Hot-erase printer and working control method thereof

A printer and print head technology, applied in printing devices, printing, etc., can solve the problems of failing to meet the convenience needs of the masses, not being able to update surface information in time, and large-scale certification equipment, so as to meet the needs of convenience and reduce the number of card applications time, high human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

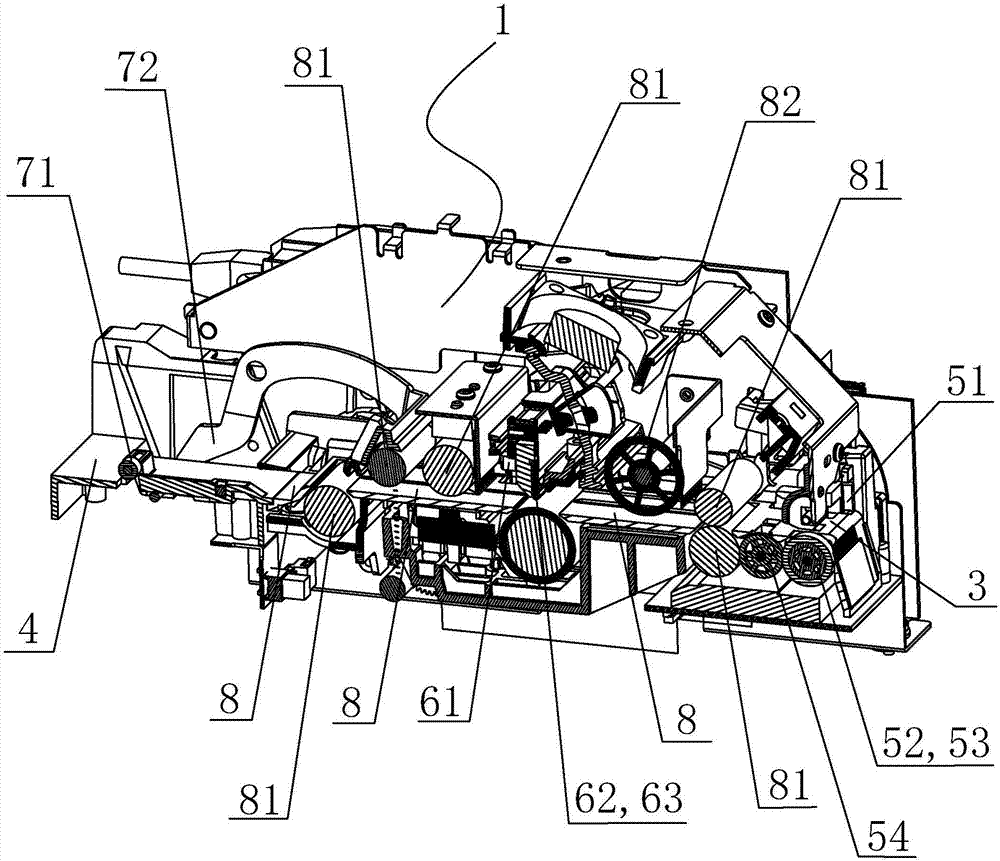

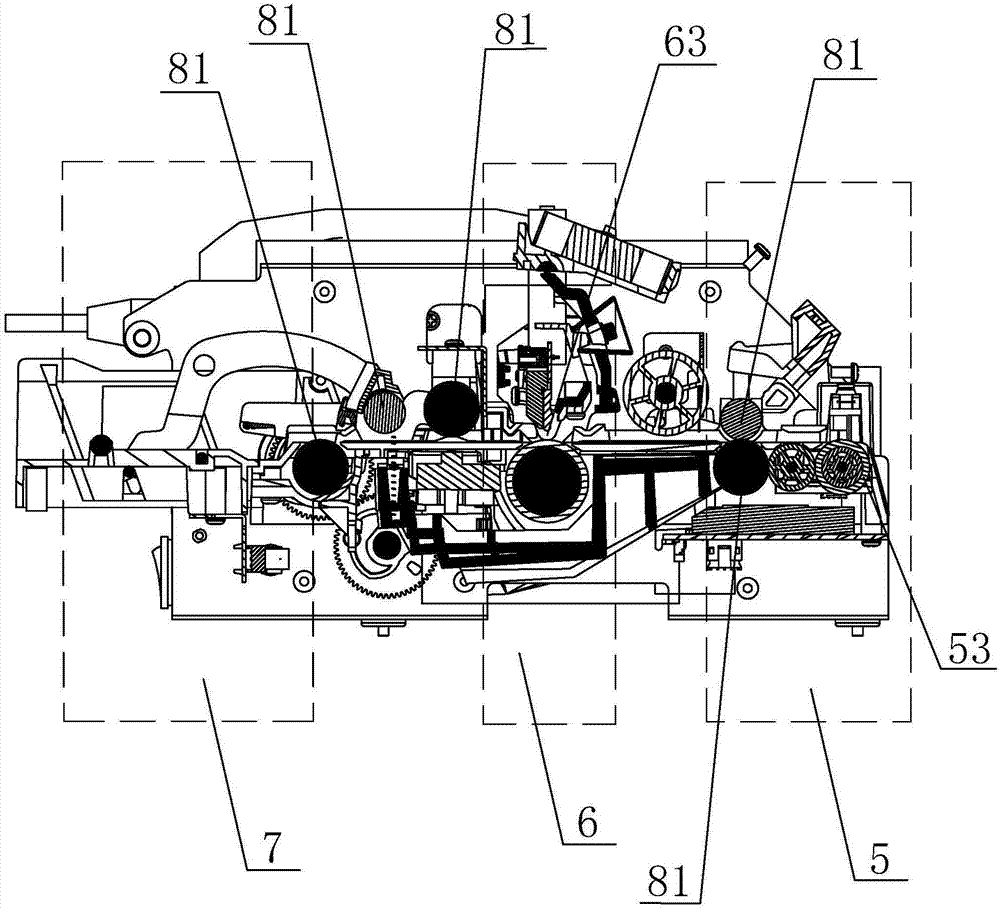

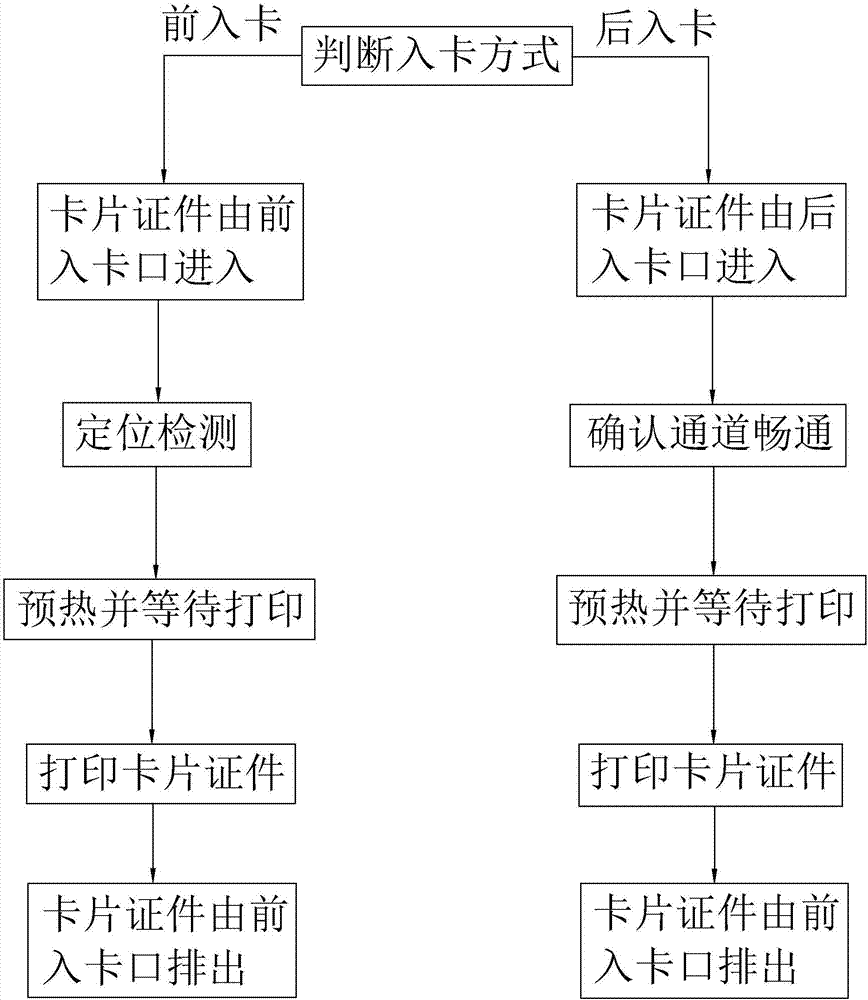

[0061] refer to figure 1 - image 3 , when the card certificate is inserted into the thermal rewritable printer from the front entry bay 3, the card entry positioning sensor 51 detects the card certificate, the control processing module controls the rear card blocking part 72 to lift, and starts the card entry transmission mechanism 52 to The card certificate is transported into the printer main body 1. When the card certificate is transported to the printing area 6 in the card feeding channel 8 and detected by the card detection sensor 61, it is confirmed that there is no missing card certificate inside the thermal rewritable printer. At this time, The card certificate is reversely transported back to the positioning area 5 to prepare for the formal printing process. Then, the card certificate is transported through the printing area 6 for preheating, and then enters the to-be-printed area 7 to wait for printing, and then the card certificate passes through the printing area ...

Embodiment 2

