Microorganism huff and puff oil recovery method

A technology of microorganisms and microbial bacteria, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

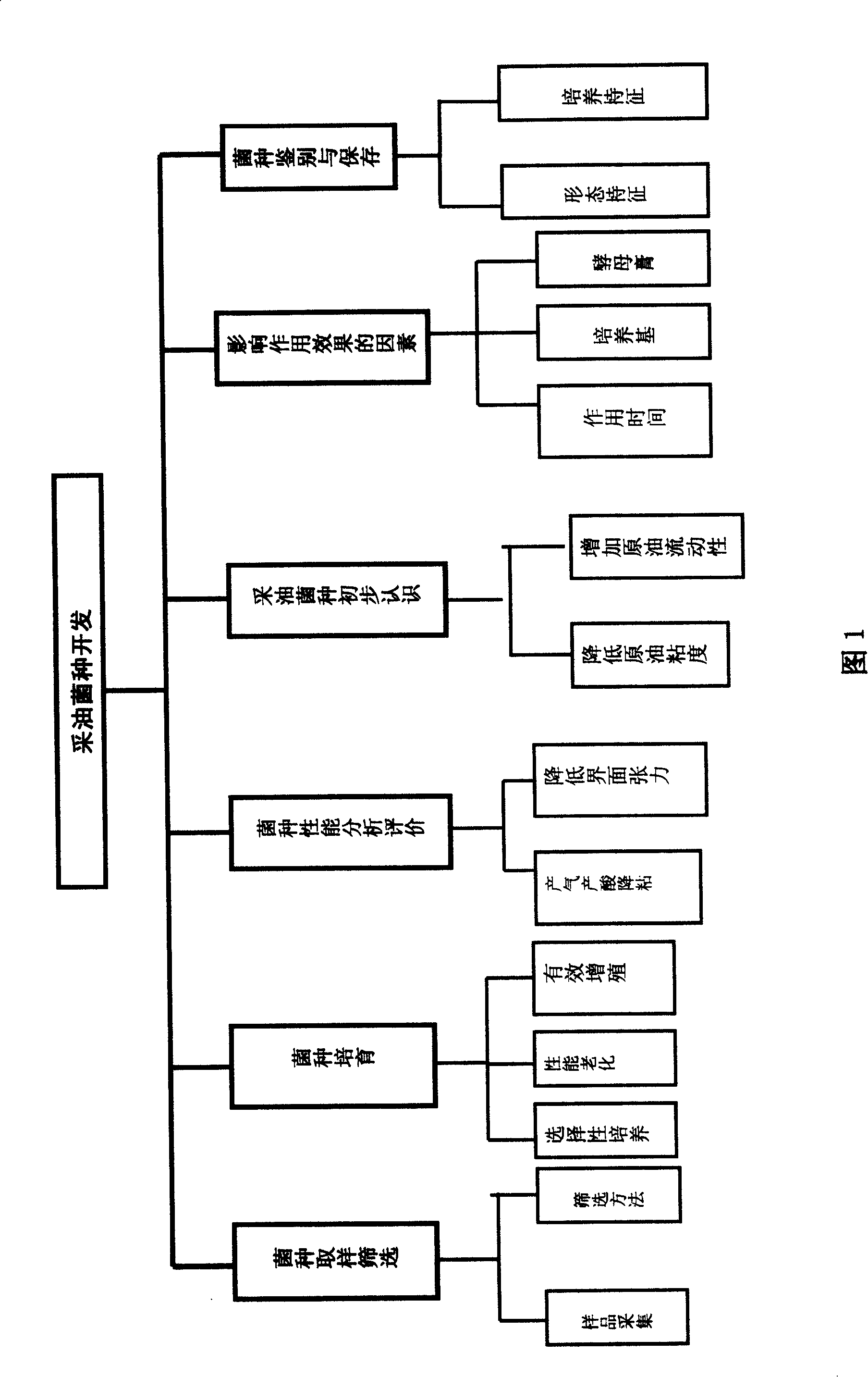

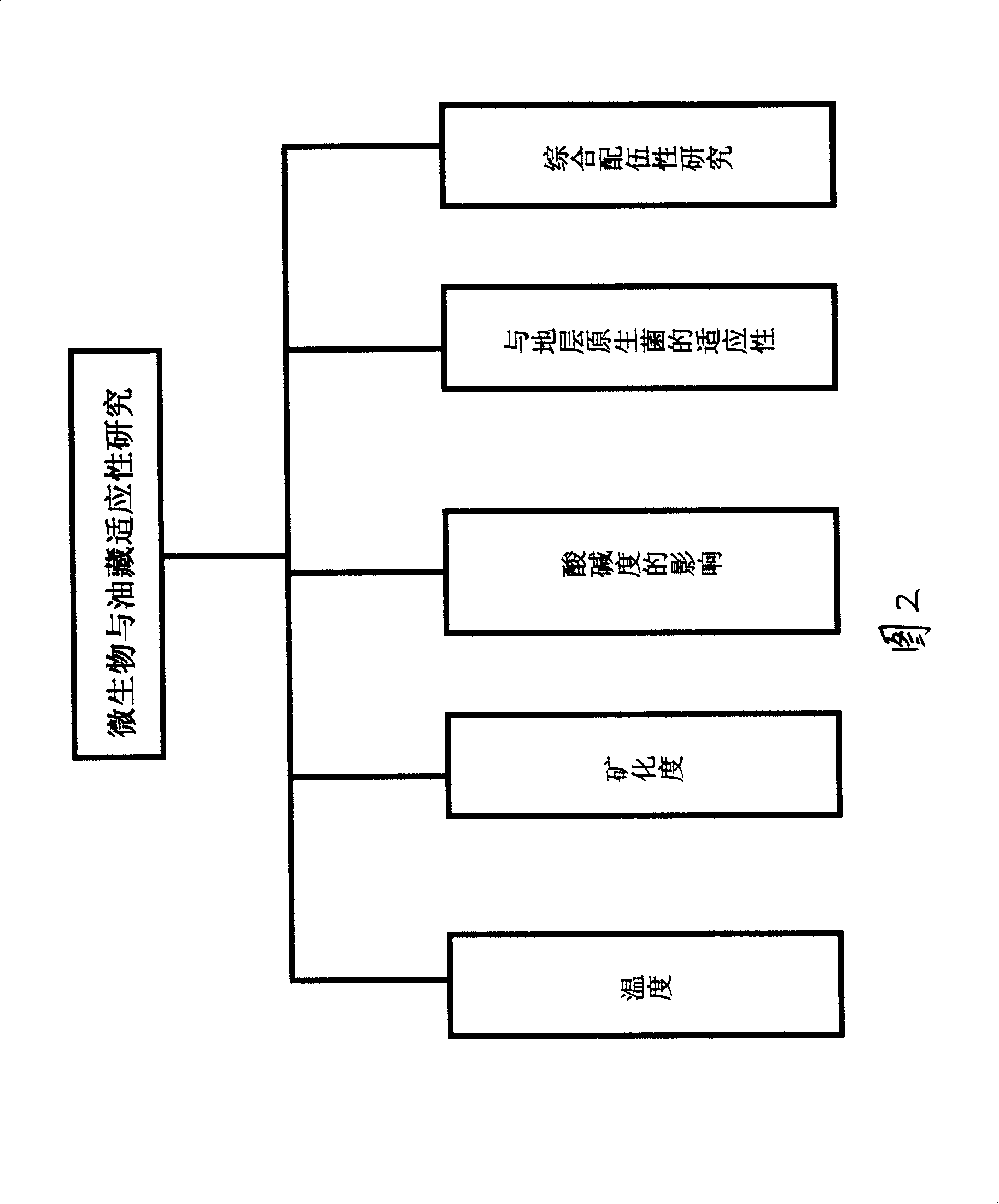

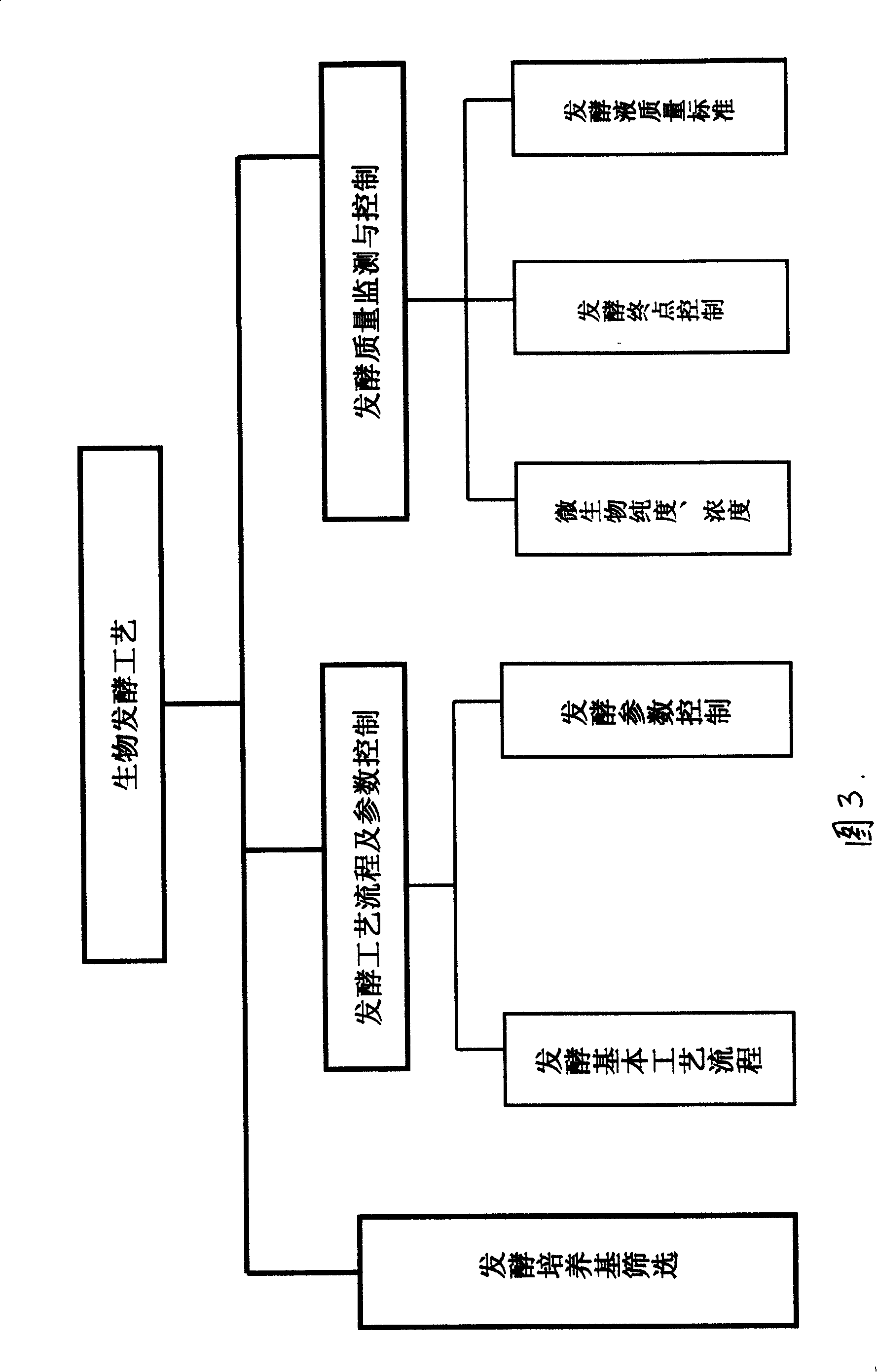

Image

Examples

Embodiment Construction

[0032] Take +5-18 Well microbial huff and puff construction scheme

[0033] 1. Screening of microorganism indoor strains

[0034] pass +5-18 For well crude oil analysis, use emulsification dispersion test and growth test test to compound suitable oil production microbial strains from a series of strains.

[0035] After compounding with different strains and media, etc., the strains suitable for the crude oil of the well are determined according to the growth of microorganisms and the effect of emulsifying and dispersing crude oil.

[0036] After screening experiments, the final determination GV6 for +5-18 Well huff and puff strains.

[0037] Comparison table of bacteria and well conditions:

[0038] project

Moisture content%

temperature °C

Motoi

41.6%

66

0.80

[0039] 1. Emulsification and dispersion experiment: ++++ is excellent, +++ is good, ++ is good, + is poor.

[0040] p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com