Method for increasing production by injecting gas at different development stages of inclined fault block oil reservoir

A gas injection technology in the development stage, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of "attic oil" that is difficult to effectively develop, achieve obvious production increase effect, increase production pressure difference, Good blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

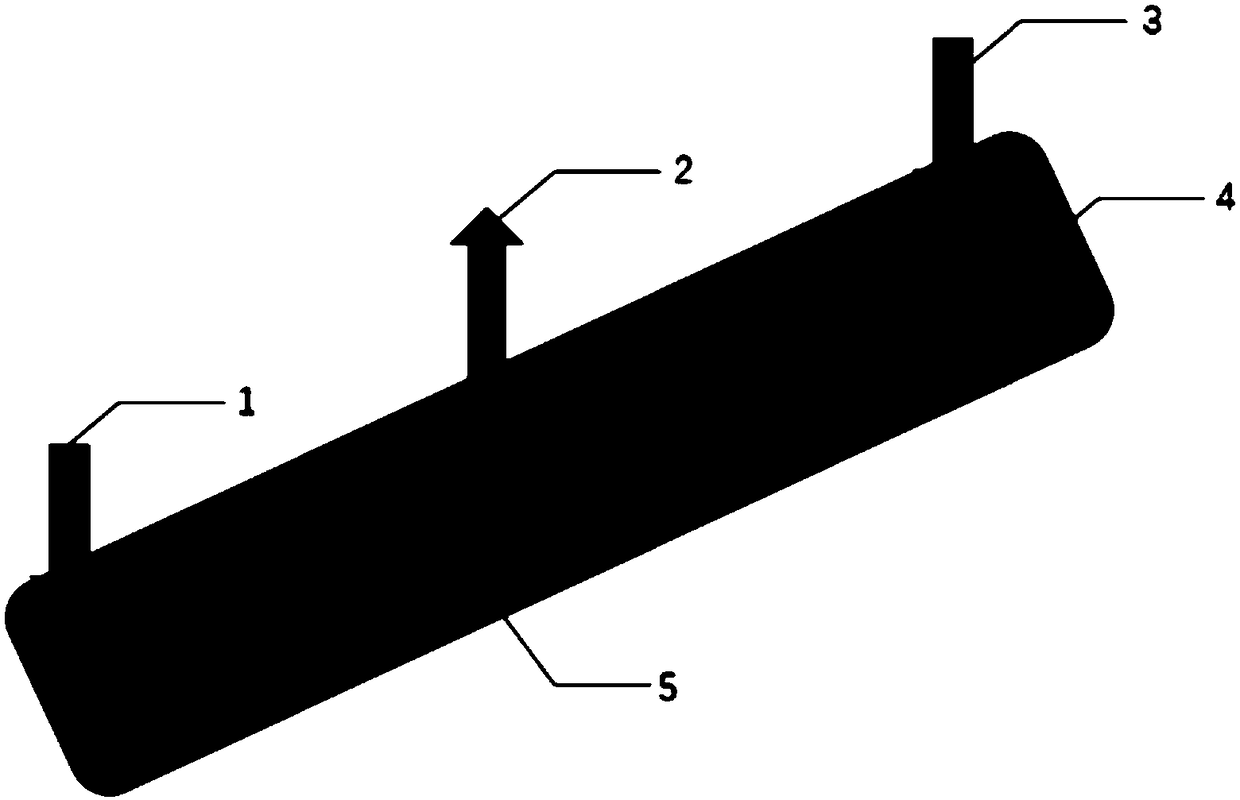

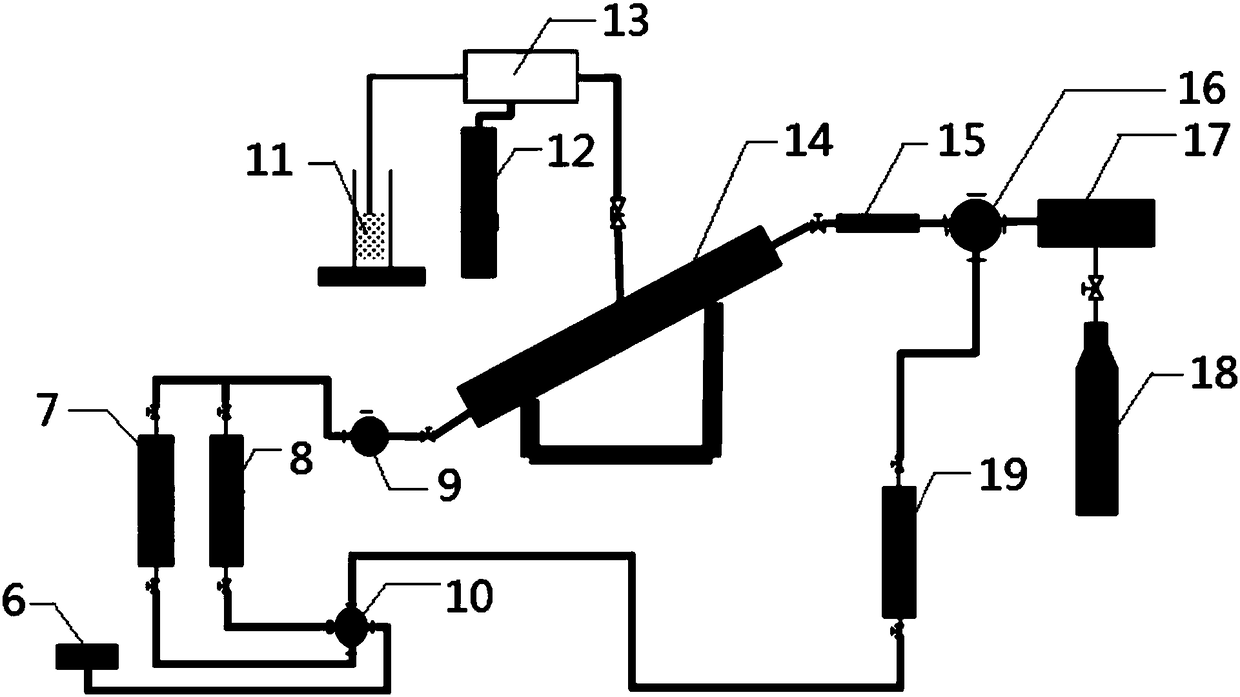

[0010] Technical scheme of the present invention is as follows:

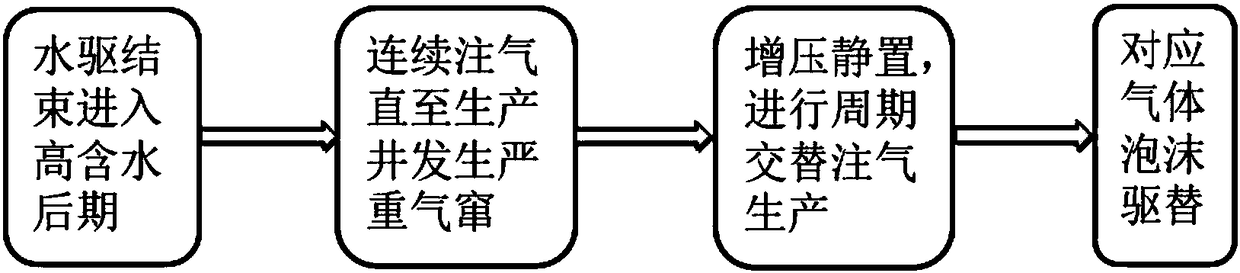

[0011] A method for increasing production by gas injection in different development stages of an inclined fault-block reservoir, which is carried out in three stages, including the following steps:

[0012] (1) The first stage—continuous gas injection: the gas injection well at the high position continuously injects gas into the inclined fault block reservoir at a constant injection rate, and the production well at the low position produces at a constant injection-production ratio. When the gas-oil ratio reaches 1000 : When 1, it is considered as severe gas channeling, stop gas injection;

[0013] (2) The second stage—periodic alternate gas injection production: close the production well after severe gas channeling, continue to inject gas at a constant injection rate, and stop gas injection when the reservoir is pressurized to 0.8 to 1.2 times the original reservoir pressure; Start the production well after sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com