Patents

Literature

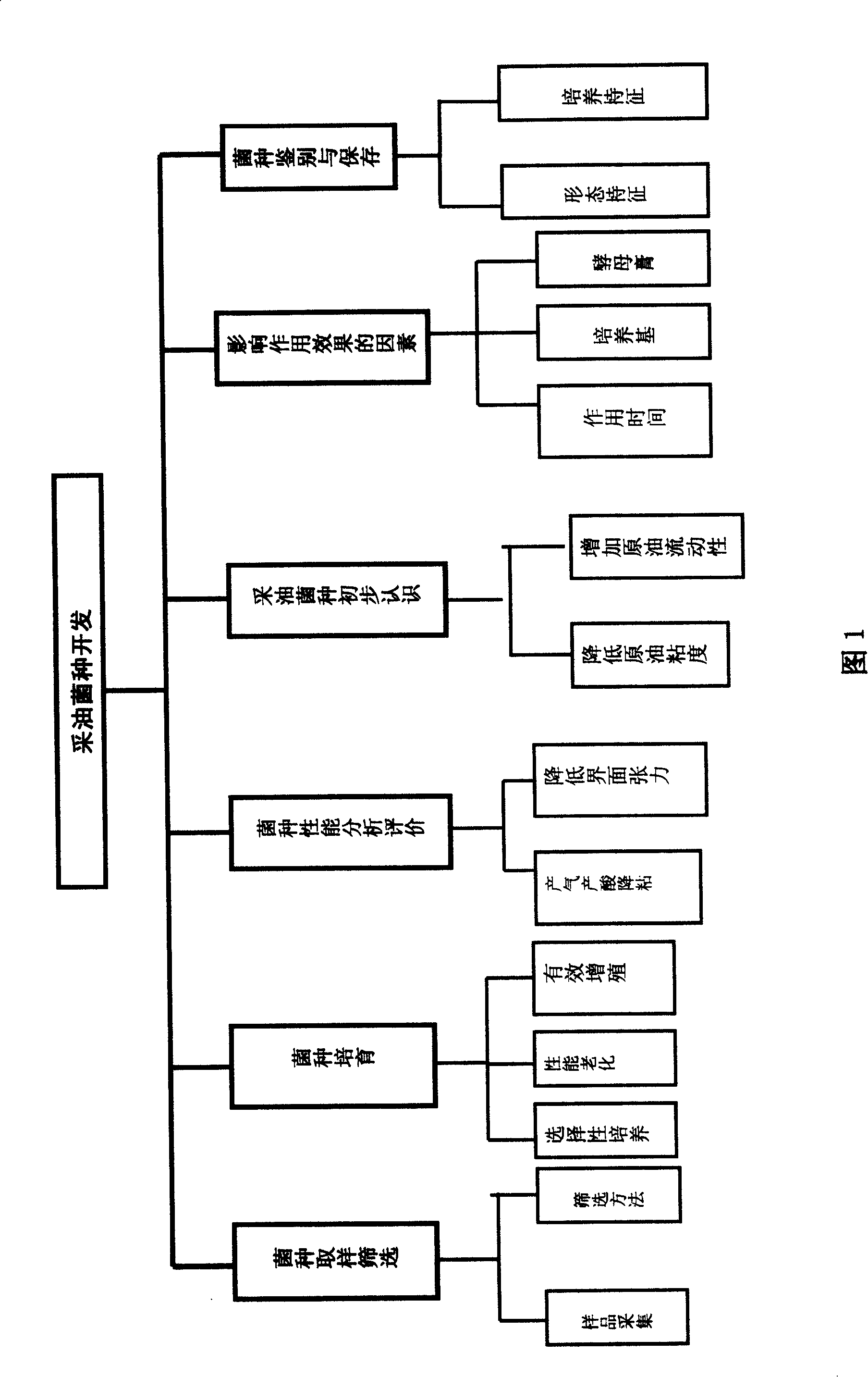

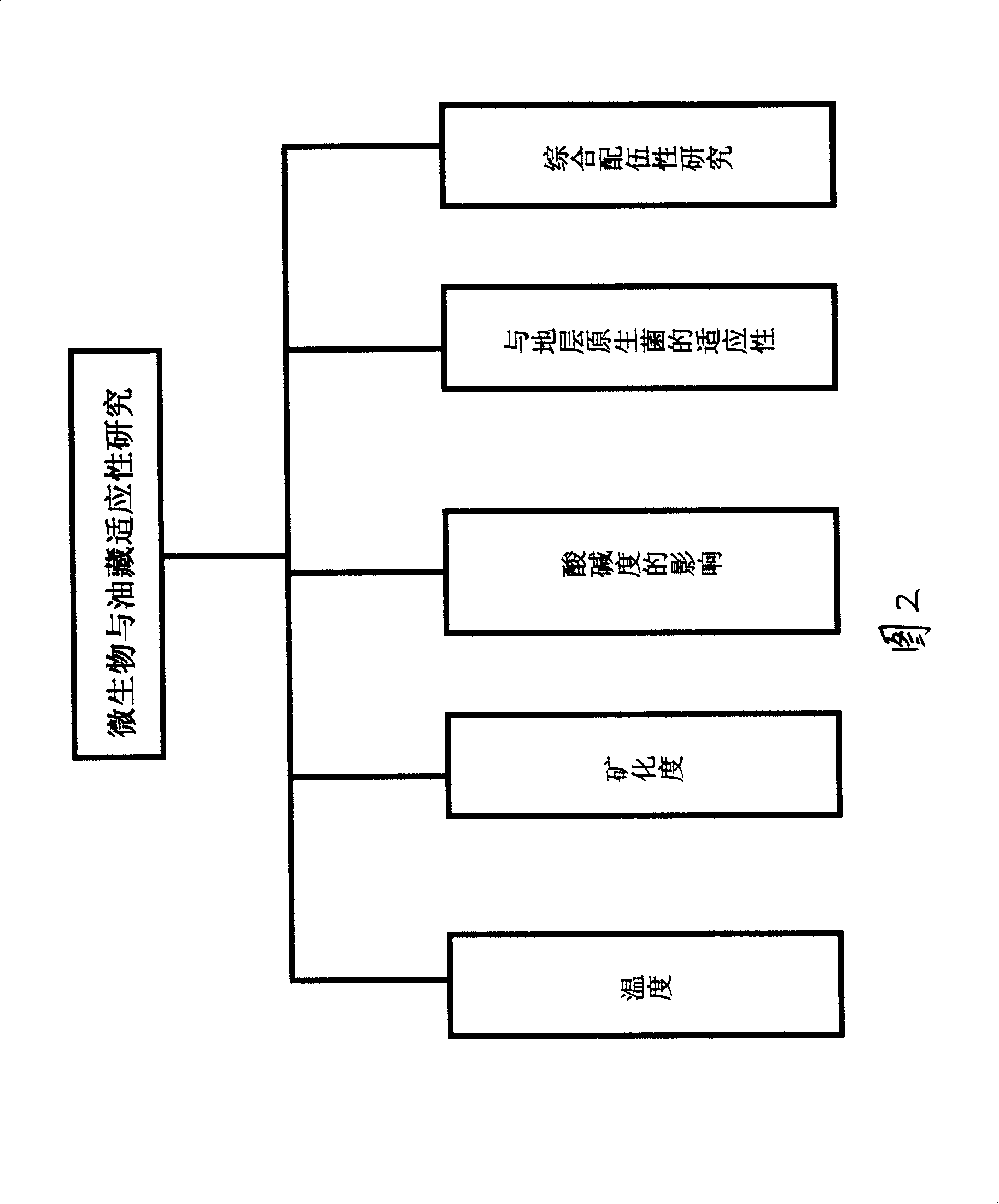

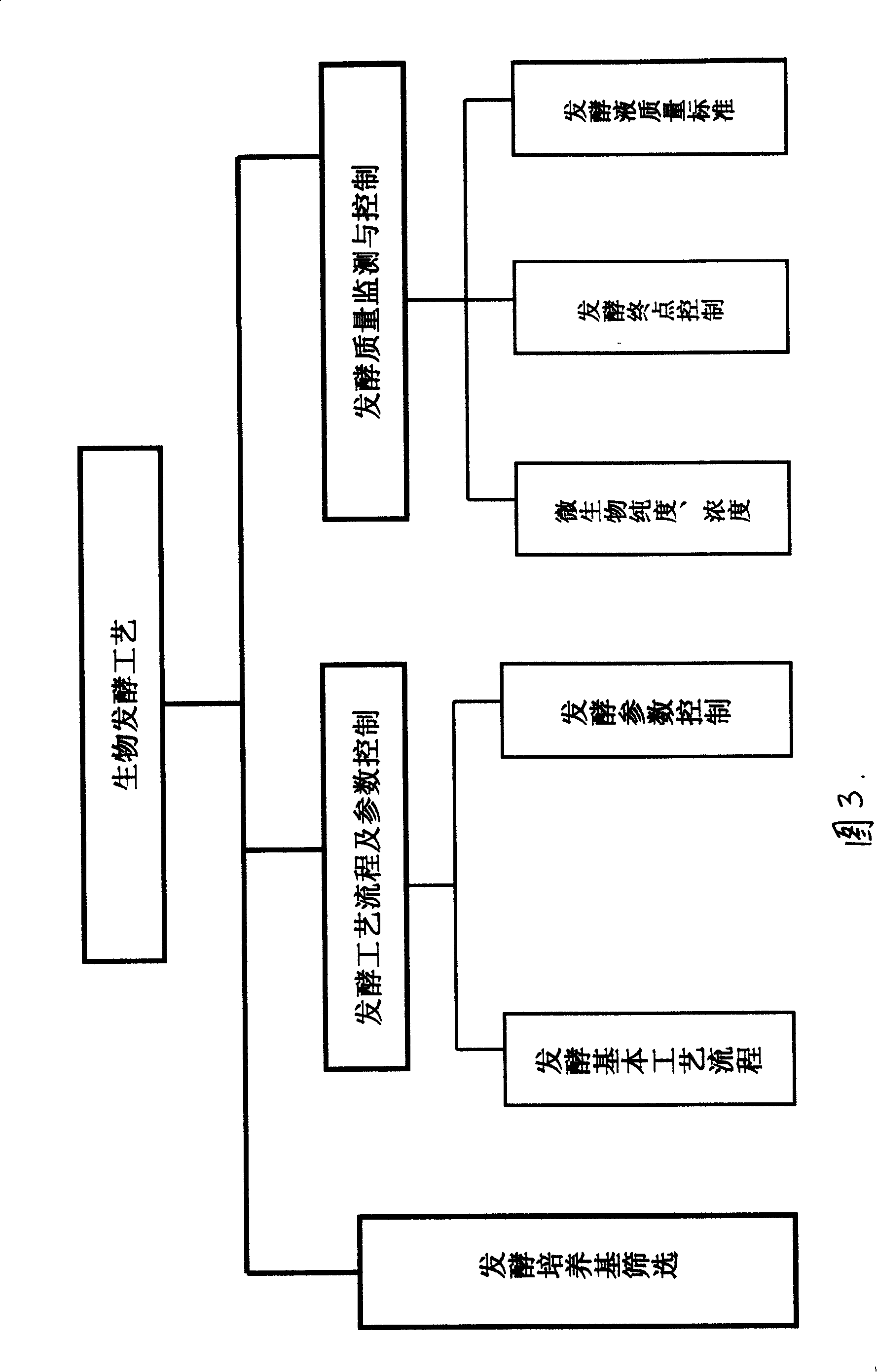

110results about How to "Improve oil recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for refinery sludge carbonization treatment and carbon recovery

ActiveCN103449701AReduce the difficulty of process controlEfficient process operationSludge treatment by thermal conditioningCarbon preparation/purificationSludgeGas phase

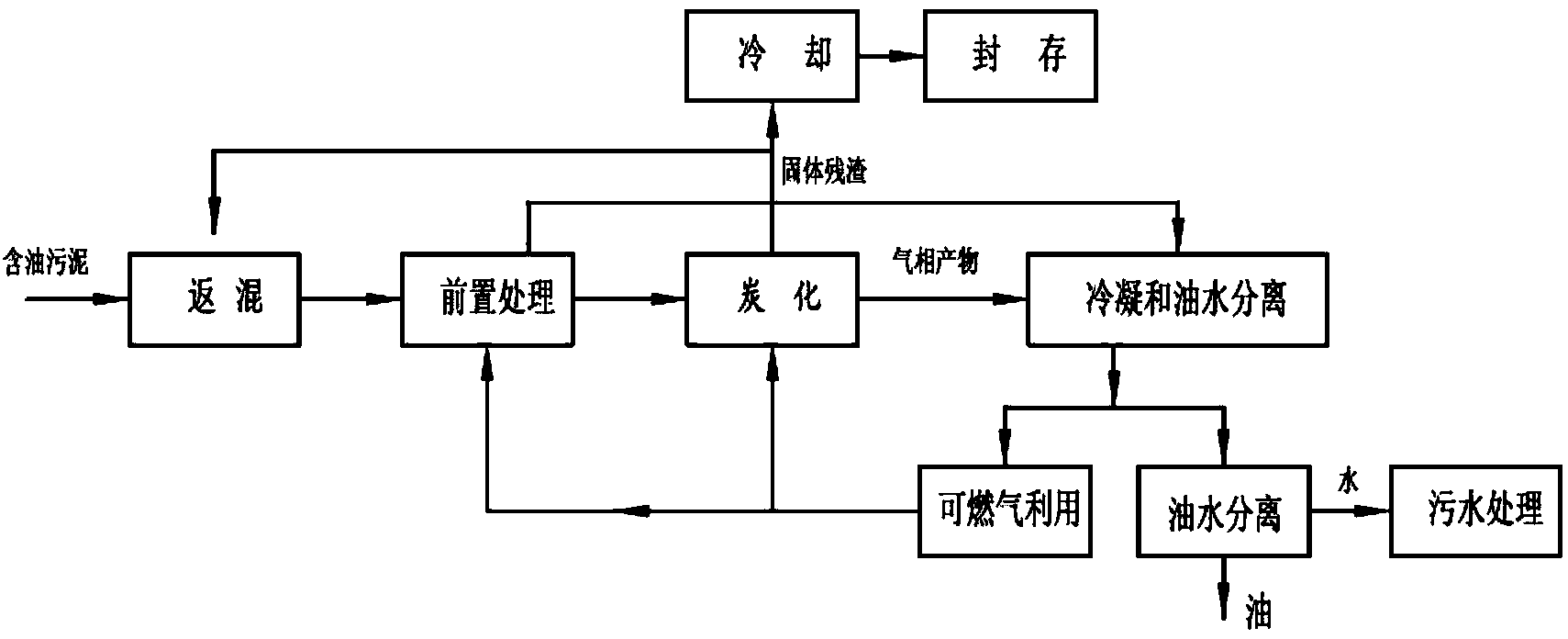

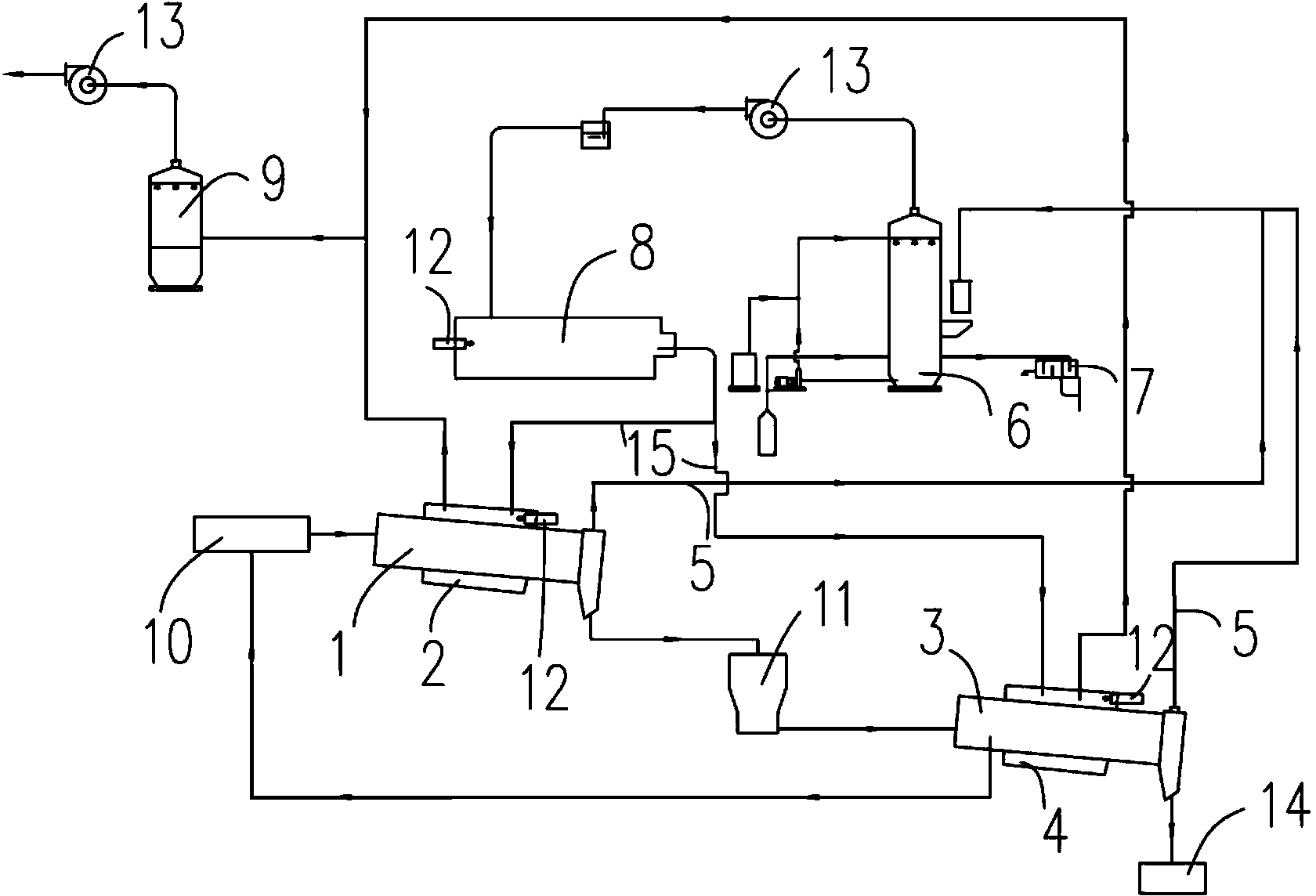

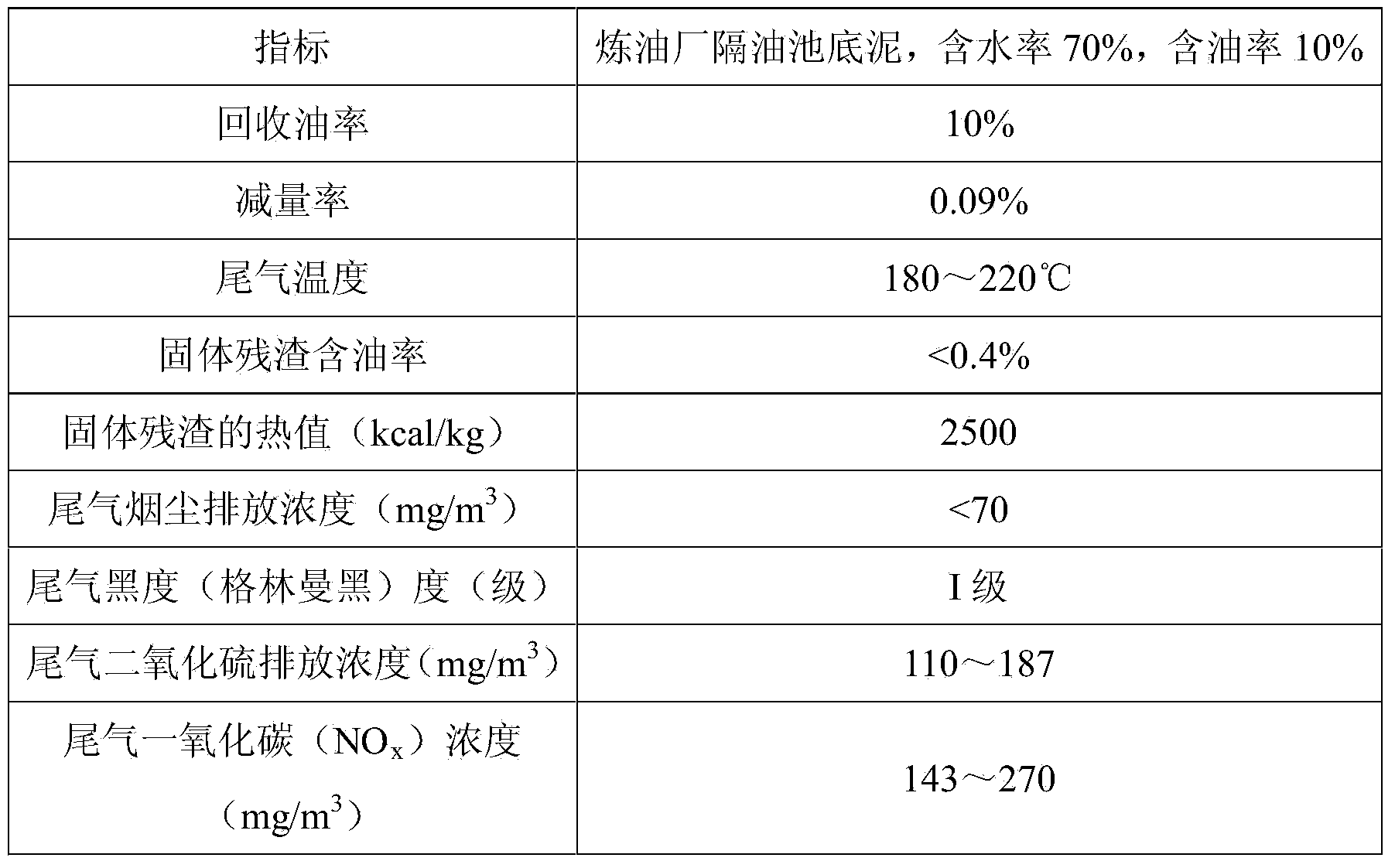

The invention relates to a method and device for refinery sludge carbonization treatment and carbon recovery. The method comprises the following steps: pre-treatment: heating oil-containing sludge to 160-180 DEG C in an external heating manner while isolating air, and ensuring that the water content of the oil-containing sludge is controlled at 20% or below; carbonization: carbonizing the oil-containing sludge at 600-650 DEG C for 30-45 minutes, and recovering the solid residue generated by carbonization; condensation and oil-water separation: collecting gas-phase products generated by pre-treatment and carbonization, condensing in a water spray manner to obtain carbonization liquid and non-condensable gas, and performing oil-water separation on the carbonization liquid to obtain carbonization oil; utilization of combustible gas: performing combustion treatment on the non-condensable gas, enabling high temperature generated by combustion to provide heat energy for pre-treatment and carbonization, and performing purification treatment on the tail gas before discharging. The invention also provides a device for realizing the method. According to the invention, the advantages of high oil content recovery rate and stable and reliable process operation are achieved.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

Microorganism huff and puff oil recovery method

A method is about microorganism throughput producing oil. First, microorganism indoor bacterial is filtrated after well is washed by heat water and is about 5 days in normal state. The ahead fluid of Xm3 nutrient fluid should be injected before microorganism bacterium liquid is injected. Microorganism bacterium liquid about X ton is injected into stratum, and the process of injecting bacterium is from high concentration to low concentration. Xm3microorganism nutrient fluid is injected for preparing postposition liquid after pouring bacterium is finished. Well is closed 5days. Well is closed 5days. The effect of the invention is: the method of microorganism throughput producing oil insures the microorganism bacterium breeding at certain number in deep well to achieving the goal of filling strata hole, solving jam by the metabolite generated by full fusion of base oil, clearing away wax and increasing oil, improving oil production.

