Method and device for researching steam cavity expansion boundary in SAGD development process

A technology to develop process, steam, applied in the field of SAGD mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

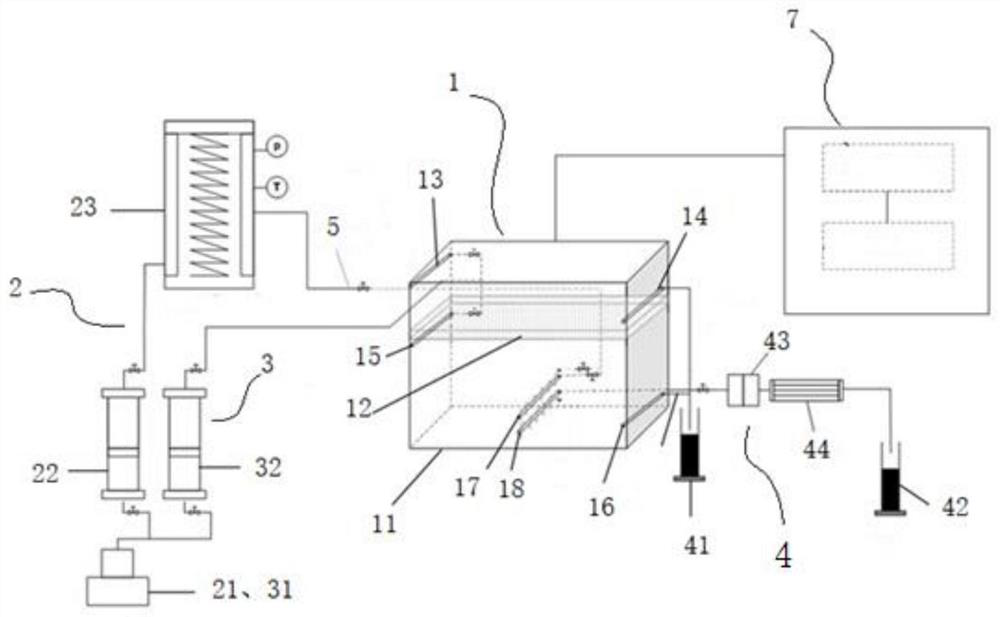

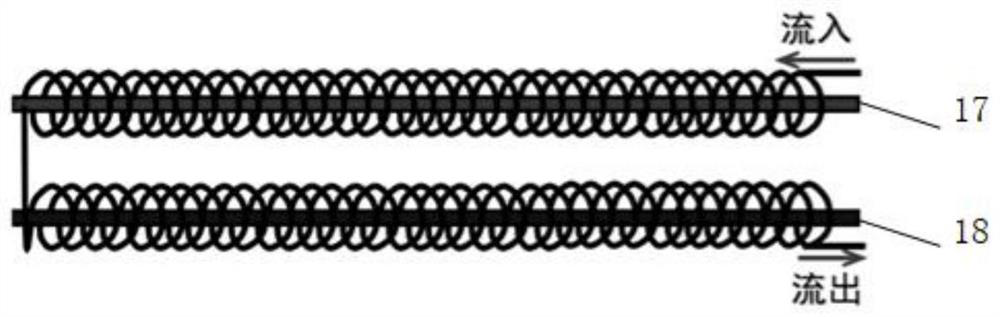

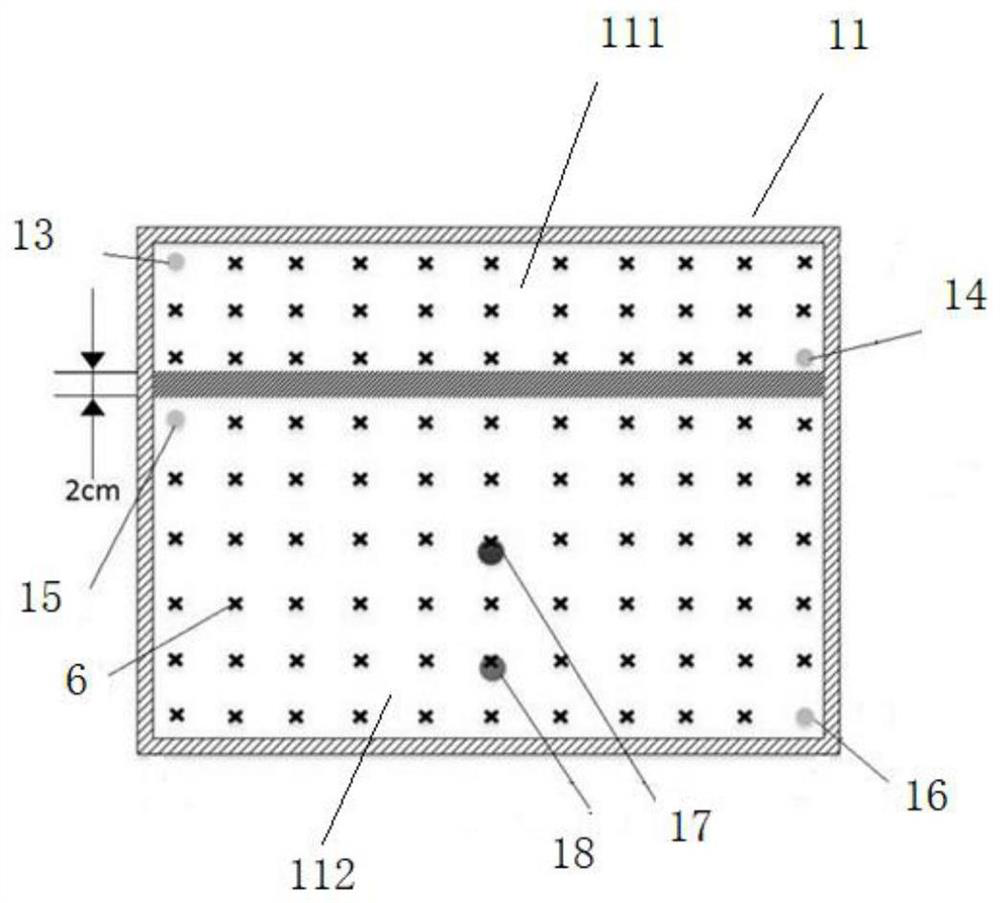

[0035] Such as figure 1 , image 3 As shown, this embodiment provides a device for studying the steam expansion limit in the SAGD development process, including a SAGD three-dimensional experimental simulation system 1, a steam supply unit 2, an oil supply unit 3 and a collection unit 4;

[0036] The SAGD three-dimensional experimental simulation system 1 includes a casing 11, a sandwich forming mold 12, a first oil injection pipe 13, a first oil production pipe 14, a second oil injection pipe 15, a second oil production pipe 16, a steam injection pipe 17 and a production pipe 18; The molding die 12 is detachably arranged in the casing 11, and is used for dismantling after forming an interlayer with a required permeability in the casing 11. The interlayer divides the interior of the casing 11 into an upper crude oil reservoir 111 and a lower crude oil reservoir 112 The first oil injection pipe 13 and the first oil production pipe 14 are arranged in the upper crude oil reservo...

Embodiment 2

[0051] In addition, based on the device for studying the expansion limit of the steam chamber in the SAGD development process in any of the above embodiments, the present invention also provides a method for studying the expansion limit of the steam chamber in the SAGD development process, which includes the following steps:

[0052] 1) Mix quartz sand and epoxy resin glue evenly, then fill them into the interlayer forming mold 12 and solidify, remove the interlayer forming mold 12 after the curing is completed, thereby prepare an interlayer in the housing 11, and evenly coat it on the inner wall of the housing 11 A number of temperature detection devices 6;

[0053] 2) filling the uniformly mixed oil sands into the upper crude oil reservoir 111 and the lower crude oil reservoir 112 in the casing 11;

[0054] 3) Mix clay and water evenly, and then evenly lay on the upper part of the oil sand; completely cover the oil sand without gaps; to ensure the tightness of the shell 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com