Improved intensified petroleum production method

A technology for oil production and carbon dioxide, which can be used in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., and can solve problems such as unspecified results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

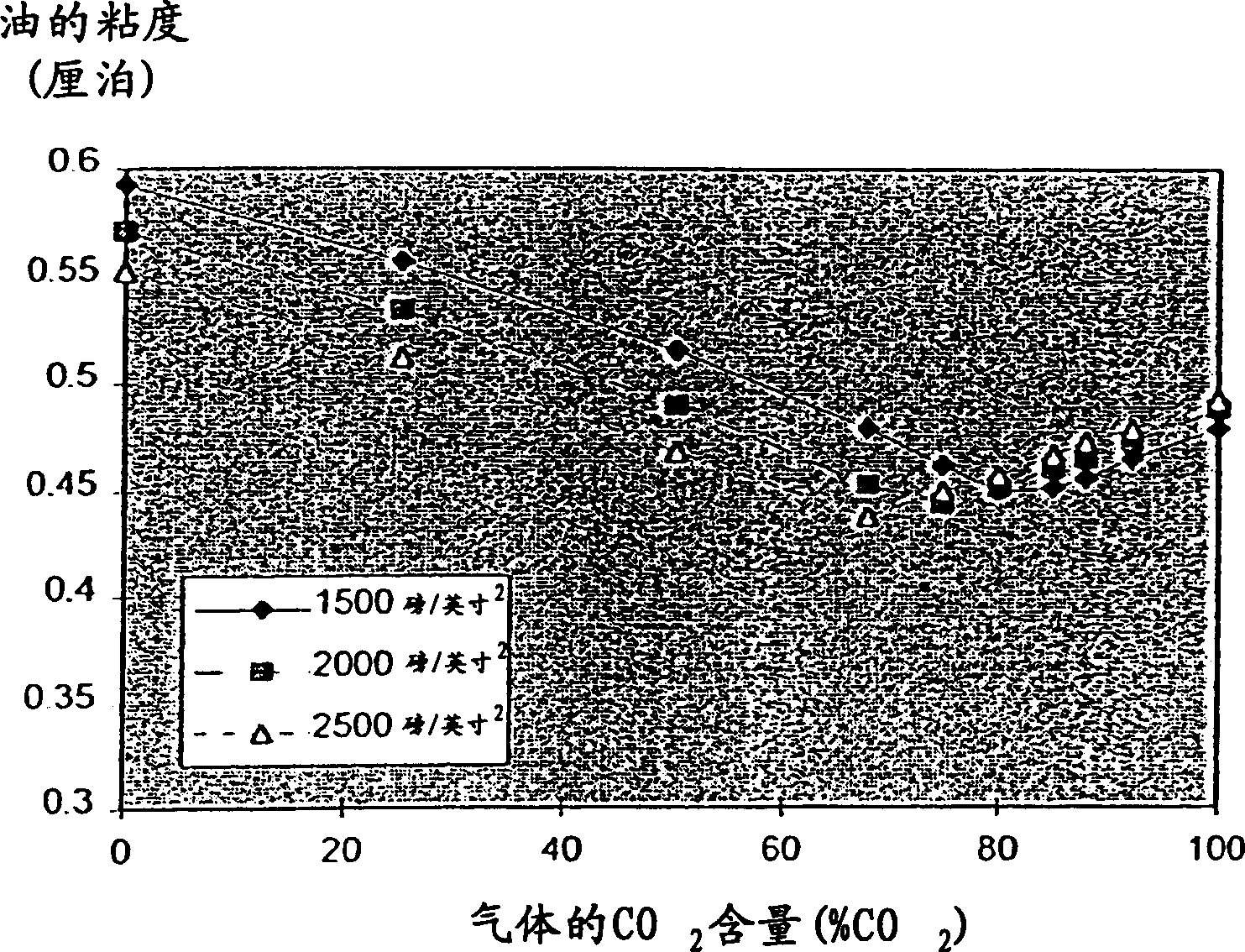

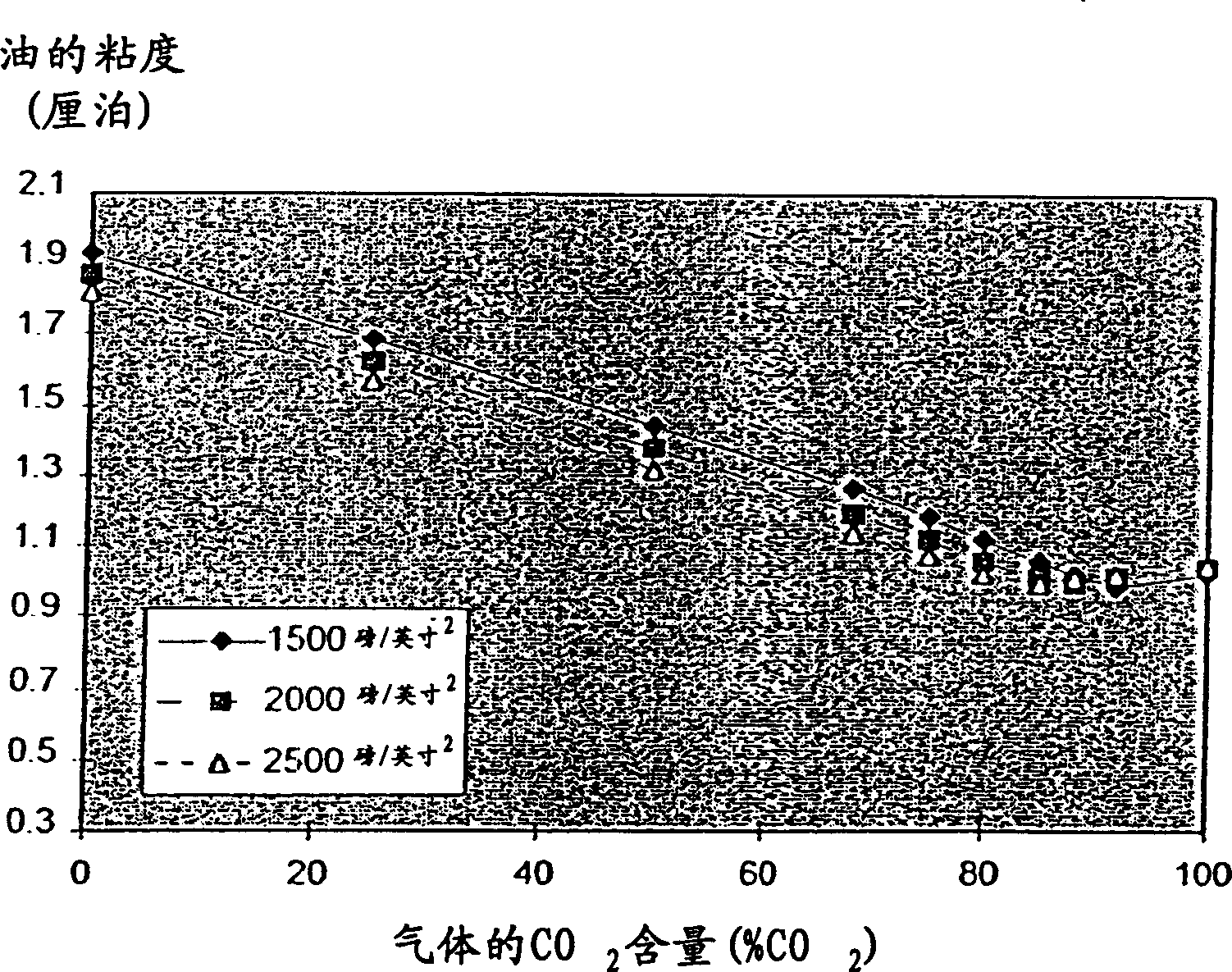

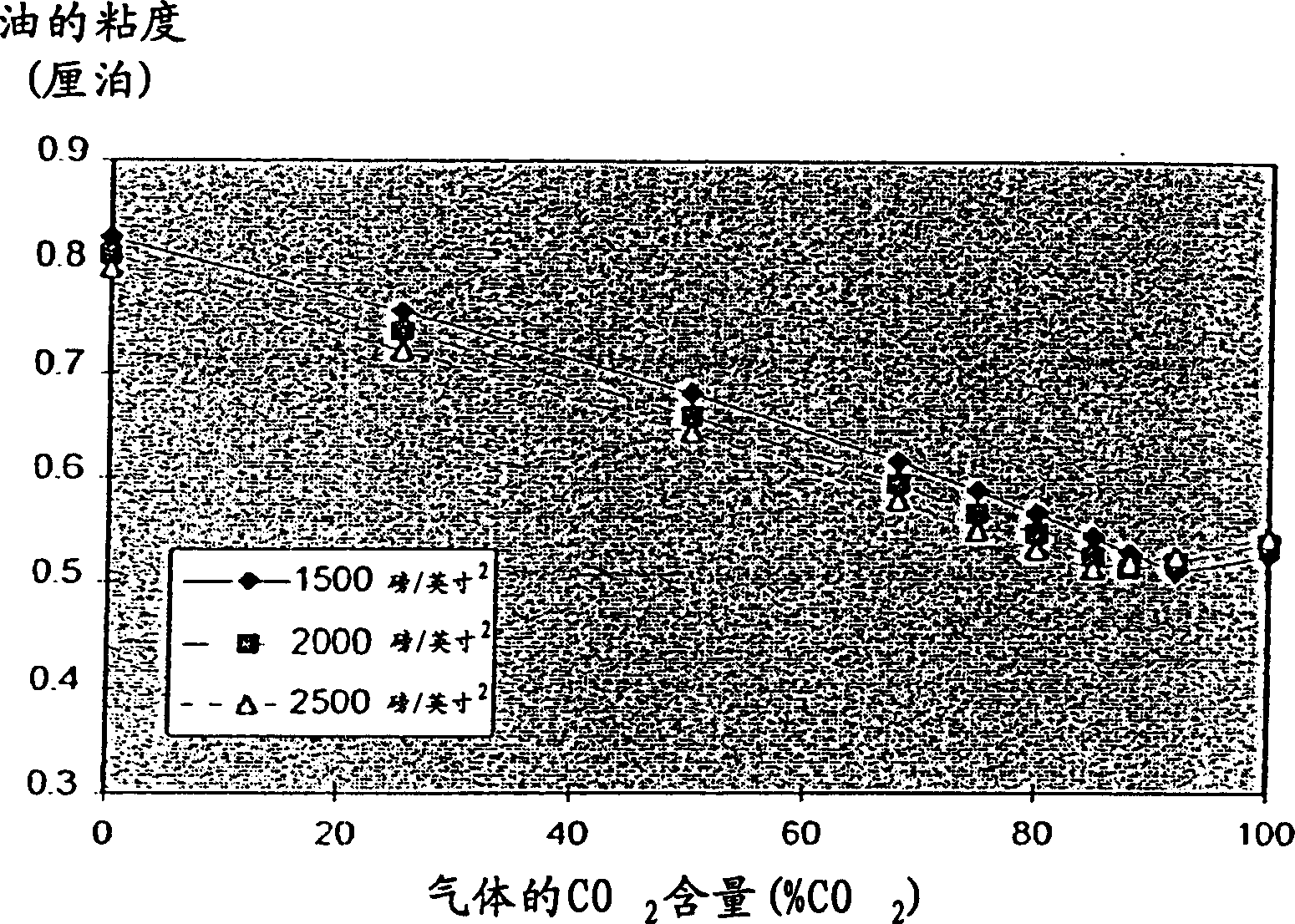

[0032]Three types of oil were studied to examine the effect of a mixture of carbon dioxide and nitrogen on enhancing oil recovery. A simulation method was developed based on the Peng-Robinson equation of state for gas-liquid equilibrium, the Twu model for liquid-phase viscosity, and the Brock and Bird equation for surface tension in a modified form. The three oils used in this study were paraffinic, naphthenic and aromatic. Assuming that the amount of mixed gas of carbon dioxide and nitrogen is 1 mole of gas / mole of oil, since the injection of carbon dioxide is usually after the water injection process, or alternately with water injection in the WAG method, a small amount of water should be added to this mixture. Water additions are based on 20% saturation of conventional oils. at 1,500-2,500 psi 2 The pressure and temperature of 75-200°F were studied.

[0033] figure 1 , 2 and 3 and Tables 1, 2 and 3 give the viscosity of paraffinic, naphthenic and aromatic oils at 75°F ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com