Method and device for refinery sludge carbonization treatment and carbon recovery

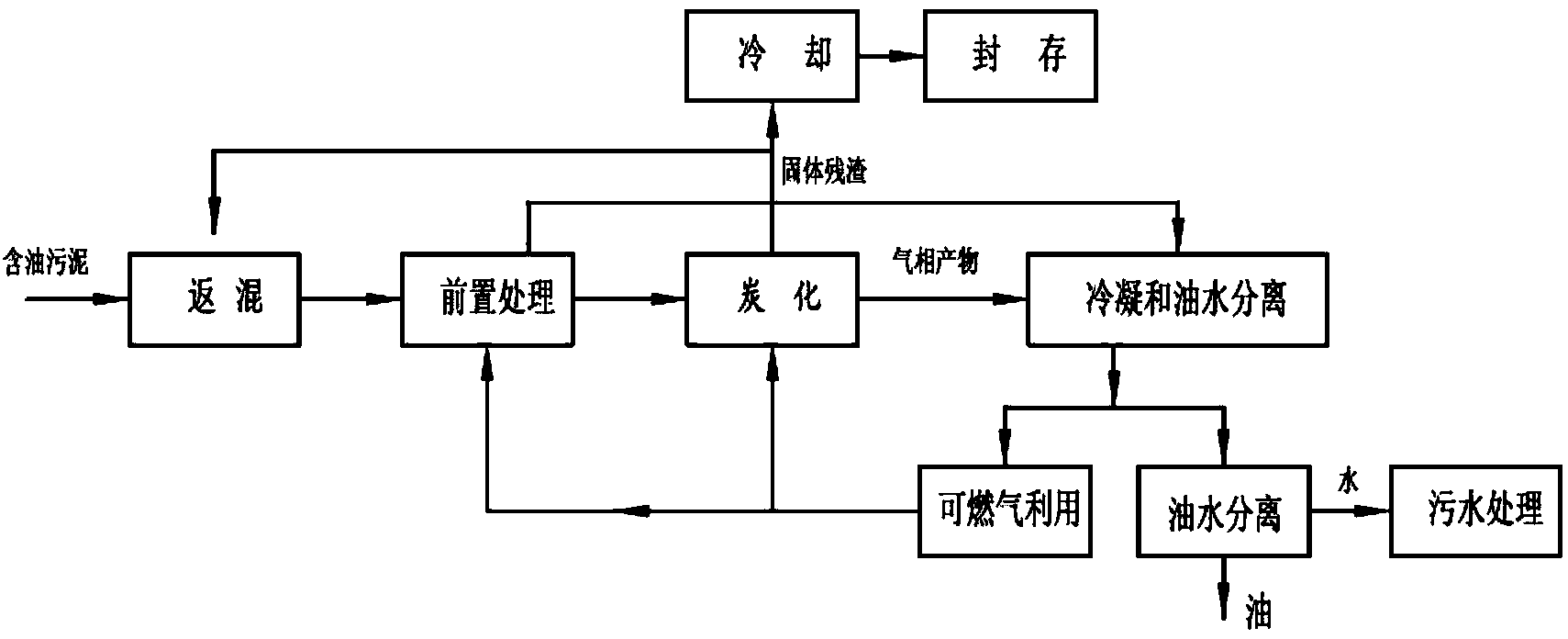

A technology for sludge charcoal and oil refinery, which is applied in the fields of sludge treatment, coke oven, and petroleum industry through temperature control. The effect of reducing the difficulty of process control and the incidence of device failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

