Method for high selectively extracting Artemisia vulgaris essential oil

A high-selectivity, extraction technology, applied in essential oils/fragrances, fat production, etc., can solve the problems of extract aroma loss, large amount of solvent consumption, large consumption of organic solvents, etc., without destroying product activity and improving solubility , The effect of improving the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Drawing of the standard curve of Artemisia argyi essential oil

[0030] Preparation of standard curve: Accurately weigh the essential oil of Artemisia argyi extracted by steam distillation and dilute it with n-hexane to a concentration of 0.015 mg / mL as a stock solution for later use. Precisely draw 1.0, 1.5, 2.0, 2.5, 3.0 mL of the stock solution into a 10 mL volumetric flask and dilute to the mark, perform wavelength scanning in the range of 200-400 nm, and record the absorbance at the maximum absorption wavelength, taking the absorbance A as the ordinate , the star anise essential oil concentration c (mg / mL) is the abscissa to draw the standard curve ( figure 2 ). And fit the regression equation:

[0031] y =149.6 x +0.049 (1)

[0032] Correlation coefficient: R 2 = 0.9875

[0033] Linear range: 0.0015-0.0045 mg / mL

[0034] Calculation of the purity of the essential oil: Accurately absorb 0.001 g of the northern Artemisia argyi essential oil extrac...

Embodiment 2

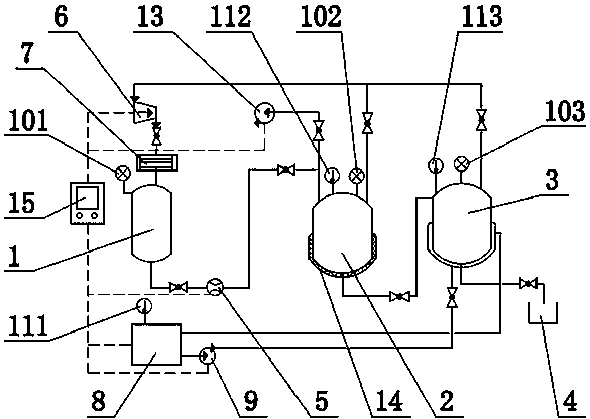

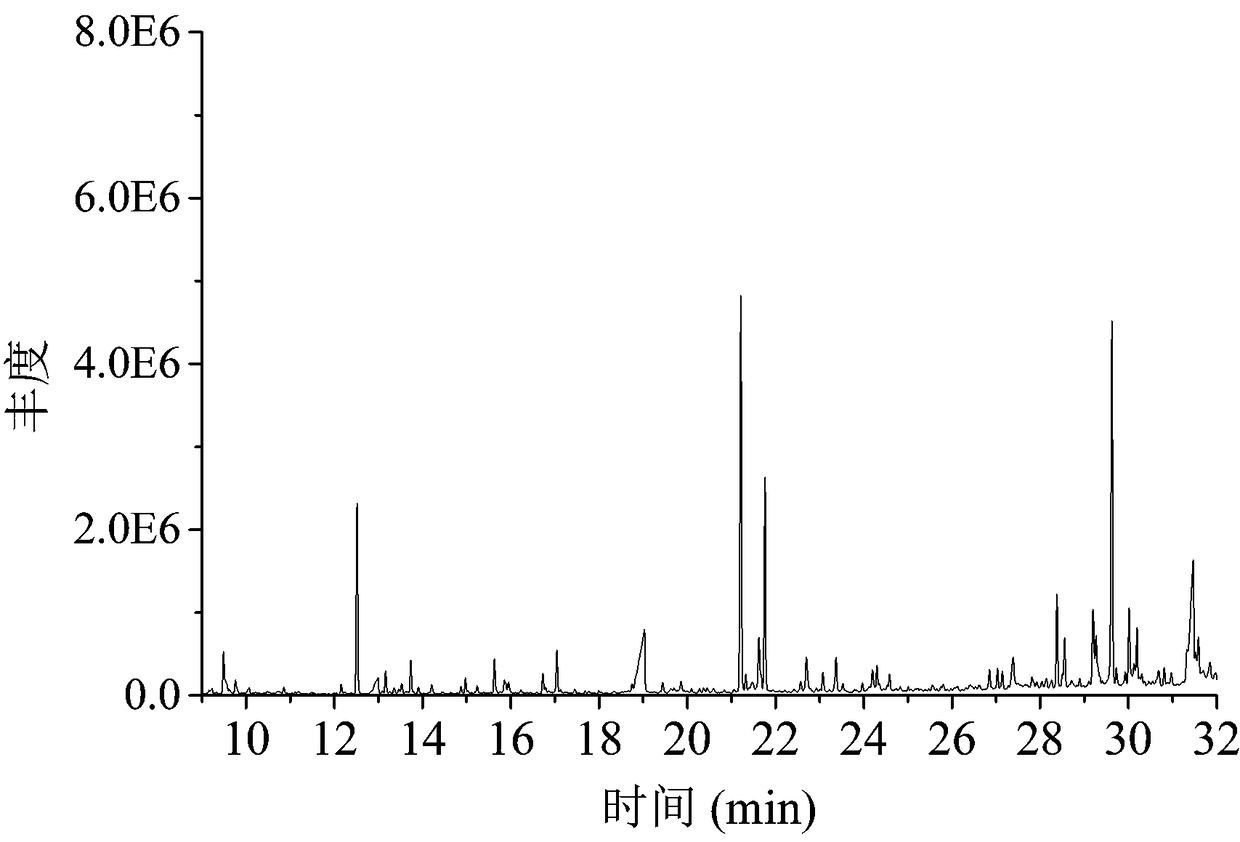

[0037] Example 2 Traditional subcritical butane extraction of Artemisia argyi essential oil

