Sieve tube with novel internal support sleeve and method for producing the same

A new type of internal support technology, applied in earth-moving drilling, production fluids, wellbore/well components, etc., can solve problems such as increasing the gap of the diversion layer, and achieve the effect of reducing flow resistance, wide application range and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

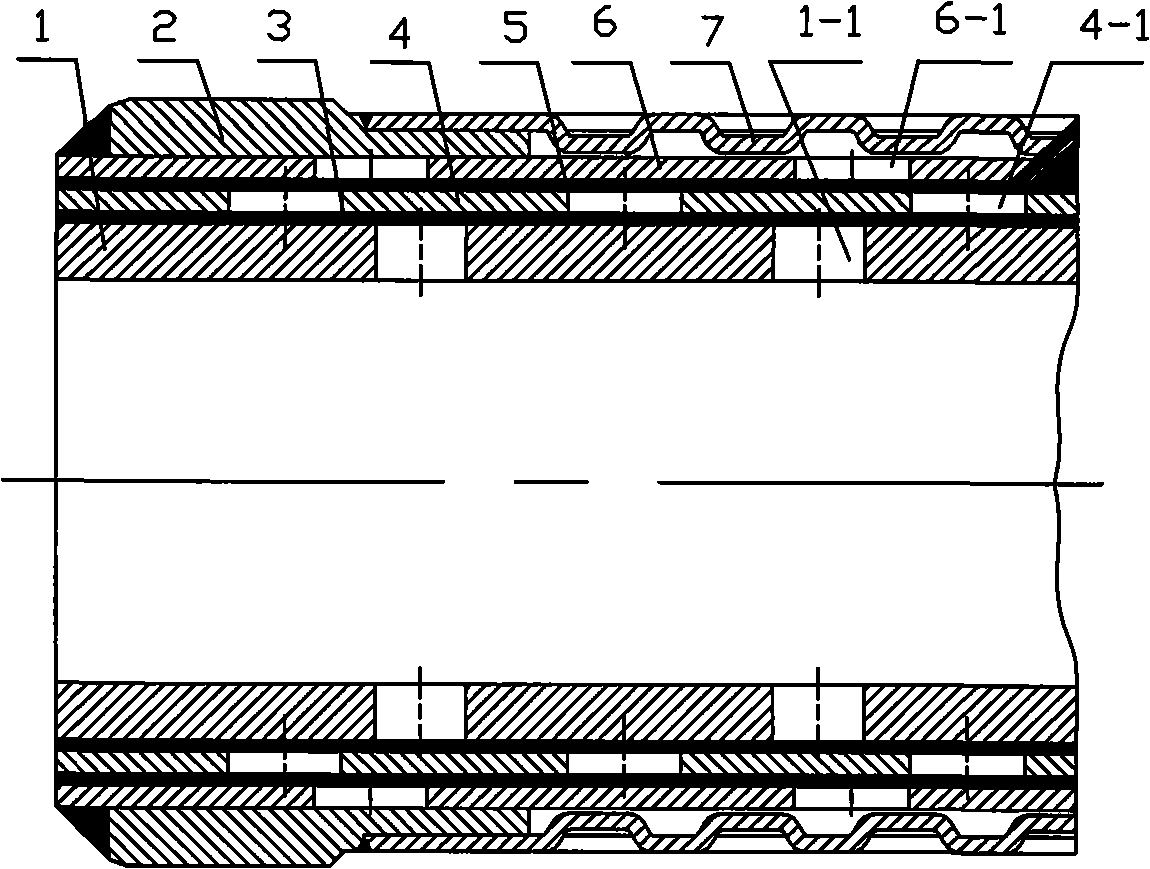

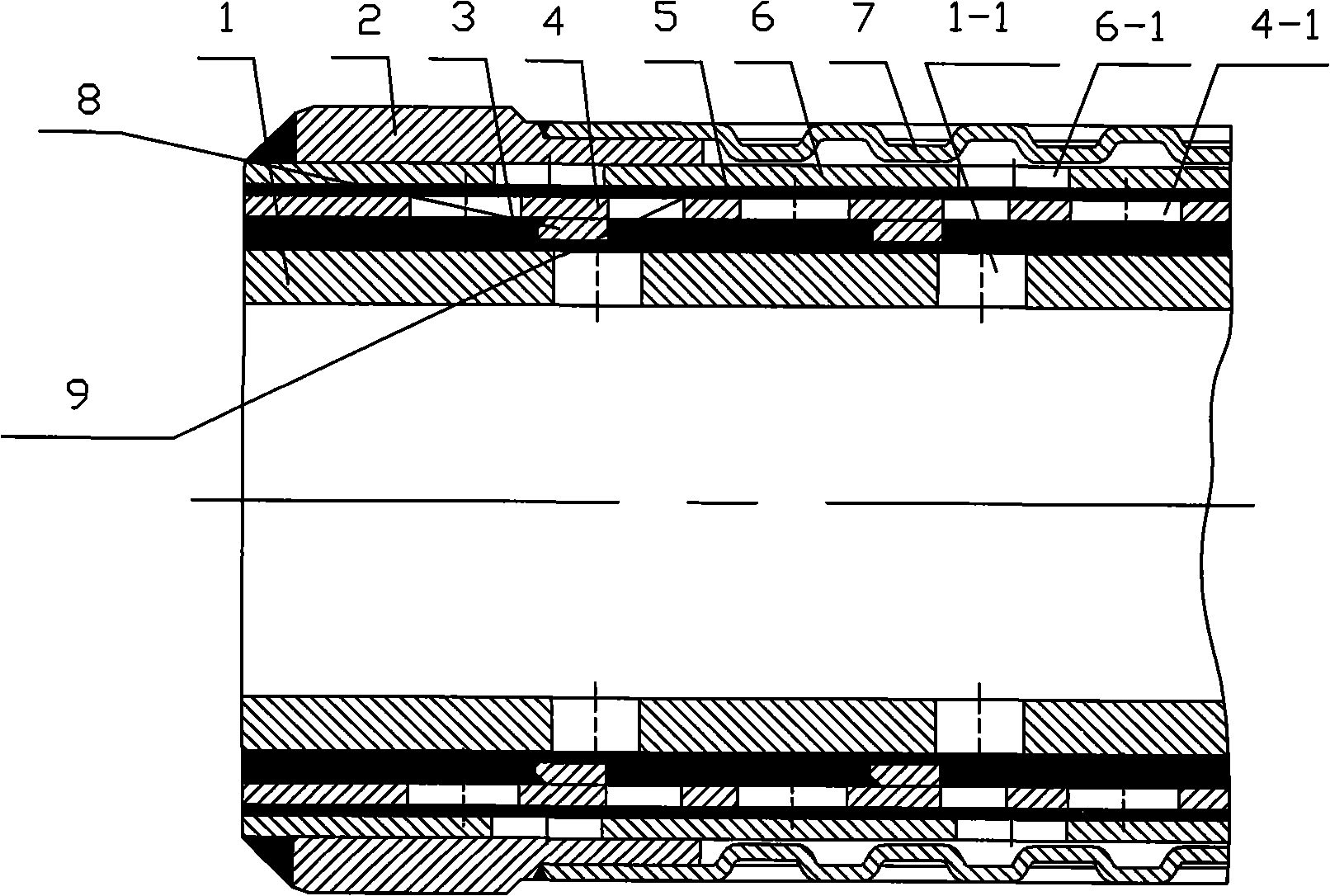

[0019] Such as figure 2 As shown, a screen pipe with a new type of inner support sleeve in the present invention includes a base pipe 1, through holes 1-1 are evenly distributed on the base pipe, and a support ring 2 is arranged on the top of the base pipe, through which the support ring The outer cover of the base pipe is provided with an inner support sleeve 4 and an outer support sleeve 6, and the inner and outer support sleeves are respectively provided with through holes 4-1 and 6-1 arranged at intervals, and the through holes on the base pipe and the through holes on the inner support sleeve The holes are arranged at intervals, the pipe seam between the base pipe and the inner support sleeve is the diversion layer gap 3, the san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com