Owner:TIANJIN JINDA GASOLINEEUM NEW TECH

Method and device for pyrolytic carbonizing treatment of sludge

ActiveCN104876414AWays to realize separate heatingControl and maintain temperatureSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustorCombustion chamber

The invention relates to a method for pyrolytic carbonizing treatment of sludge. The method comprises: a heat supplying portion: arranging a combustor, and introducing a flaming port of the combustor into a combustion chamber to obtain high-temperature flue gas; a pre-treating portion: putting the sludge into a pre-treating chamber, and introducing the high-temperature flue gas of the heat supplying portion so as to heat the sludge to the temperature of 100-250 DEG C; a carbonizing treatment portion: feeding the pre-treated sludge into a carbonizing treatment chamber, and introducing the high-temperature flue gas of the heat supplying portion so as to heat the pre-treated sludge to the temperature of 450-650 DEG C; a gas treating portion: separately collecting gas-phase products generated from pre-treating and carbonizing treatment, and condensing the collected gas-phase products correspondingly by adopting a water spraying manner, so as to respectively obtain first oil, first noncondensable gas, second oil and second noncondensable gas; and a gas utilizing portion: introducing the second noncondensable gas into the combustion chamber of the heat supplying portion for combustion. The invention also provides a device for implementing the method. The method and the device have the advantages of simplified process, small equipment quantity, stability and reliability in operation, energy saving and environmental protection, high oil recovery ratio, and the like.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

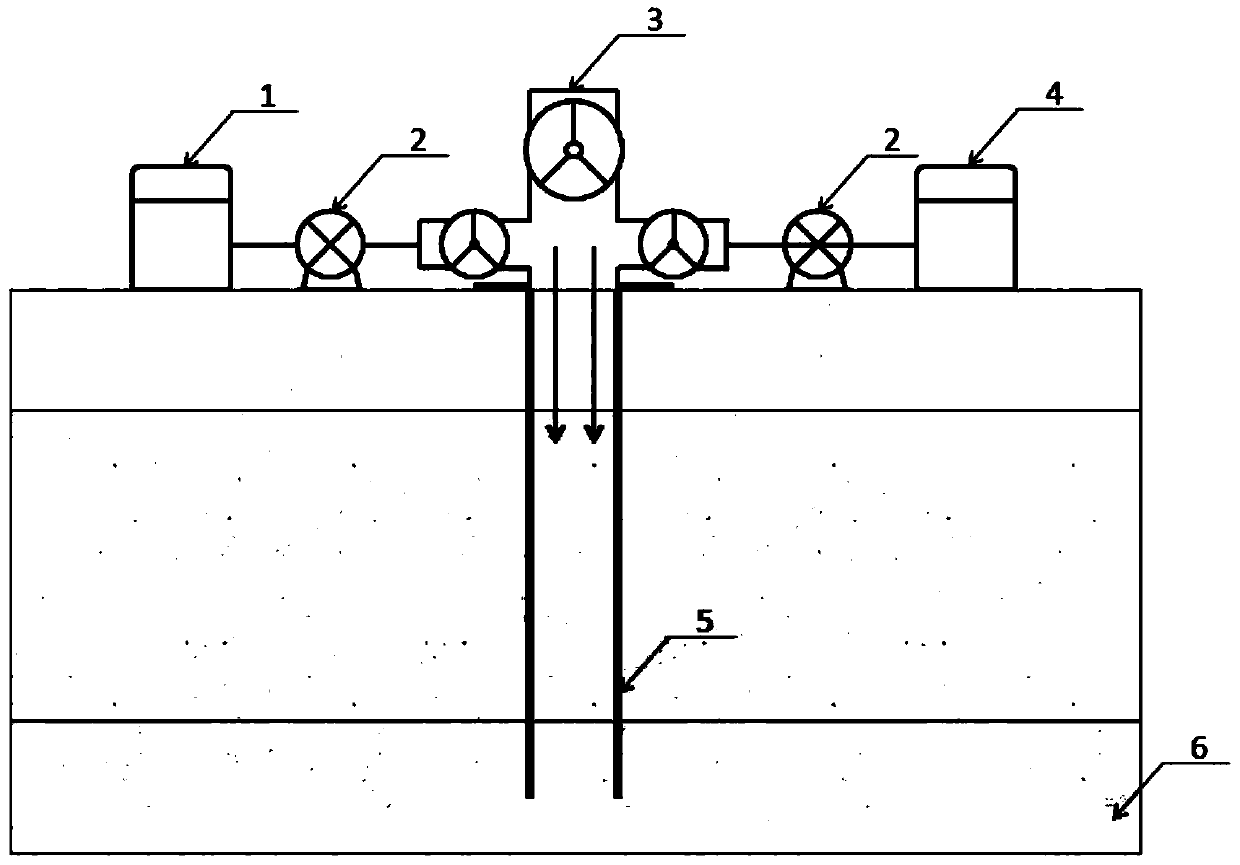

Dibasic composite horizontal well bottom water plugging technique

InactiveCN101139920AImprove the spread factorImprove oil recoveryDrilling compositionSealing/packingHorizontal wellsWater block

The invention relates to a water block operation method for horizontal wells, in particular to a binary composite technique method of sealing and water block for horizontal well downholes; the invention is characterized in that dynamic and static data of wells under execution are analyzed prior execution, in order to determine filler consumption into a binary system; then, perform well killing with fresh water before filling forced hardening flue, mixed in certain proportion of polyropylene amide, resorcinol and urotropine, and nitrogen into the well through the oil pipe; form a partition board with the filled nitrogen, and block off the water cone formed by bottom water layer in the horizontal well; the method can both improve utilization rate of medium and low permeation layers, and effectively control high permeation water content, in order to reach the target of improve collection rate of horizontal wells. The method in particular adapts to blocking for high-permeation water bearing layers in horizontal wells.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

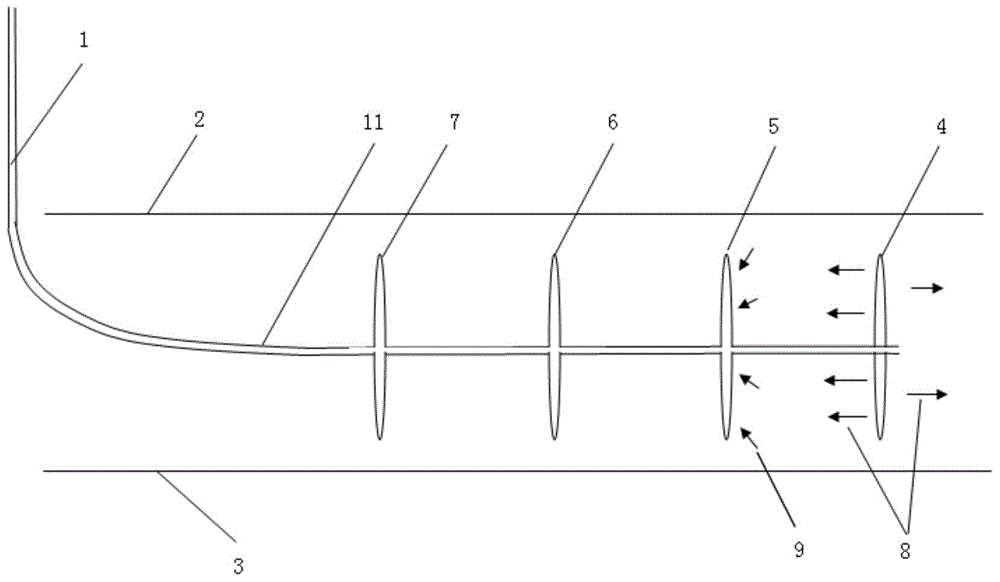

One-well multi-control method for offshore low-permeability reservoir thick oil layer exploitation

InactiveCN104818978ALow costReduce well construction costsFluid removalPrincipal stressDisplacement pressure

The invention relates to a one-well multi-control method for an offshore low-permeability reservoir single relatively thick oil layer. The method at least uses a long section horizontal well and a plurality of artificial fractures located between an oil layer top and an oil layer bottom, wherein the extension direction of a well section of the horizontal well is the maximum principal stress direction of a stratum; the artificial fracture surfaces are vertical to the horizontal well section and extend along the minor principal stress direction; injection and recovery are carried out simultaneously by implementing an offshore same-well injection and recovery technology in the horizontal well; injection water is firstly injected into the artificial fracture at the farthest end from the root of the horizontal well section; the injection water drives crude oil to enter the closest artificial fracture to enter a wellbore so as to be recovered; and when the far end artificial fractures are flooded by water in succession and water plugging is invalid, conversion is carried out in sequence from a far end to a close end. According to the method, the well building cost is reduced; the injection effect is improved; the distance between adjacent artificial fractures is adjusted, so that the small-well-distance water injection is realized, the displacement pressure gradient is favorably built, the start pressure difference is overcome, and the oil recovery effect is increased.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Ultrasonic blockage removal technology and blockage removal device

InactiveCN104712292AEffective pollutionEffectively decontaminateCleaning apparatusConvertersEngineering

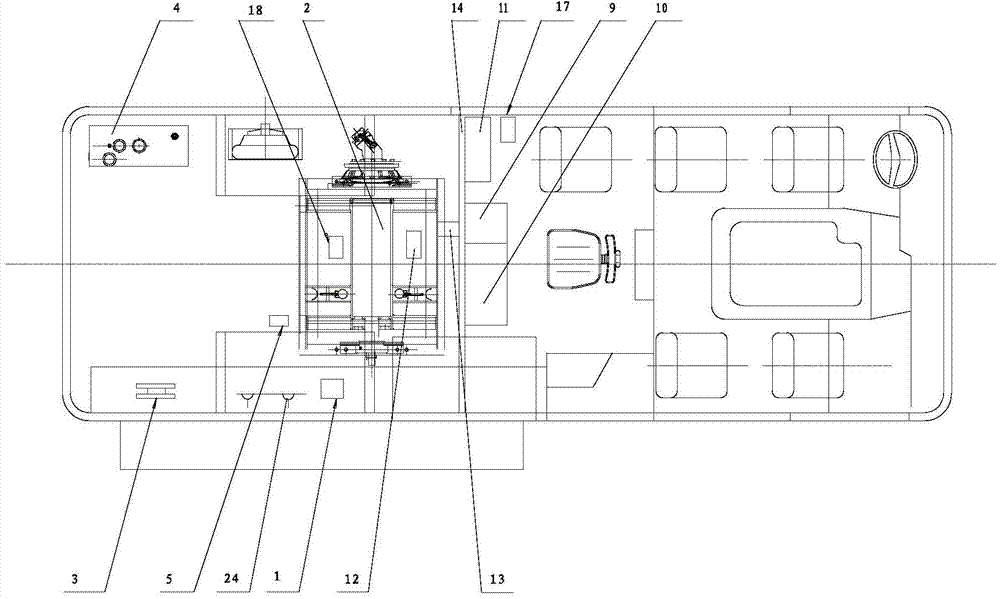

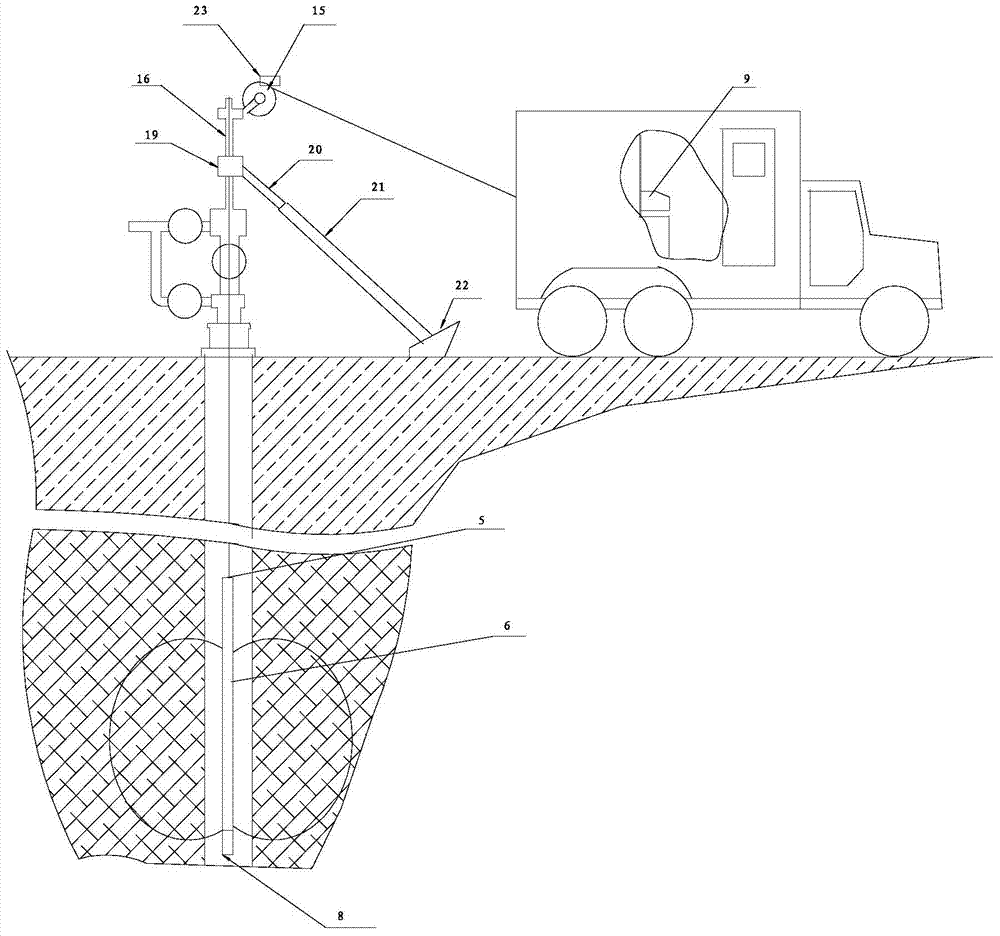

The invention relates to an ultrasonic blockage removal technology and a blockage removal device which are used for clearing blockages formed in an oil well during oil extraction. The device is mainly composed of a well testing truck, a transmission cable, a high-power ultrasonic electric signal transmitter and an ultrasonic electro-acoustic transducer. High-power pulse electric oscillation signals generated by the vehicle-mounted high-power ultrasonic transmitter on the ground are transmitted to the piezoelectric ceramic electro-acoustic transducer on an oil layer through the special transmission cable, then converted into ultrasonic waves through the electro-acoustic transducer, and injected into an oil bearing formation, so that the physical property and flow state of fluid in the oil layer are changed, the circulating condition and permeability of the bottom of the well and a near-well oil layer are improved, blockages are removed, scale prevention and removal are achieved, paraffin control is achieved, oil production capacity is improved, the viscosity of crude oil is reduced, and then permeability and recovery efficiency can be improved, injection rate is increased, and injection allocation is achieved.

Owner:牛连江

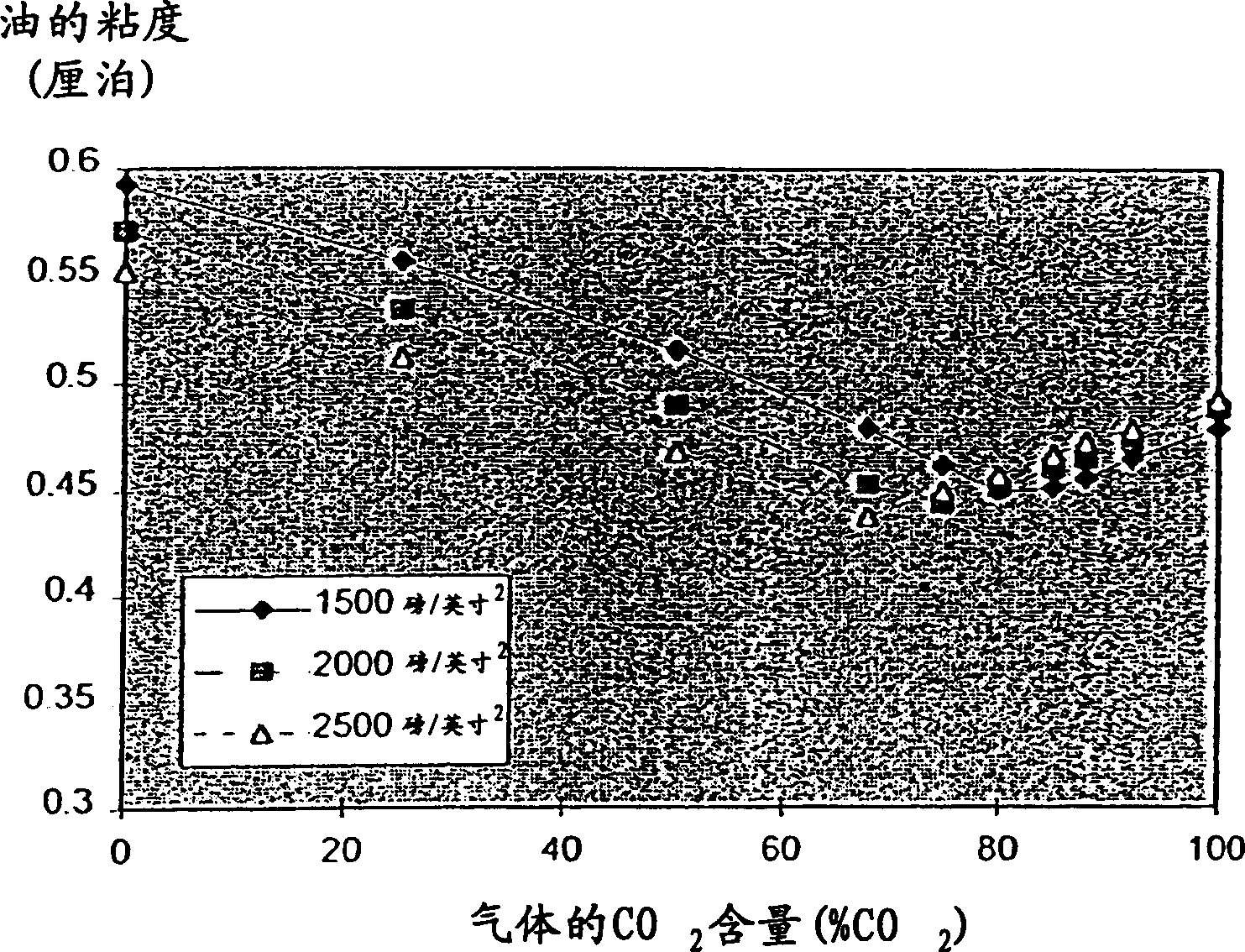

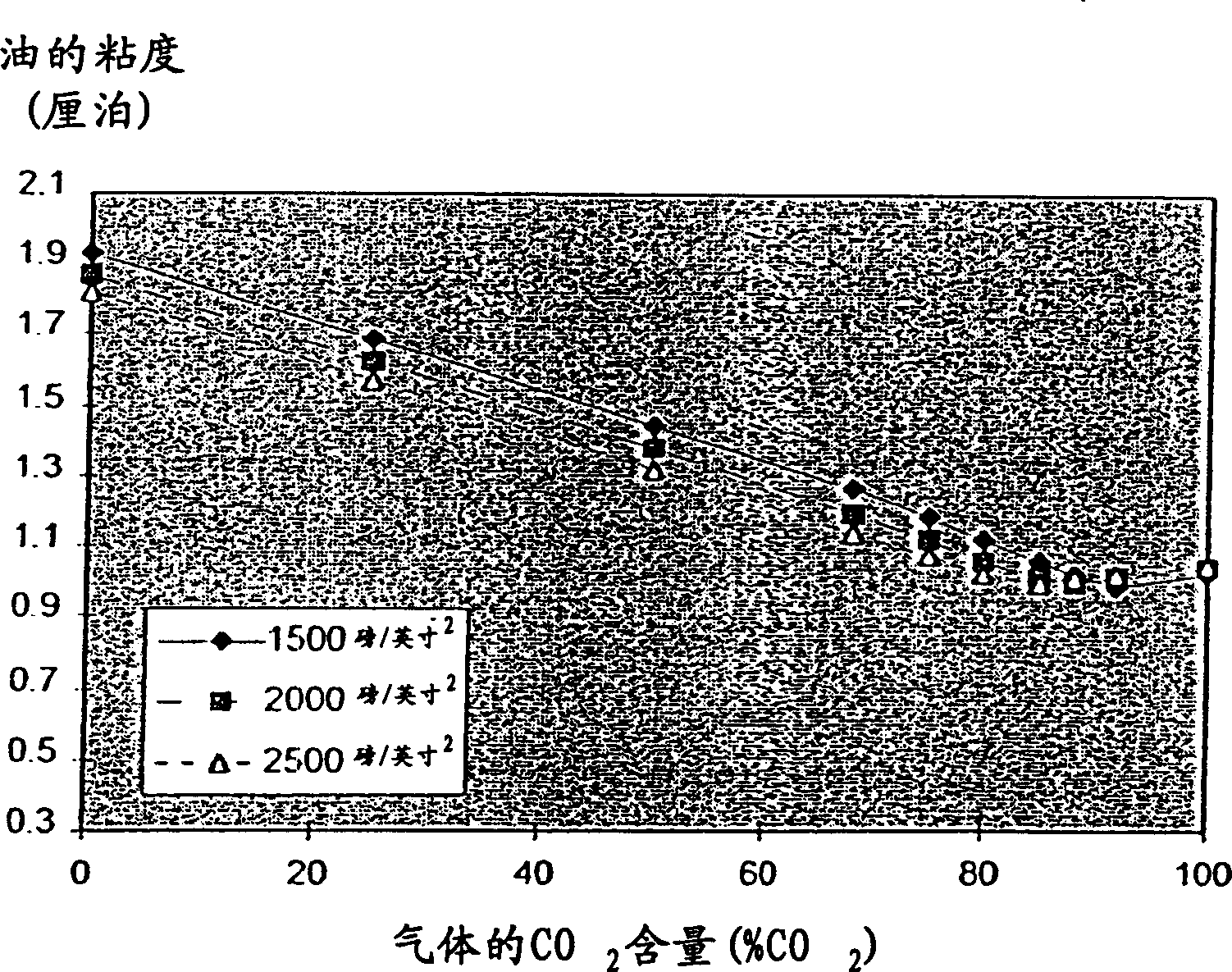

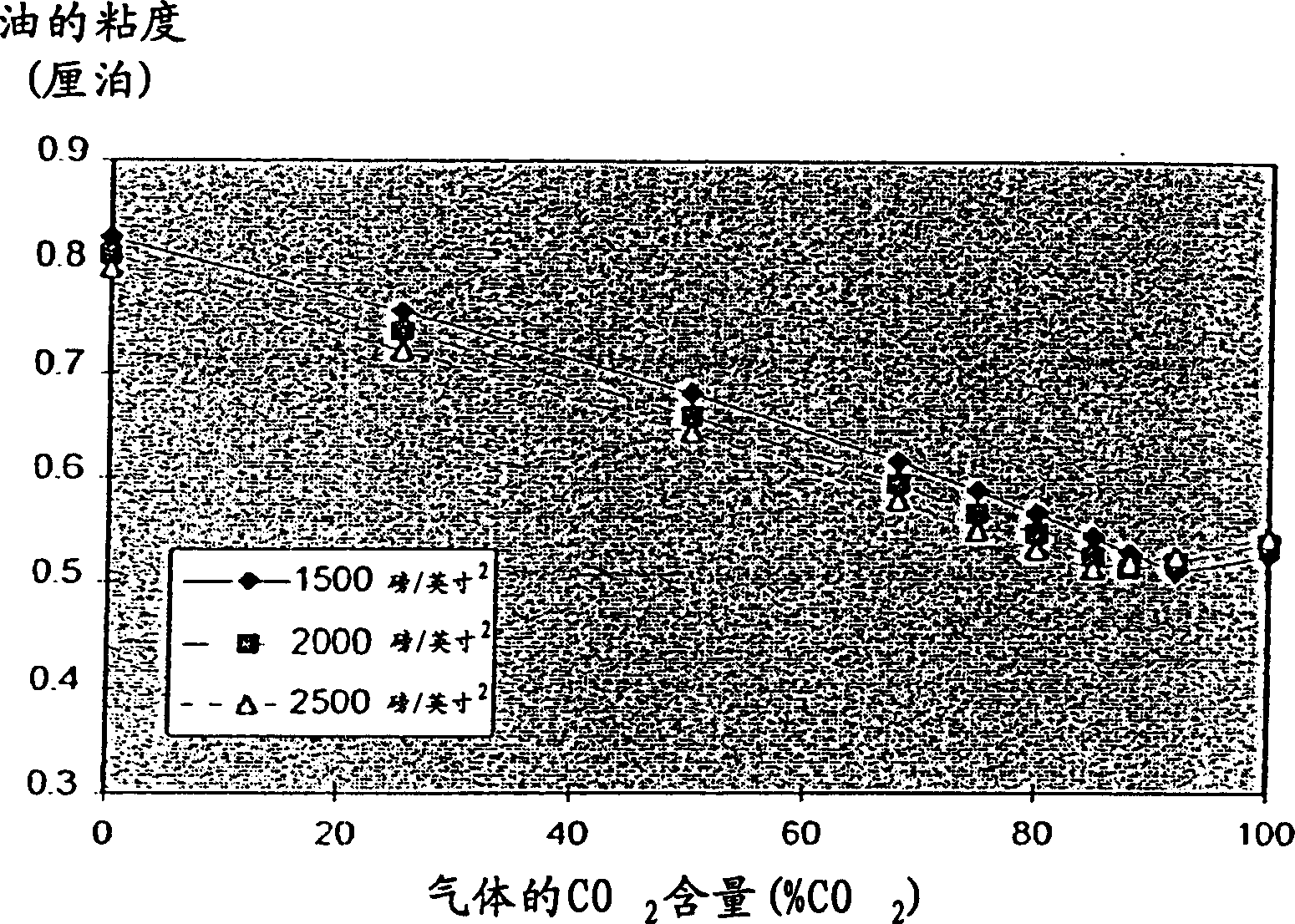

Improved intensified petroleum production method

A method of increasing oil recovery from a subterranean formation is disclosed. Inject a mixed gas containing more than 50 volume percent carbon dioxide and the rest inert gas into the underground rock formation to reduce the viscosity and surface tension of the oil and increase the swelling of the oil. A mixed gas containing more than 60% by volume of carbon dioxide is preferable, and a mixed gas containing more than 70% by volume of carbon dioxide is more preferable.

