Preparation method of titanium dioxide-polyaniline composite corrosion-resistant coating

An anti-corrosion coating and titanium dioxide technology, applied in the direction of titanium dioxide, anti-corrosion coatings, titanium oxide/hydroxide, etc., can solve the problems of time-consuming and laborious, difficult process control, and difficulty in obtaining product or semi-product quality stability and consistency Guarantee and other issues, to achieve the effect of short process flow, good quality uniformity, and simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The preparation method includes the following steps:

[0068] The first step, the preparation step of the precursor solution

[0069] Measure 0.3g aniline, 0.3g surfactant, 0.6g ammonium persulfate, 1.2ml tetrabutyl titanate, 50ml deionized water;

[0070] First mix the aniline taken with the surfactant, add deionized water, stir to prepare a solution, and adjust the pH value to 2.5 with hydrochloric acid;

[0071] Add butyl titanate dropwise while stirring. After all butyl titanate is added, continue stirring for another half an hour;

[0072] Finally, add the ammonium persulfate taken dropwise to the above solution while stirring, and after all the ammonium persulfate is added, continue to stir for half an hour to obtain a precursor solution;

[0073] The second step, the metal plate pretreatment step

[0074] Take the size as 1×1cm 2 The surface of stainless steel 304 flakes is polished first, then cleaned with deionized water, and then air-dried naturally for use;

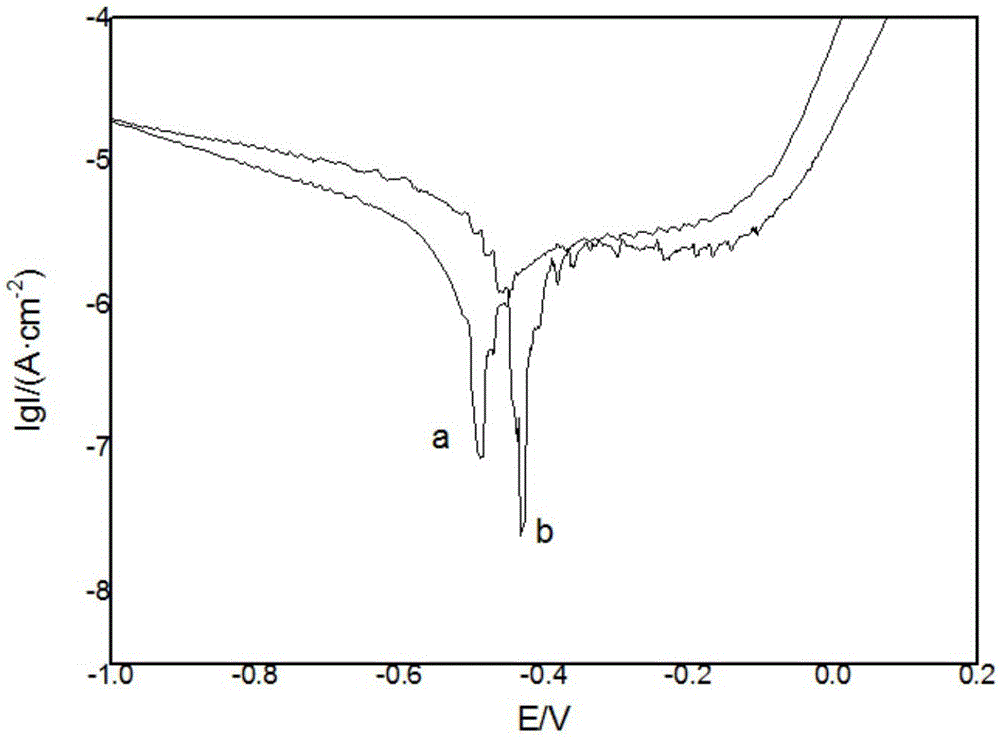

[0075] The t...

Embodiment 2

[0079] Except that the precursor solution was adjusted to pH 2 with hydrochloric acid, everything else was the same as in Example 1.

Embodiment 3

[0081] Except that the precursor solution is adjusted to pH 3 with hydrochloric acid, everything else is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com