Method for jointly treating high-fluorine sewage by utilizing waste slag

A combined treatment and high fluorine technology, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve problems such as unfavorable sustainable development, environmental pollution, harmful animal and plant growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

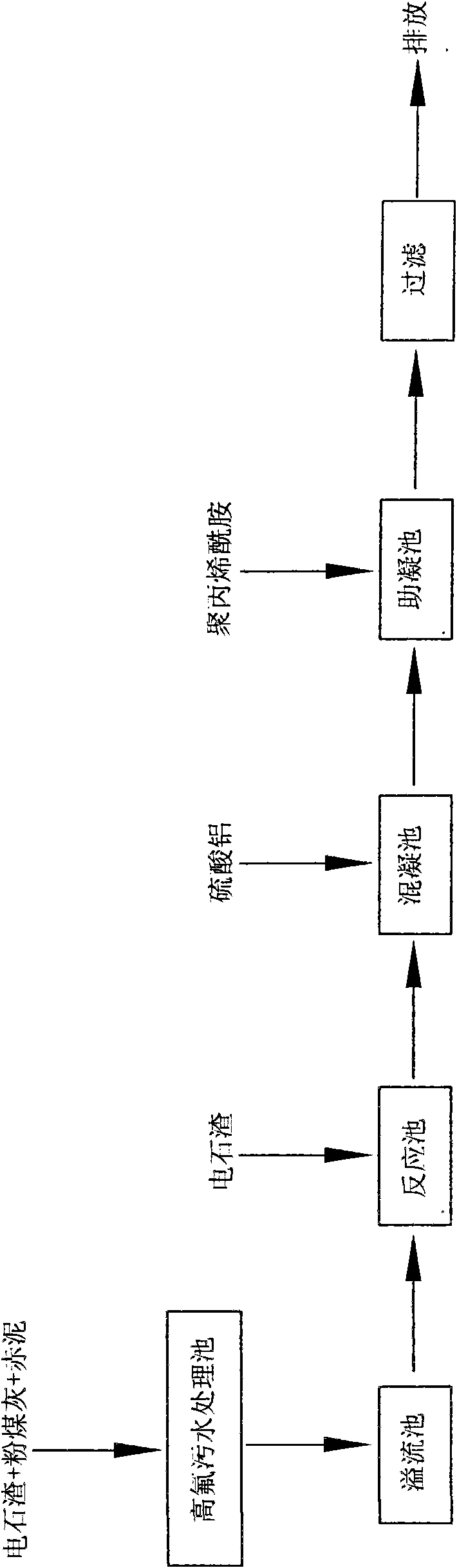

Image

Examples

Embodiment 1

[0017] Embodiment 1: the method for utilizing waste slag to jointly treat high-fluorine sewage as described in the present invention comprises the following steps: adding 50 kg of calcium carbide slag and 50 kg of powder to a treatment tank containing 1 ton of high-fluorine sewage with a fluorine content of 3000 mg / L Coal ash and 50kg red mud were stirred and reacted for 10 minutes and sent to the overflow tank, where the reaction continued for 10 minutes, and the clear liquid in the overflow tank overflowed into the reaction tank; (2) Added Carbide slag, adjust PH=9, after 10 minutes of reaction, part of the clear liquid overflows into the coagulation tank; (3) Add 0.72kg of aluminum sulfate to the coagulation tank, adjust PH=6, and after 10 minutes of reaction, the clear liquid partly overflows Enter the coagulation aid tank; (4) Add 0.01kg polyacrylamide to the coagulation aid tank, filter and discharge after 10 minutes of reaction. After testing, the fluorine content in th...

Embodiment 2

[0018] Embodiment 2: the method for utilizing waste residues to jointly treat high-fluorine sewage as described in the present invention comprises the following steps: adding 70 kg of calcium carbide slag and 70 kg of powder to a treatment tank containing 1 ton of high-fluorine sewage with a fluorine content of 5000 mg / L Coal ash and 70kg red mud were stirred and reacted for 15 minutes and sent to the overflow tank, where the reaction was continued for 15 minutes, and the clear liquid in the overflow tank partially overflowed into the reaction tank; (2) adding Carbide slag, adjust PH=9.5, after 15 minutes of reaction, the clear liquid partly overflows into the coagulation tank; (3) add 0.8kg anhydrous aluminum chloride to the coagulation tank, adjust PH=7, after 15 minutes of reaction, the clear liquid Part of the overflow enters the coagulation aid pool; (4) Add 0.02kg cationic polyacrylamide to the coagulation aid pool, react for 15 minutes, and then filter and discharge. Af...

Embodiment 3

[0019] Embodiment 3: the method for utilizing waste slag to jointly treat high-fluorine sewage as described in the present invention comprises the following steps: adding 100 kg of calcium carbide slag and 100 kg of powder to a treatment tank containing 1 ton of high-fluorine sewage with a fluorine content of 8000 mg / L Coal ash and 100kg red mud were stirred and reacted for 20 minutes and sent to the overflow tank, where the reaction continued for 20 minutes, and the clear liquid in the overflow tank overflowed into the reaction tank; (2) Added Carbide slag, adjust PH=10, after 20 minutes of reaction, part of the clear liquid overflows into the coagulation tank; (3) add 1.2kg polyaluminum sulfate to the coagulation tank, adjust PH=7.5, and part of the clear liquid overflows after 20 minutes of reaction (4) Add 0.03kg of anionic polyacrylamide to the coagulation aid pool, react for 20 minutes, and then filter and discharge. After testing, the fluorine content in the filtered se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com