Owner:THE BOC GRP INC

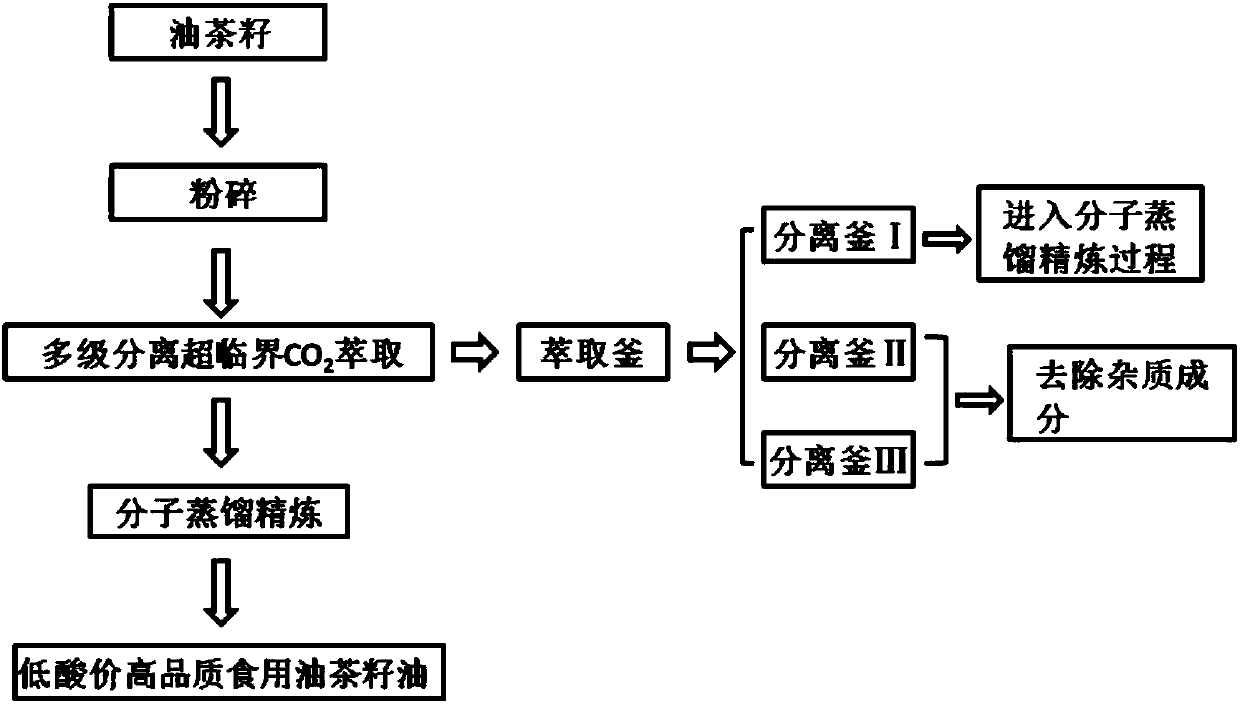

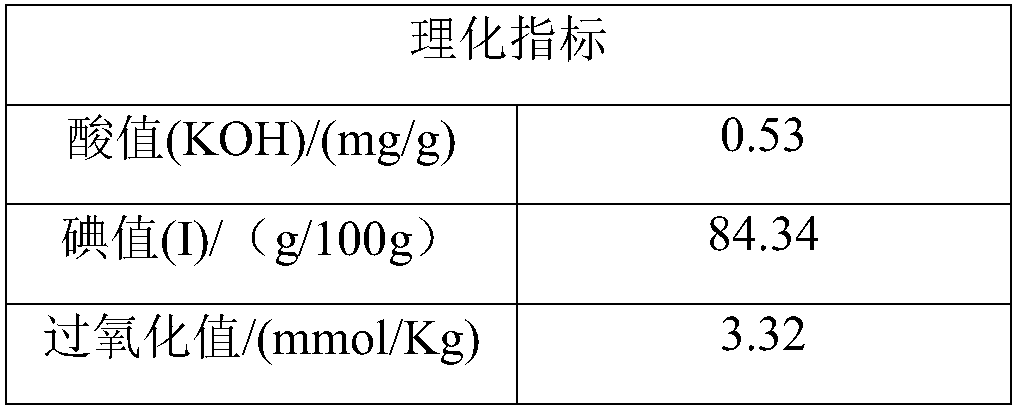

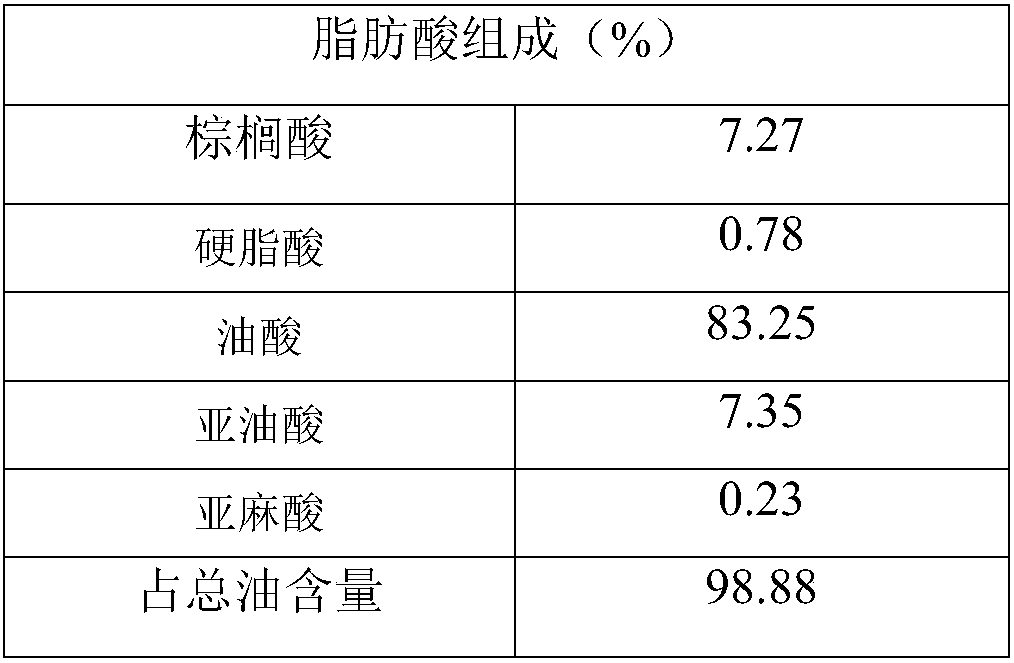

Production and processing method for edible camellia seed oil with low acid value and high quality

InactiveCN107858197APrevent oxidationPrevent rancidityFatty-oils/fats refiningFatty-oils/fats productionDistillationSolvent

The invention discloses a production and processing method for edible camellia seed oil with low acid value and high quality. The production and processing method comprises multistage separation supercritical CO2 extraction and molecular distillation refining. According to the invention, through multistage separation supercritical CO2 extraction for camellia seed oil, high extraction rate is maintained; due to multistage separation, simultaneous separation of water, free fatty acid, odor components, pigment components and the like can be realized; and through refining treatment with a molecular distillation technology, the edible camellia seed oil with low acid value and high quality is obtained, and the edible camellia seed oil can reach an oil yield of 90% or above, an acid value of lessthan 0.6 and an unsaturated fatty acid content of 90% or above, and is rich in natural anti-oxidant active components like vitamin E, squalene and beta-sitosterol. The production and processing method provided by the invention avoids traditional technical processes of degumming, deacidifying, decolorizing, dewaxing and deodorizing, and has the advantages of high oil yield, short life cycle, avoidance of product oxidation and rancidification, retention of nutrient components in oil, no flammable and explosive hazards, no environmental pollution, no solvent and heavy metal residues, natural quality ensurance of camellia oil, etc.

Owner:广东金妮宝科技发展有限公司

Composite microorganism oil-displacing agent

ActiveCN101544885AExpand the scope of fermentationExtension of timeDrilling compositionMicroorganismWater flooding

The invention relates to a composite microorganism oil-displacing agent for improving the oil recovery rate. The composite microorganism oil-displacing agent is prepared by adding mixed liquid containing 1-8 percent of byproducts of triticeae crops, 1-8 percent of byproducts of maize, 0.5-6 percent of byproducts of wood and the balanced of water by weight into 5-10mg / L trace element and 300-500mg / L polyacrylamide, wherein the particle diameters of the byproducts of crops and wood are smaller than 0.5 mm. The composite microorganism oil-displacing agent is filled with the aid of oxygen-containing air, has dual functions of providing nutrition for microorganism and plugging a high permeability zone, can enlarge the swept volume of nutrient fluid and the fermentation range of the microorganism, prolong the acting time between the microorganism and rock and fluid in an oil layer, satisfy the requirement for fermentation time, provide conditions for biological action and biochemical action and improve the whole effect of microorganism oil recovery, e.g. the recovery rate is increased by 12-15 percent based on water drive.

Owner:PETROCHINA CO LTD

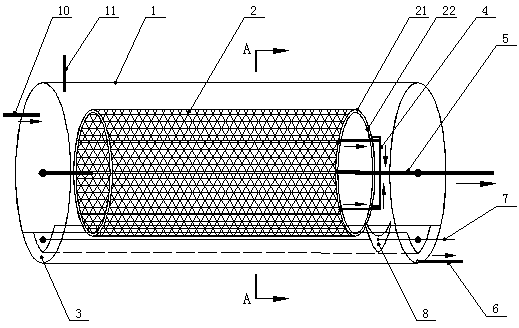

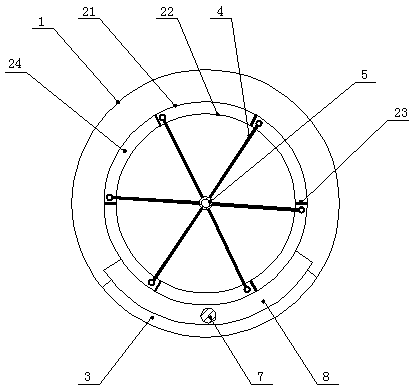

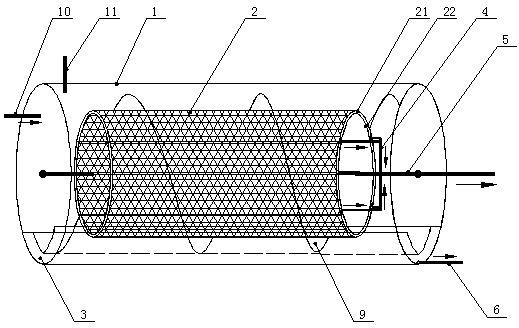

Filtering tank capable of fully filter-pressing waste oil

InactiveCN104208932AAvoid difficultiesAvoid efficiencyStationary filtering element filtersFilter pressControl valves

The invention discloses a filtering tank capable of fully filter-pressing waste oil. The filtering tank comprises an airtight tank body and a rotary filter unit, wherein the rotary filter unit is mounted inside the tank body through a rotating shaft provided with an oil outlet hole; the outer layer of the rotary filter unit is provided with a filter screen, and the inner layer of the rotary filter unit is provided with a cylinder; the rotating shaft is fixedly connected onto two side surface of the cylinder along a rotating center; an annular percolating area is formed between the inner side of the filter screen and the outer wall of the cylinder and divided into a plurality of mutually-isolated filtering separated areas through separating blocks, every filtering separated area is provided with an oil outlet branch pipe with a control valve, and all the oil outlet branch pipes with the control valves are communicated with the central oil outlet hole of the rotating shaft; an oil inlet pipe and a pressurizing air pipe are arranged on the tank body. The filtering tank capable of fully filter-pressing the waste oil has the advantages of being capable of fully filter-pressing the waste oil inside the filtering tank through air pressure filtering, improving the oil recovery rate of waste oil purification equipment and meanwhile automatically cleaning dirt and oil residue attached on the filter screen.

Owner:重庆市控能净化设备有限公司

Preparation method of biomass oil absorption carbon aerogel

InactiveCN109621914AAvoid seasonal effectsAvoid high temperature roastingFatty/oily/floating substances removal devicesOther chemical processesBiomass carbonRoom temperature

The invention discloses a preparation method of biomass oil absorption carbon aerogel. The preparation method includes the following steps that a, biomass raw materials are cut to be in an appropriateshape, put into a hydrothermal reaction kettle for a hydrothermal reaction, and cooled to have room temperature, so that black carbon aerogel is obtained; b, the obtained black carbon aerogel in thestep a is washed and dried to obtain biomass carbon aerogel; c, polydimethylsiloxane and a solidifying agent are dissolved in n-hexane to prepare a modifying solution, wherein the mass ratio of polydimethylsiloxane to the solidifying agent to n-hexane is 10:1:15-25, the solidifying agent comprises a polydimethylsiloxane crosslinking agent, the biomass carbon aerogel is put into the modifying solution to be soaked for 1-2 min and then taken out to stand for 10-12 h at room temperature, and then the biomass oil absorption carbon aerogel is obtained through solidification at the temperature of 100-120 DEG C. The preparation method has the advantages of being low in cost, wide in application range and suitable for industrialized production, and saving energy, and the prepared carbon aerogel has a high oil absorption rate and a high oil absorption recovery rate.

Owner:ZHEJIANG UNIV OF TECH

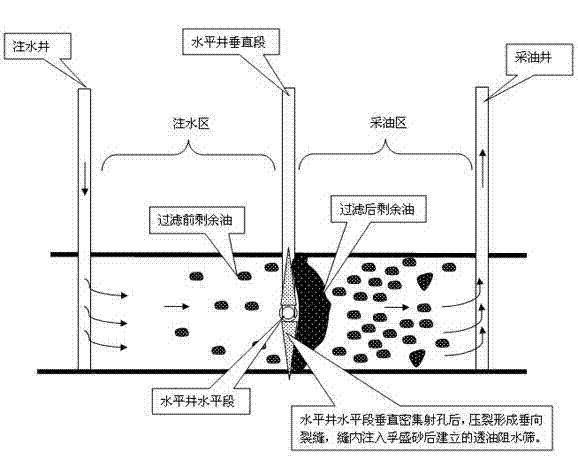

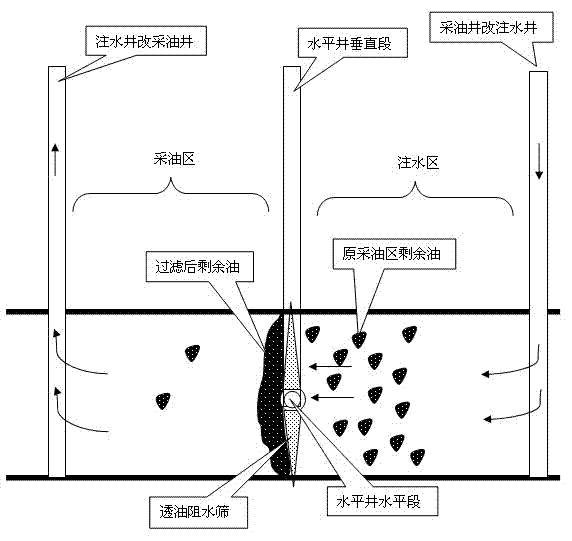

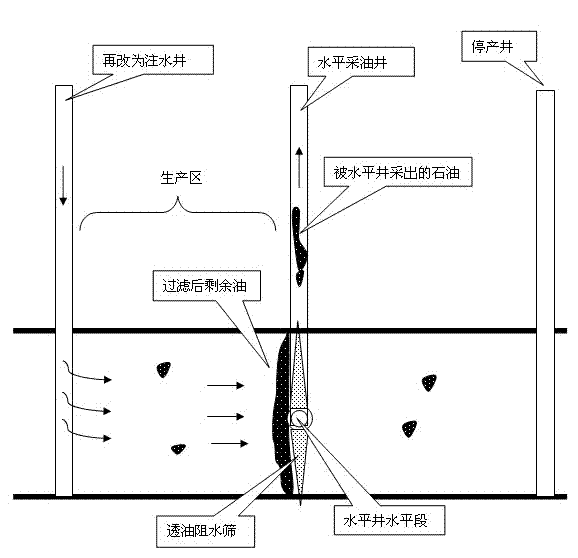

Oil extraction method for establishing oil permeable water stop sieve by filling fusheng sand in horizontal well fracture

ActiveCN102364041AReasonable designReduce water outputFluid removalDrilling compositionPetroleumOil well

The invention discloses an oil extraction method for establishing an oil permeable water stop sieve by filling fusheng sand in a horizontal well fracture, and relates to a new method for petroleum exploitation. The fusheng sand with an oil permeable and water stop function is filled in a horizontal well vertical fracture in the middle of a water injection well row and an oil extraction well row to serve as a supporting agent, so that an oil permeable and water stop sieve is formed in the middle of a water injection well and an oil extraction well, and a petroleum exploitation region is partitioned into a water injection region and an oil extraction region by the oil permeable and water stop sieve. Under the action of injection water pressure, when oil and water mixture passes through the oil permeable and water stop sieve, water is intercepted at the water injection region, and crude oil is then gathered on one side of the oil extraction region of the sieve through the sieve. After all petroleum of the water injection region completely passes through the sieve to enter the oil extraction region, the water injection pressure of the water injection region is abruptly increased, so that the sieve becomes a water permeable sieve, and the permeated water continuously pushes remaining oil at the oil extraction region to enter the oil well. By using the method, most of remaining oil of an oil field can be extracted, so that the petroleum recovery ratio is close to 100 percent.

Owner:王胜存

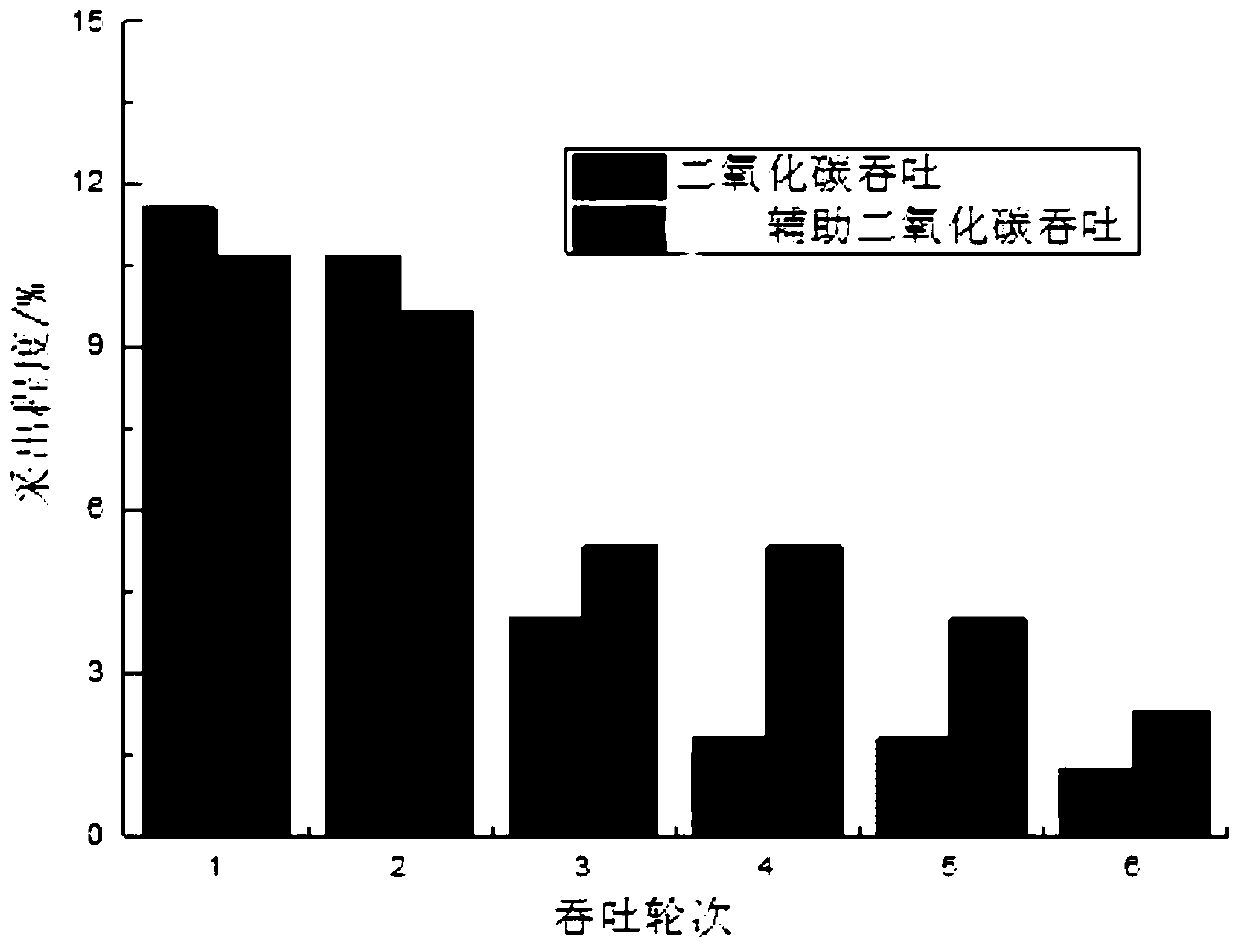

A chemical agent-assisted CO2 huff and puff method to improve the recovery of ordinary heavy oil reservoirs

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

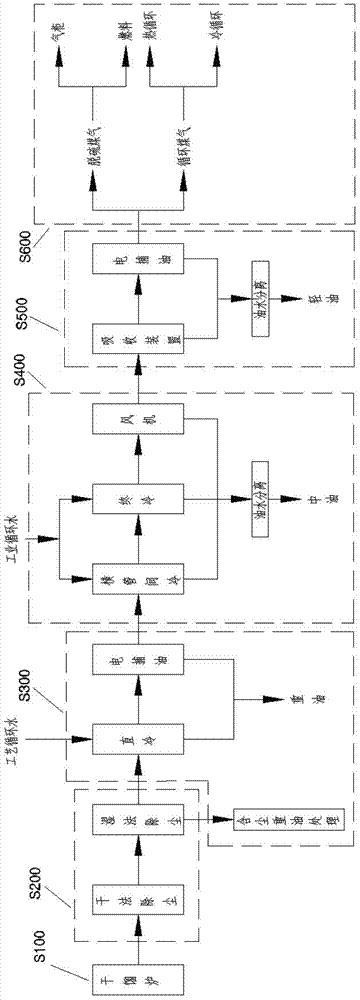

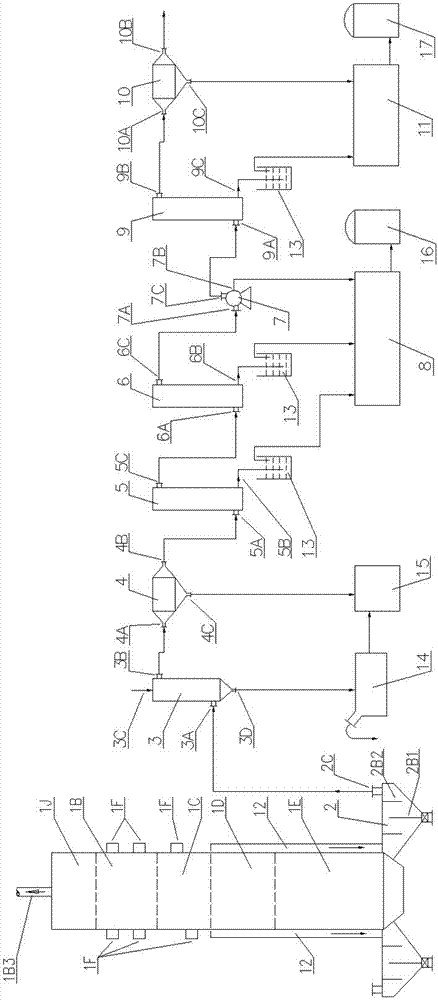

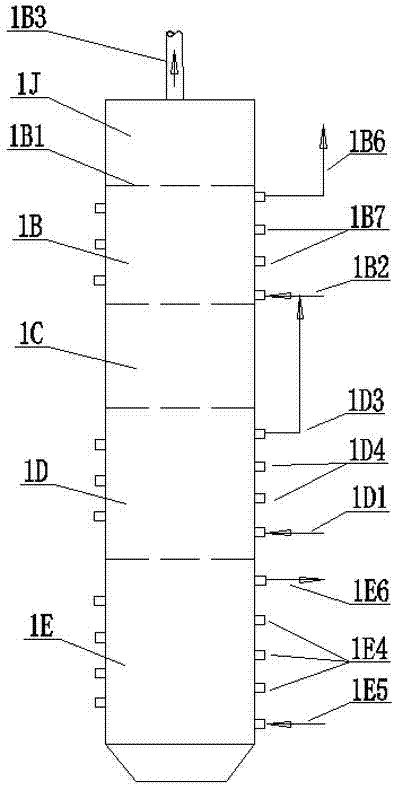

Fine and granule dry distillation oil-gas high-quality recycling method and recycling device thereof

ActiveCN104745221AReduce the chance of secondary breakageReduce dust contentDirect heating destructive distillationLiquid hydrocarbon mixture productionFuel oilPyrolysis

The invention discloses a fine and granule dry distillation oil-gas high-quality recycling method and a recycling device thereof. The fine and granule dry distillation oil-gas high-quality recycling method comprises the following steps: gradually heating a dry distillation furnace, and carrying out pyrolysis to obtain a volatile component; introducing the volatile component into a separating plate settling chamber and / or cyclone dust collector to obtain dedusted oil gas; condensing the dedusted oil gas, and then recycling heavy oil by adopting an electric oil trapper; cooling the oil gas to the temperature lower than 80 DEG C after the heavy oil is recycled, cooling by virtue of a final cooler to obtain oil-water mixed condensate and finally cooled oil gas, centrifuging and separating the finally cooled oil gas to obtain centrifuged condensate and residual oil gas, and carrying out oil-water separation on the oil-water mixed condensate and the centrifuged condensate to obtain medium oil; and carrying out oil-water separation on mixed liquid obtained from the residual oil gas by virtue of an absorption tower and the electric oil trapper, so that light oil is obtained. The recycling device comprises a dry distillation furnace, a separating plate settling chamber, a direct-cooling dust remover, a heavy oil electric trapper, an intercooling device, a final cooler, a centrifugal fan, a medium oil oil-water separator, a light oil absorption tower, a light oil electric trapper and a light oil oil-water separator. The fine and granule dry distillation oil-gas high-quality recycling method and the recycling device have the characteristics that oil yield is high, oil product quality is good, subsequent processing is convenient and coal gas quality is good.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Oil shale dry distillation device and method

InactiveCN103146405ASimple structureImprove oil recoverySpecial form destructive distillationInlet channelDistilled oil

The invention relates to oil shale dry distillation device and method. The device comprises an internal combustion retort furnace, and an oil-gas separating device, wherein the internal combustion retort furnace is used for distilling oil shale particles; the oil-gas separating device is used for separating oil shale and gas in smoke generated after oil shale combustion; the internal combustion retort furnace comprises a feeding device, a smoke outlet, a furnace body, a slag discharge device, an air inlet channel and a gas inlet channel; the feeding device is arranged on the top of the internal combustion retort furnace; the smoke outlet is formed in the upper part of the internal combustion retort furnace; the slag discharge device is arranged at the bottom of the internal combustion retort furnace; and the air inlet channel and the gas inlet channel penetrate through the bottom of the internal combustion retort furnace. The oil shale dry distillation device is simple and reasonable in structure, high in oil yield, easy to industrially amplify, convenient to operate, low in production cost, and free of selectivity on grain size of the oil shale; and the oil shale of which the grain size is less than 120mm can be applied to the oil shale dry distillation device.

