3D (Three-Dimensional) printing subtask scheduling method and device

A printing task and task scheduling technology, applied in the field of 3D printing, can solve problems such as powerlessness, and achieve the effect of saving materials and printing complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and examples.

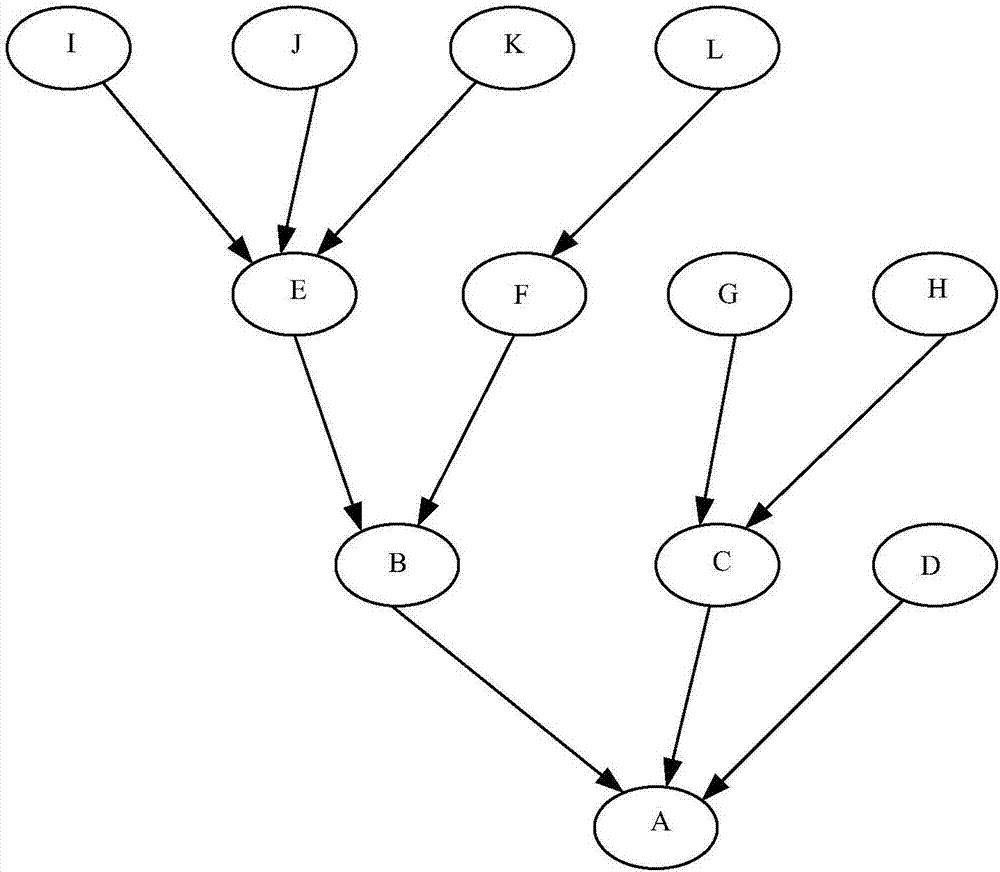

[0021] A complex product is often composed of different components, and the material of each component is special, requiring a specific 3D printer to produce; and there are often complex dependencies between these components, for example, the printing of a certain component requires another 3D printer. It can only be carried out when one or a group of components has been completed.

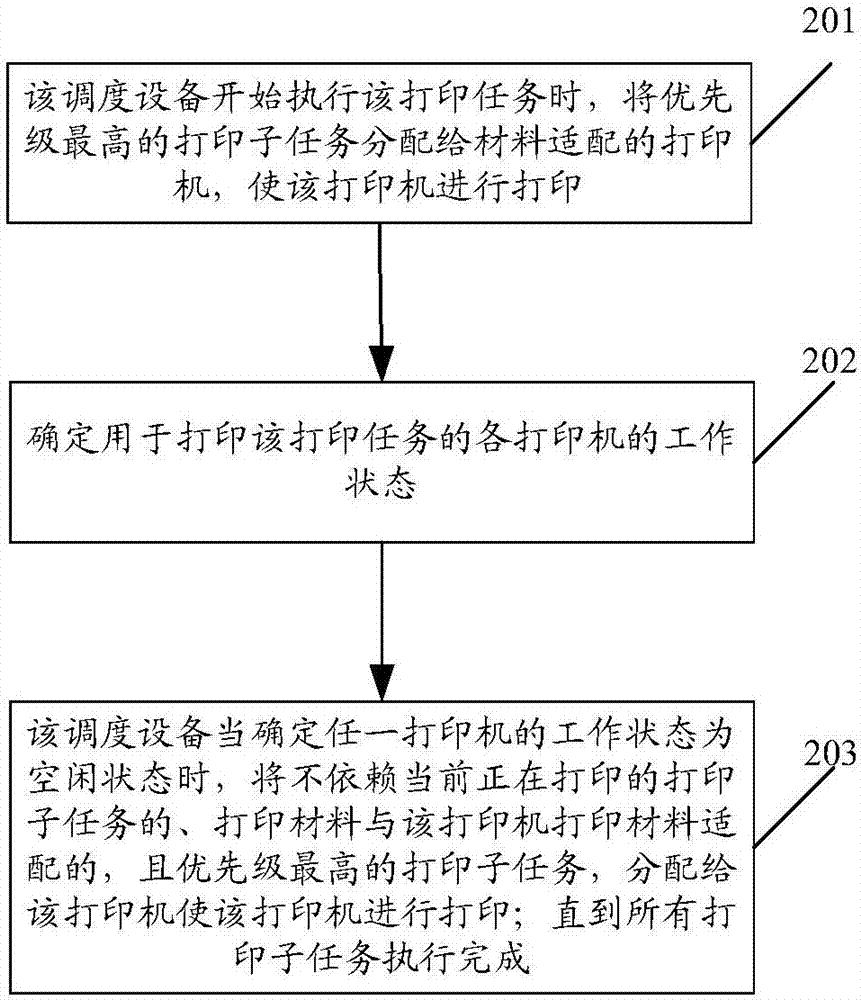

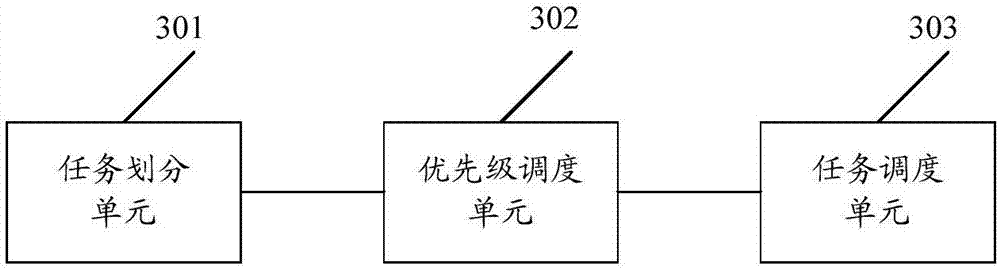

[0022] This involves a set of different 3D printers and a set of different 3D printing subtasks, forming a scheduling problem for 3D printing subtasks. How to schedule 3D printing sub-tasks, so that different printers can effectively cooperate to print a complex product composed of different components and different materials, and greatly save materials, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com