Patents

Literature

57results about How to "Improve range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

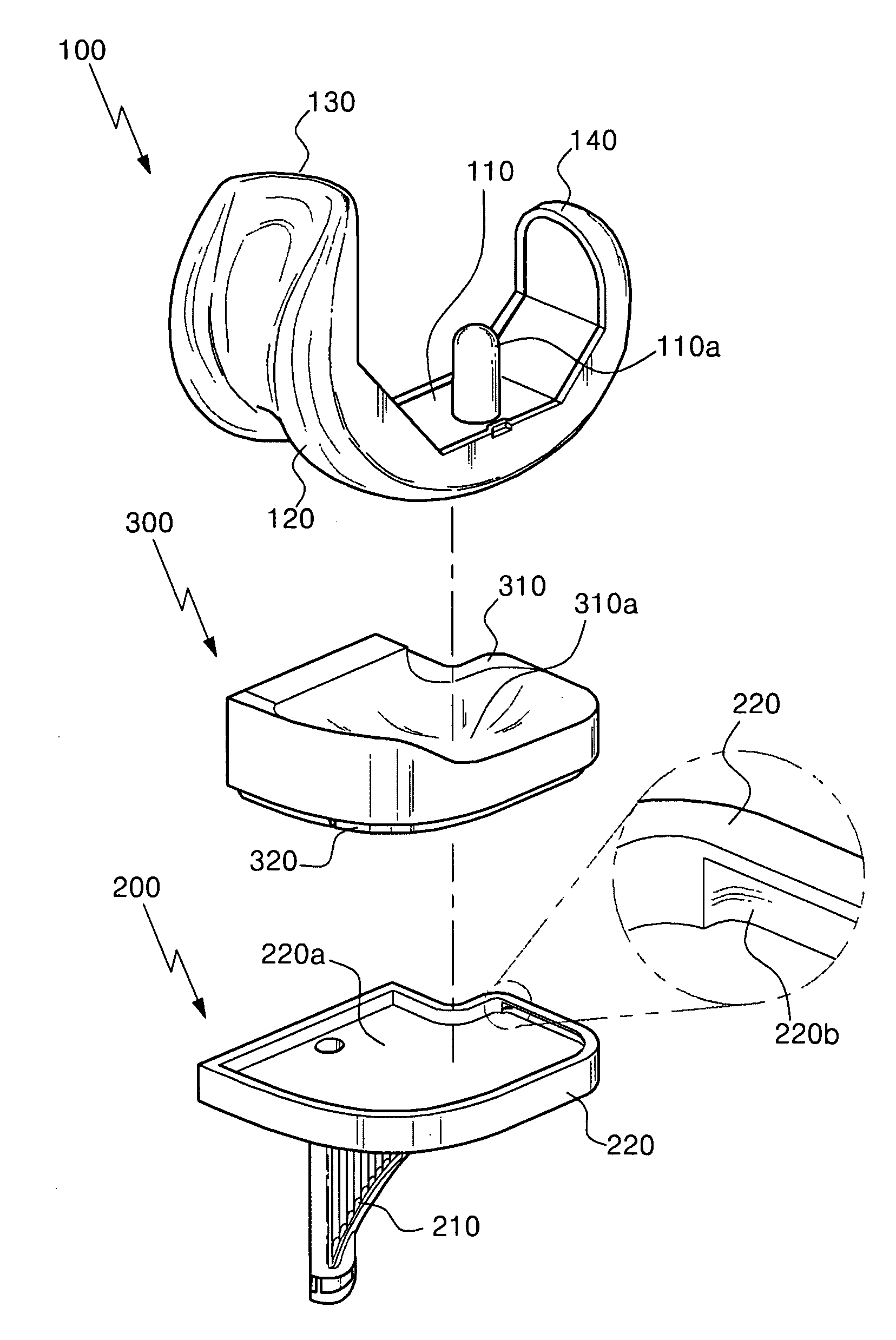

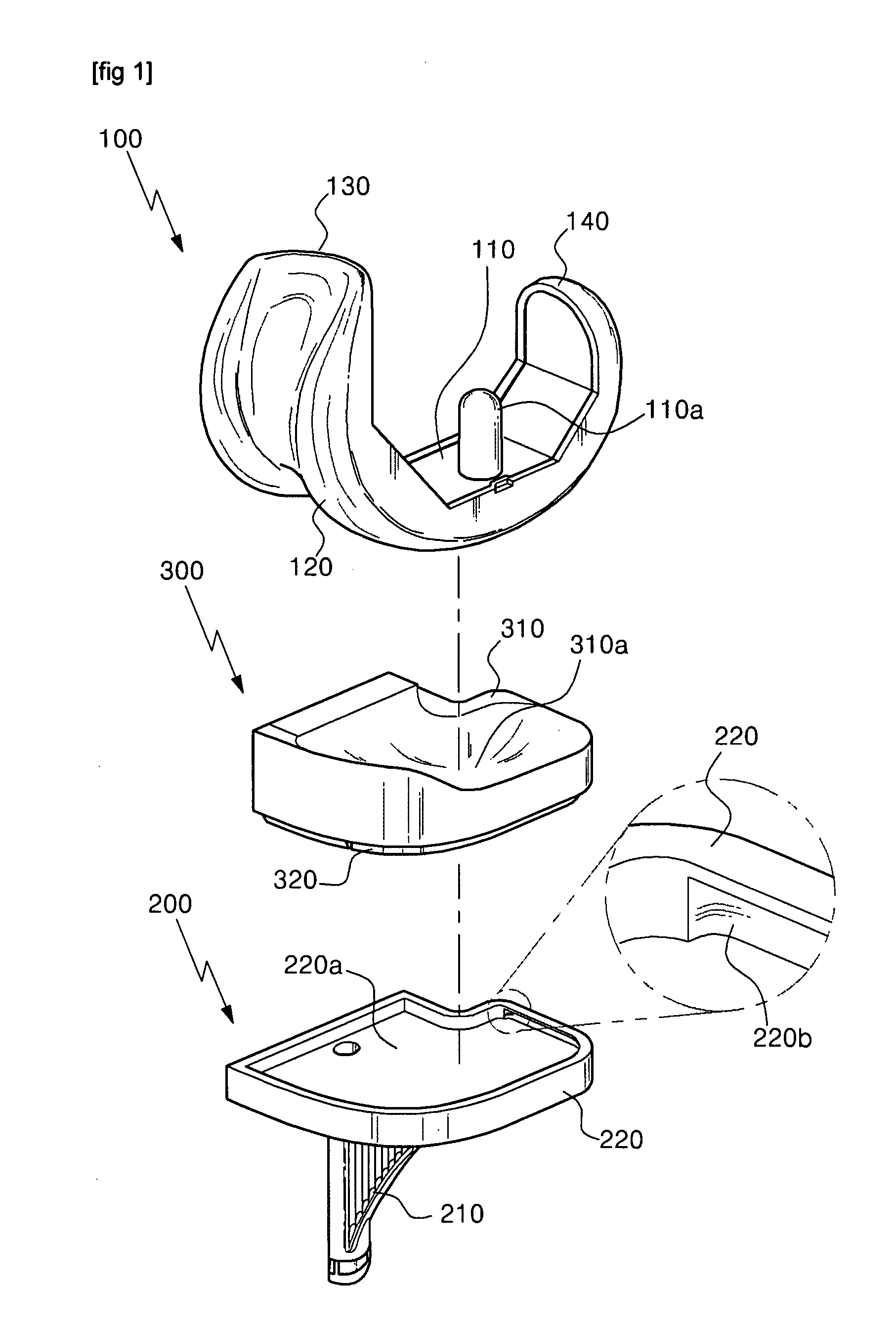

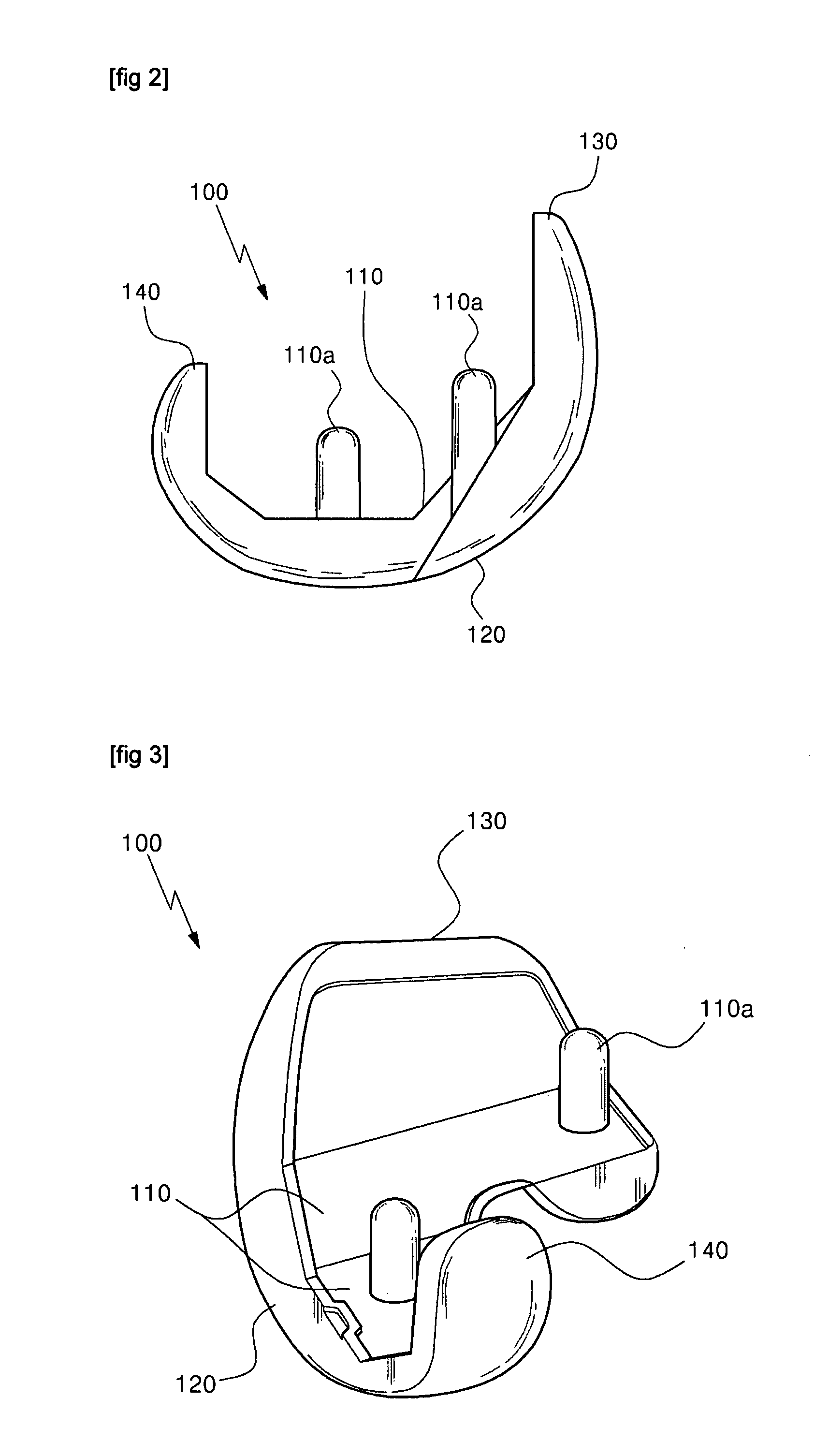

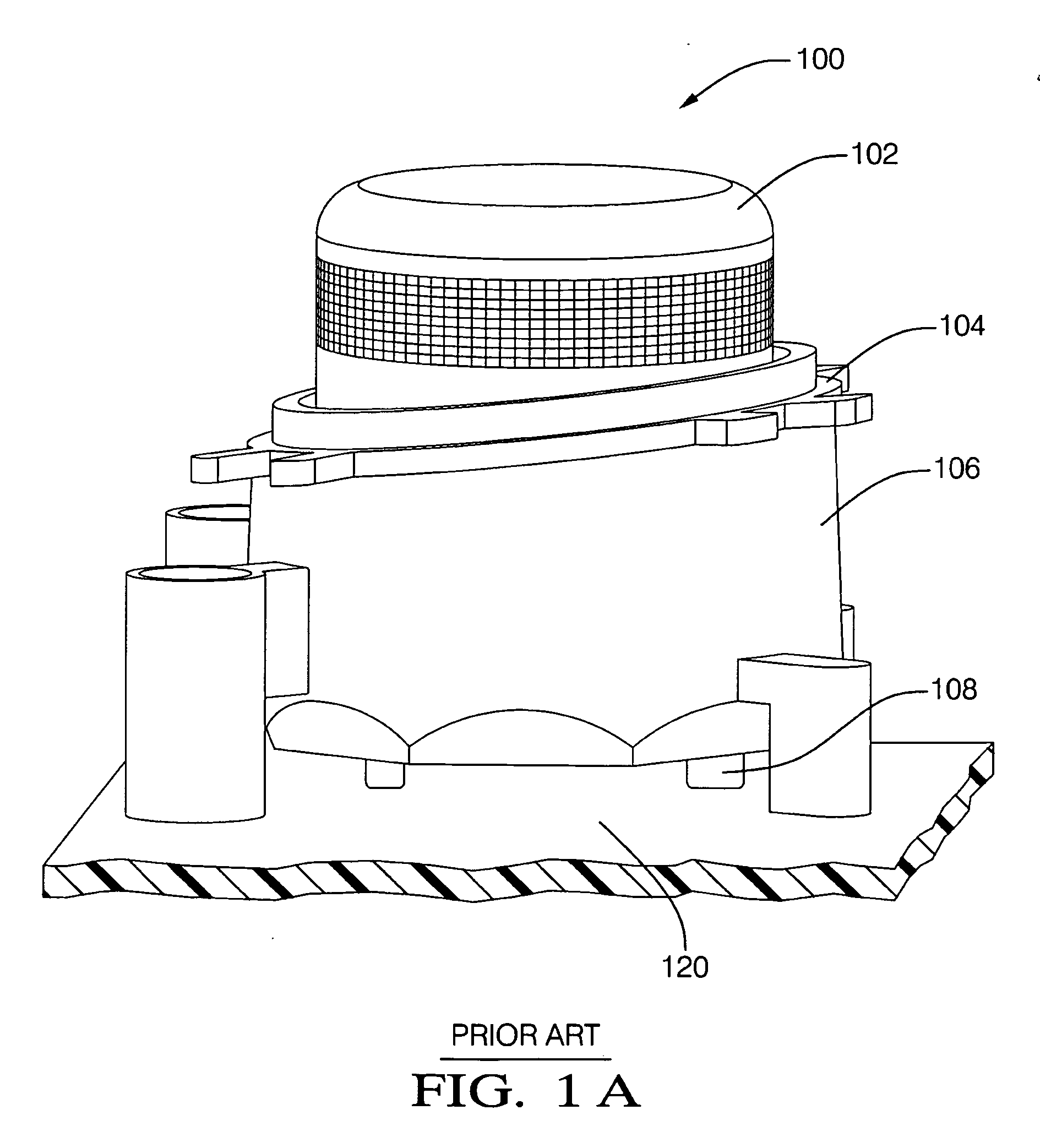

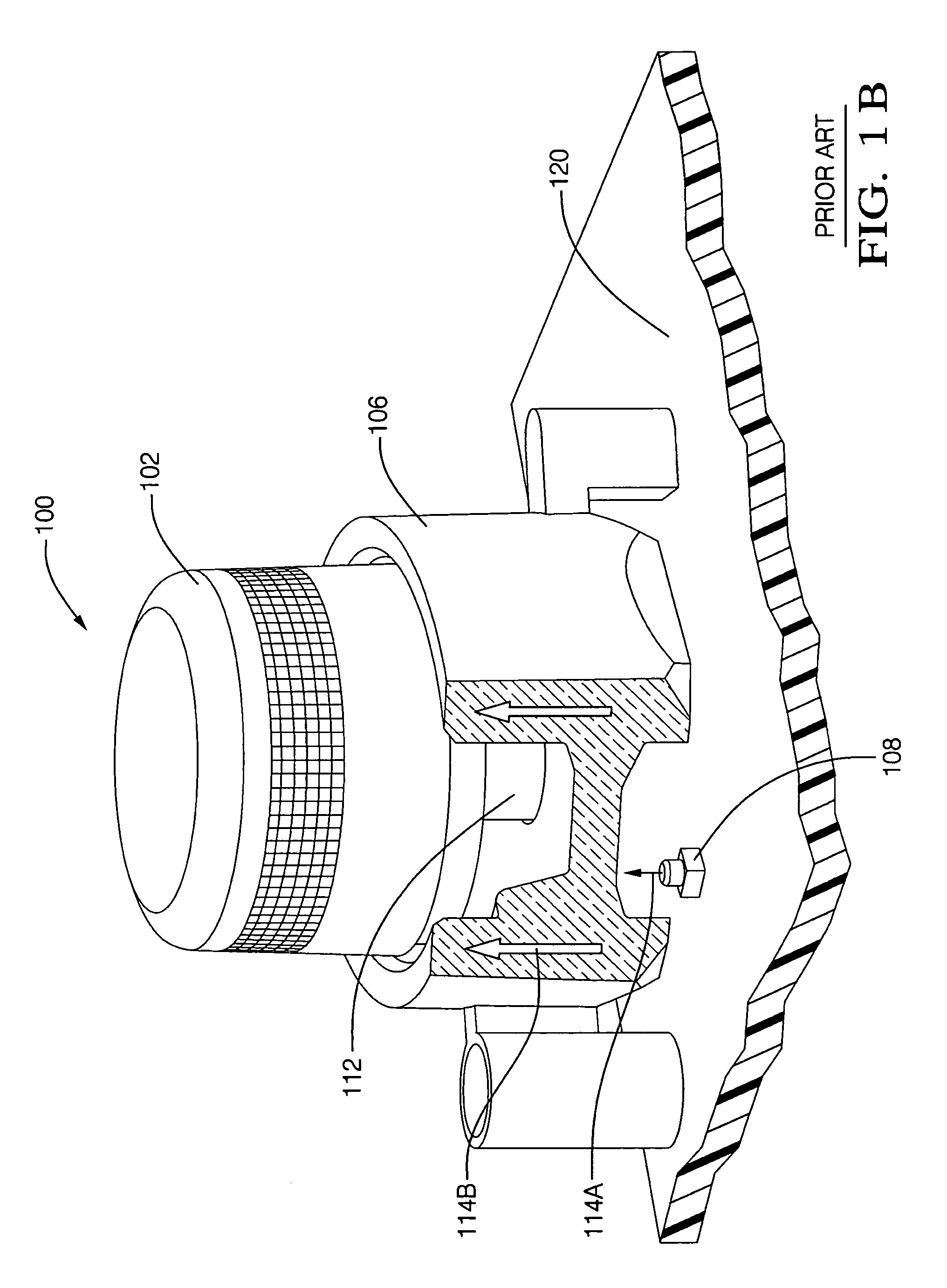

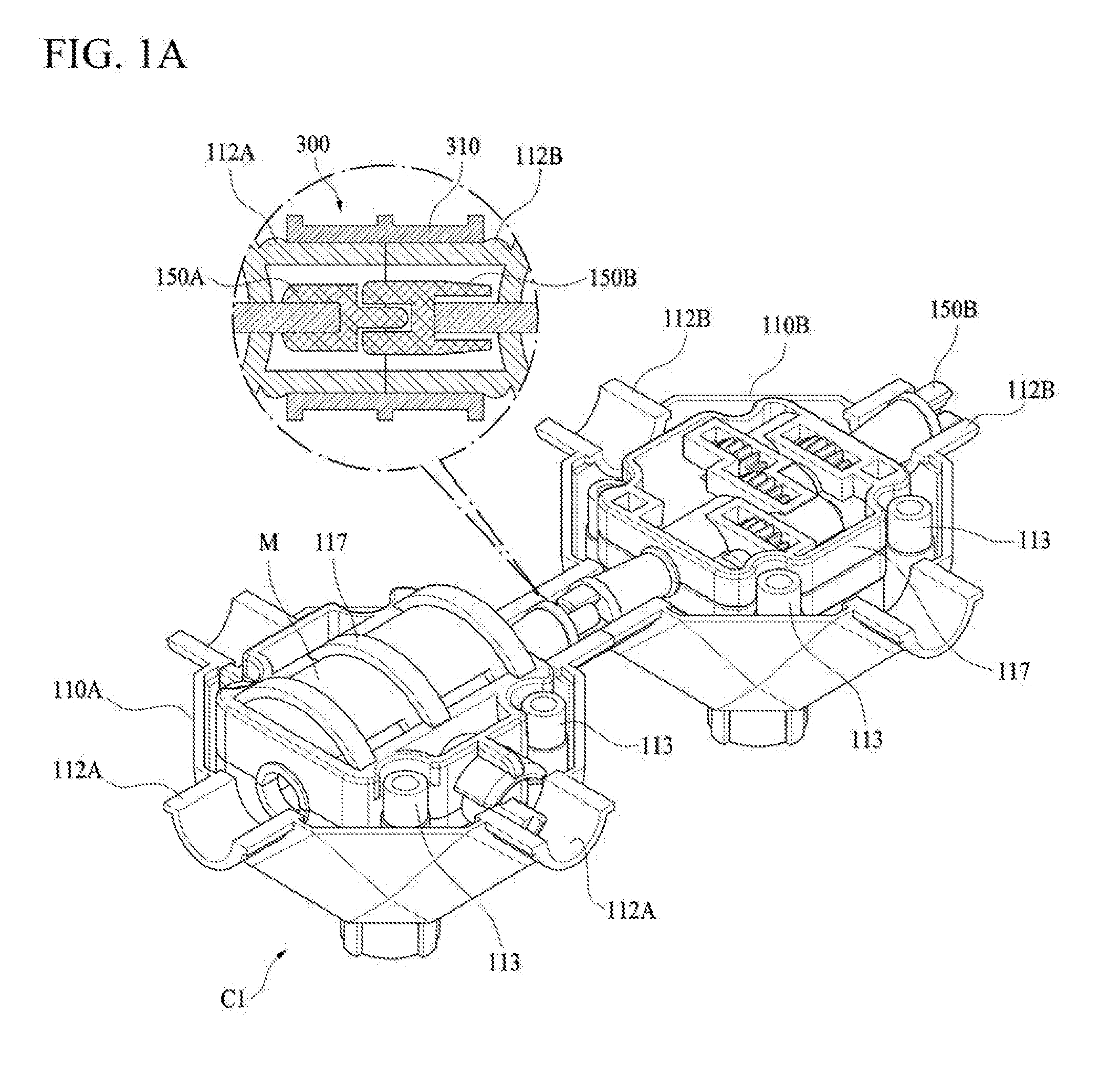

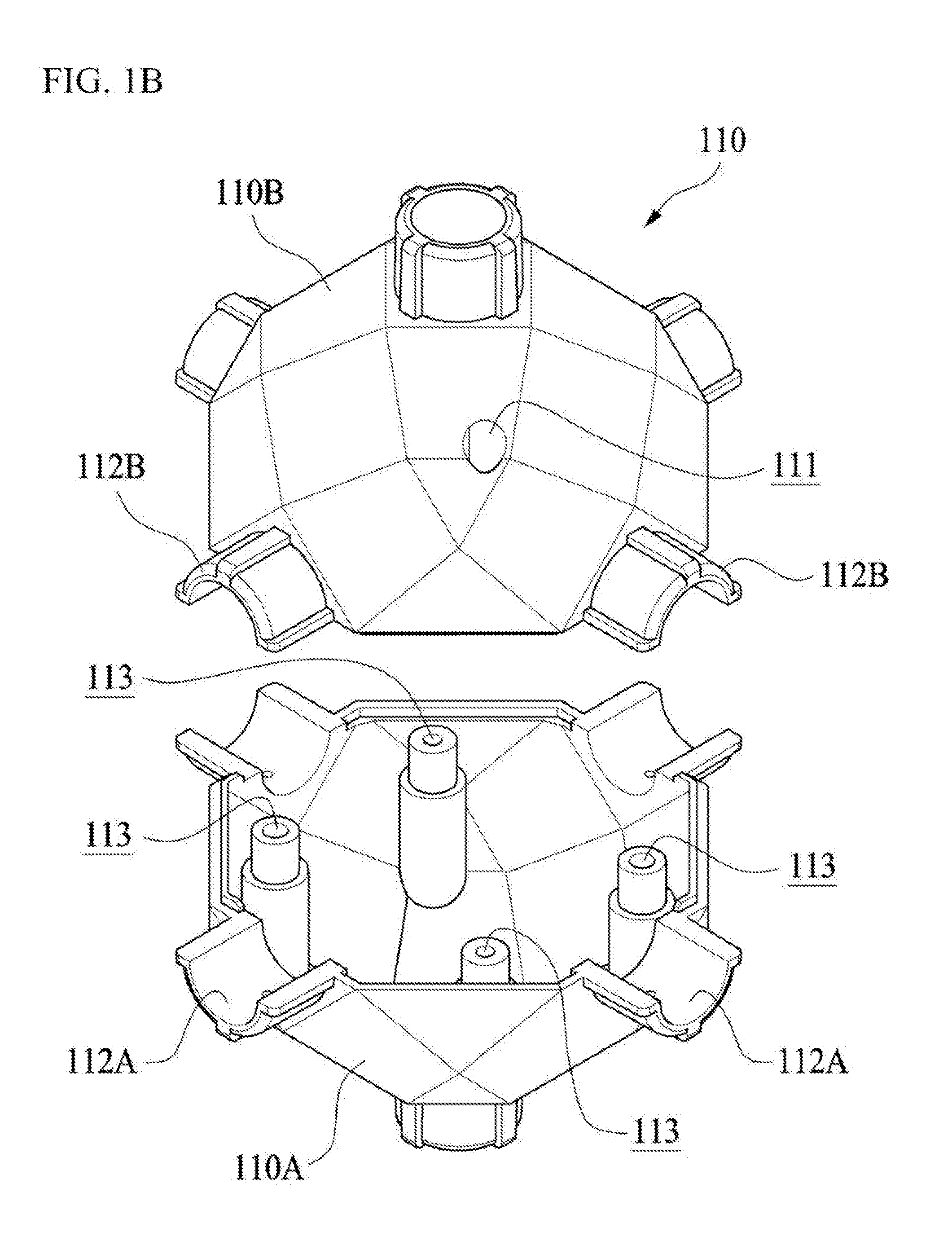

Knee joint prosthesis for bi-compartmental knee replacement and surgical devices thereof

InactiveUS20080119938A1Improve rangePreventing malalignment and shakingJoint implantsKnee jointsFlexion deformitySacroiliac joint

There are provided a knee joint prosthesis for a bi-compartmental knee replacement and surgical devices thereof, wherein the knee joint prosthesis for the bi-compartmental knee replacement, which is performed on a patient with degenerative arthritis at any one of an inside compartment and an outside compartment of the knee and between the femur and the patella, is configured to position a femoral component at the inside or outside of the femur of the patient, to position a tibial component at the inside or outside of the tibia, and to properly position a tibial bearing member between the femoral component and the tibial component, thereby having the effects of improving the range of sense and motion after surgery by preserving other normal joints and reducing blood loss compared to a conventional prosthesis; improving the accuracy of the surgery to prevent the malalignment of the prosthesis, reduce the shaking of the prosthesis and extend the use life of the prosthesis; significantly improving a securing force compared to a conventional prosthesis; and using the knee joint prosthesis for the bi-compartmental knee replacement for patients with bi-compartmental arthritis, genu varum and genu valgum and flexion deformity, and anterior cruciate ligament loss.