Owner:李伟

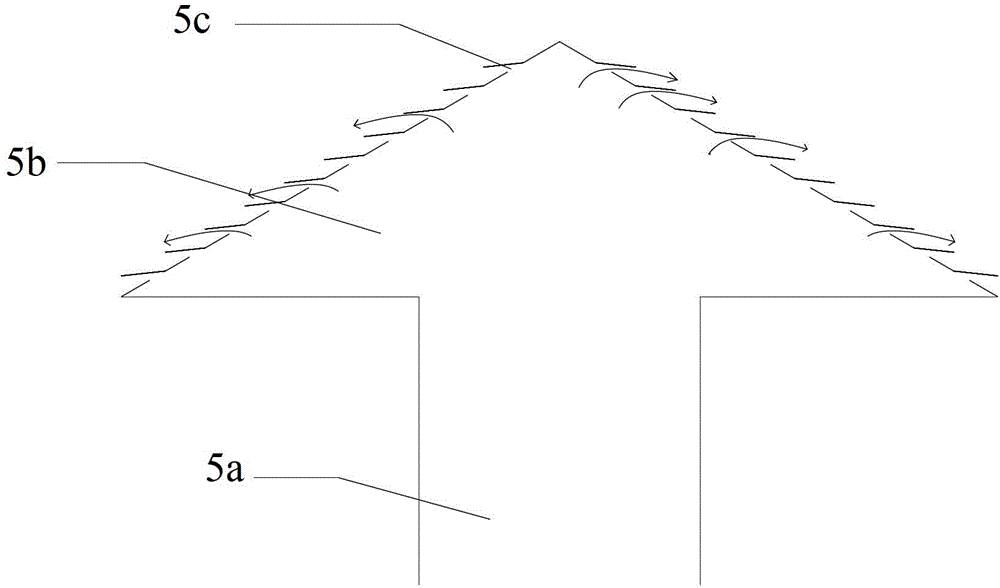

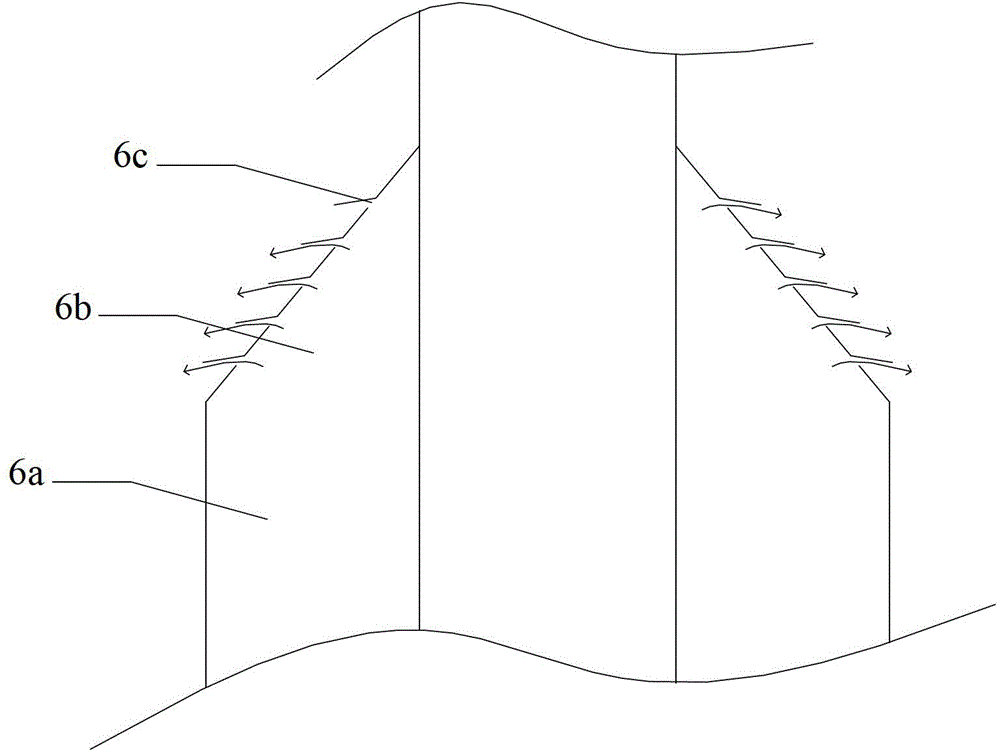

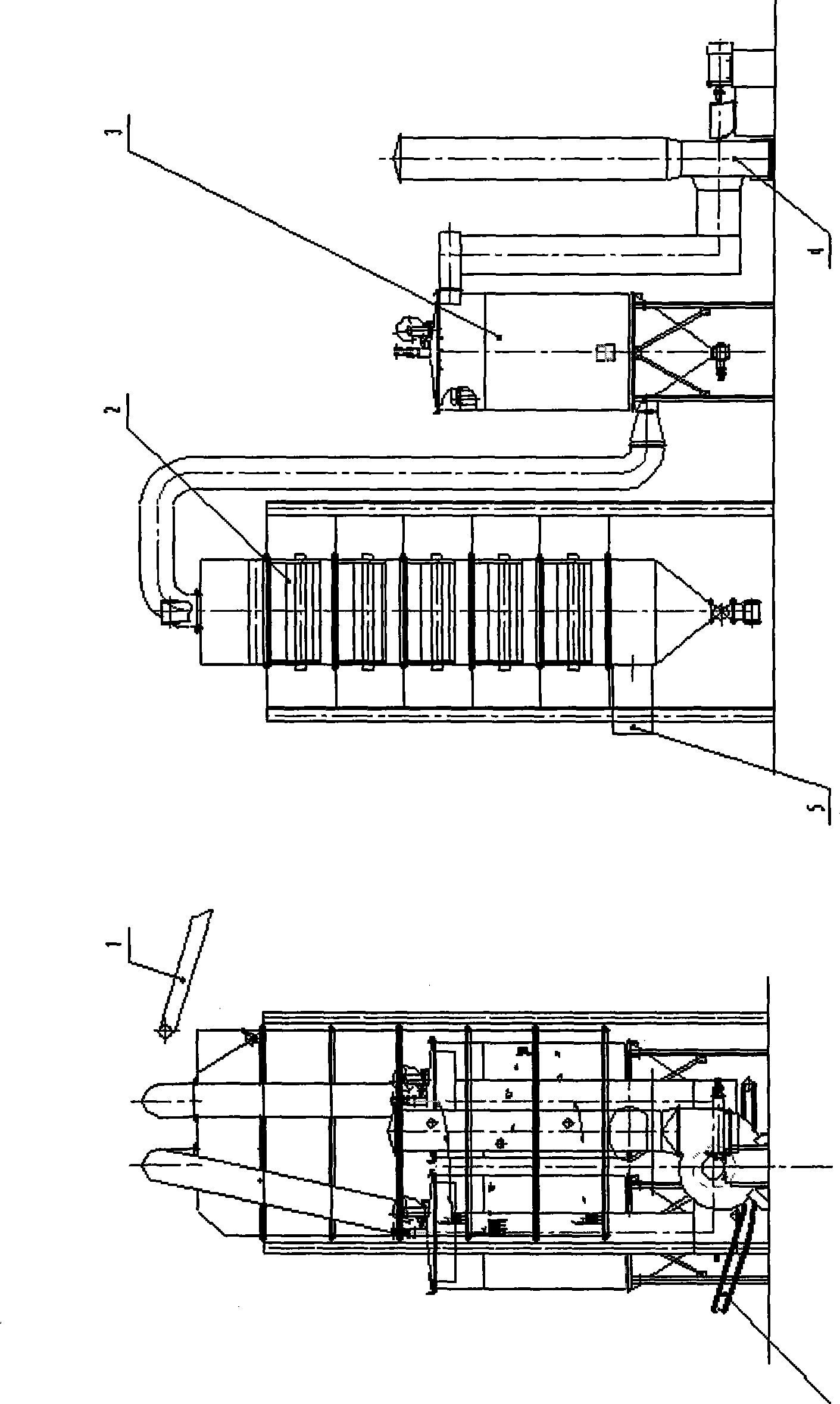

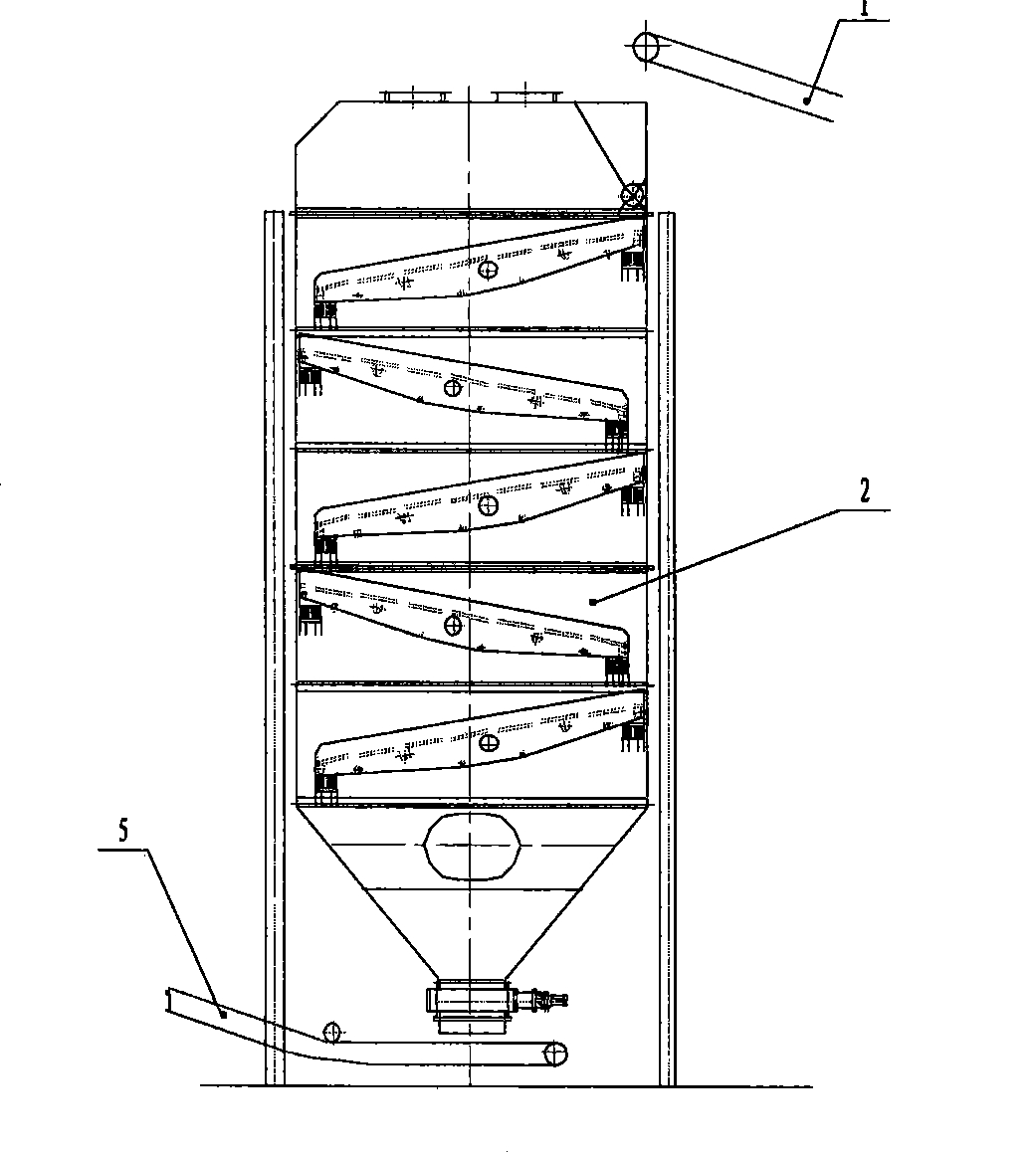

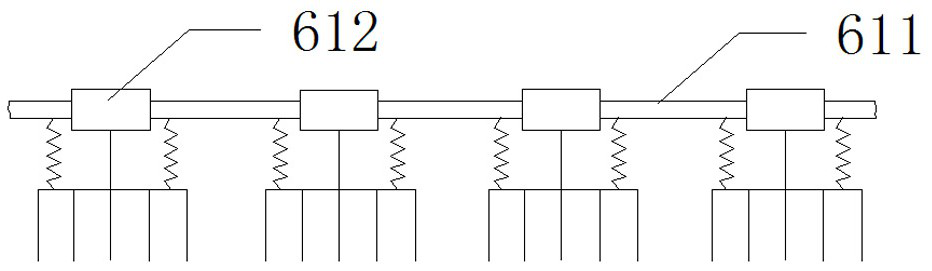

Wax shale vibration turn-back pre-heating dryer

InactiveCN101464092ARaise the furnace temperatureReduce consumptionDrying solid materials with heatHearth type furnacesDistillationCarbonization

A device for preheating and drying oil shale by utilizing the flue gas exhausted by a heating furnace is characterized in that multi-layer vibration beds are distributed in a zigzag manner in a drying machine; and wet materials are dispersed into flat and pudgy material flows in a zigzag shape under the action of the multi-layer drying beds after entering the drying machine from the top thereof. Hot flue gas produced by the heating furnace is transmitted to the bottom of the drying machine after being pressurized by air distribution, so as to form a vertical airflow and a horizontal airflow which are in full and high-intensity contact with the materials. During the mixing flow process with hot wind, the material is evenly preheated and dried after the repeated process of mixing, separating, remixing and re-separating. The device can remove most of moisture in the oil shale and preheat the oil shale to about 80 DEG C without any loss of oleaginous materials in the oil shale. The device is energy-saving, can reduce the heat quantity required by an oil shale carbonization furnace by more than one third, and reduce the heat consumption by 60,000 to 80,000 kcal / ton of oil shale distillation.

Owner:辽宁成大能源科技有限公司

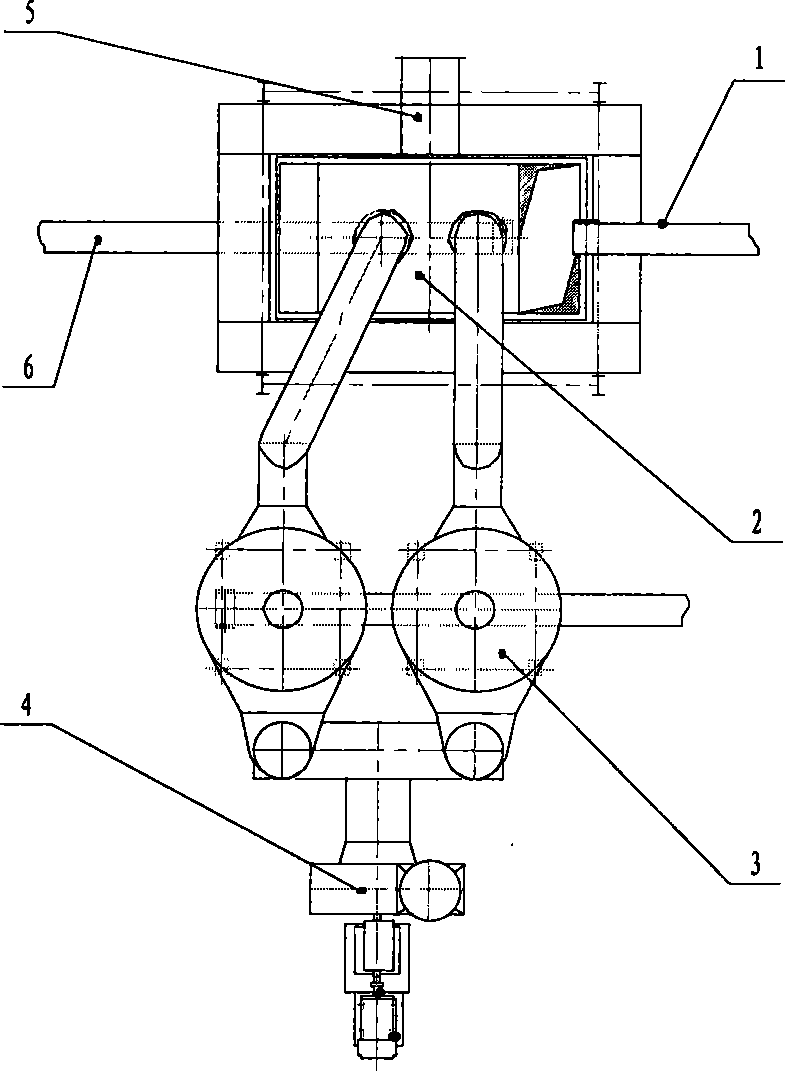

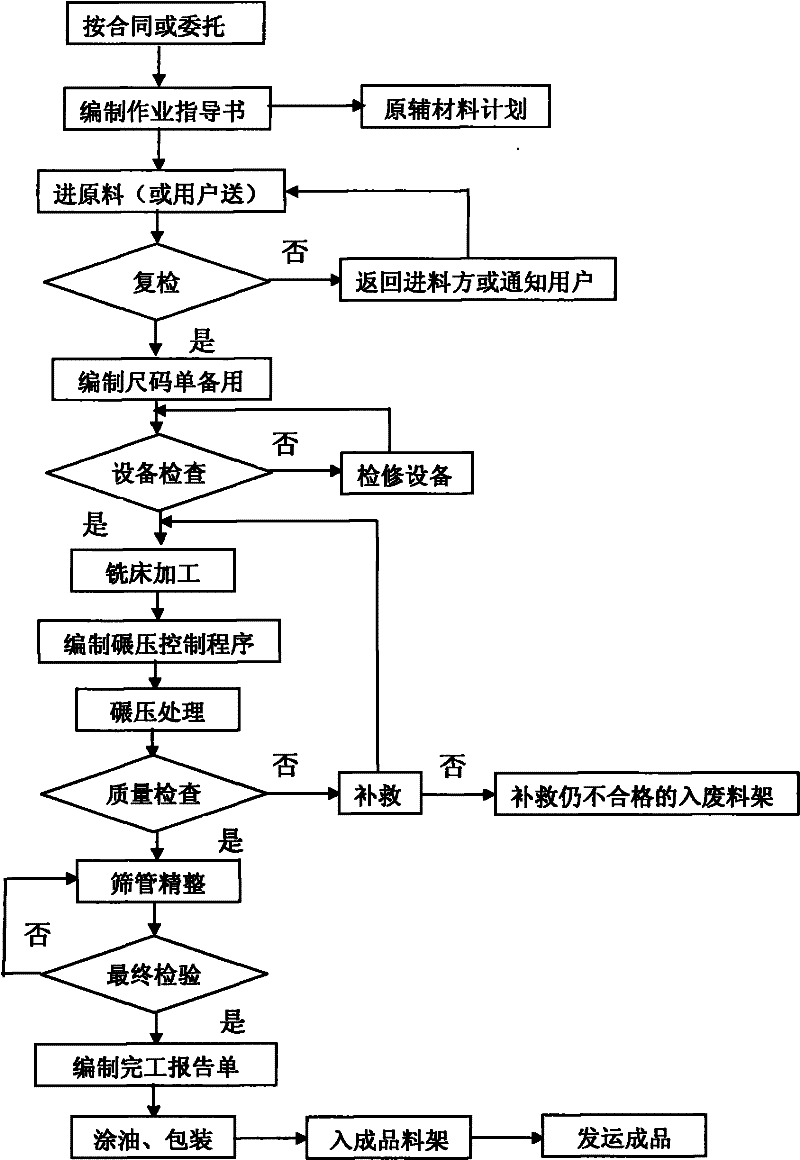

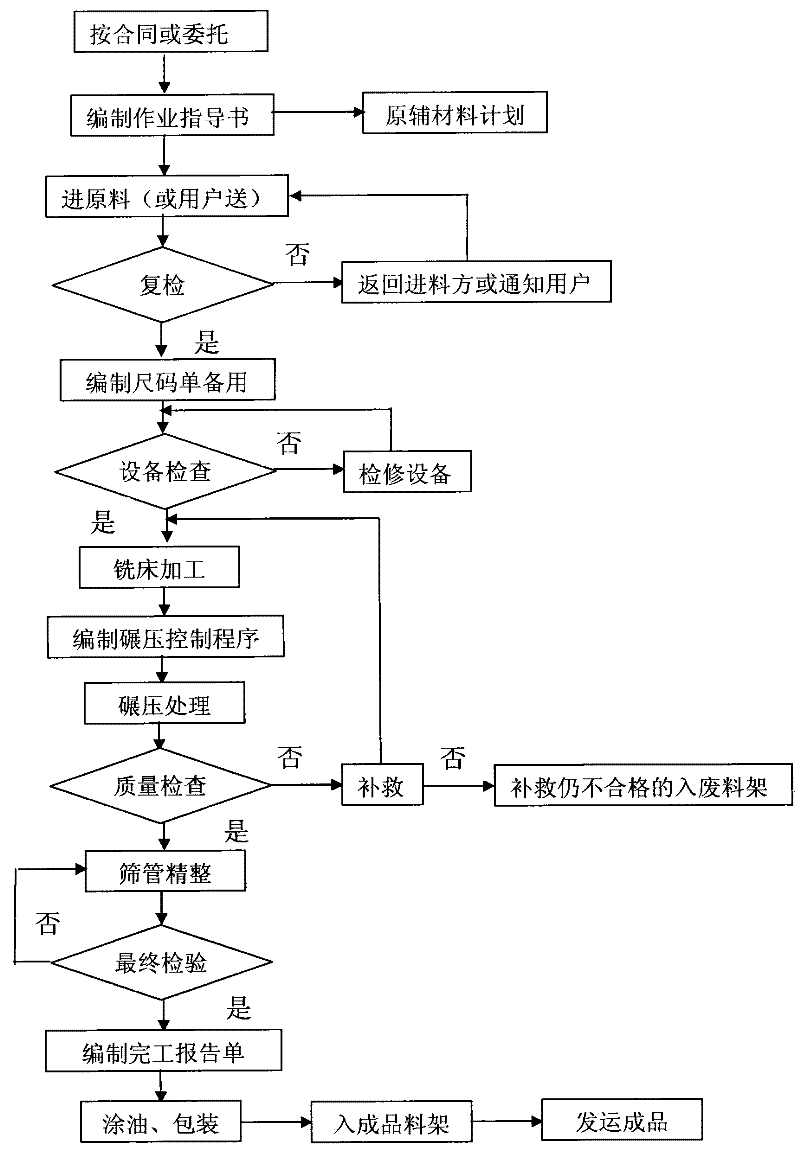

Method for processing trapezoid slit sieve tube by adopting rolling treating device

The invention provides a method for processing a wide slit sieve tube into a narrow trapezoid slit sieve tube by rolling process treatment, comprising the following steps of: applying a reasonable rolling control program as the basic guarantee of processing high-quality trapezoid slit sieve tubes; overhauling machine tools, regulating parameters, cutting processing and finally processing a jackettube into the trapezoid slit sieve tube by rolling treatment. The invention has the effects that a rectangular slit sieve tube processed by a milling machine is treated into the trapezoid slit sieve tube (can reach less than 0.1 mm) of an expanding slit by rolling, thereby reducing the resistance of oil / water penetrating a slit and avoiding grits blocking off the slit, and further, the oil / water yield of an oil / water well is increased. In the process of rolling treatment, equipment has higher stability and rigidity and higher degree of automation, which are the essential conditions of processing, thereby ensuring that the outside diameter dimension precision, the ovality and the surface quality of the trapezoid slit sieve tube meet the demands of product quality standard.

