Oil extraction method for establishing oil permeable water stop sieve by filling fusheng sand in horizontal well fracture

A technology for horizontal wells and fracturing, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of reduced water blocking and oil permeability, inability to penetrate Fusheng sand, and discount on oil and water blocking functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

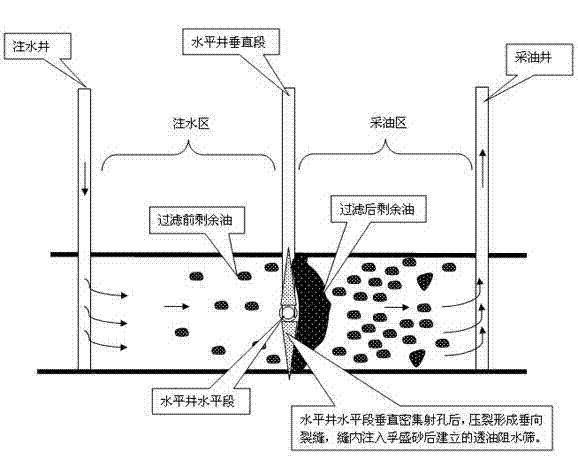

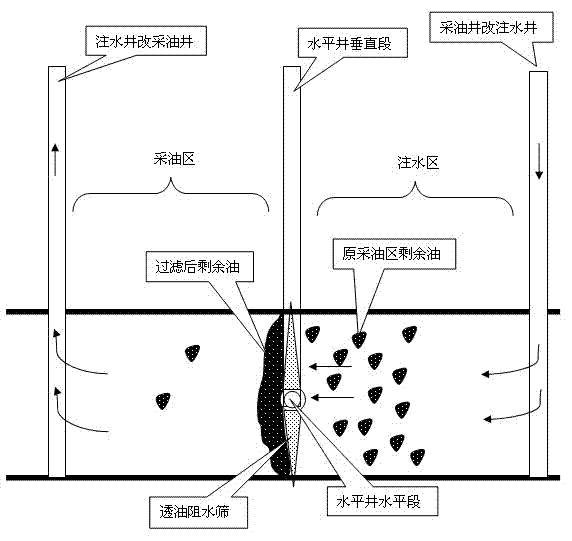

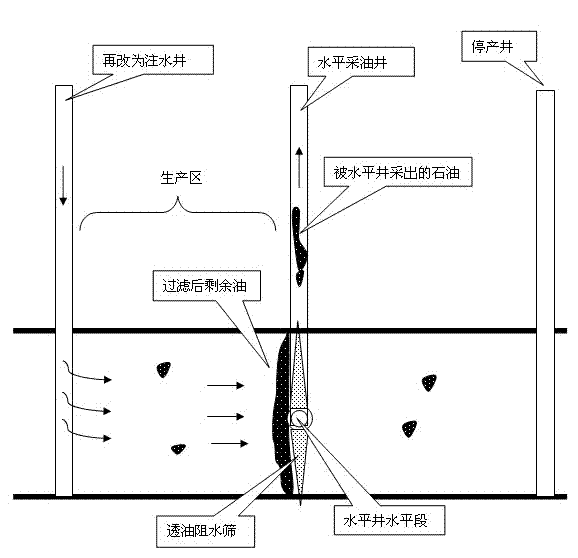

[0022] The oil production method of filling Fusheng sand in horizontal wells of the present invention to establish oil-permeable water-blocking screens is characterized in that horizontal wells are vertically perforated and fractured one by one between the water injection well row and the oil production well row. Fusheng sand with oil-permeable and water-repelling function is filled in the medium as a proppant, and an oil-permeable and water-repelling screen is built to filter the oil-water mixture.

[0023] The horizontal and vertical fracturing of the present invention is to drill a horizontal well in the oil layer between the water injection well row and the oil production well row in the direction perpendicular to the minimum in-situ stress, and perform fracturing after the vertical intensive perforation.

[0024] The oil-permeable water-blocking screen of the present invention injects Fusheng sand into the vertical fractures of horizontal wells one by one. The oil-permeabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com