Pluggable oil-layer anti-leakage valve

A plug-in, oil layer technology, applied in wellbore/well valve devices, wellbore/well components, sealing/packaging, etc. The effect of improving work efficiency, saving work time, and simplifying work procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

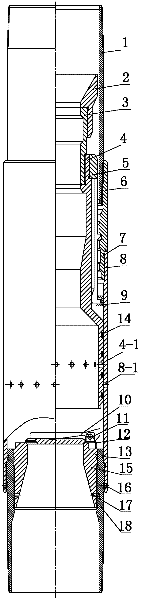

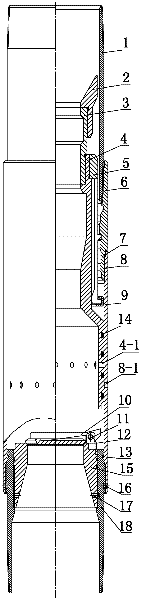

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0014] see figure 1 , a pluggable oil layer anti-leakage valve, including an upper joint 1, a switch sleeve 4, an outer sleeve 8, a plate valve and a lower joint 18 parts, the upper joint is threaded to the outer sleeve 8 through an intermediate joint 6, and one end of the outer sleeve is threaded and tightened The firmware 16 is connected to the lower joint, and an O-shaped rubber sealing ring 13 is arranged between the outer casing and the lower joint. The upper joint is provided with an upper guide head 2 and an elastic claw seat 3 threaded therewith, and the inner upper opening of the upper guide head 2 is a tapered mouth. One end of the locking claw seat is provided with a switch sleeve 4 with a pressure balance hole 4-1 on its circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com