Maintenance free long life electrolysis anti-soil apparatus

A long-life, maintenance-free technology, used in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of inability to eliminate the influence of Mn, difficult process control, and high price. The effect of saving material loss and human resources, good prospects for use and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

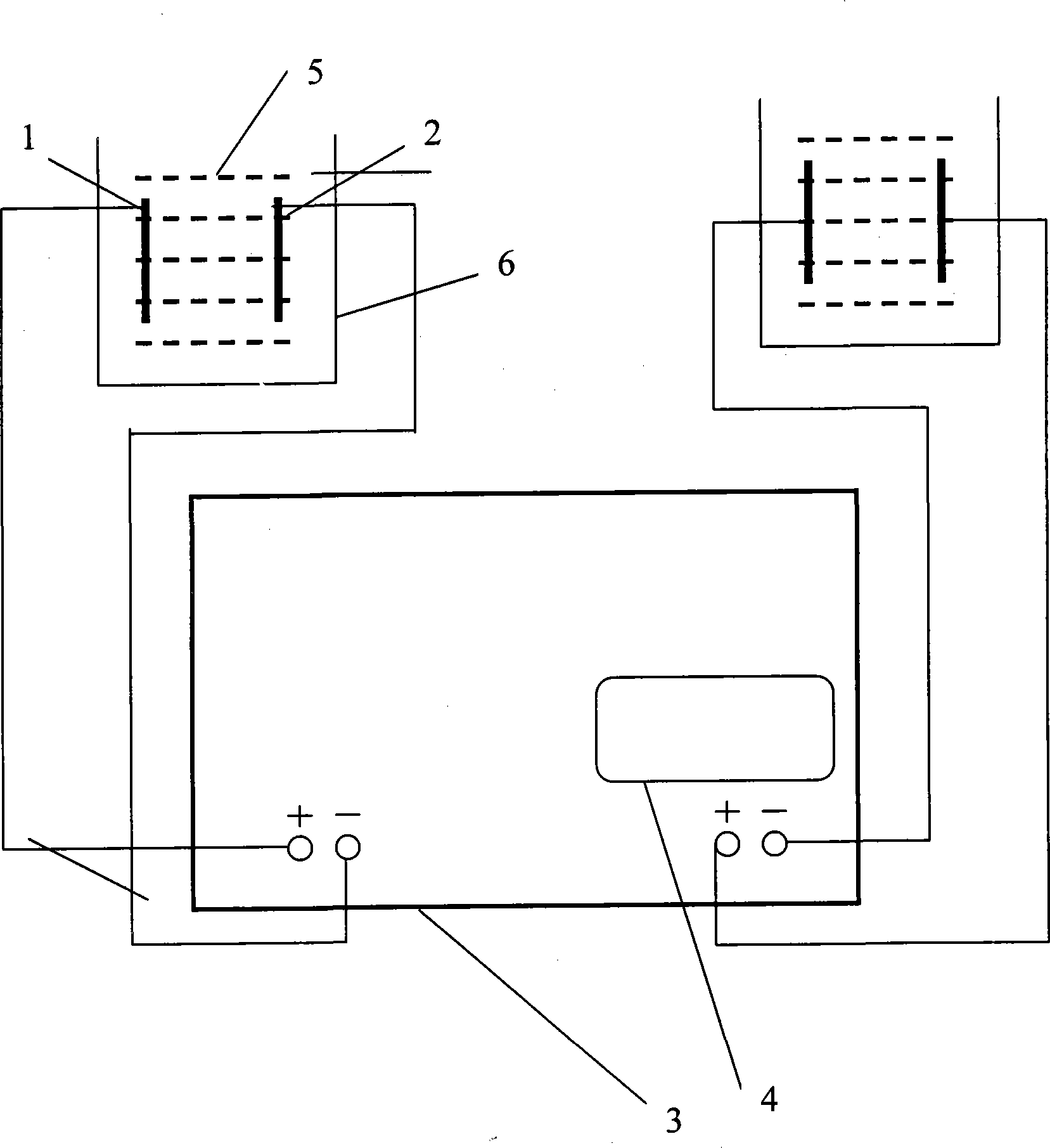

[0014] The device designed in this embodiment uses a small reverse current to be applied to the electrolytic cell regularly to remove scale and achieve the goal of maintenance-free. The main body of the device includes a reversible DC electrolysis power supply 3 and a long-life oxide electrolysis anode 1 that produces antifouling agents. , a nickel alloy cathode 2 that conducts current, an adjustable time relay 4, an electrolytic cell shell 6 and a connecting cable; wherein the DC electrolytic power supply 3 outputs current in different directions, and the parameters such as the time and magnitude of the output current can be set by the panel or computer program; The electrolytic anode 1 that produces the antifouling agent is metal platinum coating or mixed metal oxide coating, which will not significantly reduce the current efficiency after electrolysis in various seawater environments for more than 30 days; the cathode that conducts current is made of flat and smooth Hastelloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com