Owner:TIANJIN STEEL PIPE MFG CO LTD

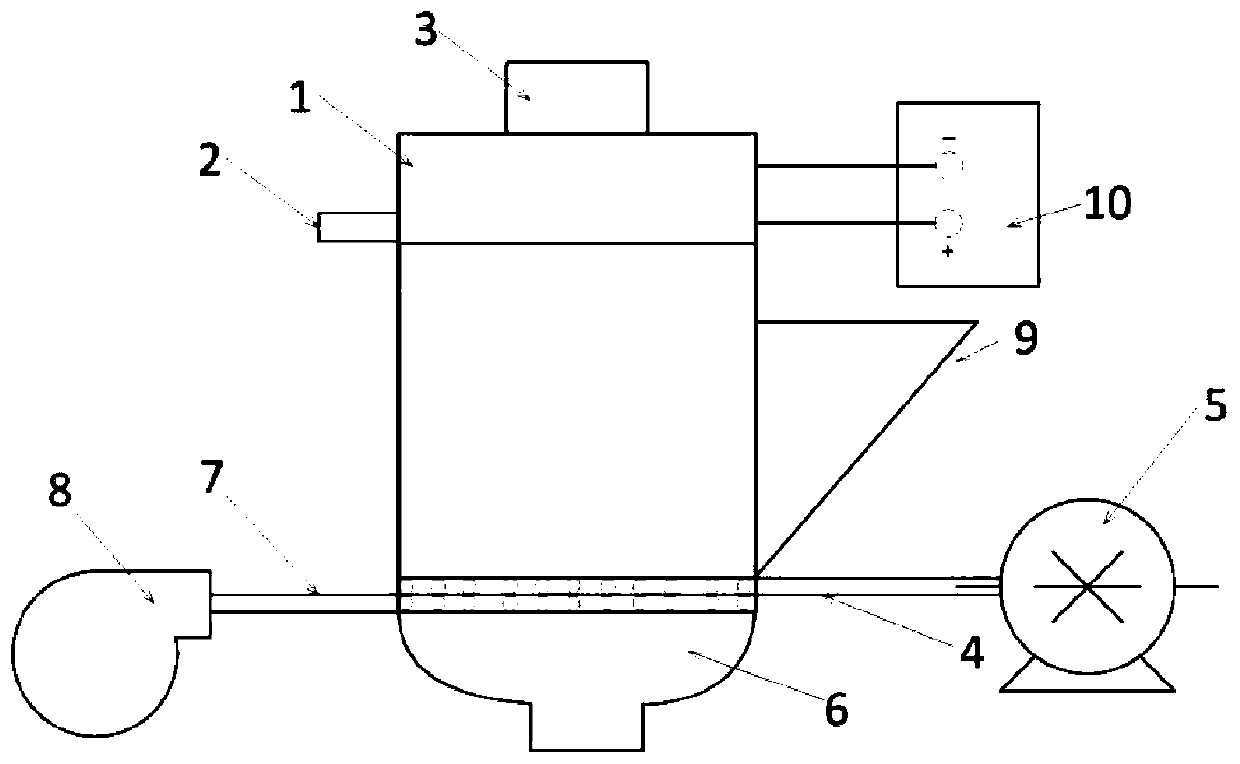

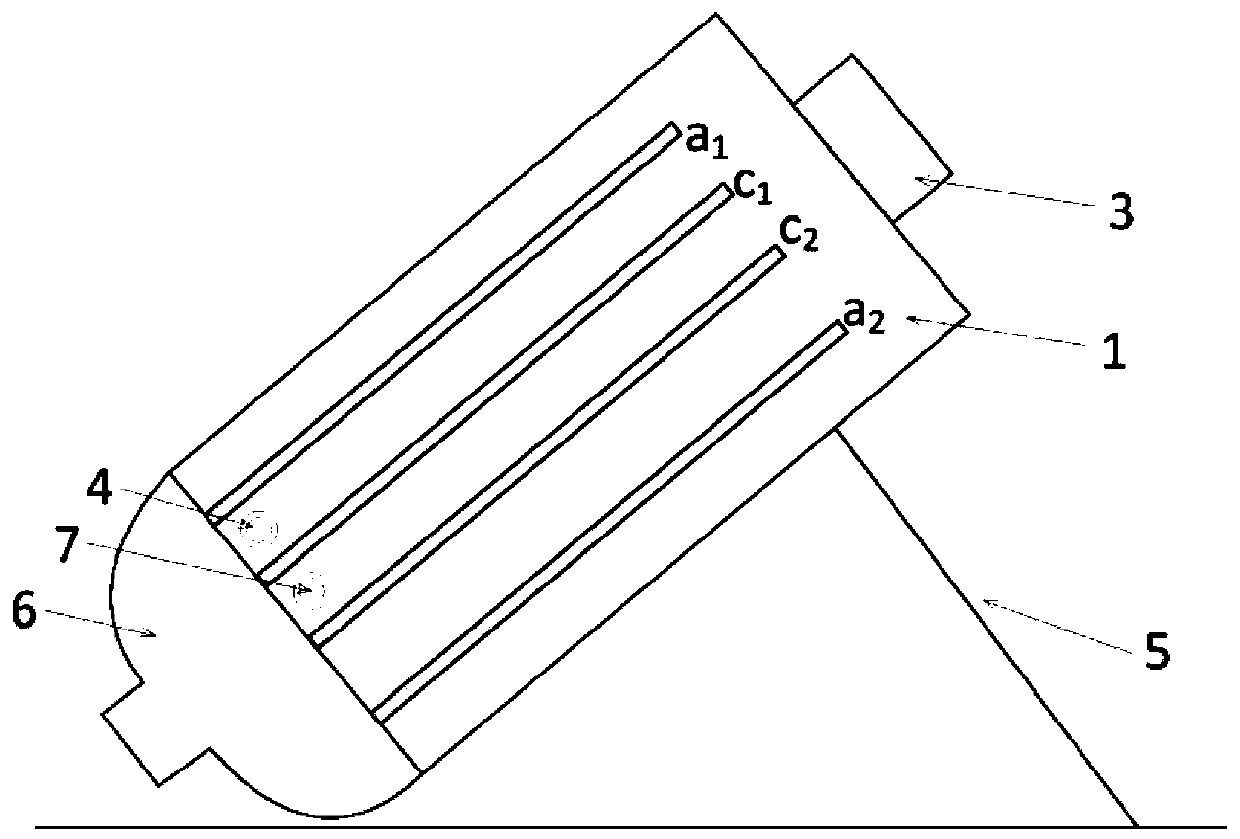

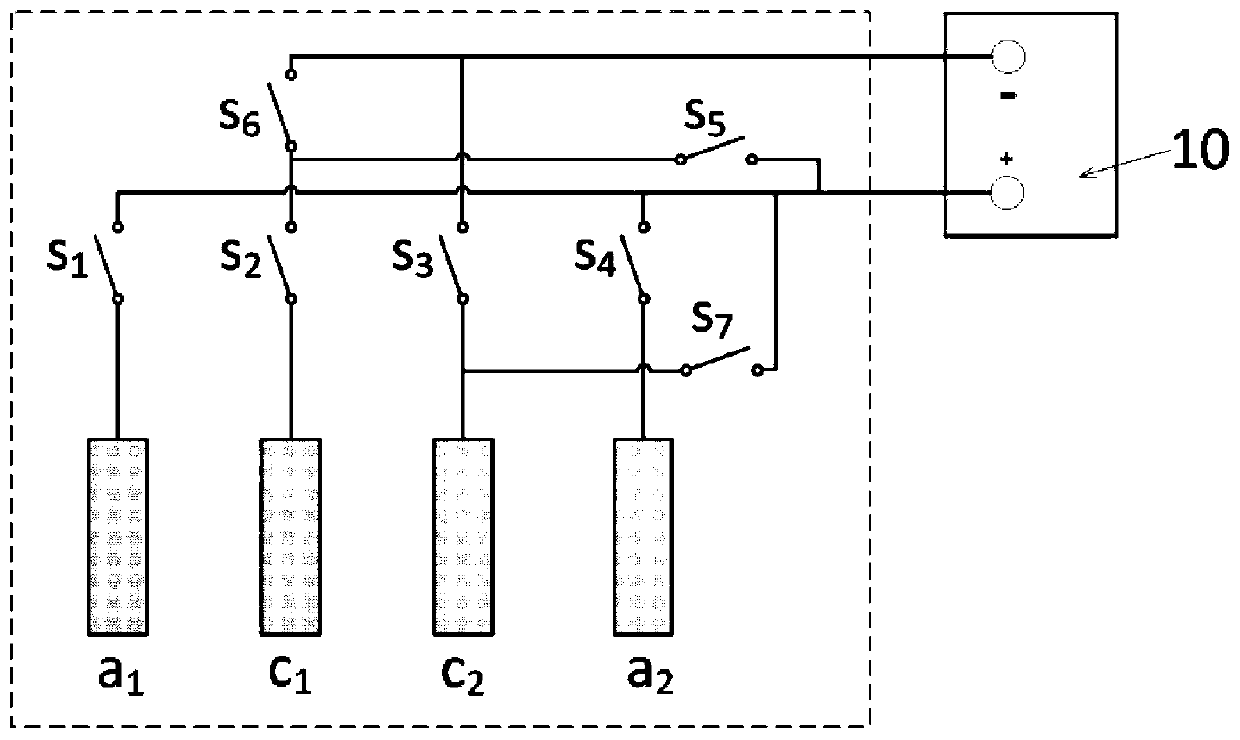

Anodic protection type automatic descaling salt-containing organic wastewater electrolysis device

InactiveCN110937666AReduce accumulationAvoid lossWaste water treatment from quariesWater contaminantsHemt circuitsPhysical chemistry

The invention discloses an anodic protection type automatic descaling salt-containing organic wastewater electrolysis device which is characterized in that a first anode a1, a second anode a2, a firstcathode c1 and a second cathode c2 are arranged in an electrolytic cell 1, and the first cathode c1 and the second cathode c2 are arranged between the first anode a1 and the second anode a2; during electrolysis, the first anode a1 and the second anode a2 are connected in parallel and then are connected with the positive electrode of a power supply 10 in series; and the first cathode c1 and the second cathode c2 are connected in parallel and then are connected with the negative electrode of the power supply 10 in series; when the electrodes are reversed, a first anode a1 circuit and a second anode a2 circuit in an original electrolysis circuit are disconnected, the first cathode c1 and the second cathode c2 are alternately connected with the positive electrode and the negative electrode ofthe power supply 10 respectively to serve as the positive electrode and the negative electrode in an electrode reversing circuit, and therefore surface descaling of the first cathode c1 and the second cathode c2 is achieved. The electrolysis device can effectively reduce scaling on the surface of the cathodes, anode loss is avoided, the electrolysis efficiency is high, and the sewage treatment energy consumption is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

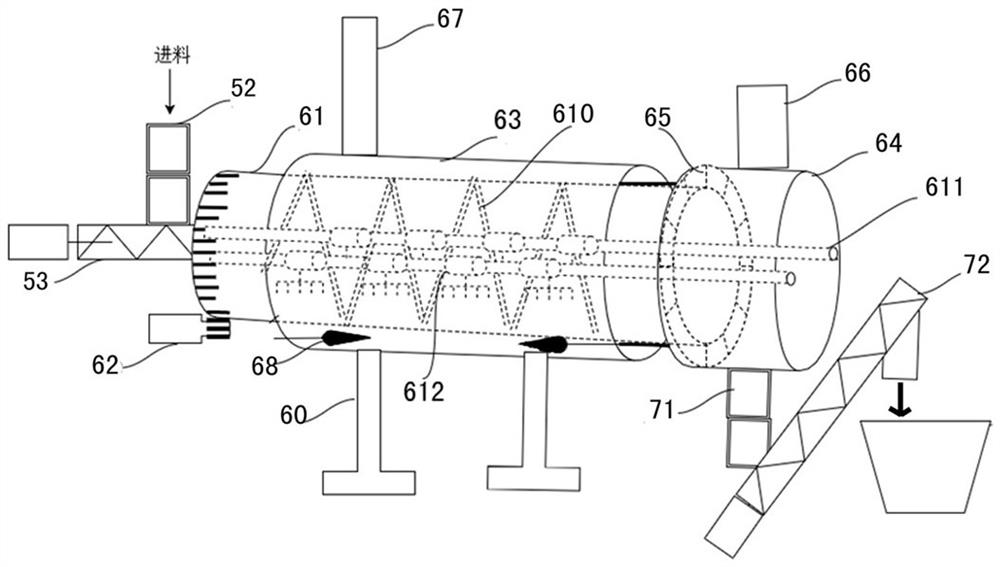

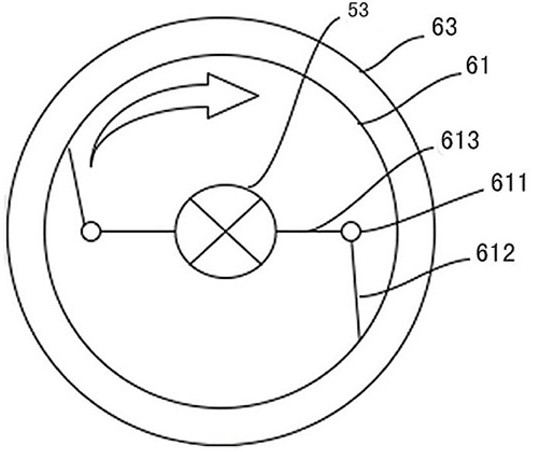

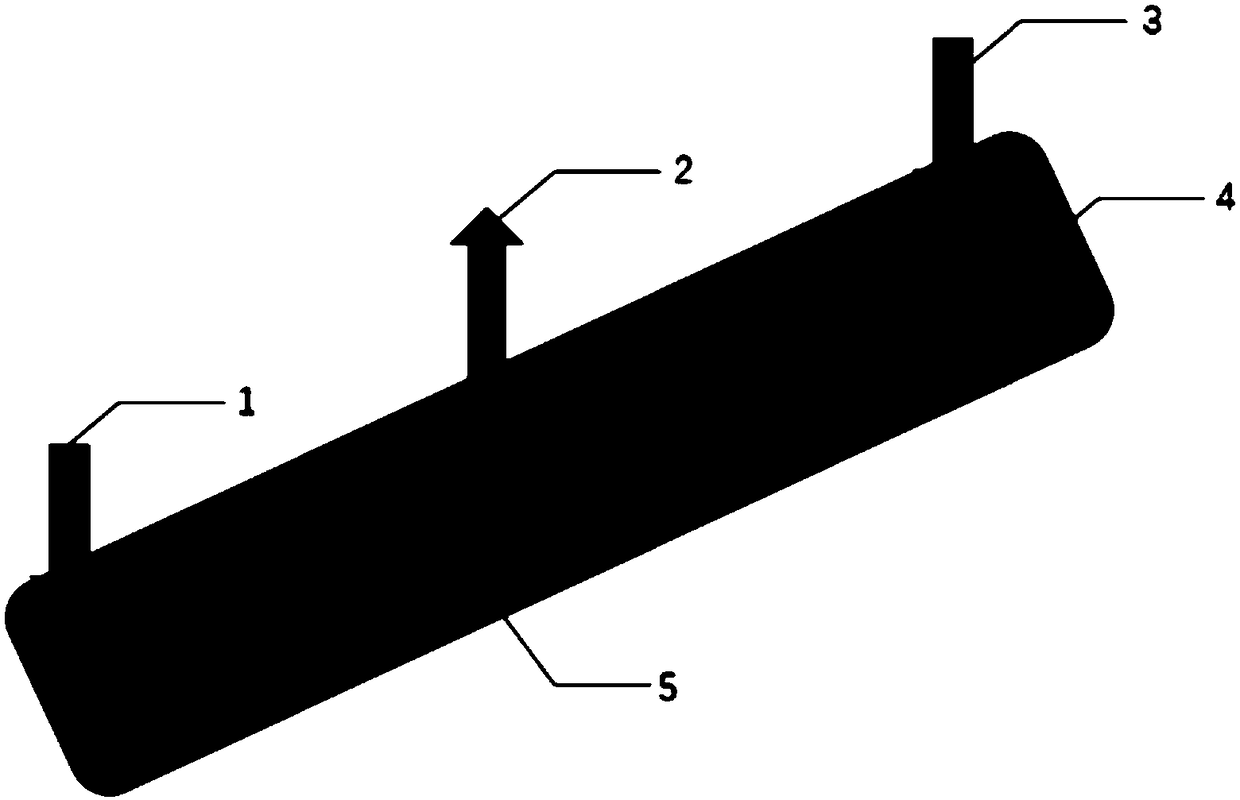

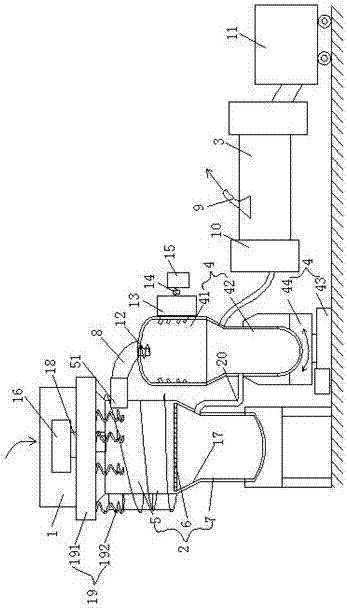

Production method and production system for extracting oil in oil sludge

ActiveCN111875208ARealize continuous industrial productionSuitable for harmless treatmentSludge treatment by pyrolysisByproduct vaporizationThermodynamicsCoke

The invention discloses a production method and a production system for extracting oil in oil sludge. An oil sludge pyrolysis device comprises a rotary drum, wherein the open end of the rotary drum iscommunicated with a fixed cylindrical discharge end socket, and the rotary drum is in rotary sealing fit with the discharge end socket; a spiral guide plate is fixedly arranged on the inner wall of the rotary drum, the rotary drum rotates, and the spiral guide plate pushes and throws oil sludge; oil steam and residues after pyrolysis are discharged from the discharging seal head; a decoking and crushing device in the rotary drum comprises a fixed shaft parallel to the axis of the rotary drum, a plurality of decoking tooth claws are arranged on the fixed shaft at intervals in the axial direction, the handle ends of the decoking tooth claws are rotatably arranged on the fixed shaft in a sleeving mode, the claw ends elastically press and contact the inner wall of the rotary drum through springs, and the rotating direction of the claw ends is opposite to that of the rotary drum under the action of the springs; the decoking tooth claws grab and dig the inner wall of the rotary drum along with the rotation of the rotary drum to remove inner wall cokes and crush oil sludge blocks. The method realizes continuous industrial production of extracting the oil in the oil sludge, and is high inpyrolysis efficiency, thorough in harmless treatment of the oil sludge and high in oil recovery rate.

