Method and system for planning auxiliary discrete movement of computer

A computer-aided, discrete motion technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of large contour error, neglect of non-European error of tool path curve, no active axis and linkage axis, etc., and achieve outstanding substantial progress, The effect is remarkable and the effect of saving software and hardware computing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

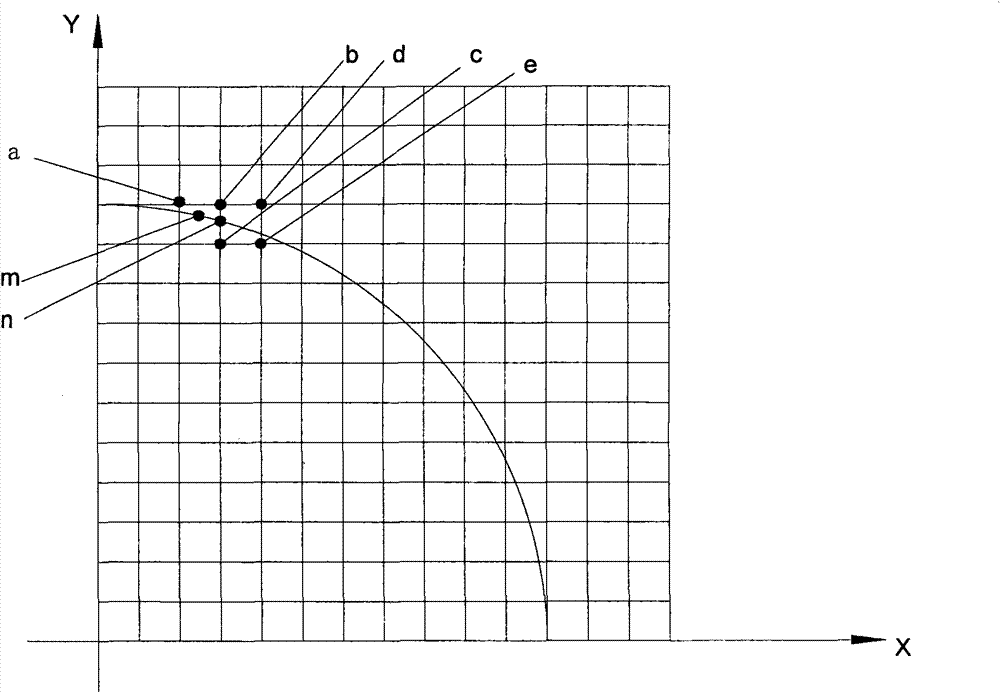

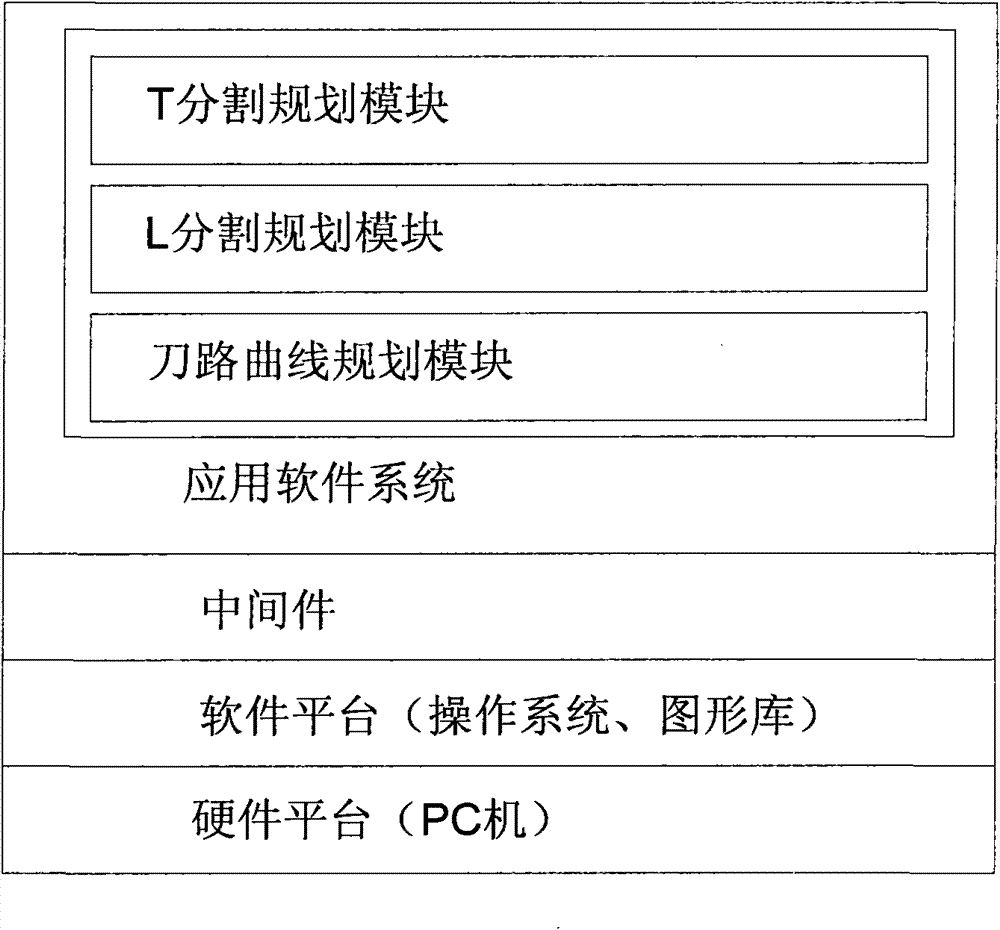

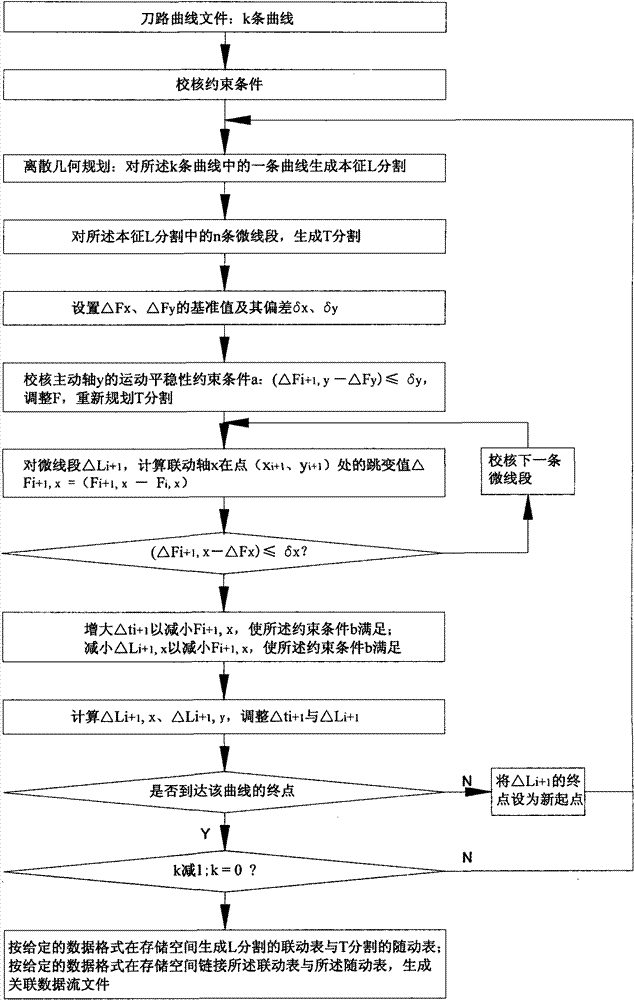

[0084]The geometric structure of the workpiece contour is predetermined, therefore, the kinematic relationship between the coordinate axes is deterministic. The core task of the digital control system is to manufacture digital control information, and realize the tool path curve through the synthesis of the displacement (angular displacement) of the relevant coordinate axes, which is used to control the coordinate axes in the working machine to complete a given deterministic mechanical movement. The composite displacement generated by the displacement of the relevant coordinate axes must be realized by the linkage of the relevant coordinate axes; the continuous synthesis of the composite displacement needs to control the time interval between the composite displacements. The linkage of related coordinate axes is a geometric problem, and the continuous synthesis of the combined displacement involves feed speed and acceleration and deceleration control, which is a motion planning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com