Cold-rolling emulsion and preparation method thereof

An emulsion and emulsifier technology, applied in the petroleum industry, lubricating composition and other directions, can solve the problem of high production cost, save energy and loss, have good annealing and cleaning performance, and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

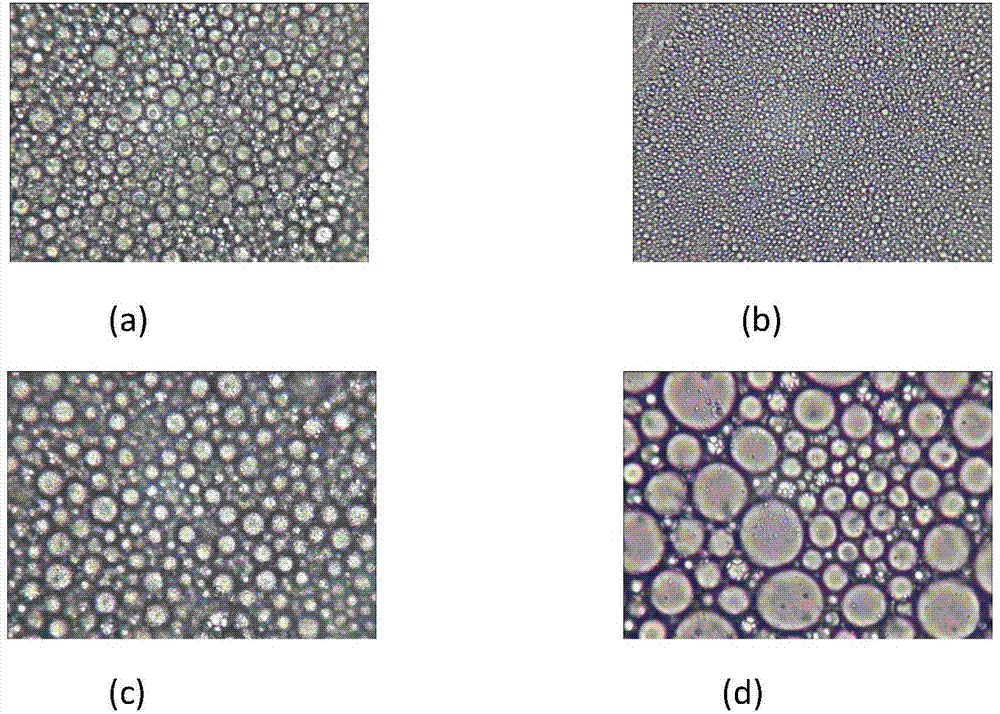

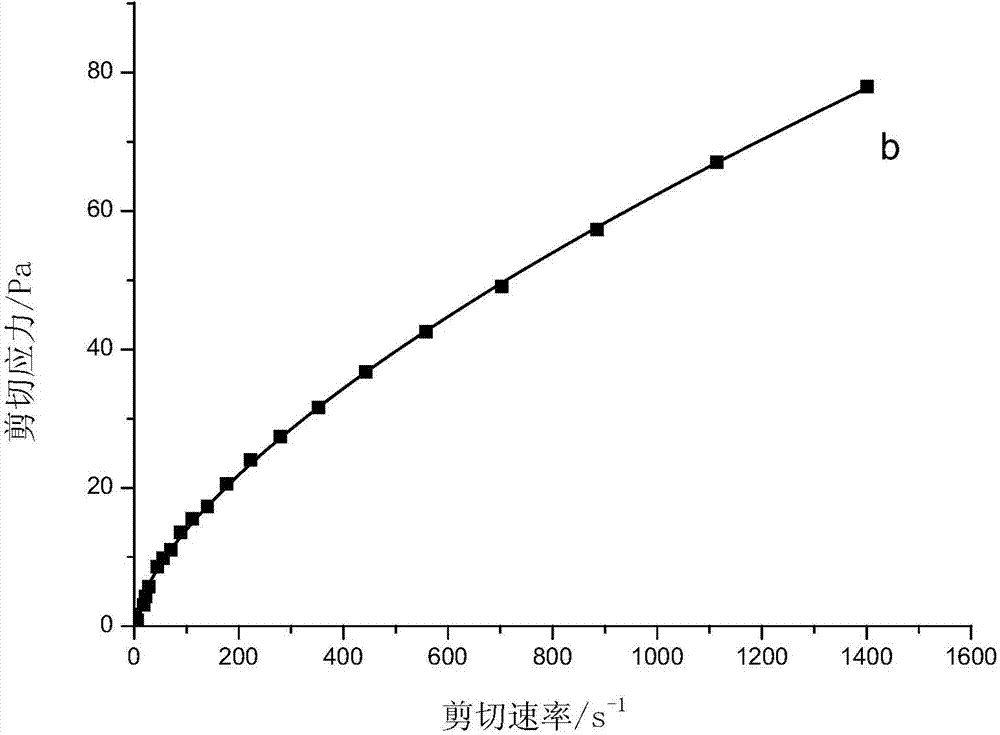

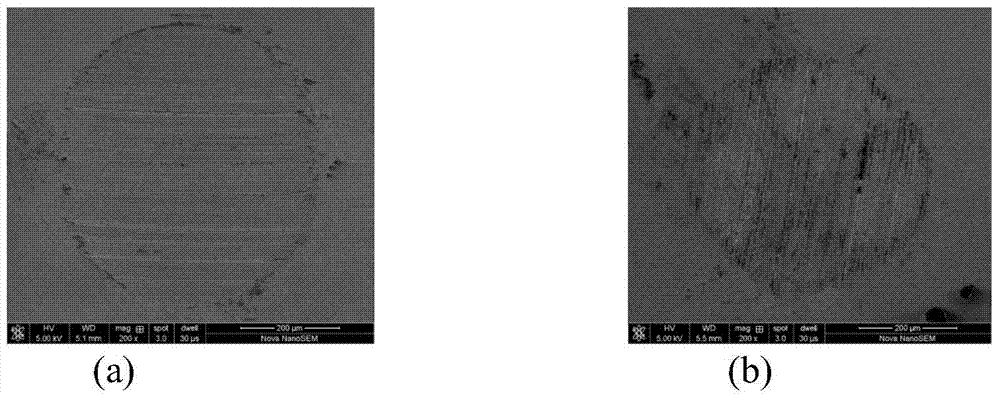

Image

Examples

Embodiment Construction

[0031] The preparation method of cold rolling emulsion of the present invention mainly comprises the steps:

[0032] (1) Dissolving the emulsifier in the regenerated lubricating oil to obtain an oil phase;

[0033] (2) Dissolving other surfactants such as bactericides in water to obtain an aqueous phase;

[0034] (3) Fully mix the oil phase and the water phase (for example, at a stirring speed of 500-900 rpm) with a mass ratio of X:(100-X) (mixing time is 60-120 minutes, preferably 100 minutes) to A cold rolling emulsion is obtained, wherein X is between 48-60, preferably between 52-54.

[0035] The raw material oil used in the present invention comes from the waste lubricating oil produced by Baosteel’s cold rolling process. Since the waste lubricating oil contains impurities such as metal and oil sludge, it must undergo a series of physical and chemical removal of impurities, and then be obtained by molecular distillation. Regenerated lubricating oil with the physical para...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| liquidity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com