Owner:OH SANG SOO

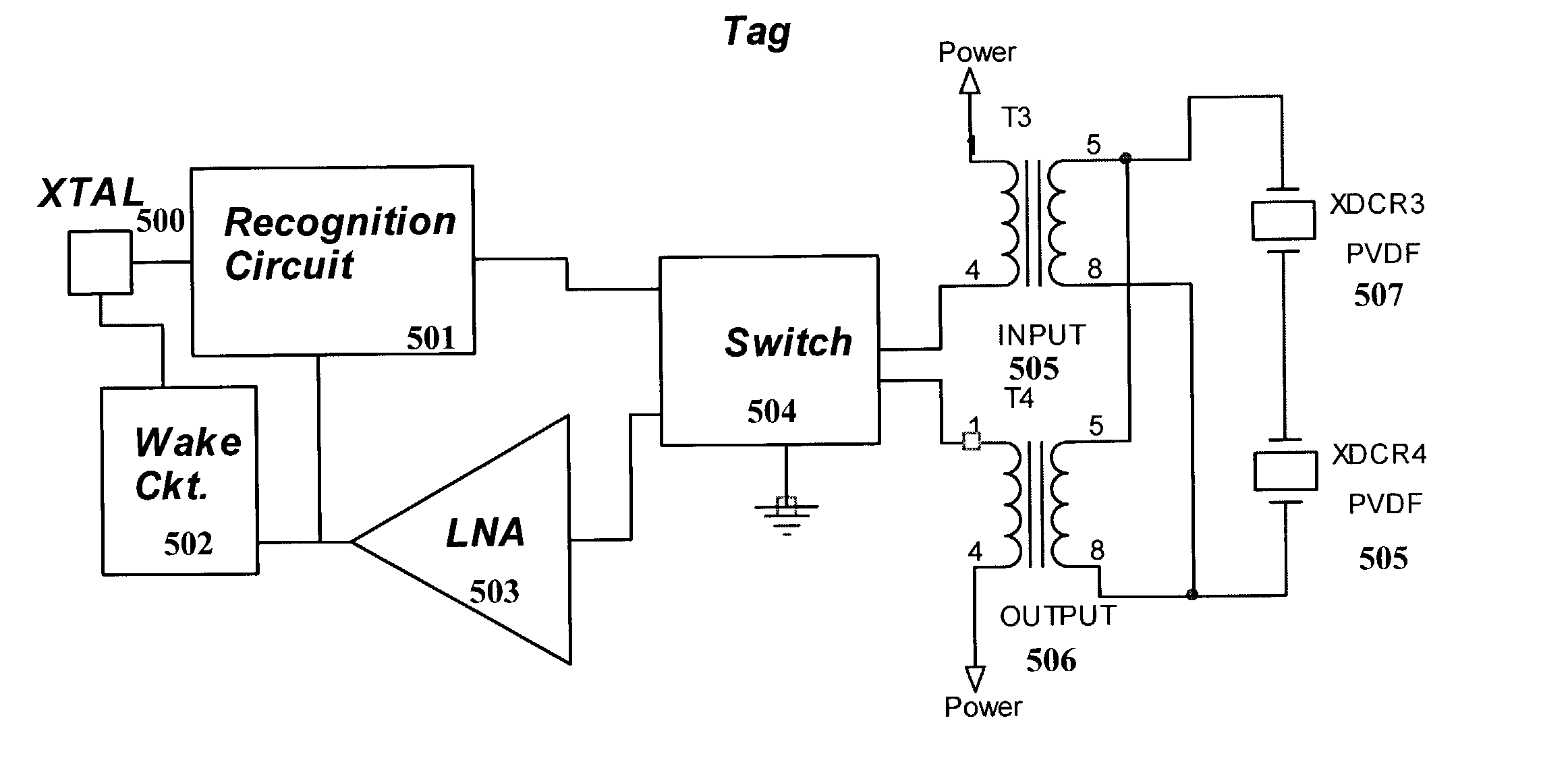

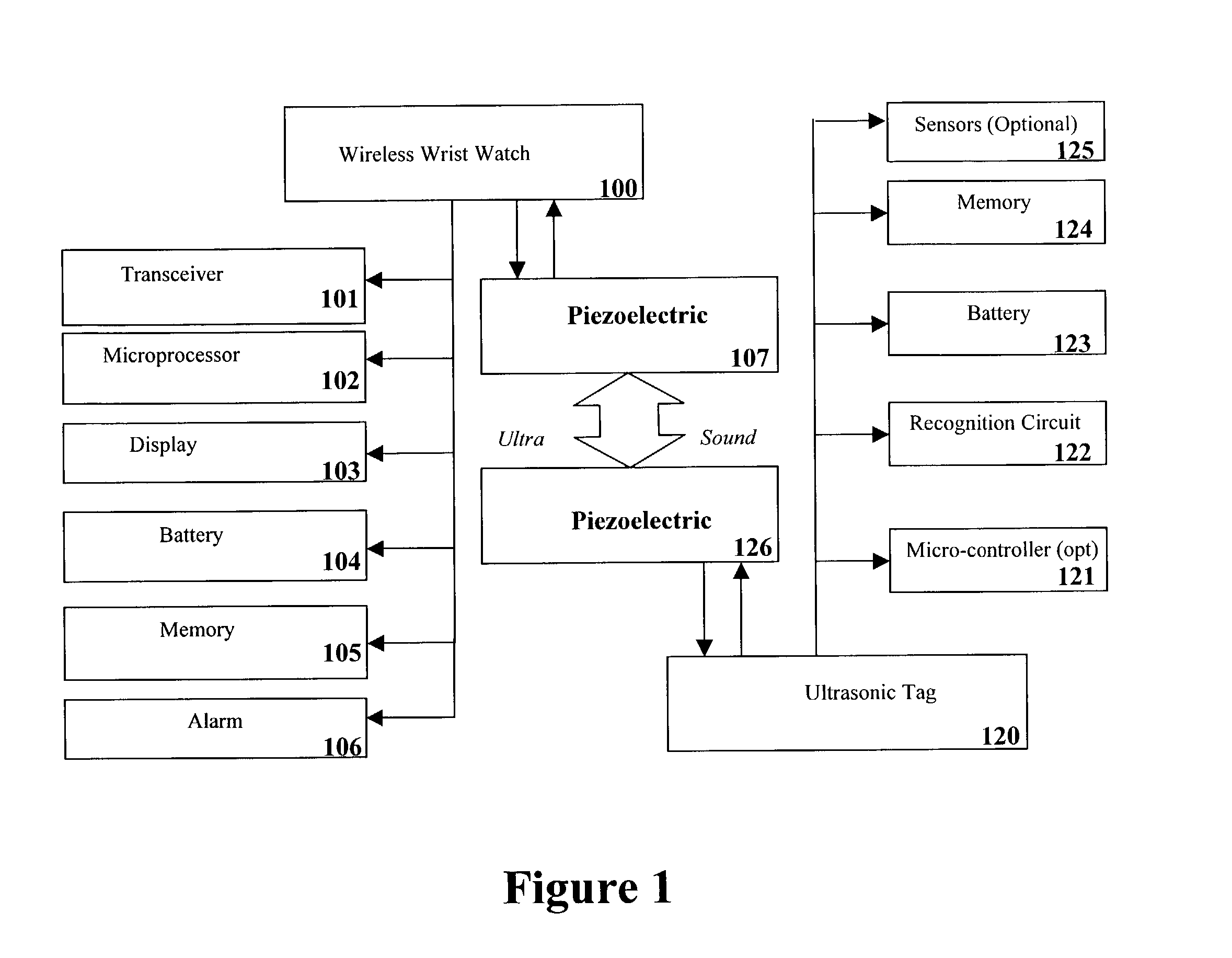

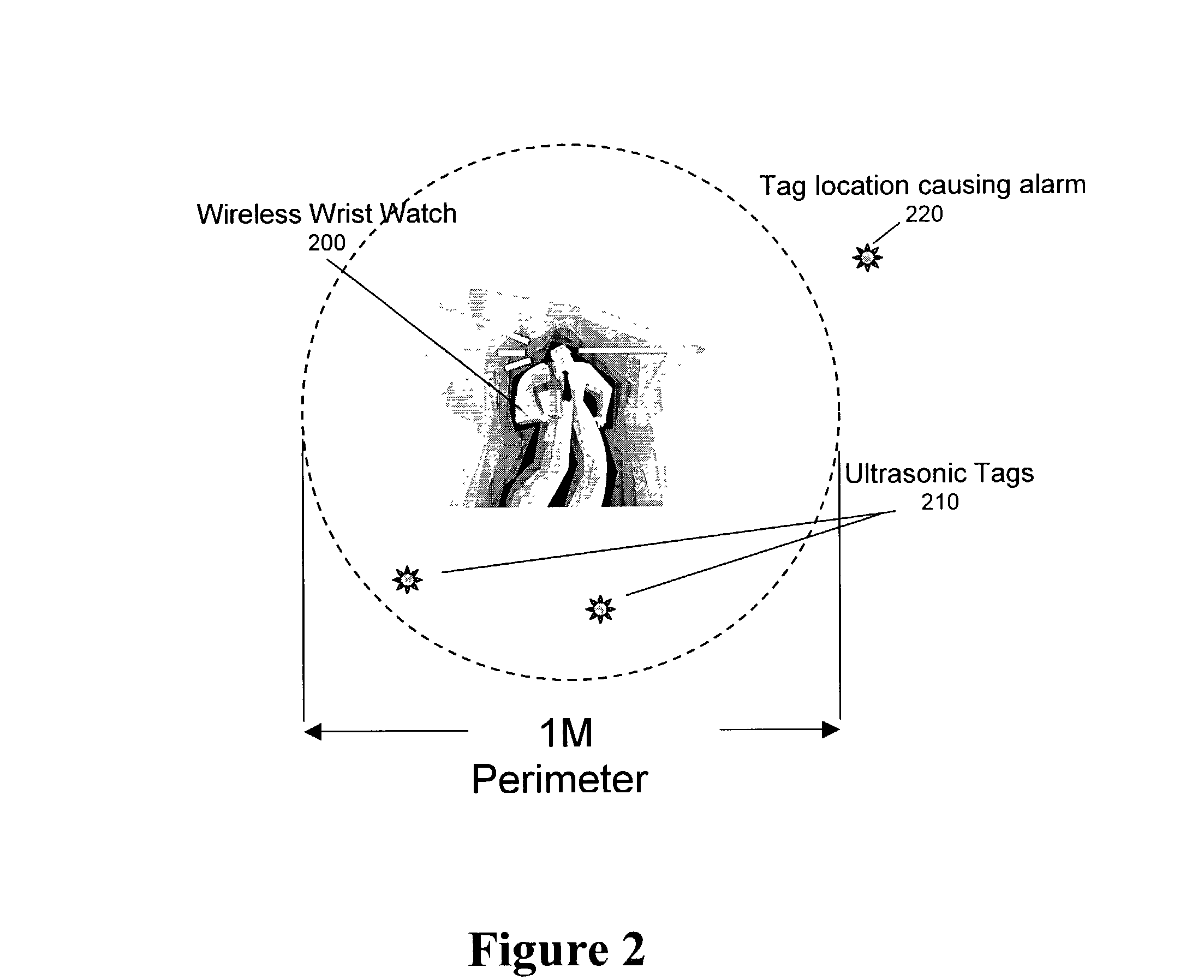

Ultrasonic transmitter and receiver systems and products using the same

InactiveUS7061381B2Improve rangeReasonable distanceSonic/ultrasonic/infrasonic transmissionRecord carriers used with machinesRadio frequencyTransceiver

A transceiver preferably embedded within a wearable security watch, PDA, or other device which achieves a variety of wireless ultrasonic and / or radio-frequency based functions, including digital identification and proximity and sensation monitoring of assets, individuals, pets, and the like. The portable or wearable device realizes these functions by periodically polling and receiving information tags within the transmitting distance of the device. The invention can help reduce the likelihood of the theft, loss, or misplacement by detecting that a tag associated with or attached to an entity has left an individual's proximity and sounding an alarm. The device can also assist individuals with sensory impairments, including persons who are deaf, diabetic, and the like, by detecting a tagged entity as it enters the space around an individual, or by detecting environmental stimuli, such as excessive heat in an individual's proximity or vital sign changes, and sounding an alarm.

