Bubbling fluidized bed type O2/H20 pressurized oxygen-enriched combustion system

A bubbling fluidized bed, oxygen-enriched combustion technology, applied in fluidized bed combustion equipment, fuels burned in a molten state, combustion methods, etc., can solve the problem of large amount of flue gas recirculation, poor economy, and large energy consumption and other problems, to achieve the effect of reducing fan energy consumption, reducing compression energy consumption and pressure drop loss, and reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

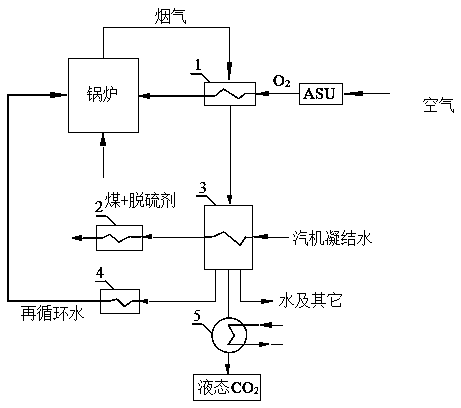

[0012] The invention provides a kind of: bubbling fluidized bed type O 2 / H 2 O supercharged oxygen-enriched combustion system, combined with the following figure 1 The present invention will be further described with specific embodiments.

[0013] A bubbling fluidized bed type O 2 / H 2 O pressurized oxygen-enriched combustion system, its special feature is that it includes fluidized bed, evaporation heating surface, reheater, superheater, steam turbine generator set, waste heat boiler, condenser, condensate pump, low pressure heater, Working fluid recirculation system composed of high-pressure heater, deaerator and feed water pump. The evaporation heating surface, reheater and superheater are arranged in the fluidized bed furnace; Flowing through the high-pressure heater, waste heat boiler, and evaporation heating surface to absorb heat to obtain saturated steam, then heated by the heater to become superheated steam at 550-600°C, the superheated steam enters the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com