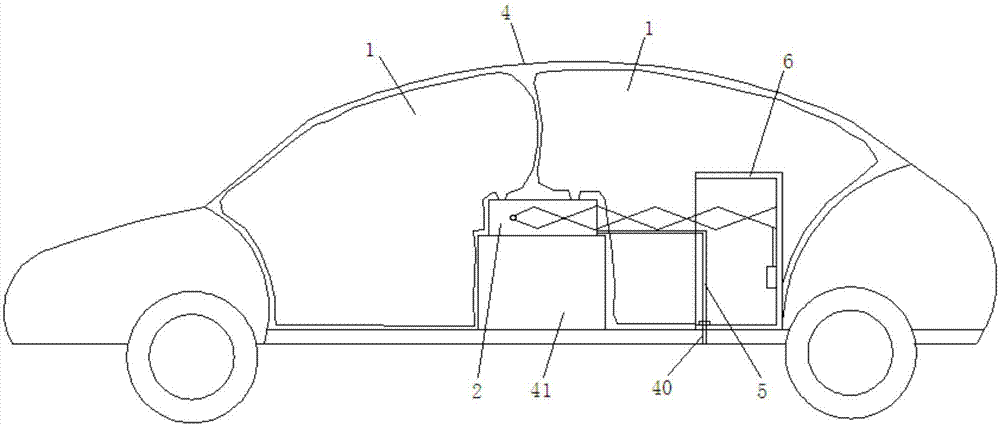

Can hide the cup holder structure and the car

ActiveCN112158115BSave space for other storage boxesSave lossVehicle arrangementsEngineeringMechanical engineering

Owner:DONGFENG VISTEON AUTOMOTIVE TRIM SYST CO LTD

Waxberry fruit vinegar and preparation method thereof

The invention discloses waxberry fruit vinegar and a preparation method thereof. Waxberry fresh fruits as a raw material are prepared into waxberry juice by adopting a CO2 immersion method, the juice is prepared into swort through alcohol fermentation, and the swort is brewed into the waxberry fruit vinegar through the processes such as acetic fermentation, sterilization and the like. A product prepared by the method is red, clear and transparent, has soft and long acid taste, has the peculiar fragrance of waxberry, can be drunk as beverage, has the functions of supplementing substances such as vitamins, amino acid, trace elements and the like for human body, simultaneously has the functions of eliminating fatigue and adjusting immunity of organisms, and is ideal novel health-care beverage.

Owner:武世新

Automobile sun protection air purification device

The invention relates to an automobile sun protection air purification device. The device comprises an inflatable airbag arranged inside a vehicle, an airbag storage container containing the inflatable airbag, a charging and discharging device conducting charging and discharging on the airbag and a remote control device controlling the charging and discharging device to operate; an exhaust pipe communicated with the exterior of the vehicle is arranged on the charging and discharging device; the inflatable airbag is prepared from an ultraviolet-proof material, or an ultraviolet-proof coating is arranged on the surface of the inflatable airbag; when the vehicle parks, a person gets off the vehicle and then controls the charging and discharging device to charge cold air into the vehicle through a remote control device, the interior of the vehicle is made to be filled with the cold air, and then the sun protection effect is achieved; operation is conducted conveniently, the airbag cannot be blown away by the wind, and meanwhile the shading and anti-theft effects are achieved; when the vehicle needs to be used, the charging and discharging device is controlled by the remote control device to discharge hot air in the inflatable airbag, the hot air is discharged to the exterior of the vehicle from the drain pipe, use is convenient, and meanwhile the internal air is subjected to replacement and purification one time, energy consumption is saved, and the waiting time is shortened.

Owner:深圳市明思洁科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com