[0038] Grind and pass through a 40-mesh sieve with a water content of less than 8%. Take 100 g and place it in an extraction tank. Vacuumize until the vacuum in the extraction tank reaches -100 kPa. Inject subcritical butane for extraction into the extraction tank. As the extraction solvent, the Artemisia argyi sample was completely submerged, the mass volume ratio of Artemisia argyi and butane was 1:10 g / ml, the extraction temperature was controlled at 30°C by an automatic controller and thermal circulating water, the extraction pressure was 0.3 Mpa, and the extraction time was 30 minutes, 3 times of circular extraction; after the extraction, the liquid solvent is pumped into the evaporation tank, and the mugwort leaf residue and the liquid solvent are subjected to constant temperature and reduced pressure precipitating treatment respectively. The precipitating temperature is 30°C. G...

Embodiment 3

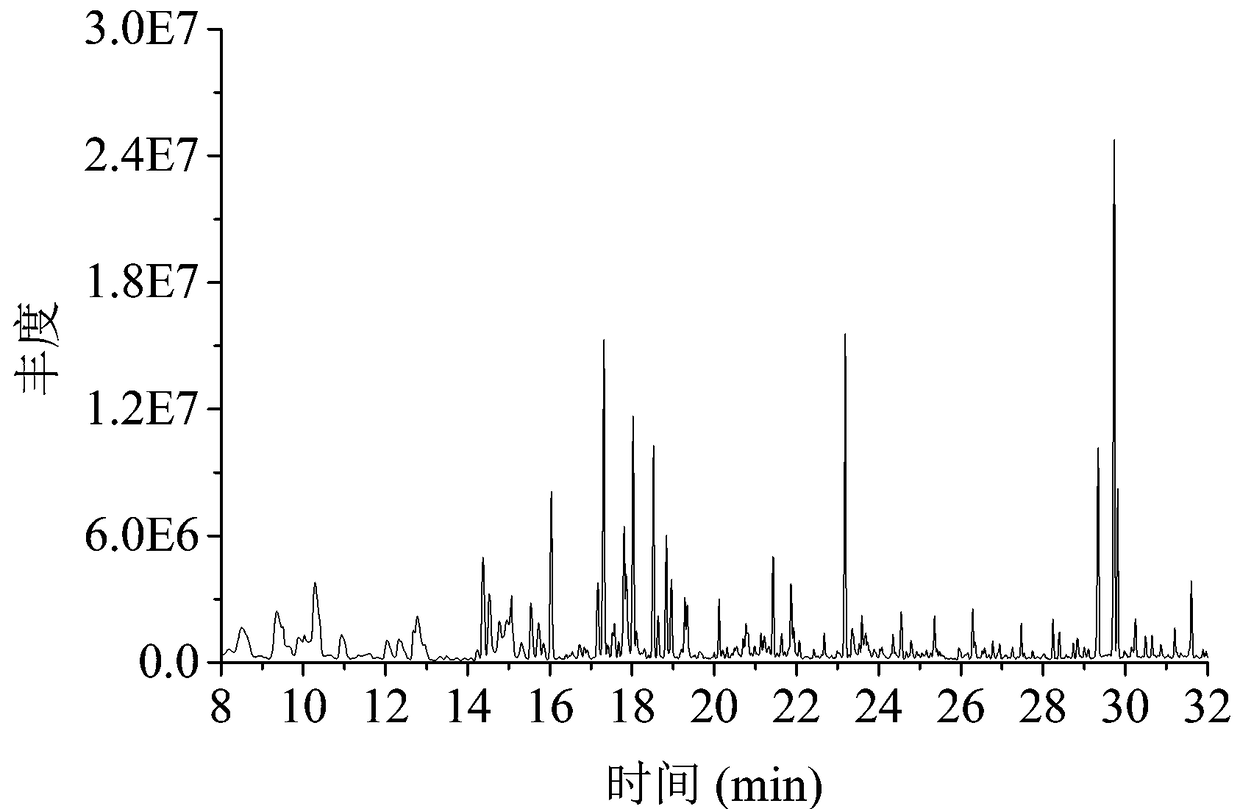

[0041] Embodiment 3 The method used in the present invention extracts Artemisia argyi essential oil

[0042] Grind and pass through a 40-mesh sieve with a water content of less than 8%. Take 100 g and place it in an extraction tank. Vacuumize until the vacuum in the extraction tank reaches -100 kPa. Inject subcritical butane for extraction into the extraction tank. As the extraction solvent, the Artemisia argyi sample was completely submerged, the mass volume ratio of Artemisia argyi and butane was 1:10 g / ml, and the entrainer for extraction was [C 4 C 10 im] CF 3 SO 3 The ionic liquid is 5g, the extraction temperature is controlled by the automatic controller and the far-infrared generator at the bottom of the extraction tank at 30°C, the far-infrared power is 800 W, the wavelength range is 25-200 μm, the extraction pressure is 0.3 Mpa, and the extraction time is 8 minutes. Circulate the extraction twice; after the extraction, the liquid solvent is pumped into the evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com