Owner:BEEZERBUG

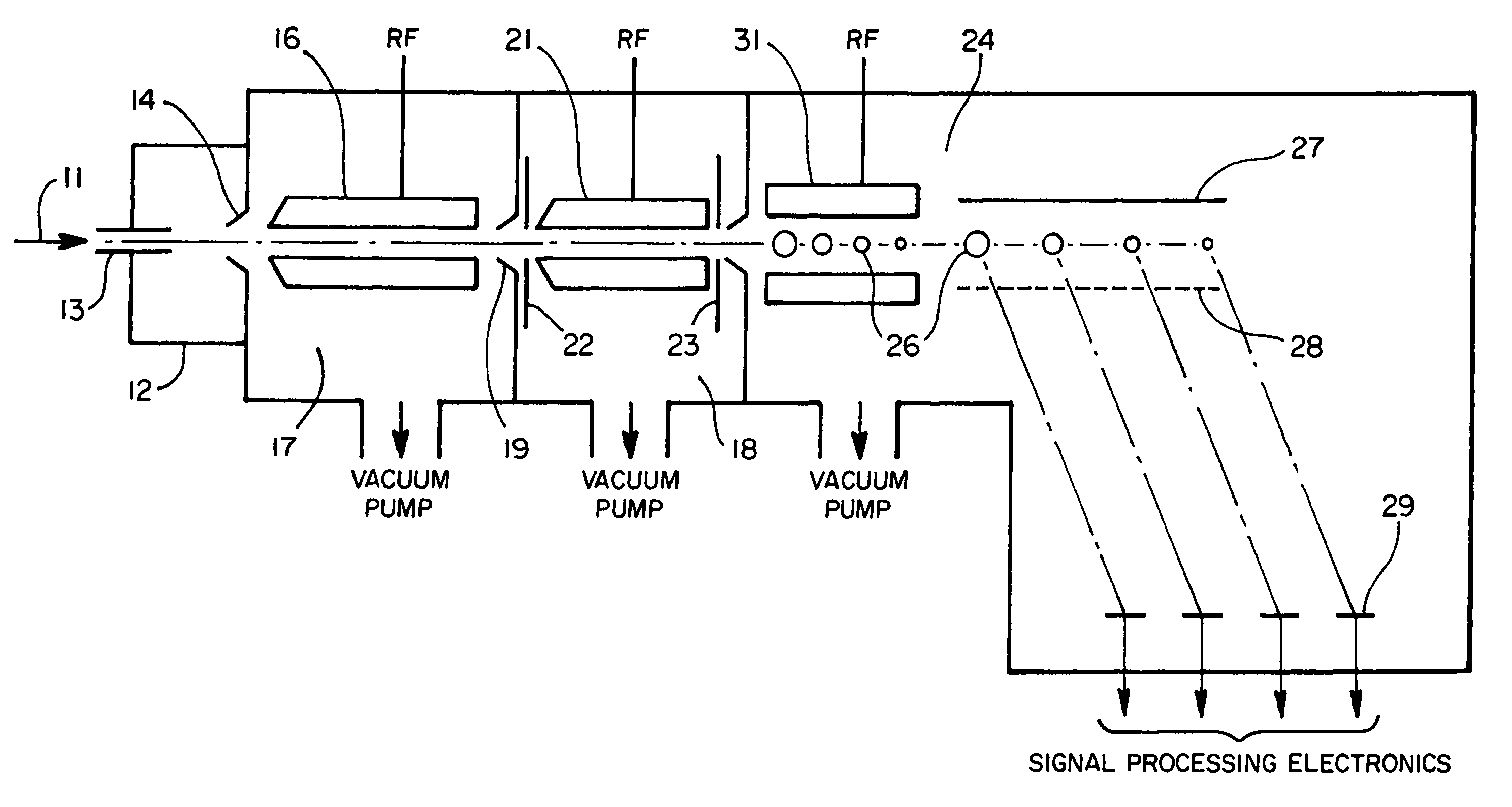

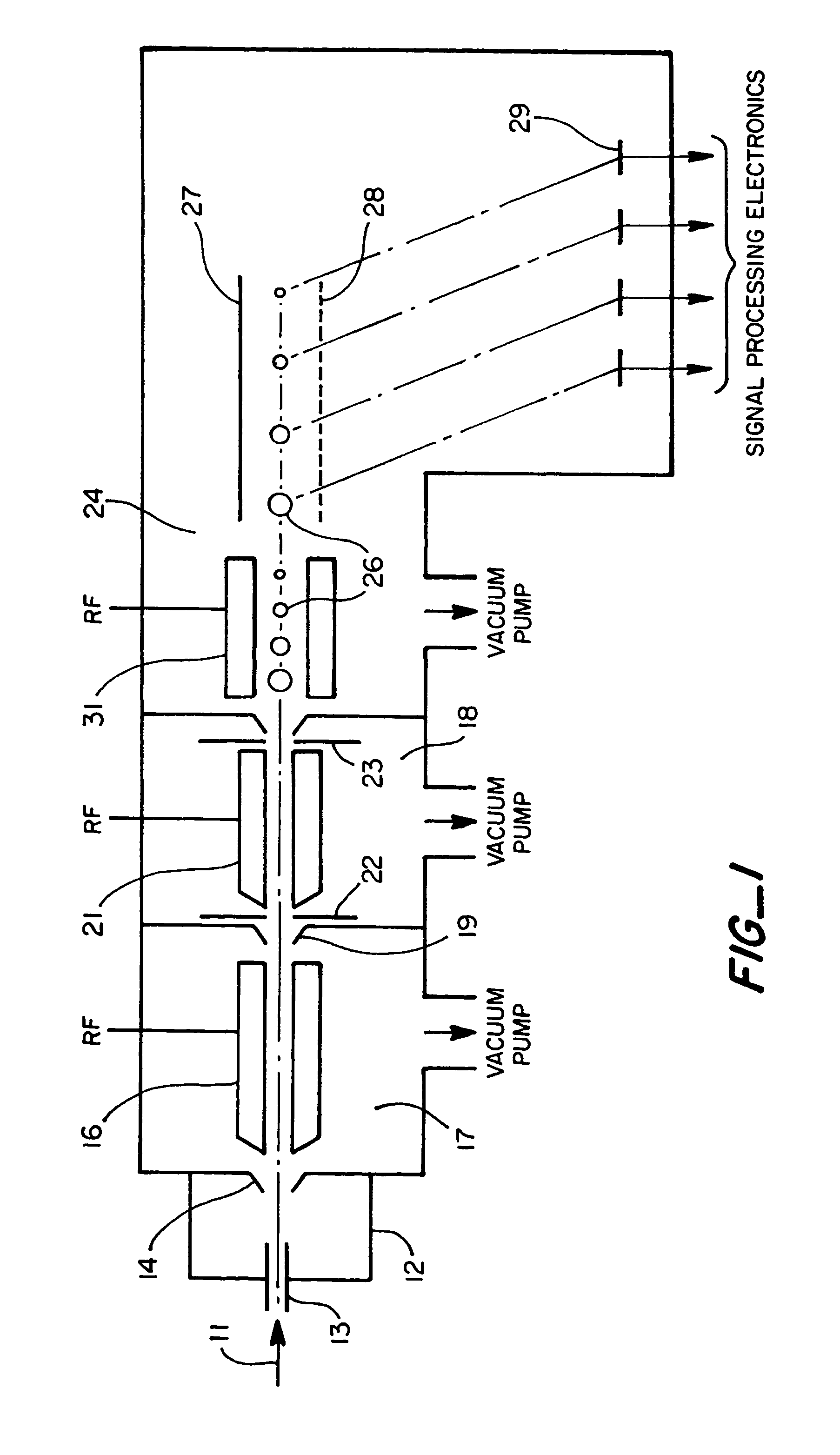

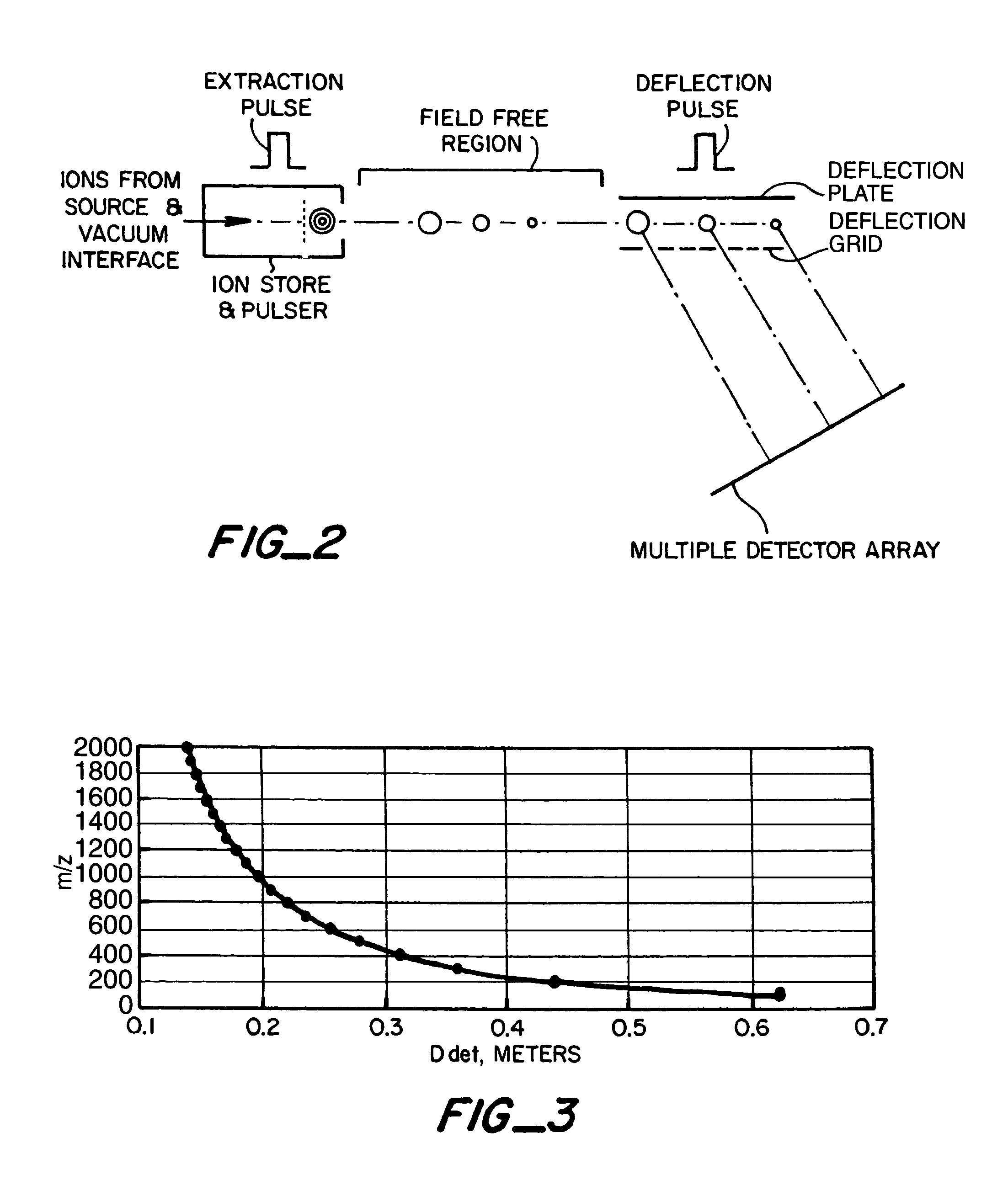

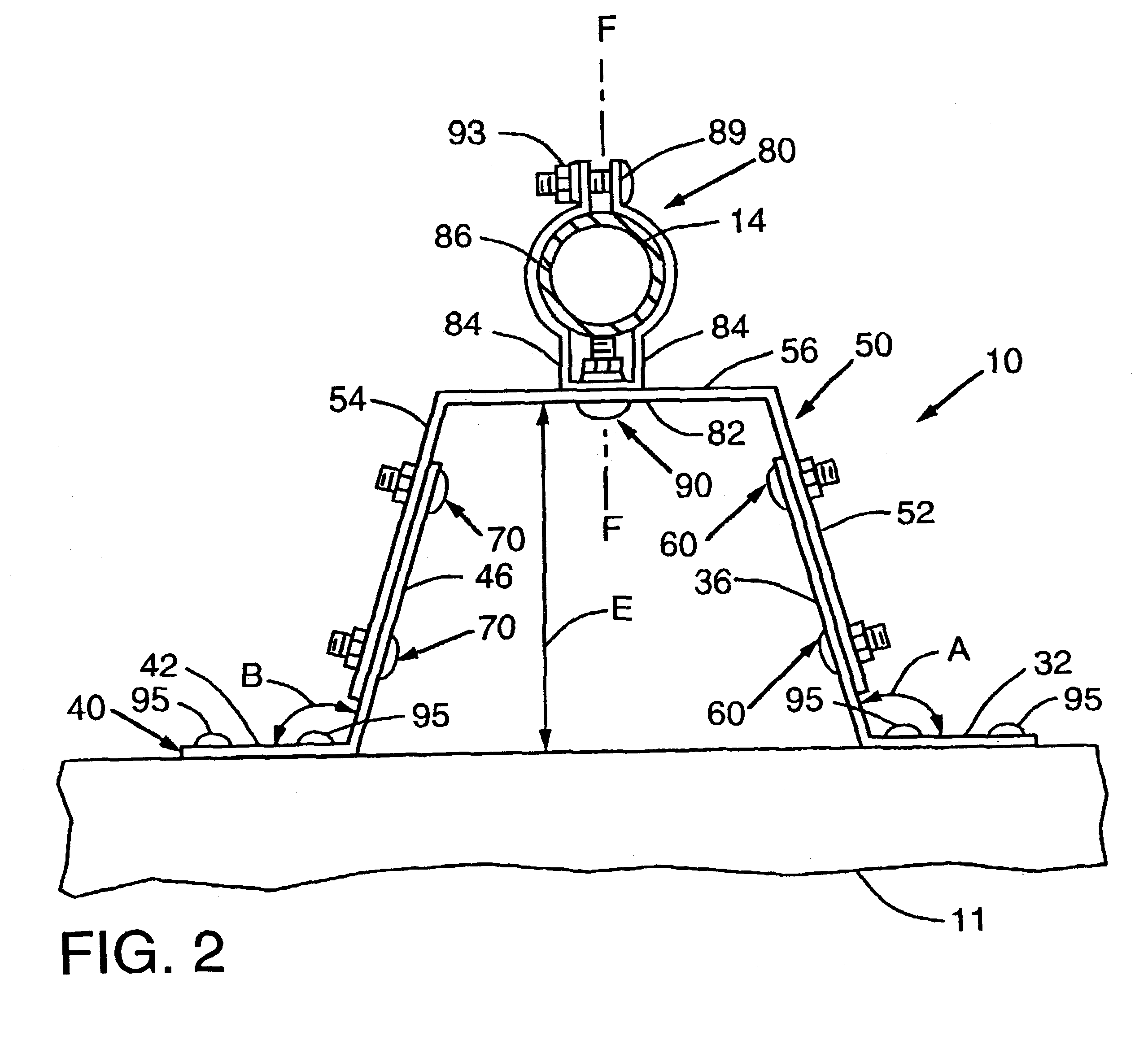

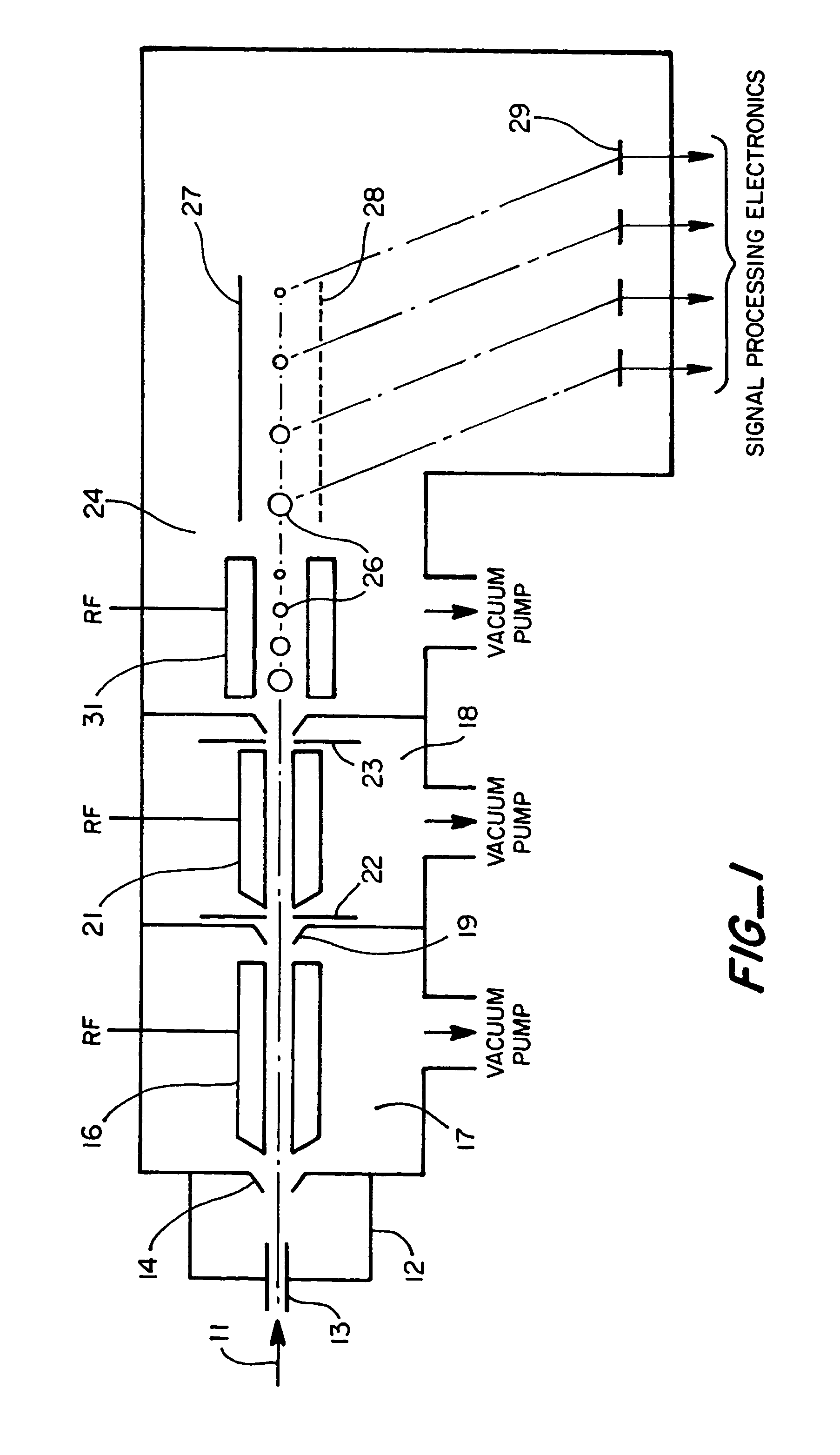

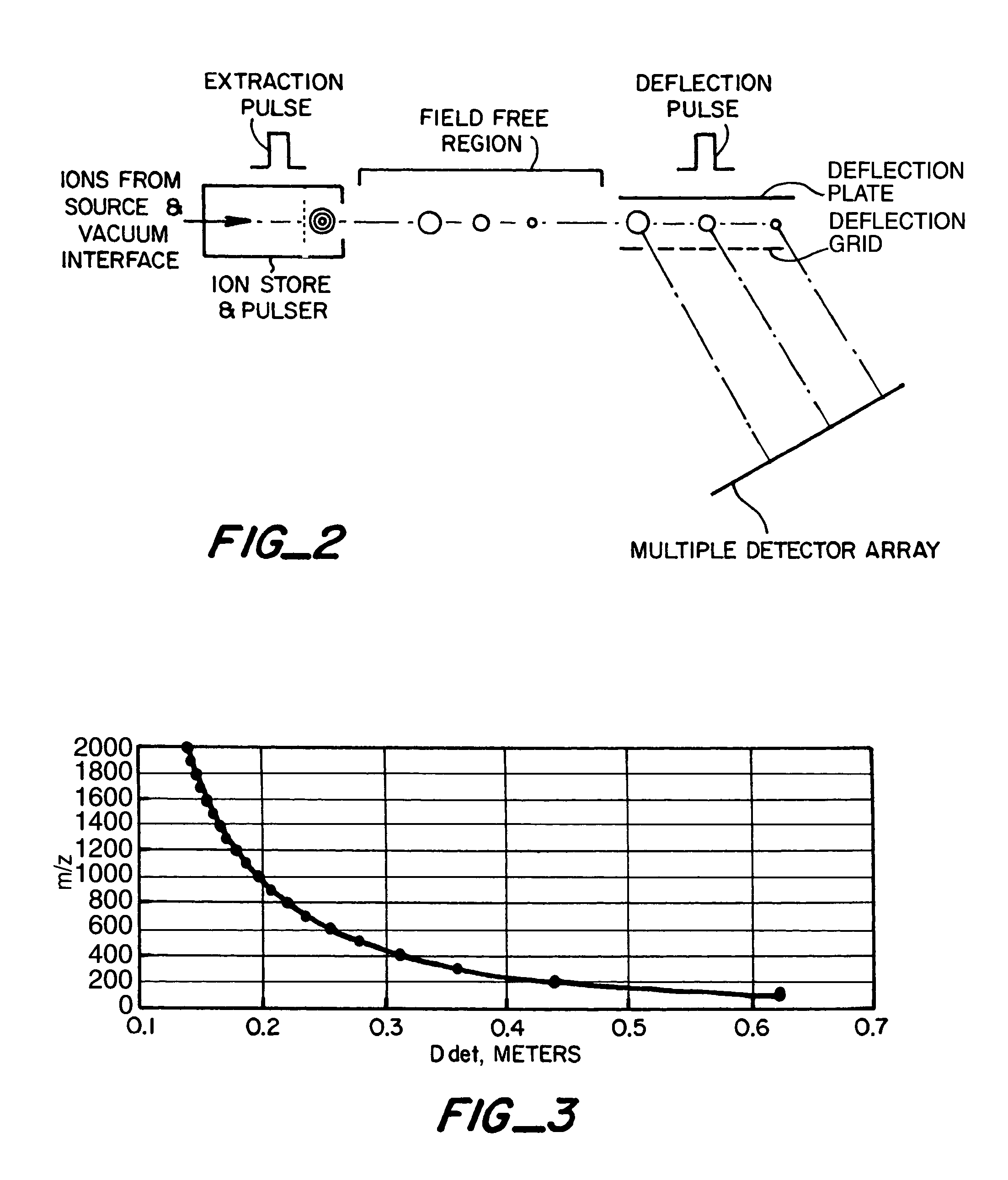

Distance of flight spectrometer for MS and simultaneous scanless MS/MS

ActiveUS20050040326A1Improve detection limitImprove precisionStability-of-path spectrometersTime-of-flight spectrometersTwo dimensional detectorImage resolution

A distance of flight (DOF) approach to mass spectroscopy in which the resolution among the various ion masses is accomplished in space rather than time. A separate detector is associated with each ion mass resolution element. The DOF mass spectrometer can serve as one element in a tandem arrangement which has the capability to produce a full two-dimensional precursor / product spectrum for each bunch of ions extracted from the source. A “distance-of-flight” (DOF) mass analyzer is used in combination with time-of-flight (TOF) mass analysis for precursor and product dispersion. All the precursor ions can undergo a mass changing reaction simultaneously, while still retaining the essential information about the particular precursor m / z value from which each product ion m / z value emanated. Through the use of a two-dimensional detector, all the products ions from all the precursors can be detected for each batch of ions analyzed.