Owner:舟山麦哲伦环保科技有限公司

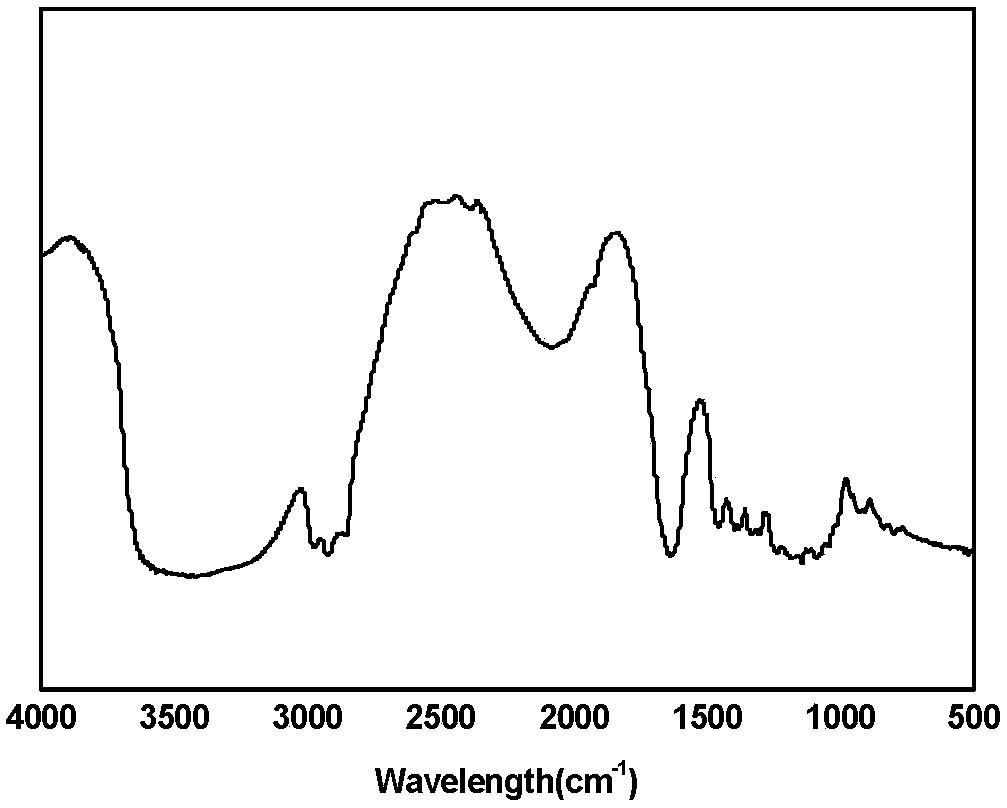

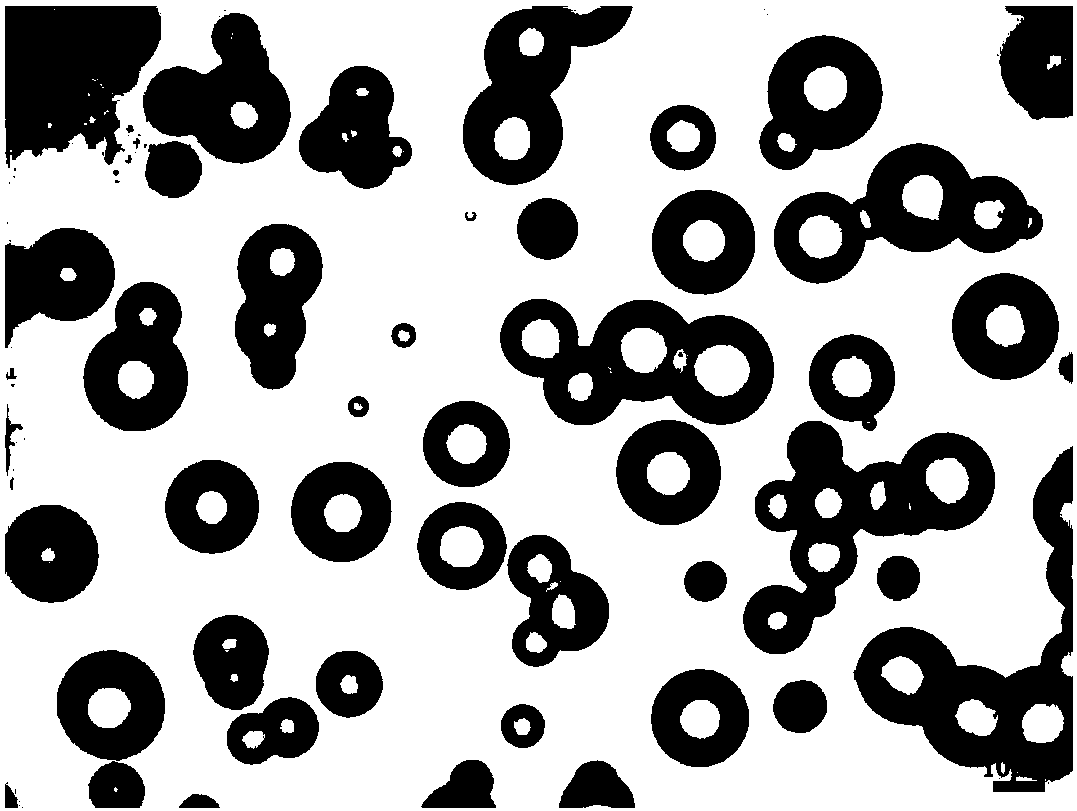

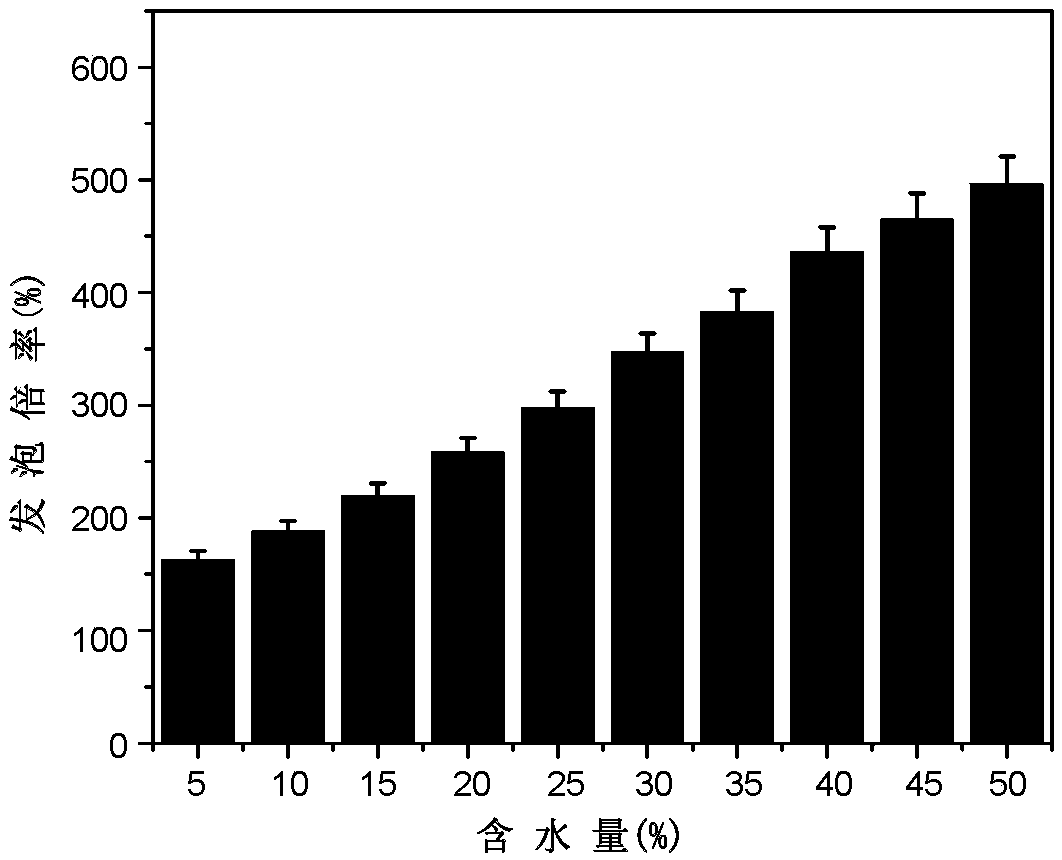

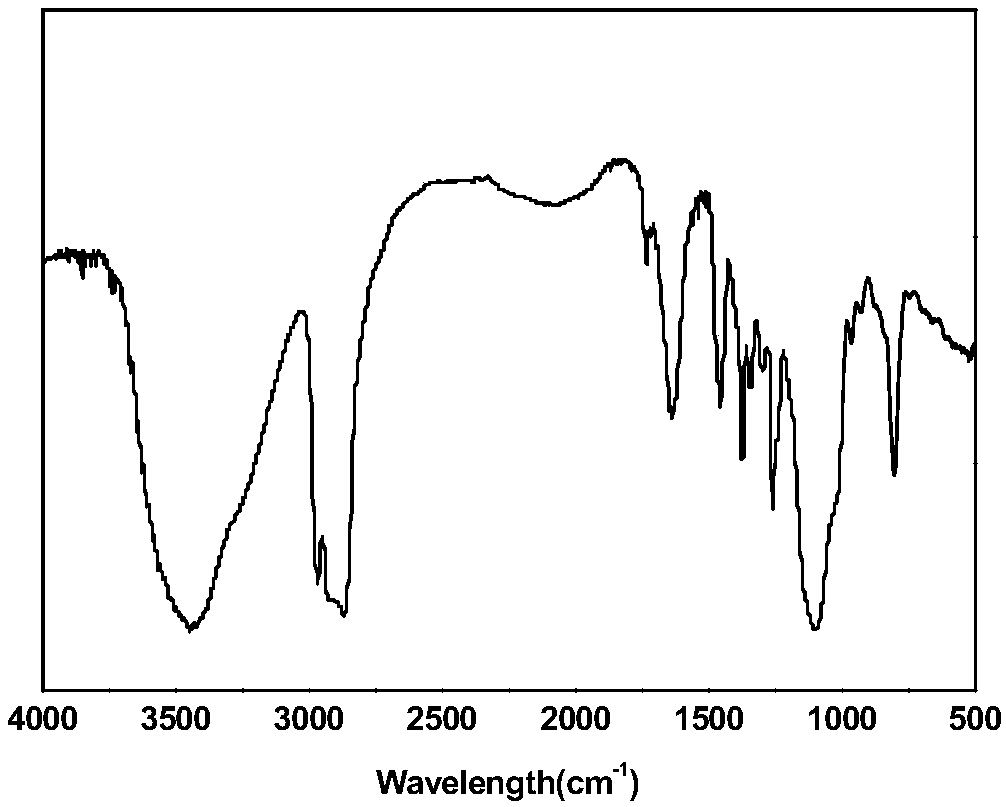

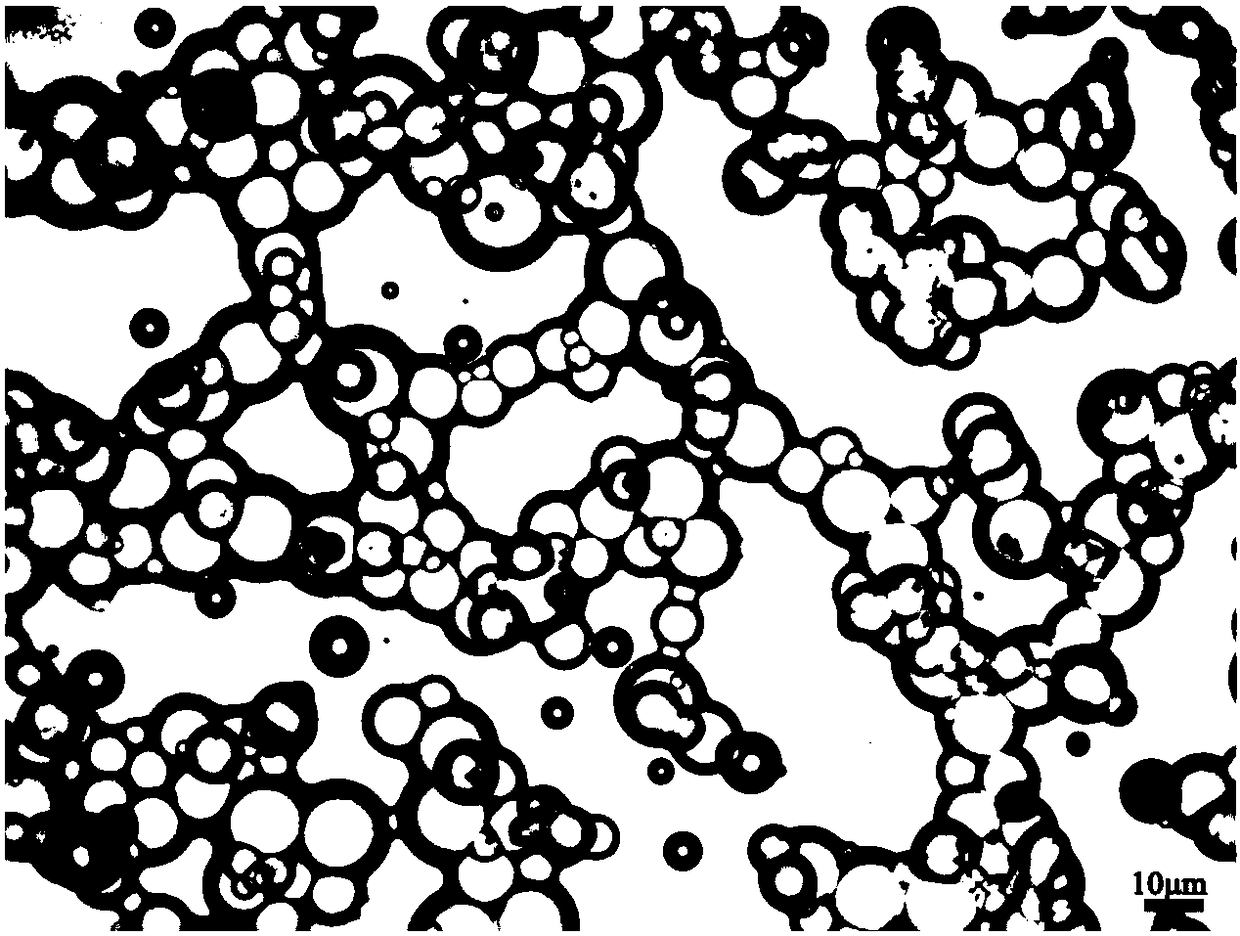

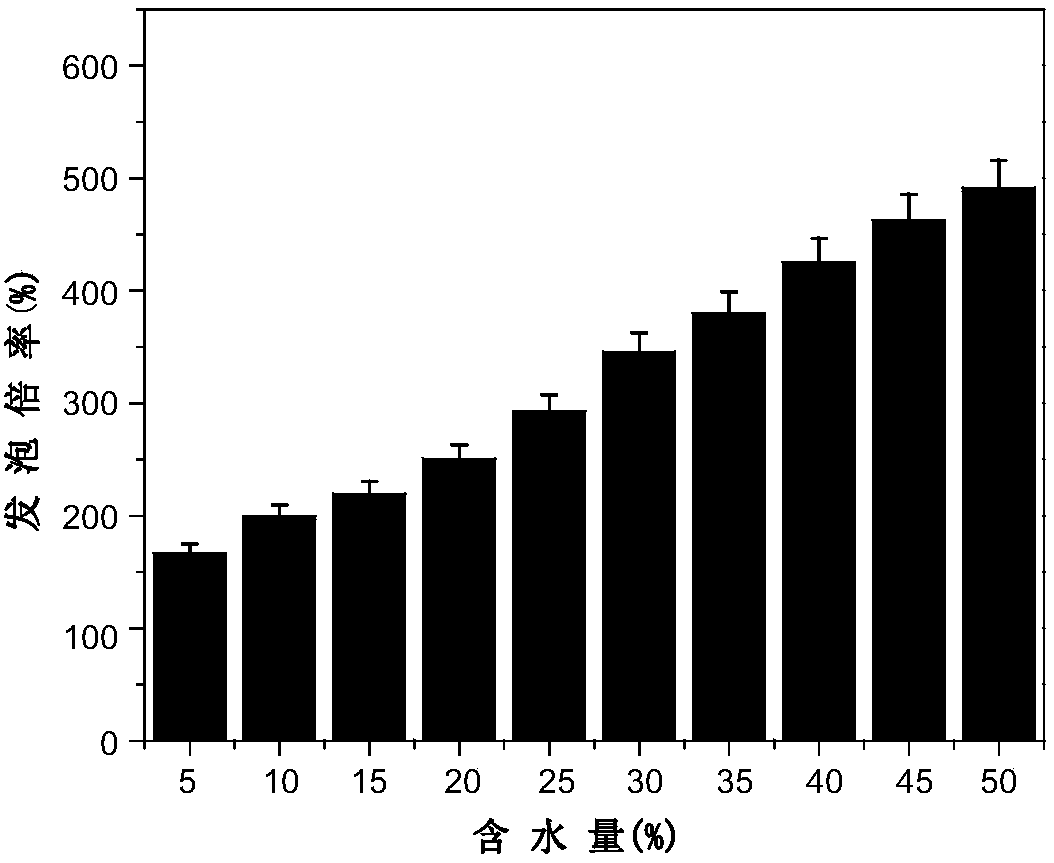

Tri-perfluor decyl silicon-polyethyoxyl-naphthalenesulfonic acid sodium multielement compound as well as preparation method and application thereof

InactiveCN108558929AAchieving FoamingFine foamSilicon organic compoundsFluid removalWaxEthylene oxide

The invention discloses a tri-perfluor decyl silicon-polyethyoxyl-naphthalenesulfonic acid sodium multielement compound as well as a preparation method and application thereof. The multielement compound is prepared from perfluor decane, trifluoroalkyl silane, ethylene oxide and p-croceic acid through compounding. The preparation method comprises the following steps: mixing the perfluor decane andthe trifluoroalkyl silane, acidifying, heating to 150-170 DEG C, adding ethylene oxide, further adding p-croceic acid after reactions, and finally adjusting the pH value to 8-9.5, thereby obtaining the multielement compound. The multielement compound disclosed by the invention is applied to oil fields to carry out foam oil expelling. The multielement compound disclosed by the invention is not onlycapable of generating foams efficiently, but also good in foam stabilization effect, has no spectrum separation in stratum migration, particularly has a good foam oil expelling effect on high oil content (the oil content is 80-95%) and high wax foam systems, and meanwhile is simple in preparation method, high in operability and low in cost.

Owner:NANJING NORMAL UNIVERSITY

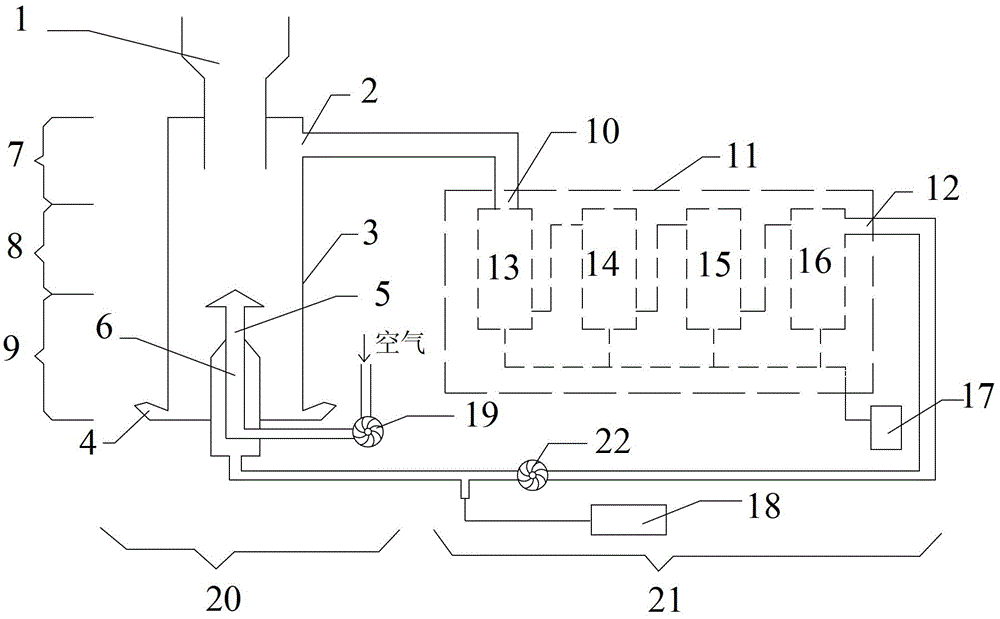

Device and method for homogenizing oil shale powder

ActiveCN103394302AHighlight Substantial ProgressThe composition is uniform and stableTransportation and packagingMixersOil shalePetroleum engineering

The invention discloses a device and a method for homogenizing oil shale powder. The device is characterized by mainly comprising a round bin, and a homogenizing chamber, a discharging chamber, a high-position unloading device, a low-position unloading device, a soft inflation system, a forced inflation system, a plurality of open type inflation boxes and a roots blower which are arranged in the round bin. By using the device, inflation air passing through the inflation boxes enters the oil shale powder in the round bin so as to be uniformly and fully mixed with the oil shale powder; then the mixed oil shale powder is continuously unloaded by the high-position unloading device connected with the round bin; as the device and the method are used, the fluctuation range of the oil content of the oil shale powder can be reduced to be below + / -0.2%, and the homogenizing coefficient can be up to 8-13.

Owner:SHENYANG XINBO IND TECH

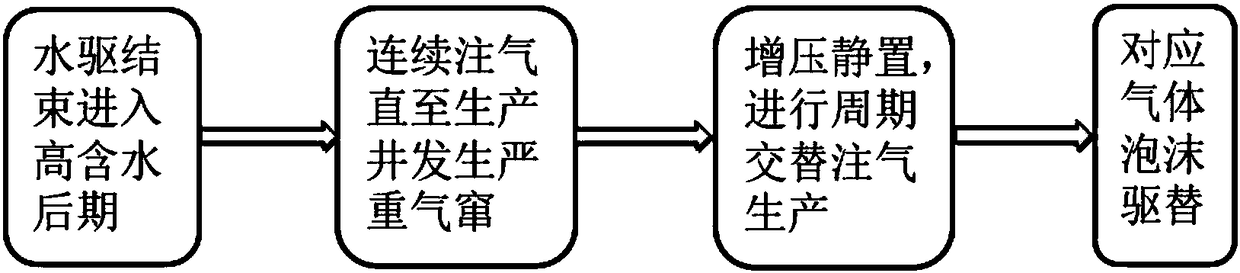

Method for increasing production by injecting gas at different development stages of inclined fault block oil reservoir

InactiveCN108361008AAddressing Rapidly Declining Oil ProductionImprove oil recoveryFluid removalPeriodic alternatingFoaming agent

The invention relates to a method for increasing production by injecting gas at different development stages of an inclined fault block oil reservoir. The method comprises three stages that firstly, gas is injected into a high position of a fault block oil reservoir structure to drive the top remaining oil, production is carried out in production wells at low positions, while due to the serious gas channeling, the production wells produce a large amount of gas very quickly and produce little or no more oil; secondly, the production wells are shut down, and the gas injection pressurization is continued, a gas injection well is closed for standing when pressure is increased to a certain level, oil and gas are transported again due to gravity differentiation, a gas channeling channel is filled, and a certain scale of gas cap is formed, and then a well is opened for production, due to the redistribution of the gas channeling channel and the expansion energy of the gas cap, a better increasing production effect is obtained, and the gas well and the production wells are periodically and alternately switched until the development effect of the production wells deteriorates; and thirdly, the gas and foaming agent solutions are injected into a reservoir from the gas injection well at the same time and after forming foams, the foams have a good plugging effect on the gas channeling channel, and thus the development effect is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

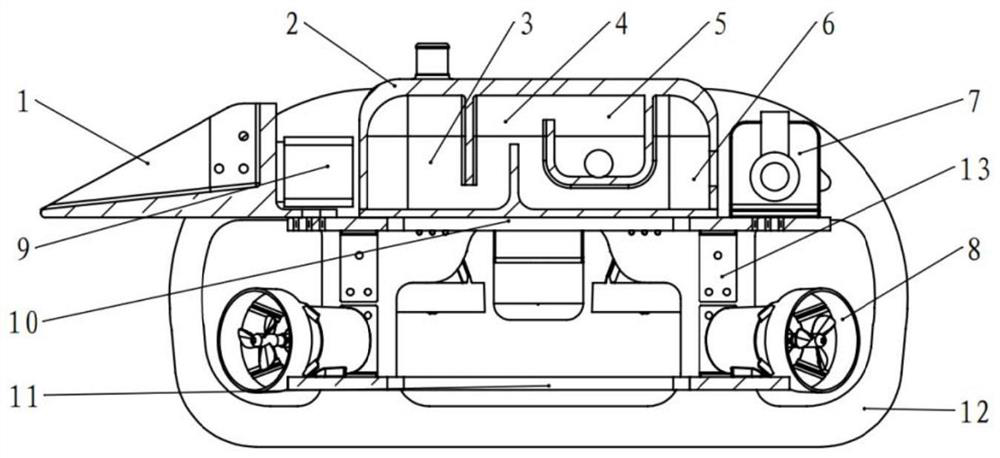

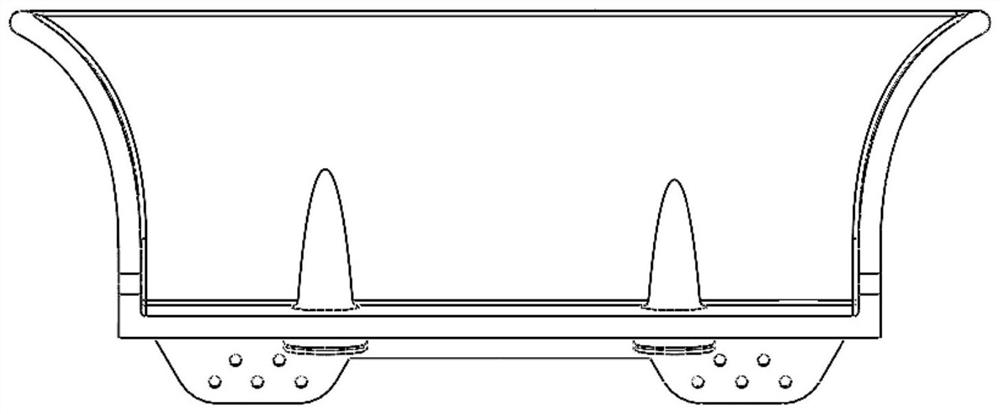

Offshore floating oil collecting device

PendingCN113800596AStrong mobilityHigh oil leakage collection efficiencyFatty/oily/floating substances removal devicesSeawater treatmentSeawaterBuoyant flow

The invention provides an offshore floating oil collecting device. The device comprises a shell, a power device, a shovel type oil collecting device, a water pump, an oil-water separation tank and a control device; the power device is mounted on the shell, connected with the control device and used for providing power and buoyancy for the shell, and the shovel type oil collecting device is arranged at the front end of the shell and used for collecting floating oil; an oil outlet of the shovel type oil collecting device is connected with the oil-water separation tank through the water pump, the oil-water separation tank comprises a cabin for separating oil from water, and the cabin is provided with an oil outlet and a seawater discharge port; and floating oil collected by the shovel type oil collecting device is sucked into the oil-water separation tank through the water pump to be separated, and oil and water are respectively discharged from the oil outlet and the seawater discharge port. Leaked oil is treated through a physical method, an oil-water mixture is collected into the oil-water separation tank through the water pump to be preliminarily separated, the oil-water mixture is preliminarily separated through the oil-water separation tank and rapidly transferred to a cabin or a shore, and the leaked oil collection efficiency is high.

Owner:DALIAN MARITIME UNIVERSITY

Working position adjusting device for large-scale generator

InactiveCN101016936AImprove oil recoveryExtended service lifeGearingFlexible member pumpsReducerSignal generator

The invention relates to a working position adjuster of large motor, wherein two sides of a base are symmetry arranged with two support, which have a transmission lead screw arranged between, two sides of the lead screw are symmetry arranged with feed shafts, the feed shafts and the upper part of the lead screw are arranged with a movable base disposed with a motor base, the lower part of the movable base relative to two feed shafts is arranged with a locking handle, and the outer side of the support is arranged with a speed reducer and a motor of the reducer. The invention can prolong the service life of belt and reduce cost.

