One-well multi-control method for offshore low-permeability reservoir thick oil layer exploitation

A thick oil layer and oil seepage technology, which is applied in the field of multiple control of one well in the development of thick oil layers in offshore low-permeability reservoirs, can solve the limitations of recovery degree, oil recovery speed and economy, difficulty in underground flow of oil and gas, poor reservoir permeability, etc. problem, to achieve the effect of improving development effect, increasing oil recovery effect and reducing well construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

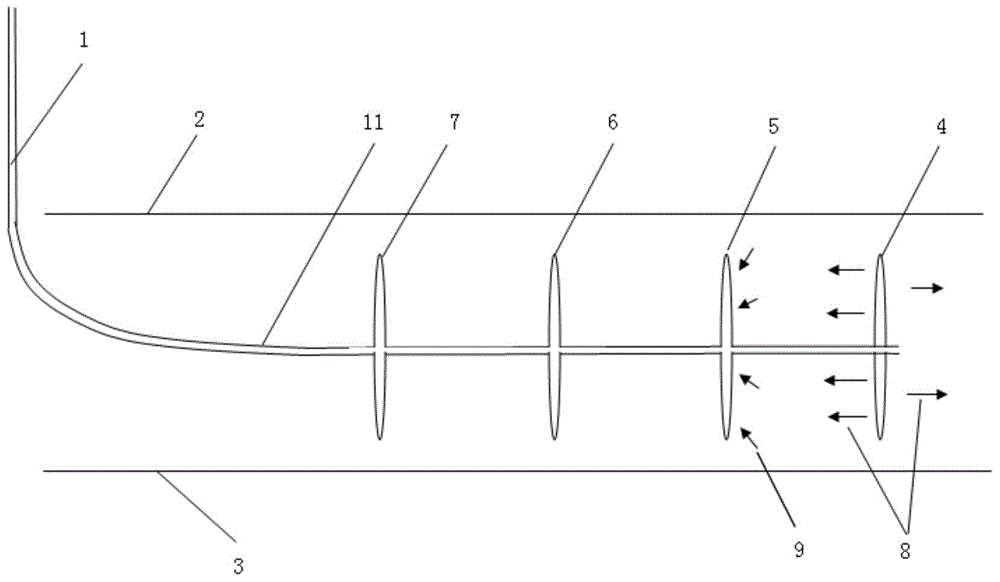

[0013] The multi-control method for one well in a single thicker oil layer in an offshore low-permeability oil reservoir according to the present invention at least includes a long horizontal well 1 located between the top 2 of the oil layer and the bottom 3 of the oil layer, and a plurality of artificial fractures 4 and 5 , artificial fracture 6, artificial fracture 7, the extension direction of the horizontal well section 11 is the direction of the maximum principal stress of the formation, the fracture surfaces of the artificial fracture 4, artificial fracture 5, artificial fracture 6, and artificial fracture 7 are perpendicular to the horizontal well section 11 and along the The minimum principal stress direction is extended, and the mature offshore injection-production technology is implemented in horizontal wells to realize simultaneous injection and production. The injection water is firstly injected from the artificial fracture 4 farthest from the root of the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com