Dispersion compensation optical fibre

A technology of dispersion compensating fiber and fiber core, applied in the directions of light guide, optics, optical components, etc., can solve the problems of small variation range of RDS value, difficult process control, and more difficult PMD control of bending characteristics, so as to reduce the difficulty of process control. , The effect of fine control of profile and excellent dispersion compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

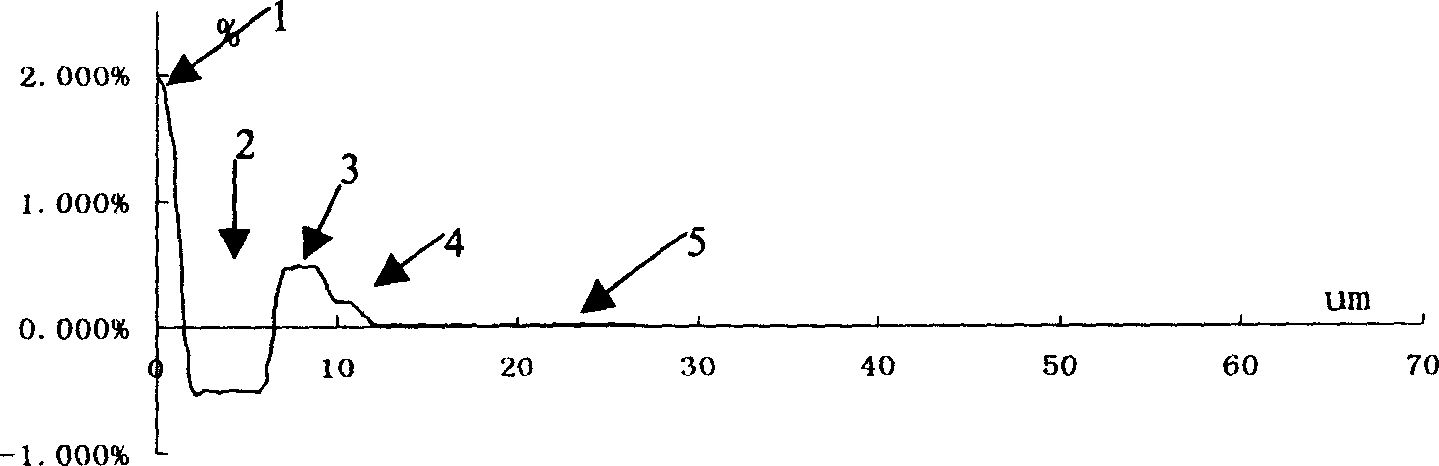

[0025] The first example is figure 1 As shown, the core contains four core layers 1, 2, 3, and 4 as doped regions, and the radius ranges of each core layer from r1 to r4 are: 1.63 μm to 1.65 μm, 6.58 μm to 6.62 μm , 9.80 μm to 10.20 μm, 11.00 μm to 12.00 μm. where the r2 / r1 value is 4.03. The radius r5 of the cladding layer 5 is 124 μm to 126 μm. The relative refractive index difference of each core layer from Δ1% to Δ4% is: 1.966%, -0.527%, 0.462%, 0.186%, wherein the difference between Δ1% and Δ2% is 2.493%. The fluctuation range of the relative refractive index difference of each fiber core layer is ±0.020%. The relative refractive index difference Δ5% of the cladding layer 5 is pure SiO 2 refractive index. Between layers, especially between the first and second core layers, a refractive index distribution gradient is set to transition smoothly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com