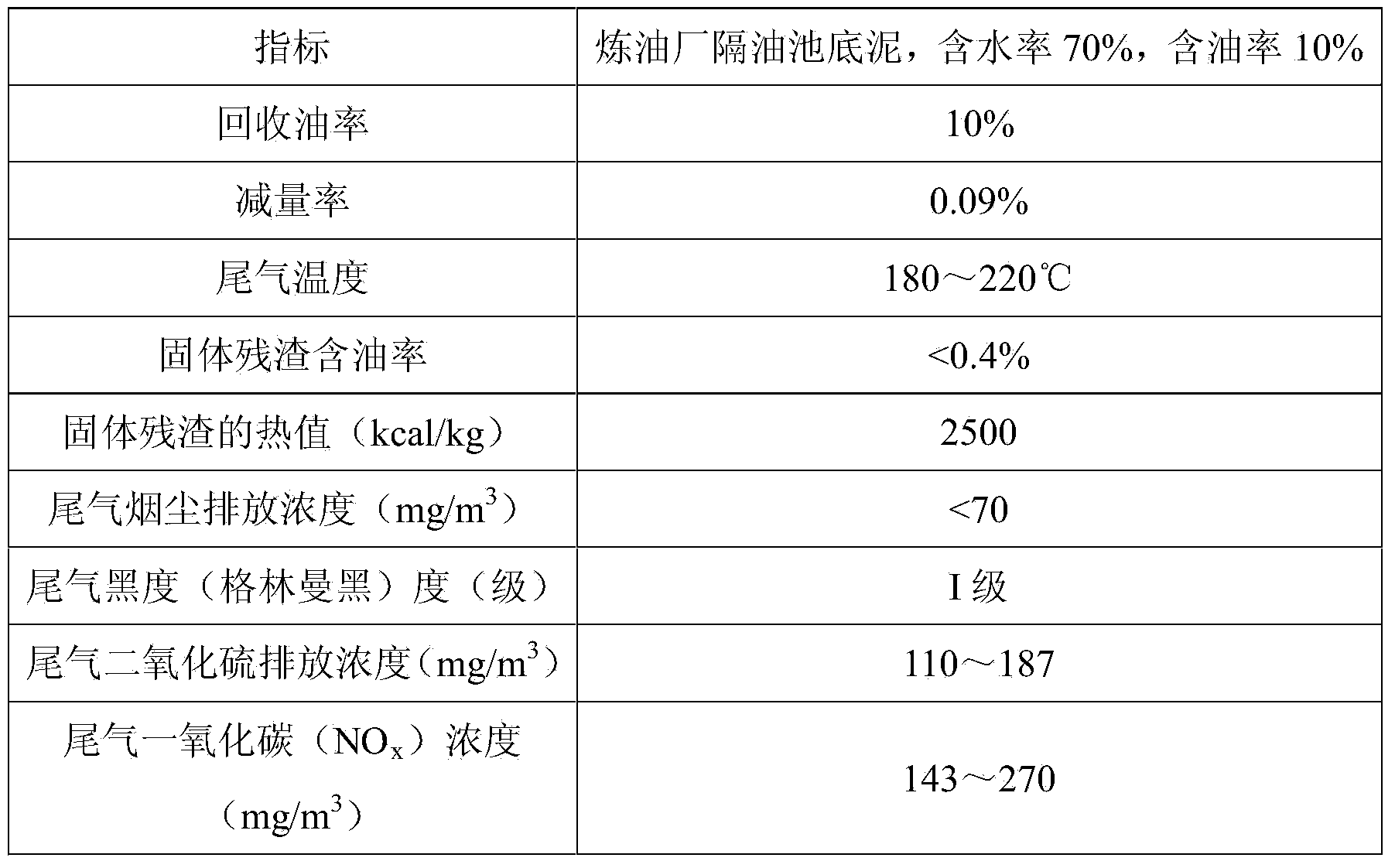

[0044] Embodiment 1 Refinery grease trap bottom sludge treatment, water content 70%, oil content 10%:

