Anodic protection type automatic descaling salt-containing organic wastewater electrolysis device

An automatic descaling, organic wastewater technology, applied in mining wastewater treatment, water pollutants, water/sewage treatment, etc., can solve the problems of cathode plate scaling, anode plate loss, etc. The effect of oil rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

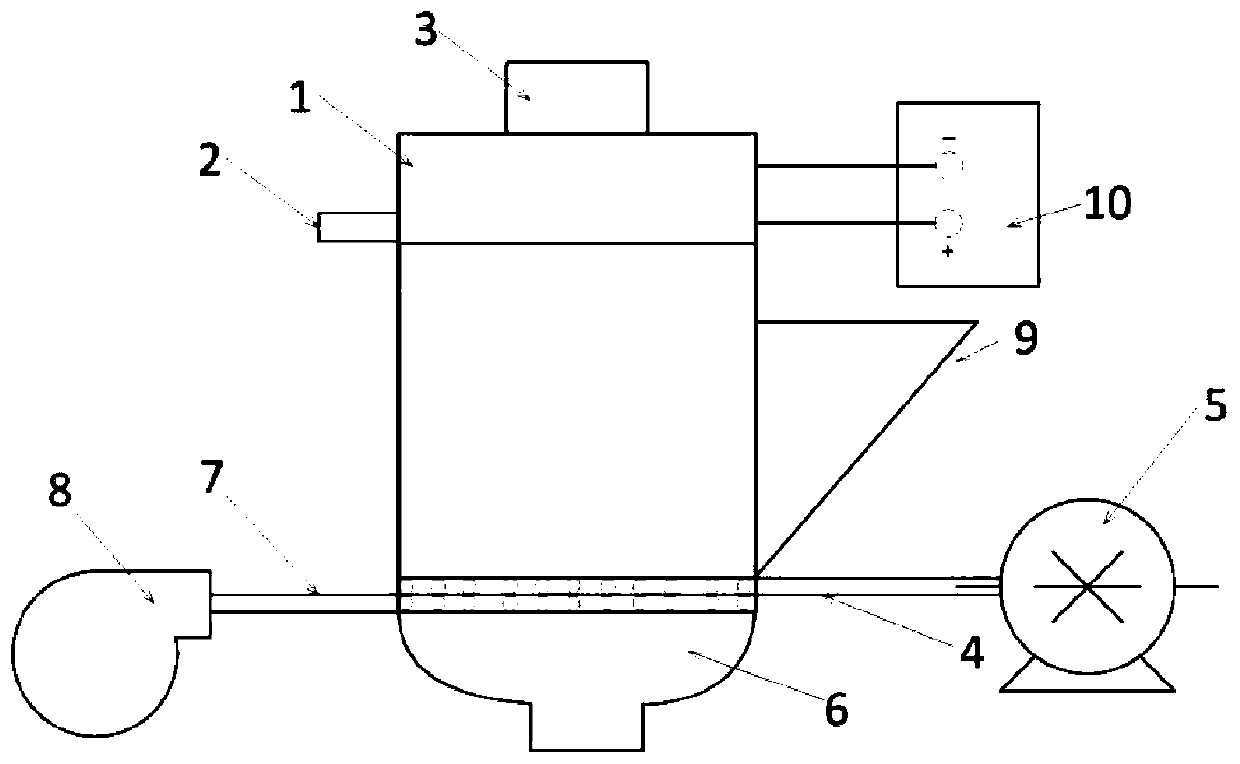

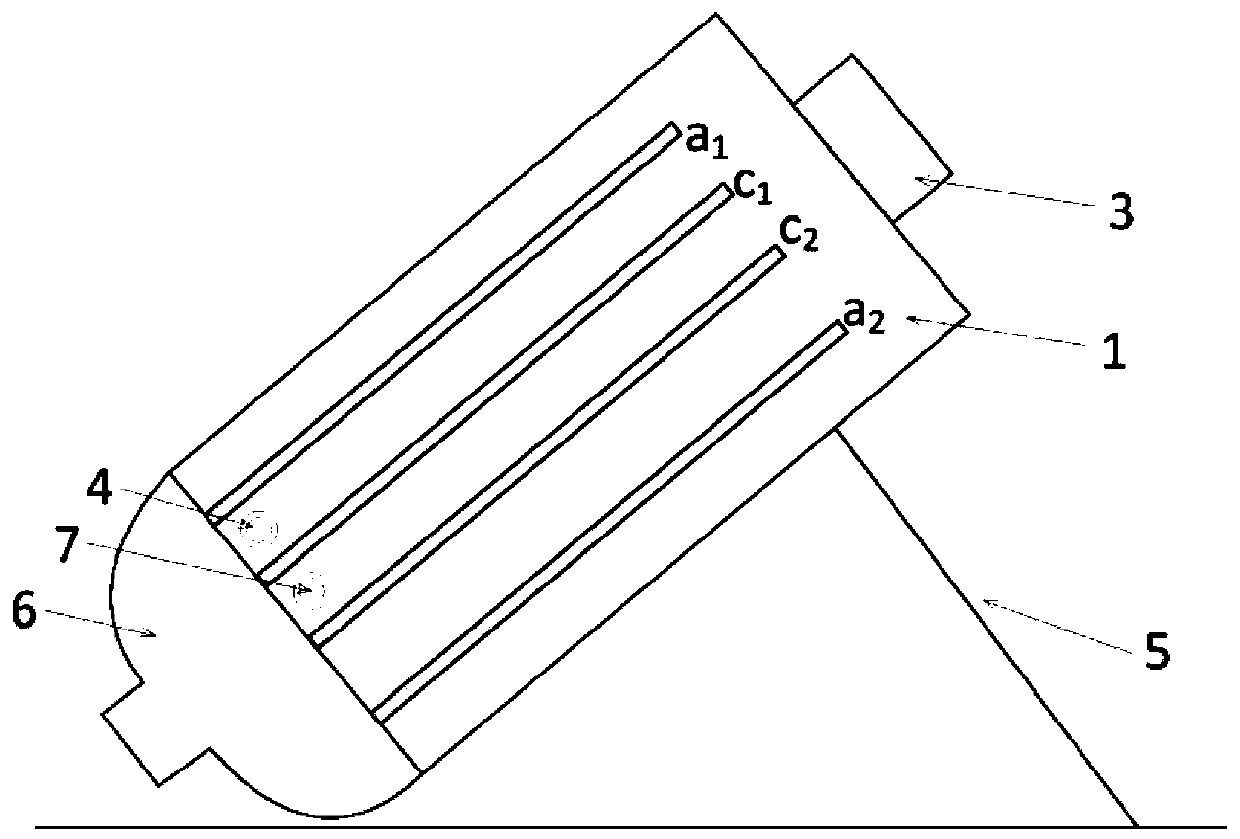

[0041] For the specific process flow of this embodiment, please refer to figure 1 .