Owner:齐红军

Well group well spacing method of microbial oil displacement oil recovery technology

The invention discloses a well group well spacing method of a microbial oil displacement oil recovery technology. A set of combined injection-production well pattern of horizontal well exploitation and vertical well injection is deployed in a thicker sandstone oil reservoir by utilizing a microbial tertiary oil recovery technology, and the combined injection-production well pattern needs to meet the requirements of plane correspondence, longitudinal three-dimension and bottom injection and top production; the vertical well injection refers to injecting microorganisms into a bottom area of a sandstone reservoir by using a vertical well, and the horizontal well exploitation refers to deploying the horizontal section of a production well in a top area of a thicker sandstone reservoir; the plane correspondence refers to overlapping the horizontal section of the injection vertical well and the horizontal section of the production well after being projected to the plane in an overlooking state, and an up-and-down corresponding relation is achieved; and the longitudinal three-dimensional refers to that the injection section of the vertical well and the horizontal section of the productionwell are arranged in parallel at different depths in the sandstone reservoir, and a three-dimensional well pattern is formed in the section parallel to the gravity direction and perpendicular to a main shaft of the horizontal section of the production well. The well group well spacing method has the advantages of being higher in oil sweeping efficiency, high in oil extraction capacity, higher infinal recovery ratio and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

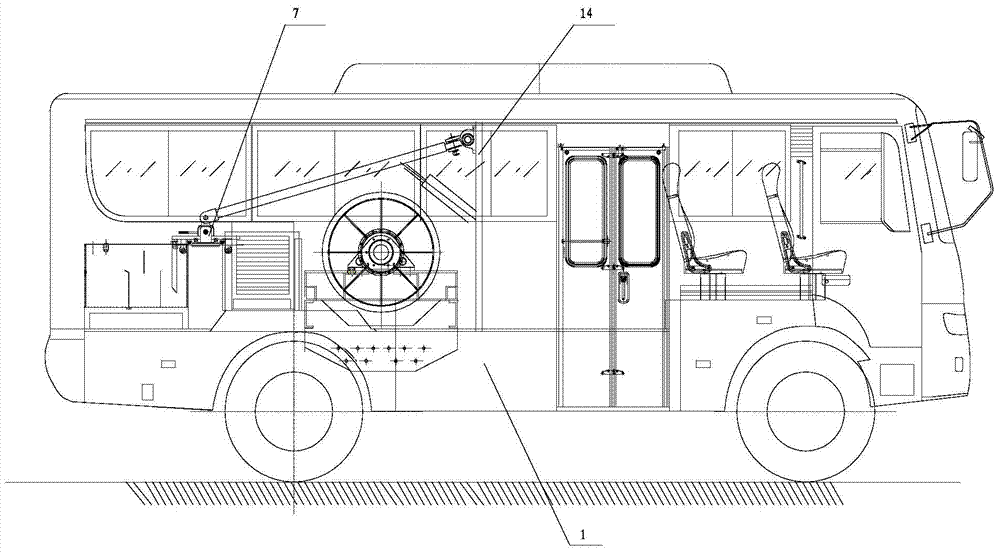

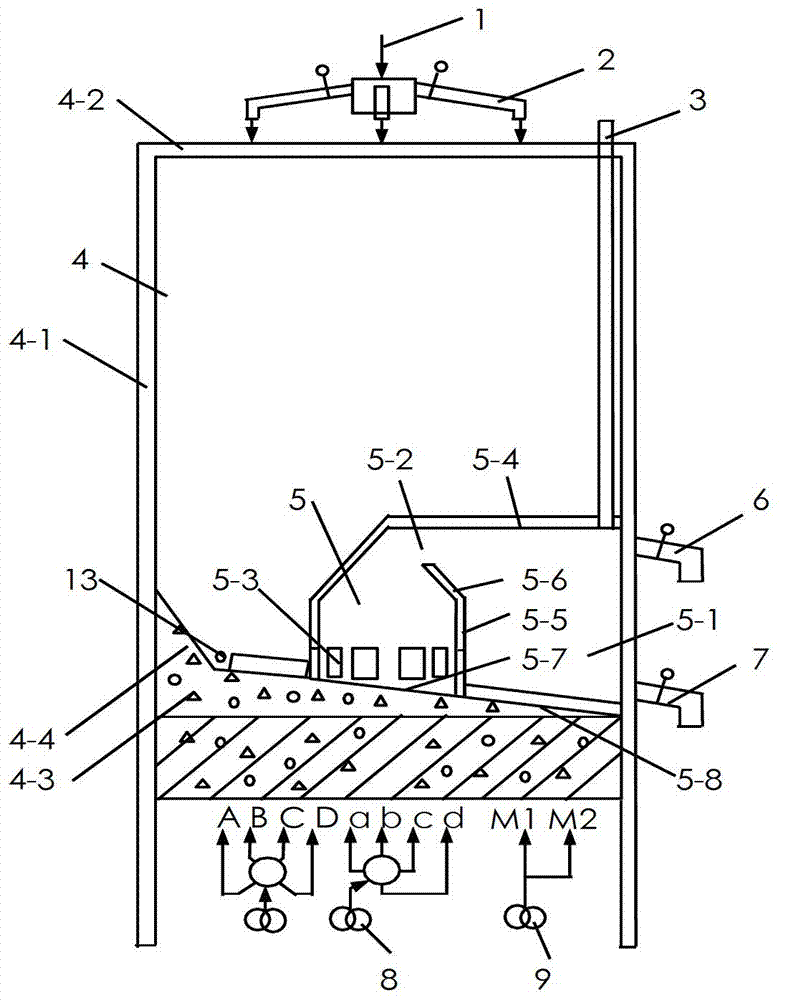

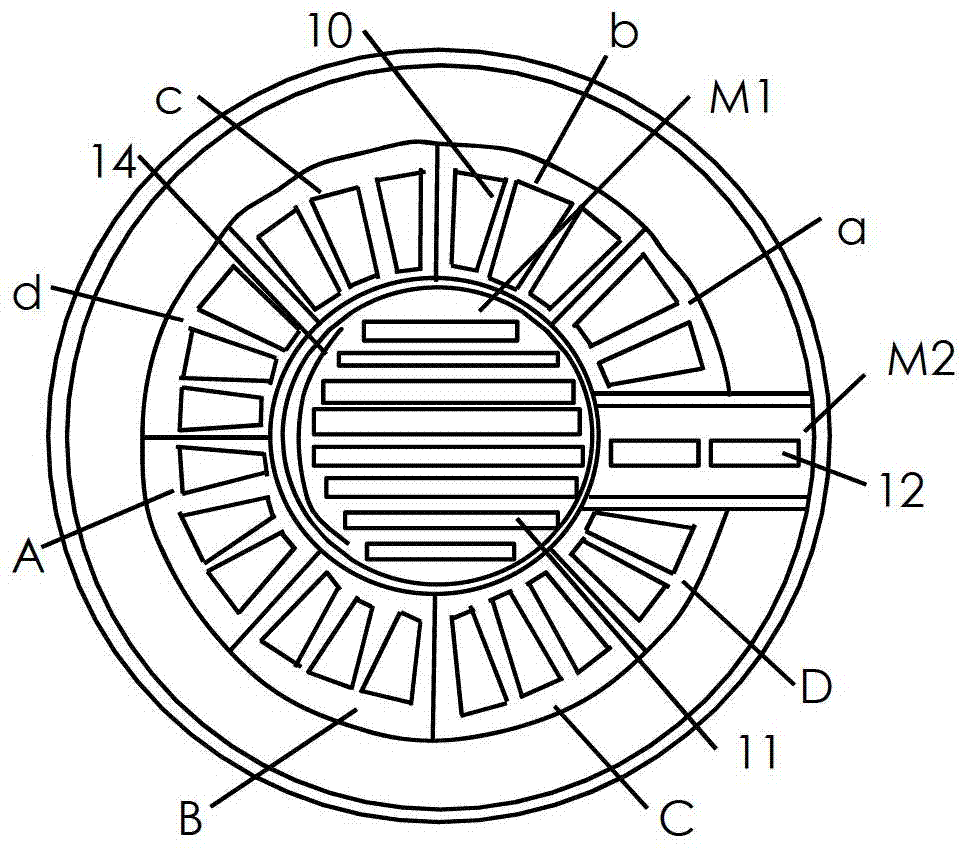

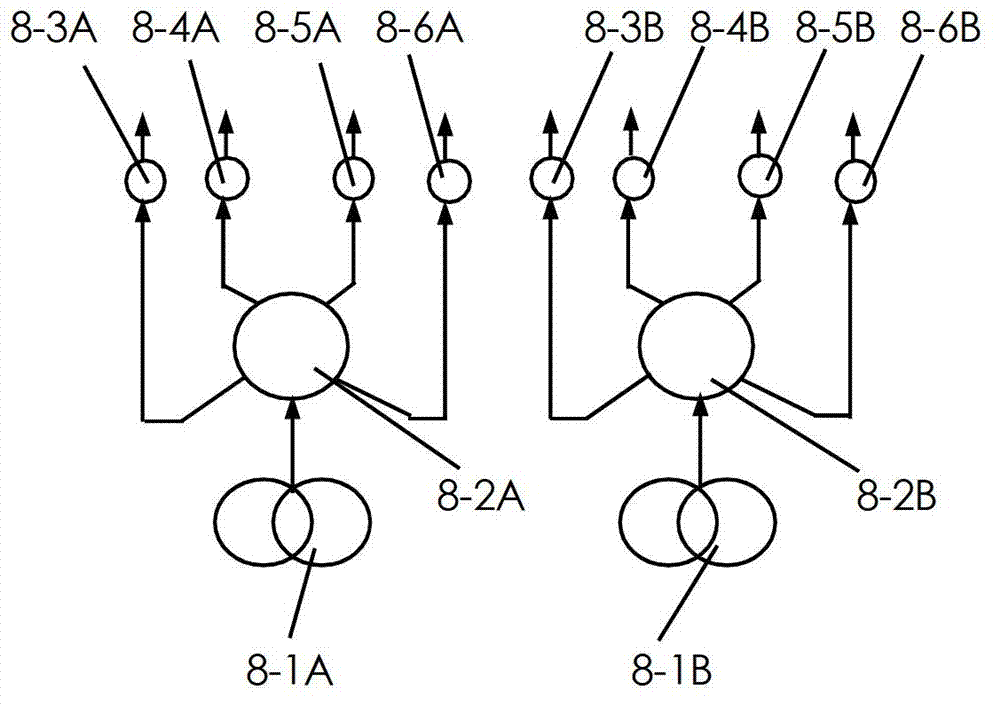

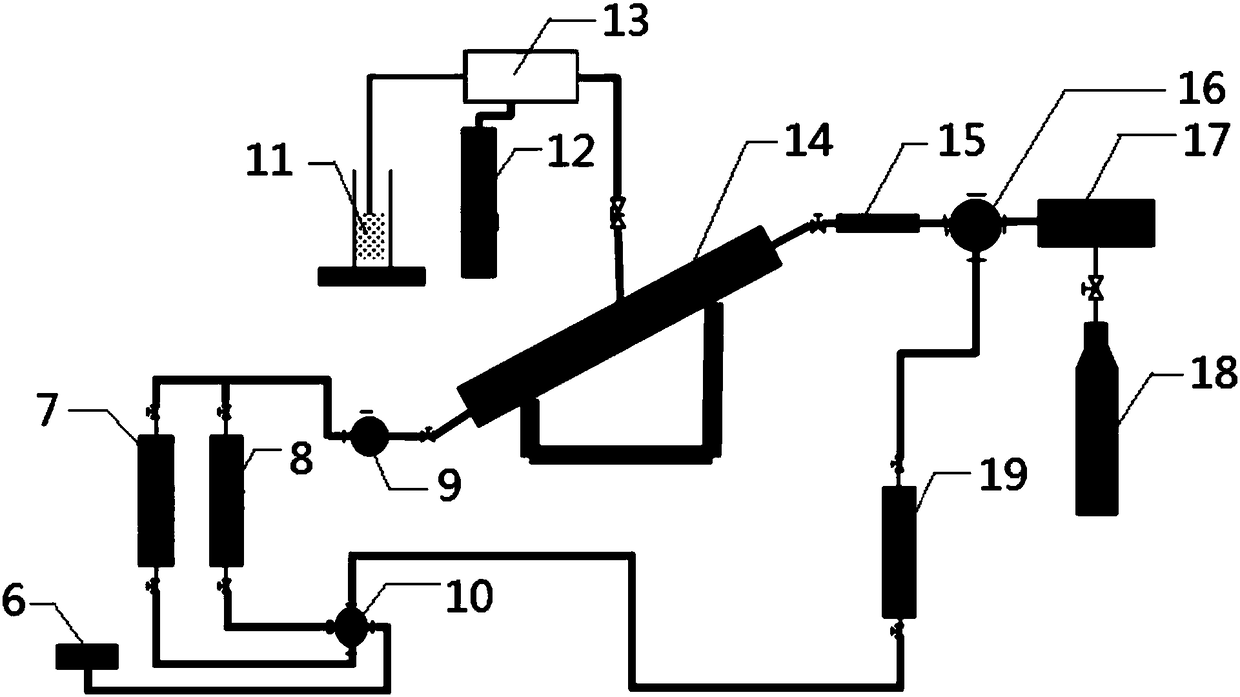

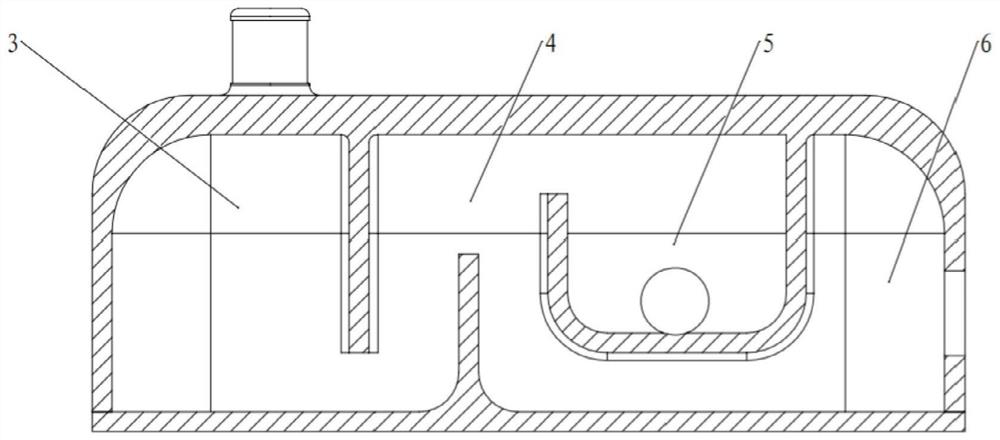

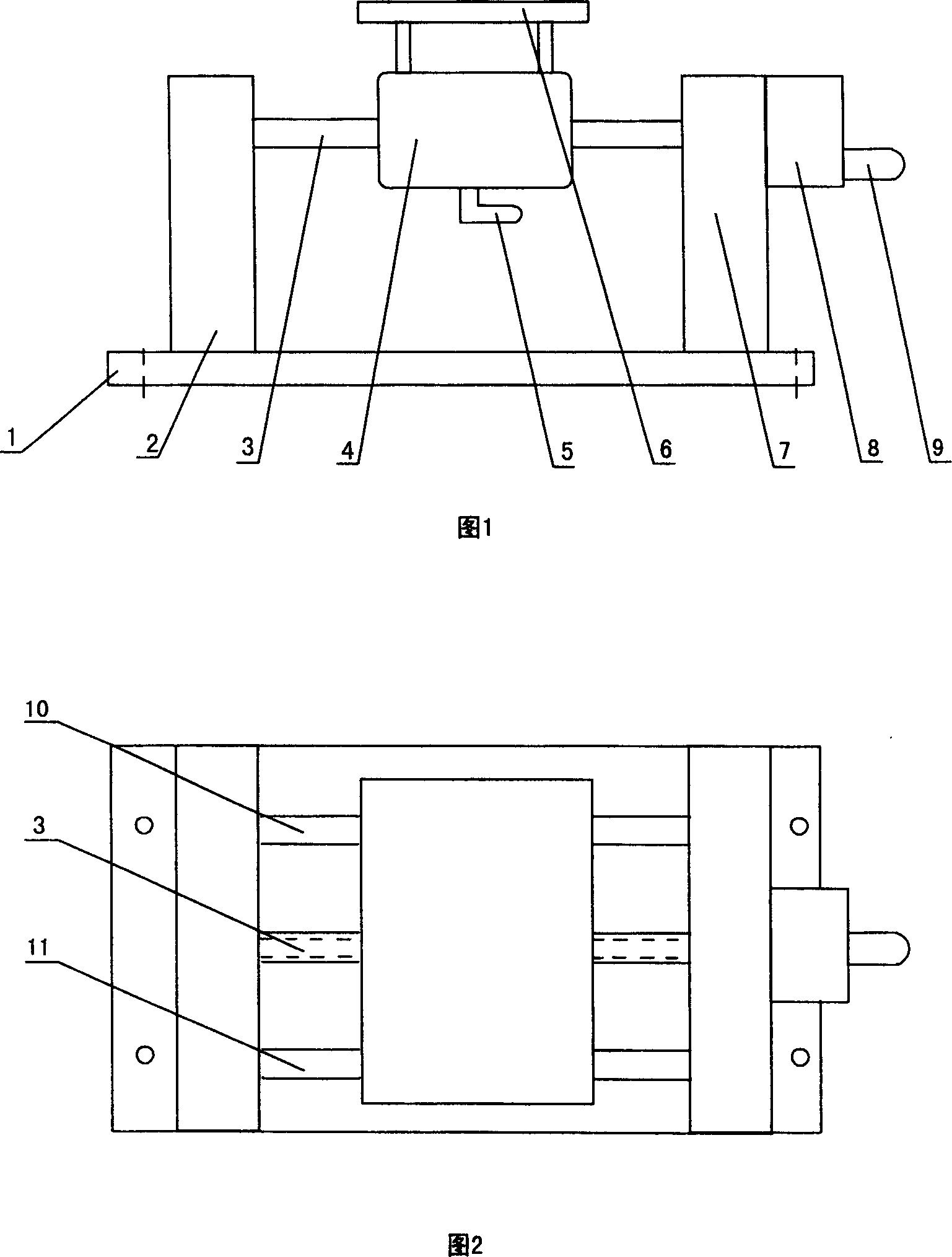

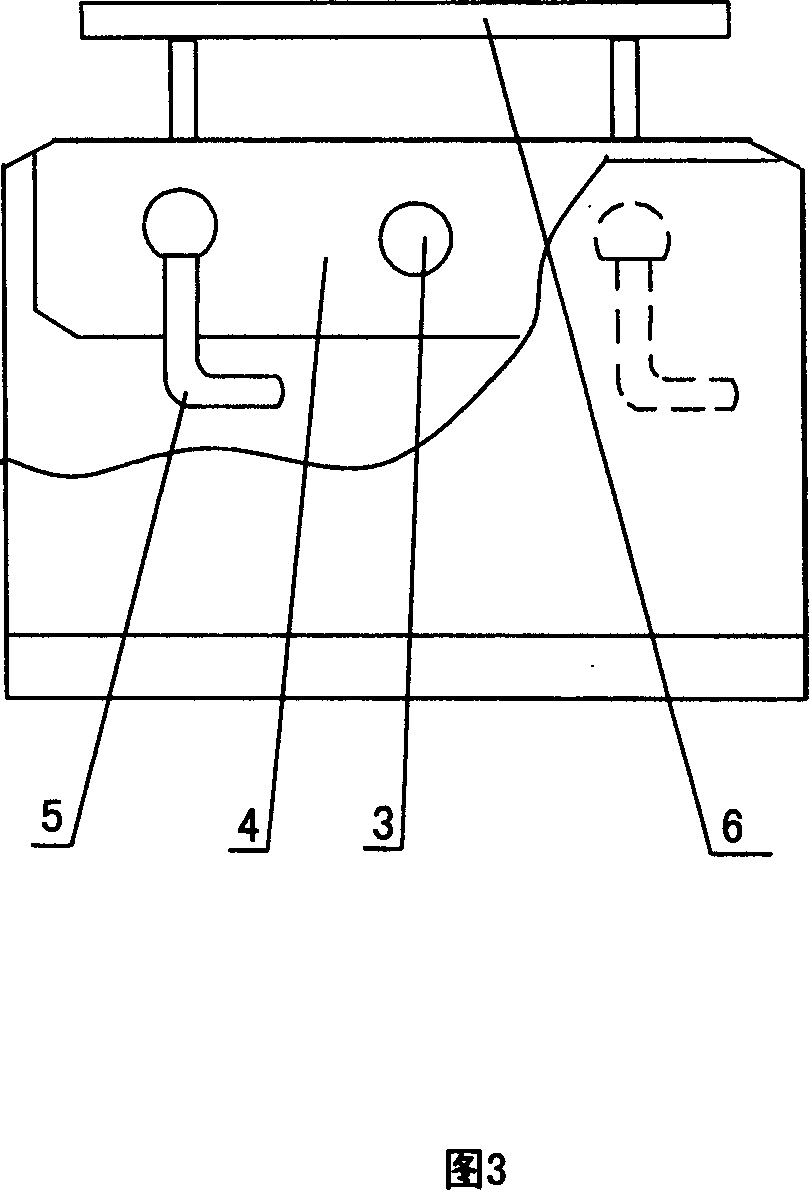

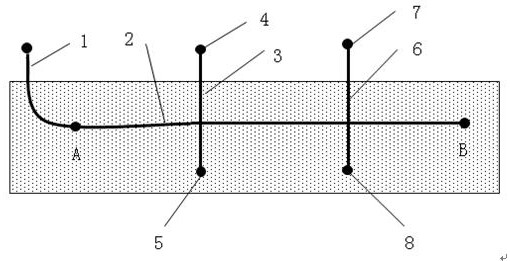

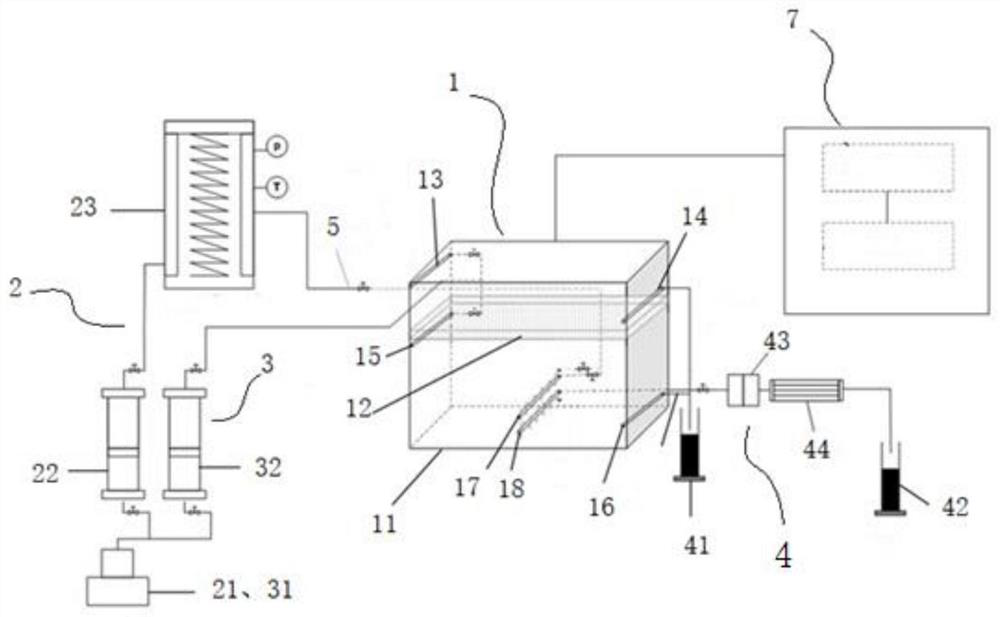

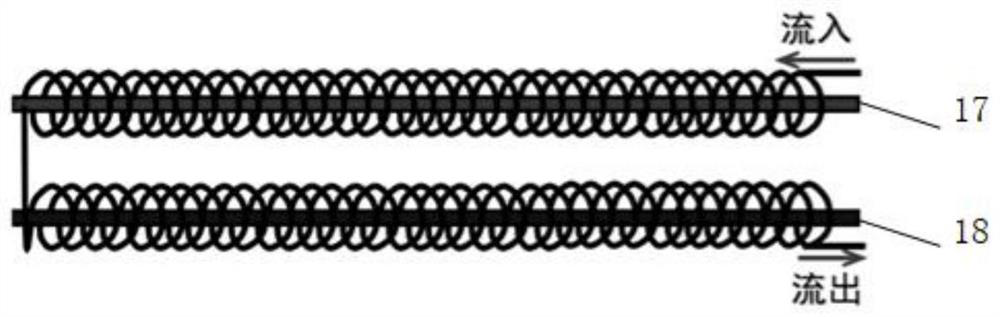

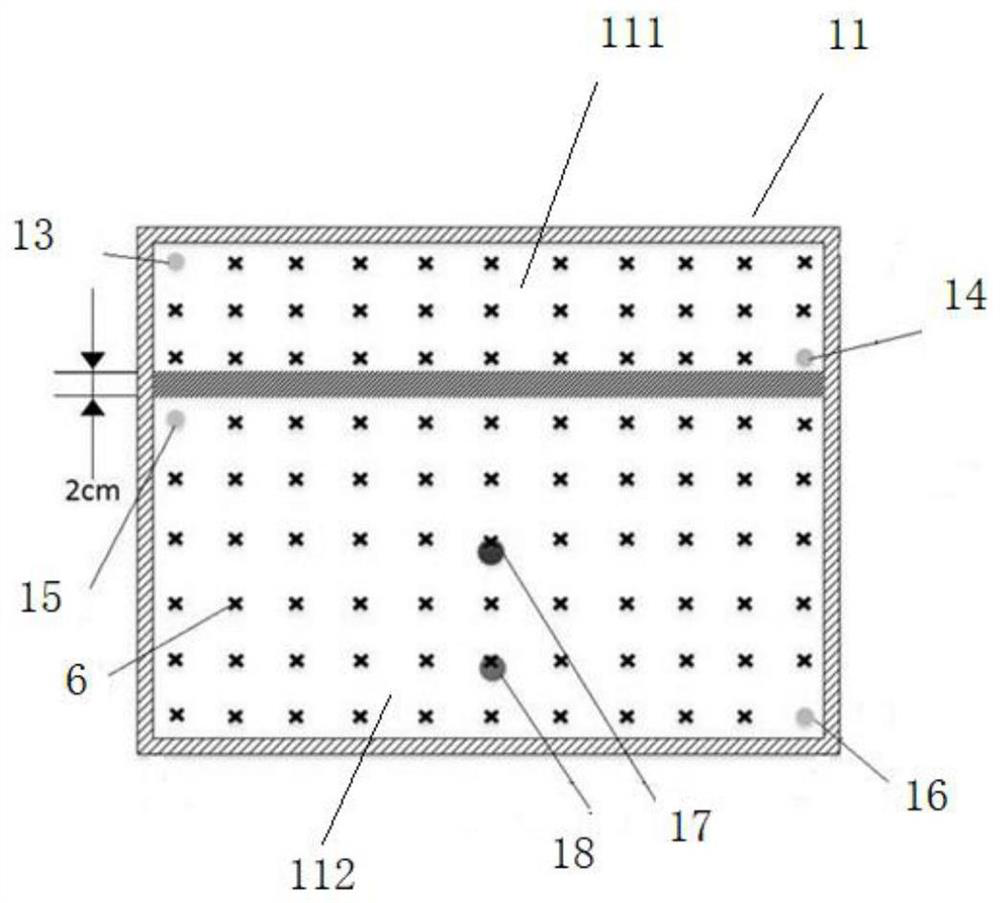

Method and device for researching steam cavity expansion boundary in SAGD development process

PendingCN112324407ASimulation is accurateImprove oil recoveryFluid removalEducational modelsThermodynamicsOil production

The invention discloses a method and device for researching a steam expansion boundary in an SAGD development process. The device comprises an SAGD three-dimensional experiment simulation system, a steam supply unit, an oil supply unit and a collection unit. The SAGD three-dimensional experiment simulation system comprises a shell, an interlayer forming mold, a first oil injection pipe, a first oil production pipe, a second oil injection pipe, a second oil production pipe, a steam injection pipe and a production pipe. The interlayer forming mold is detachably arranged in the shell and used forbeing detached after an interlayer with the needed permeability is formed in the shell, and the interior of the shell is divided into an upper crude oil storage layer and a lower crude oil storage layer through the interlayer. The first oil injection pipe and the second oil production pipe are arranged in the upper crude oil storage layer; the second oil injection pipe, the second oil productionpipe, the steam injection pipe and the production pipe are arranged in the lower crude oil storage layer; the steam supply unit is connected with the steam injection pipe; the oil supply unit is connected with the first oil injection pipe and the second oil injection pipe; and the first oil production pipe, the second oil production pipe and the production pipe are connected with the collection unit.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Compression calcining type oil shale dry-distillation system

PendingCN107298982AImprove retort efficiencyImprove oil recoveryIndirect heating destructive distillationSpecial form destructive distillationSand blastingHeat energy

The invention discloses a compression calcining type oil shale dry distillation system, which comprises a crushing device, a compression classification device, a sandblasting dry distillation device, a filter, an oil gas separation device, an oil gas dust collector, and an oil collection device connected in sequence, wherein: compression classification The device includes sequentially connected capsule-type grading compression chambers, fixed mesh screens, and first-stage dry distillation and calcining chambers. The capsule-type grading compression chambers are equipped with vertically telescopic power sources, telescopic sleeves, and automatic recovery devices. The outlet of small grains of oil shale passes through The conveying pipe transports the small particle oil shale to the sandblasting and retorting device, and the sandblasting and retorting device includes a vertical sandblasting section and a secondary calcining device; the primary retorting and calcining chamber is also connected to the secondary calcining device. The dry distillation system of the present invention compresses and grades oil shale according to particle size, and is accompanied by sandblasting in the second stage of calcination, and heat energy can be shared between the two stages of calcination. It is a highly efficient, low-loss graded dry distillation system for calcination.

