Waterproof coating device

A technology of coating device and coating chamber, which is applied to spray device, device for coating liquid on surface, spray booth, etc., can solve the problems of inconvenience, inability to connect, and high cost, achieve good coating effect, increase the content of active ingredients and Uniformity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

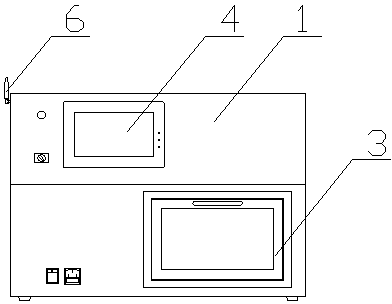

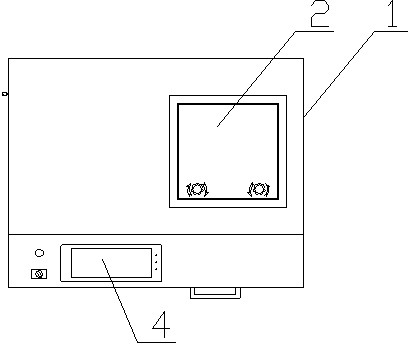

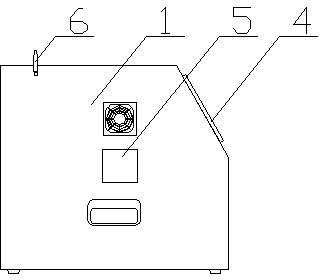

[0020] As shown in the figure: a waterproof coating device, including a fuselage 1, the fuselage 1 is provided with an atomizing device 2 and a drying device 3, the atomizing device 2 is arranged on the top of the fuselage, and the drying The device 3 is arranged in the middle and lower part of the fuselage 1, a touch screen 4 is provided on the front panel of the fuselage 1, the touch screen 4 is connected with the electric control device 5 in the fuselage 1, and an antenna 6 is arranged on the fuselage 1 , the antenna 5 is connected to the electric control device. The atomization device 2 includes an atomization box 21, the top of the atomization box 21 is provided with a sealing cover 26, and the atomization box 21 is provided with a liquid medicine placement chamber 28 and a coating chamber 23 which communicate with each other. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com