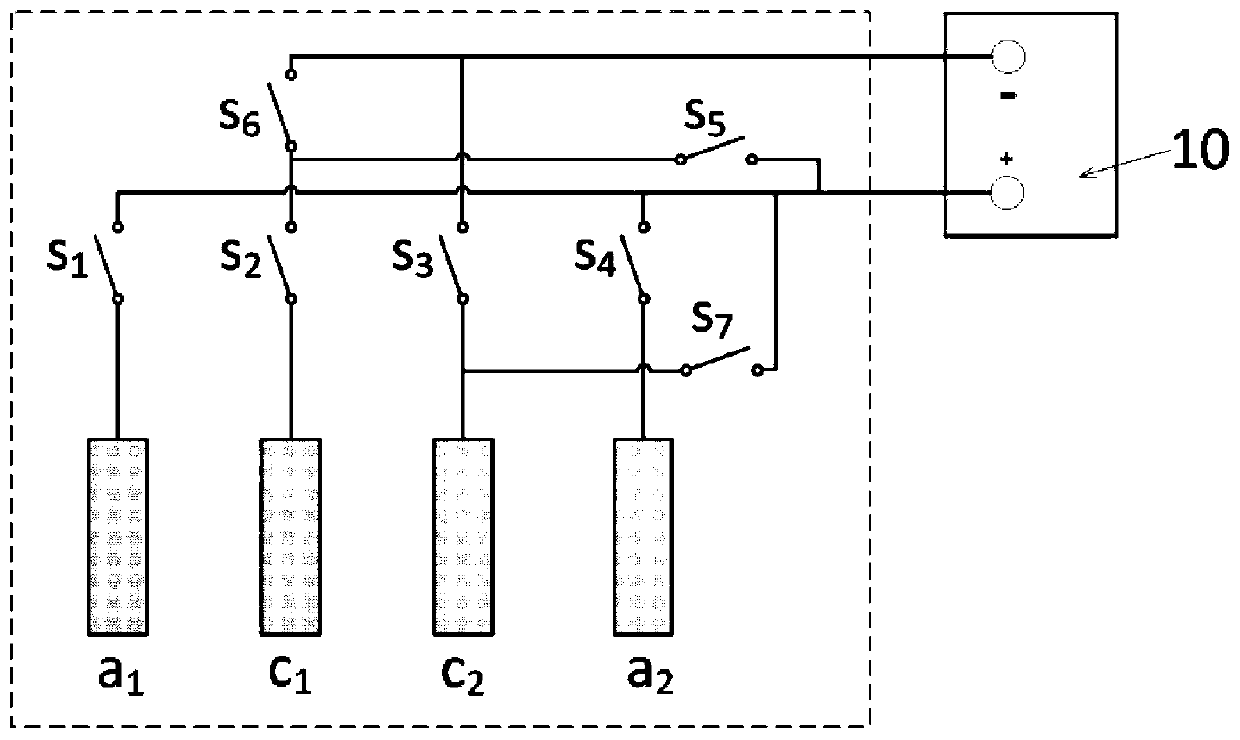

[0042] The electrolytic cell is provided with a first anode a 1 , the first cathode c 1 , the second anode a 2 , the second cathode c 2 . During electrolysis, the first anode a 1with the second anode a 2 connected in parallel and in series with the positive pole of the power supply 10, the first cathode c 1 with the second cathode c 2 connected in parallel and in series with the negative pole of the power supply 10. first cathode c 1 via the second switch s 2 , the fifth switch s 5 connected, and connected to the positive pole of the power supply 10, the second cathode c 2 via the third switch s 3 It is connected with the negative pole of the power supply 10 to form the reverse pole circuit 1 . first cathode c 1 via the second switch s 2 , the sixth switch s 6 Connected to the negative pole of the power supply 10, the second cathode c 2 via the third switch s 3 , the sevent...

Embodiment 2

[0052] For the specific process flow of this embodiment, please refer to figure 1 .

[0053] The electrolytic cell is provided with a first anode a 1 , the first cathode c 1 , the second anode a 2 , the second cathode c 2 . During electrolysis, the first anode a 1 with the second anode a 2 connected in parallel and in series with the positive pole of the power supply 10, the first cathode c 1 with the second cathode c 2 connected in parallel and in series with the negative pole of the power supply 10. first cathode c 1 via the second switch s 2 , the fifth switch s 5 connected, and connected to the positive pole of the power supply 10, the second cathode c 2 via the third switch s 3 It is connected with the negative pole of the power supply 10 to form the reverse pole circuit 1 . first cathode c 1 via the second switch s 2 , the sixth switch s 6 Connected to the negative pole of the power supply 10, the second cathode c 2 via the third switch s 3 , the seven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com