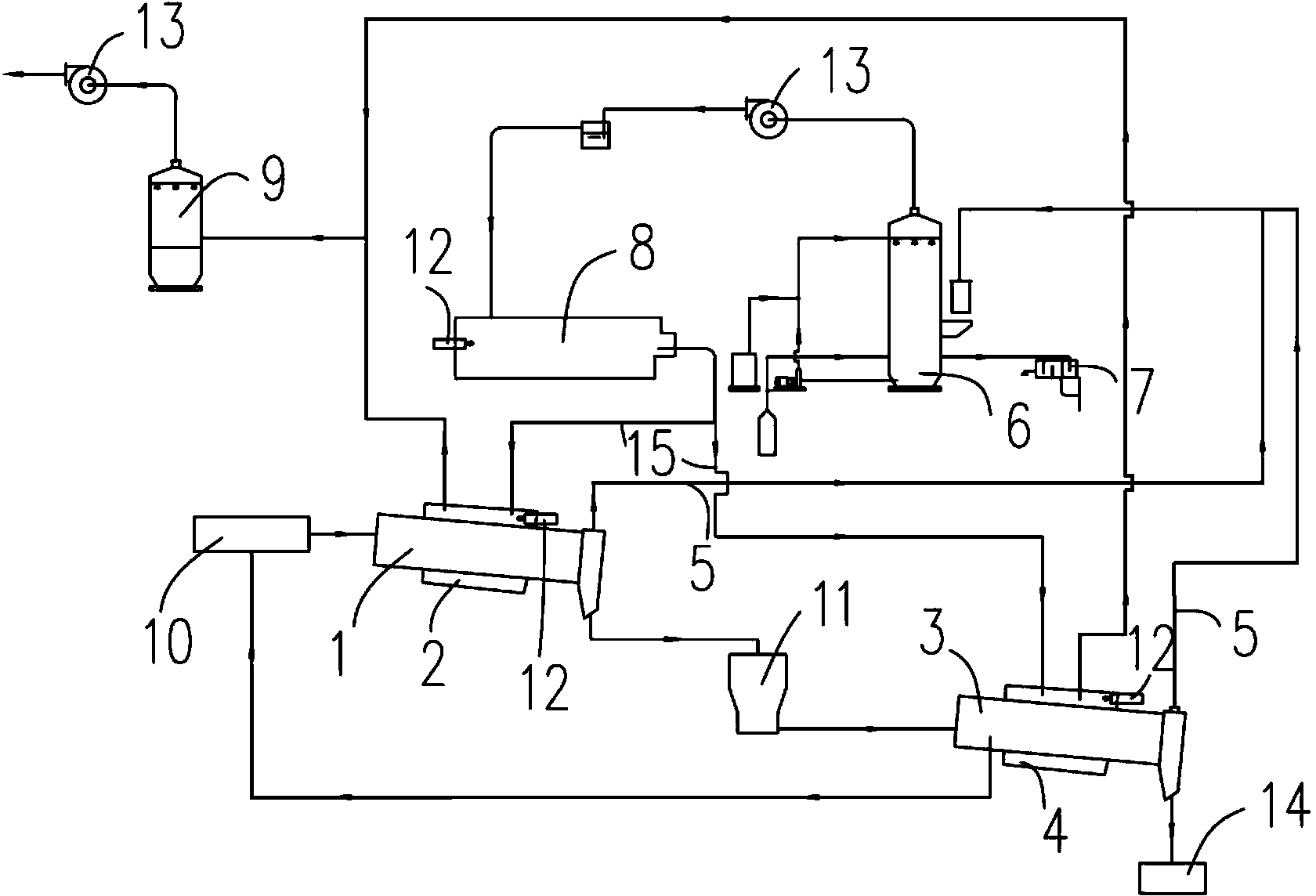

[0045] (1) Pre-treatment: oily sludge enters the back-mixing bin 10, and after adding the solid residue generated by carbonization, it is sent to the external heating dryer 1 for heating and drying. The temperature inside the external heating drying machine 1 is 160 ℃, reduce the water content of oily sludge to 10%.

[0046] (2) Carbonization: Dried sludge with a moisture content of 10% enters an externally heated rotary carbonization furnace for pyrolysis, and the carbonization temperature is 600°C for 45 minutes. After the carbonization is finished, the discharged solid residue is cooled and collected in the carbonization residue container 14;

[0047] (3) Condensation and oil-water separation: the gaseous products produced in the pre-treatment and carbonization process are introduced into the spray tower 6 for dust removal, condensation and desulfurization treatment. Af...

Embodiment 2

[0052] Embodiment 2 flotation cell scum, water content 80%, oil content 12%:

[0053] (1) Pre-treatment: oily sludge enters the back-mixing bin 10, and after adding the solid residue generated by carbonization, it is sent to the external heating dryer 1 for heating and drying. The temperature inside the external heating drying machine 1 is 160 ℃, reduce the water content of oily sludge to 15%.

[0054] (2) Carbonization: The dried sludge with a moisture content of 15% enters an externally heated rotary carbonization furnace for carbonization. The carbonization temperature is 650°C and stays for 30 minutes. After the carbonization is finished, the discharged solid residue is cooled and collected in the carbonization residue container 14;

[0055] (3) Condensation and oil-water separation: the gaseous products produced in the pre-treatment and carbonization process are introduced into the spray tower 6 for dust removal, condensation and desulfurization treatment. After being t...

Embodiment 3

[0060] Embodiment 3 remaining active mud, water content 95%, oil content 8%:

[0061] (1) Pre-treatment: Oily sludge enters the back-mixing bin 10, and after adding the solid residue produced by carbonization, it is sent to the external heating dryer 1 for heating and drying. The temperature inside the external heating drying machine 1 is 170 ℃, reduce the water content of oily sludge to 20%.

[0062] (2) Carbonization: The dried sludge with a moisture content of 20% enters an externally heated rotary carbonization furnace for carbonization. The carbonization temperature is 620°C and stays for 40 minutes. After the carbonization is finished, the discharged solid residue is cooled and collected in the carbonization residue container 14;

[0063] (3) Condensation and oil-water separation: the gaseous products produced in the pre-treatment and carbonization process are introduced into the spray tower 6 for dust removal, condensation and desulfurization treatment. After being tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com