[0063] refer to figure 1 - image 3, when the card certificate enters the thermal rewritable printer from the rear card slot 4, the tail card sensing device 71 detects the card certificate, the control processing module controls the tail card stopper 72 to lower, and controls the card feeding transmission mechanism 52 to not work , the card certificate is transported into the main body of the printer 1 under the action of the transmission roller 81, when the card certificate passes the printing area 6 in the card feeding channel 8 and is detected by the card detection sensor 61, it shows that there is nothing missing inside the thermal rewritable printer For card certificates, at this time, the control processing module controls the tail stopper 72 to lift up, and then the card certificates are preheated through the printing area 6 again and enter the area to be printed 7 to wait for printing. Under the action of the transmission roller 81, the card certificates pass through t...

Embodiment 3

[0065] refer to figure 1 - image 3 , when the card certificate is simultaneously entered into the thermal rewritable printer from the front bayonet 3 and the rear bayonet 4, the card entry positioning sensor 51 and the tail card sensing device 71 detect the card certificate at the same time, because the card entry positioning sensor 51 The detection of the tail card is prior to the detection of the tail card sensor device 71, so the control processing module controls the tail block 72 to lift up to prevent the card certificate from entering the thermal rewritable printer from the back-entry bayonet 4, and firstly execute the front-entry card mode After the printing process of the current card entry method is completed, the control processing module stops the work of the card entry transmission mechanism 52, and lowers the tail stopper 72, so that the card certificate can enter the thermal rewritable printer from the rear entry bay 4 , and then execute the printing process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com