Owner:JIANGSU PENGFEI GROUP

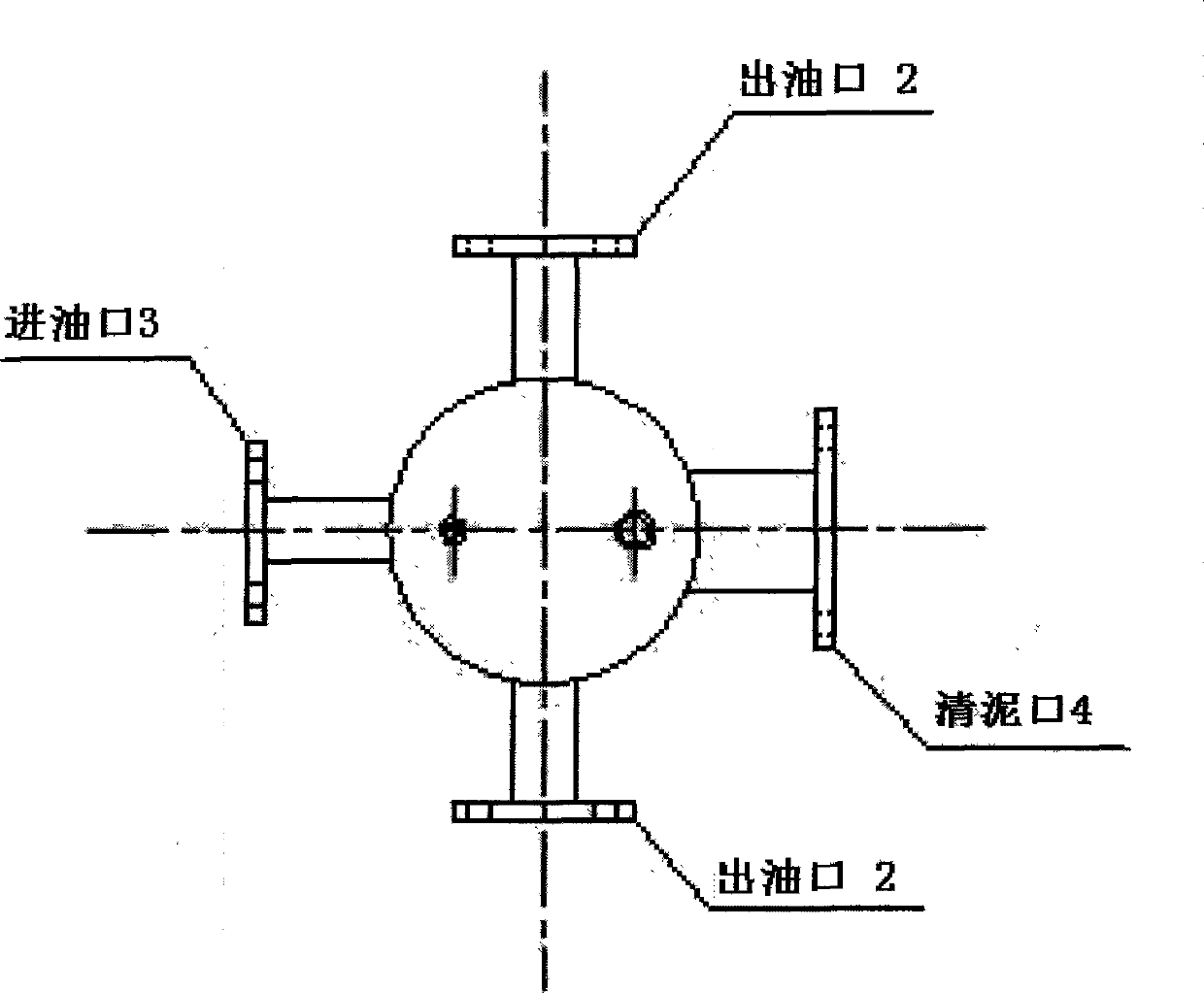

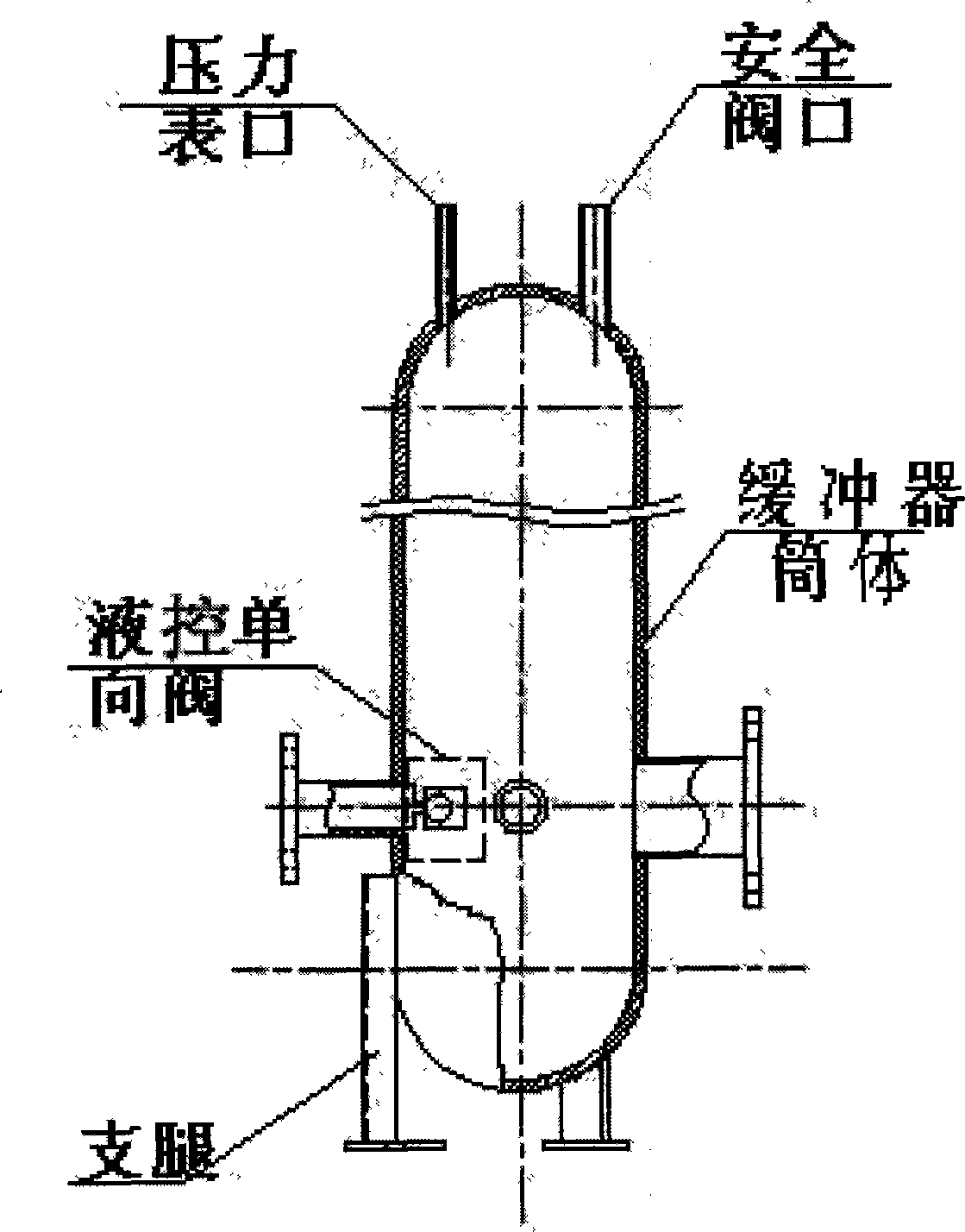

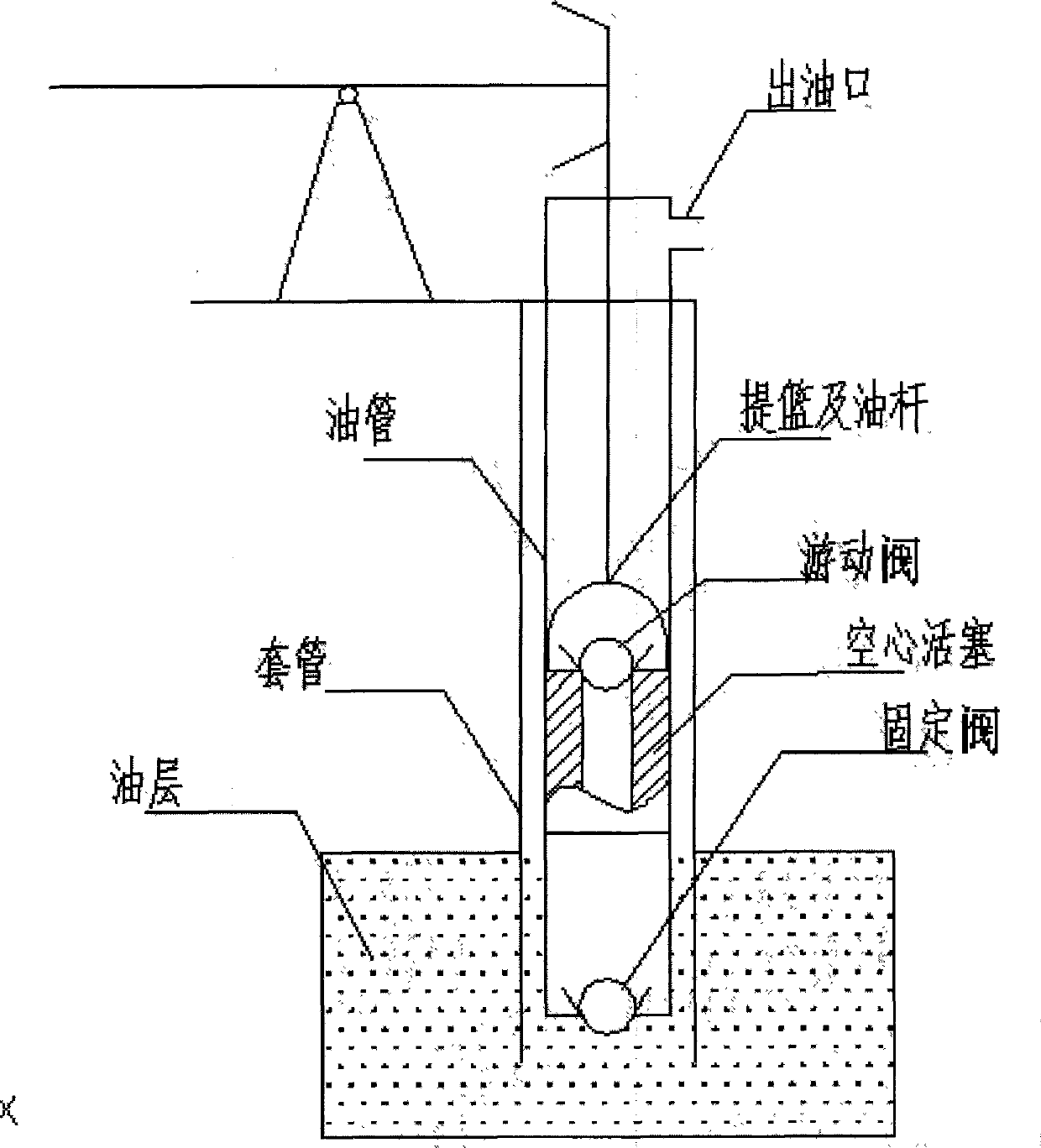

Pumping well wellhead oil charging device with ZYQ buffer

InactiveCN104213889ARelieve pressureImprove pump efficiencyFluid removalWell/borehole valve arrangementsMechanical abrasionOil well

The invention discloses a pumping well wellhead oil charging device with a ZYQ buffer. The pumping well wellhead oil charging device comprises two oil outlets, an oil inlet, a mud clearing port and a one-way valve, wherein the two oil outlets are located on the opposite sides of the pumping well wellhead oil charging device, the oil inlet is connected with an oil outlet channel of an oil well pump of an oil field, the mud clearing port is located on the opposite side of the oil inlet, and the one-way valve is located at the joint between the oil inlet and the pumping well wellhead oil charging device. The pumping well wellhead oil charging device has the advantages that the pressure in an oil conveying and pumping pipe body line on the ground is stabilized, and the pressure is kept stable; the effective filling degree and the pumping efficiency of a deep-well pump are improved, so that the oil production quantity is increased; the flow rate of liquid in an oil pumping pipe body is increased, the ability of the liquid to carry oil sand is enhanced, abrasion to a traveling valve and a fixed valve of the deep-well pump by the oil sand is reduced, and the pump inspection cycle of an oil well is prolonged; mechanical abrasion is lowered, the maintenance quantity is reduced, and the use efficiency is improved.

Owner:王传奇 +4

Triperfluor silicon-polyethyoxyl-oleate multi-element compound as well as preparation method and application thereof

InactiveCN108452745AImprove oil recoveryImprove emulsifying performanceSilicon organic compoundsTransportation and packagingWaxChemistry

The invention discloses a triperfluor silicon-polyethyoxyl-oleate multi-element compound as well as a preparation method and the application thereof. The multi-element compound is prepared from perfluor decane, trifluoro-silane, ethylene oxide and oleic acid through compounding. The preparation method comprises the following steps: mixing the perfluor decane and the trifluoro-silane, acidizing, heating to 150-170 DEG C, adding the ethylene oxide, performing a reaction, adding oleic acid, and finally adjusting the pH value to 7-8. The multi-element compound disclosed by the invention is used inan oil field for reservoir oil foam displacement. The multi-element compound disclosed by the invention is not only capable of foaming efficiently, but also good in bubble stabilization effect, freeof spectrum separation in stratum migration, particularly good in reservoir oil foam displacement effect on high oil content (the oil content is 80-95%) and high wax foam systems, meanwhile is simplein preparation method, good in operability and low in cost.

Owner:NANJING NORMAL UNIVERSITY

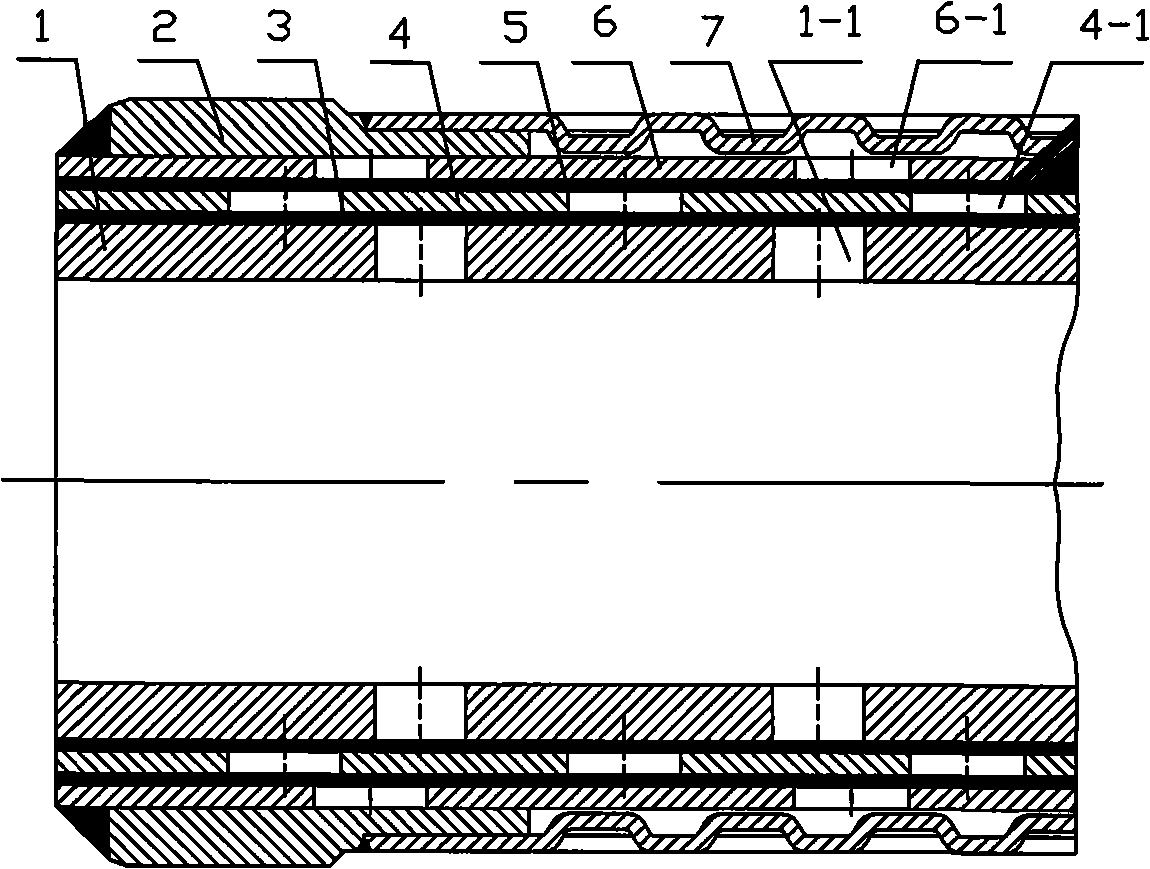

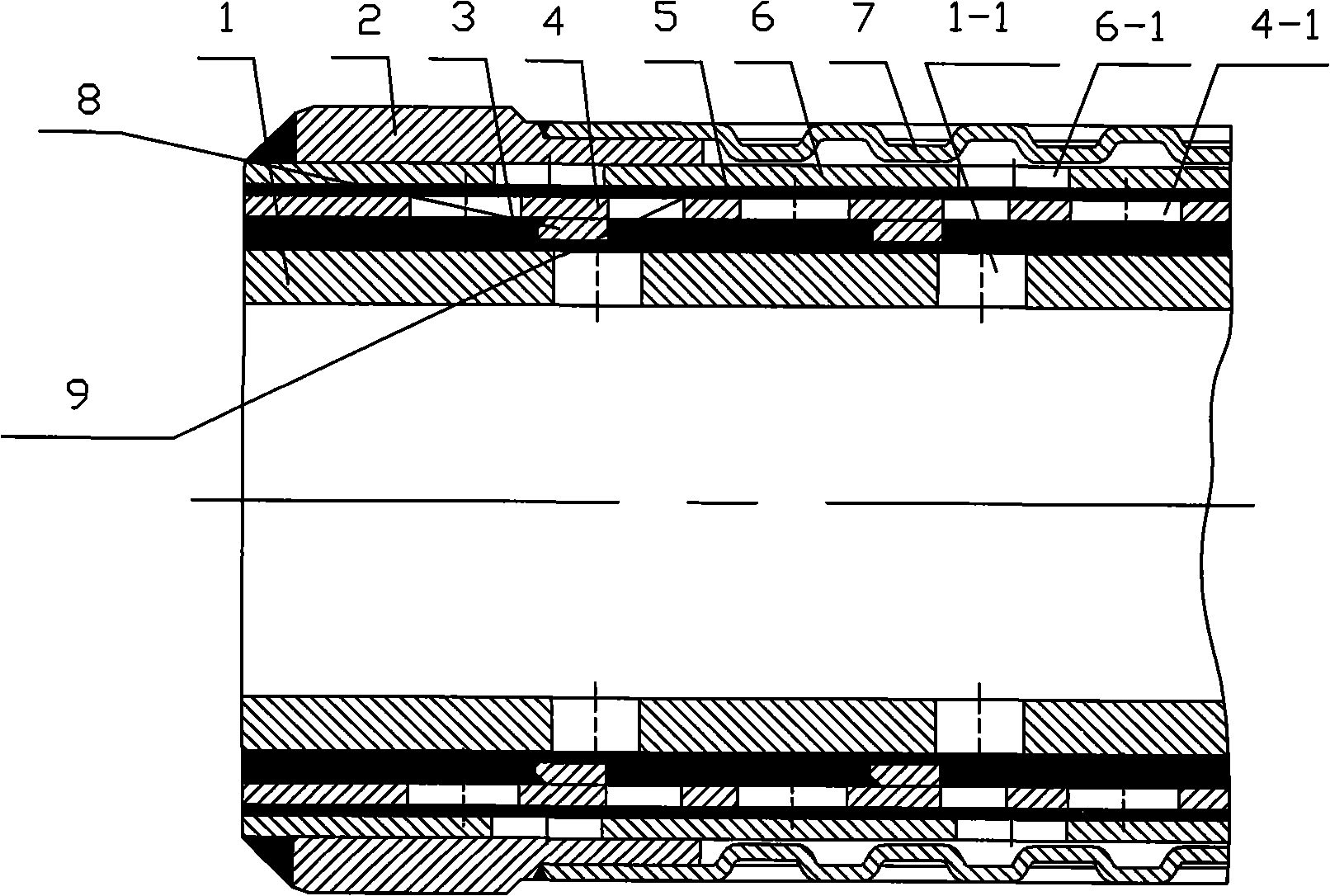

Sieve tube with novel internal support sleeve and method for producing the same

The invention discloses a sieve vessel with an internal supporting sleeve, which belongs to the field of petroleum extraction. The sieve vessel comprises a parent tube. The top of the parent tube is provided with a supporting ring. The inner supporting casing and an external supporting casing are installed via the supporting ring. A pipe seam between the parent tube and the inner supporting casing is a diversion layer gap. A sand-prevention net is arranged between the inner and the external supporting casings. The outer sleeve of the external supporting casing is provided with a punched chink sleeve. The inner supporting casing is evenly provided with fractures. The inner supporting casing is folded into one or a plurality of folded layers that are arranged between the inner supporting casing and the parent tube through the fracture to the diversion layer gap. A processing method is that the fracture on the top circle of the inner supporting casing punched by a pressing machine bends inwards to form the folded layer. The sieve vessel uses the folded layer to enlarge the diversion layer gap between the inner supporting casing and the parent tube by the folded layer arranged between the inner supporting casing and the parent tube. In addition, the diversion layer gap does not vary with the increasing of external pressure. So the sieve vessel has the effects of reducing the flowing friction of the diversion layer gap in the process of oil extraction and improving the oil production of a well.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com