Low-cadmium CIGS-based thin-film solar cell and manufacturing method thereof

A solar cell and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult process control and narrow process window, and achieve the effect of reducing the thickness of the CdS layer, broadening the process window, and increasing short-circuit current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

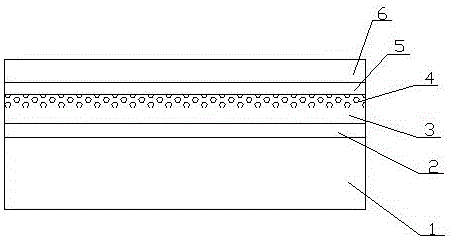

[0031] Such as figure 1 As shown, a low-cadmium CIGS-based thin-film solar cell includes a substrate 1, a back electrode 2, a CIGS absorption layer 3, a CdS layer 5, and an upper electrode 6 from bottom to top, and the Cu atoms on the surface of the CIGS absorption layer 3 are Cd atoms are partially replaced, and the thickness of the CdS layer 5 is 20 nm.

[0032] The preparation method of the low-cadmium CIGS-based thin-film solar cell includes the following steps:

[0033] a, depositing a back electrode on the substrate;

[0034] b, Depositing a CIGS absorber layer on the back electrode;

[0035] c, Depositing a CdS layer on the CIGS absorber layer;

[0036] d, depositing an upper electrode on the surface of the CdS layer;

[0037] Before the step c, modify the CIGS surface, the specific steps are: weigh CdSO 4 Powder 1.6g, dissolved in 1.276L deionized water, stirred evenly, to CdSO 4 224ml of ammonia water with a concentration of 19wt% was added to the solution, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com