Owner:NEW MEXICO UNIV OF

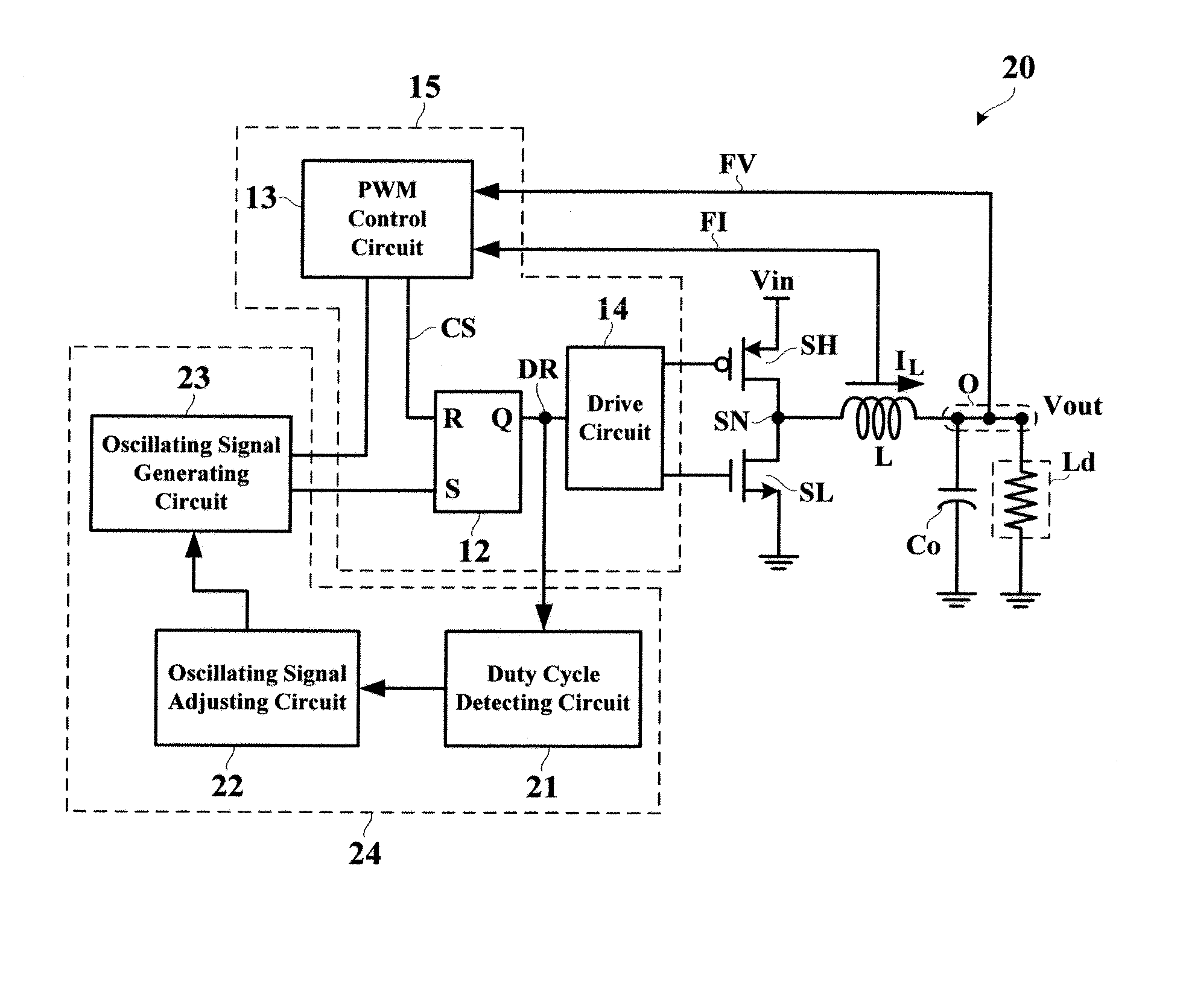

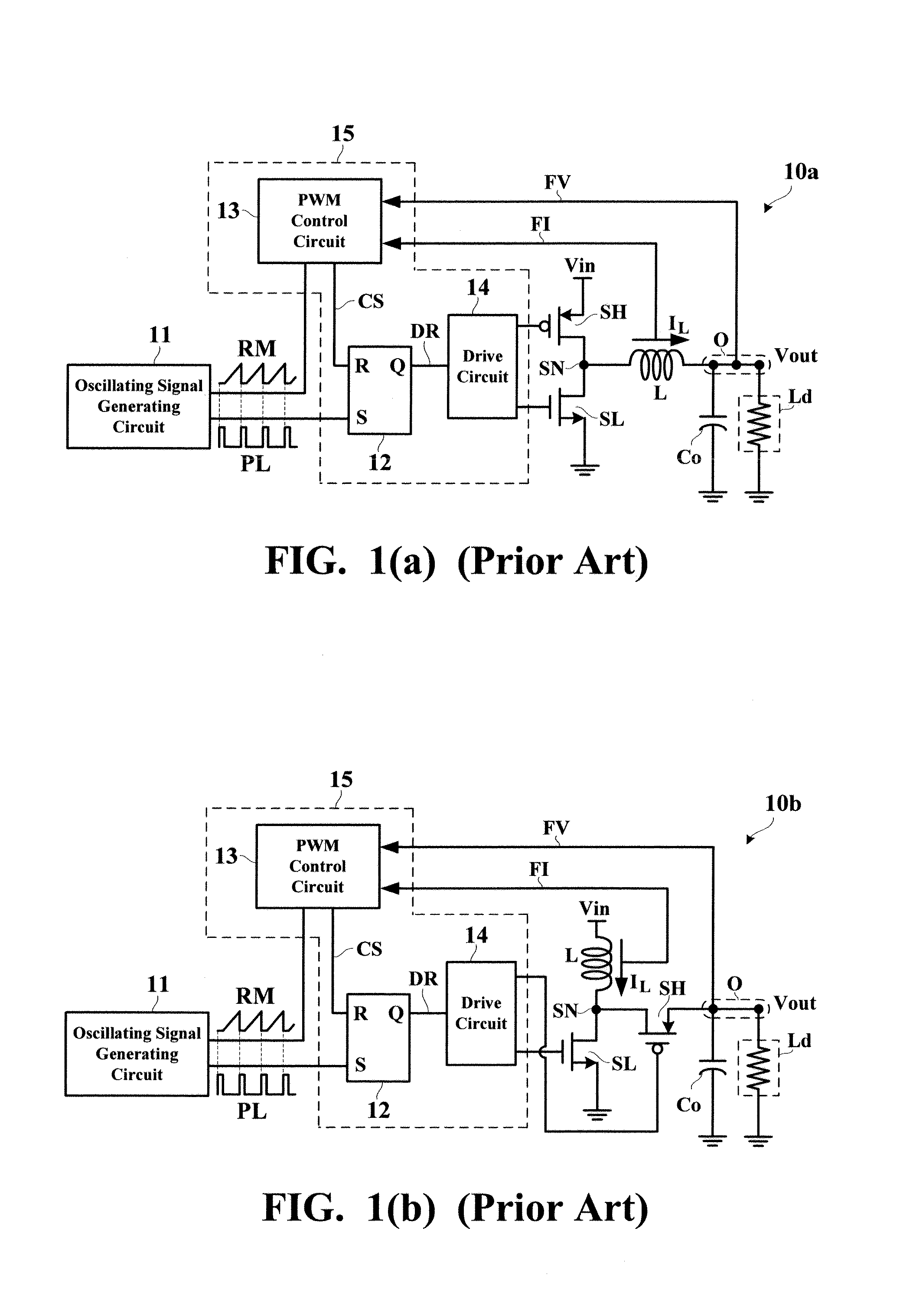

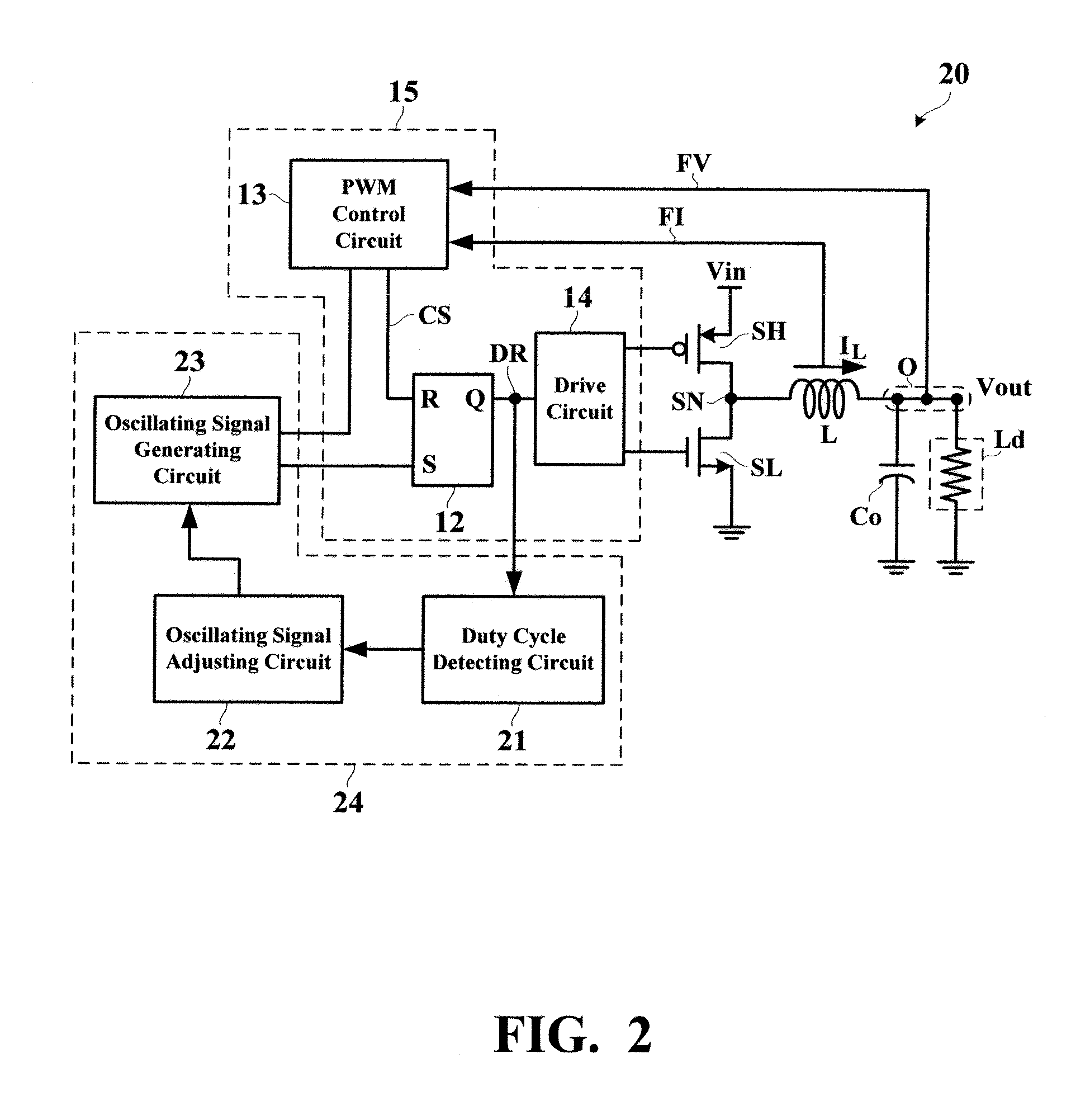

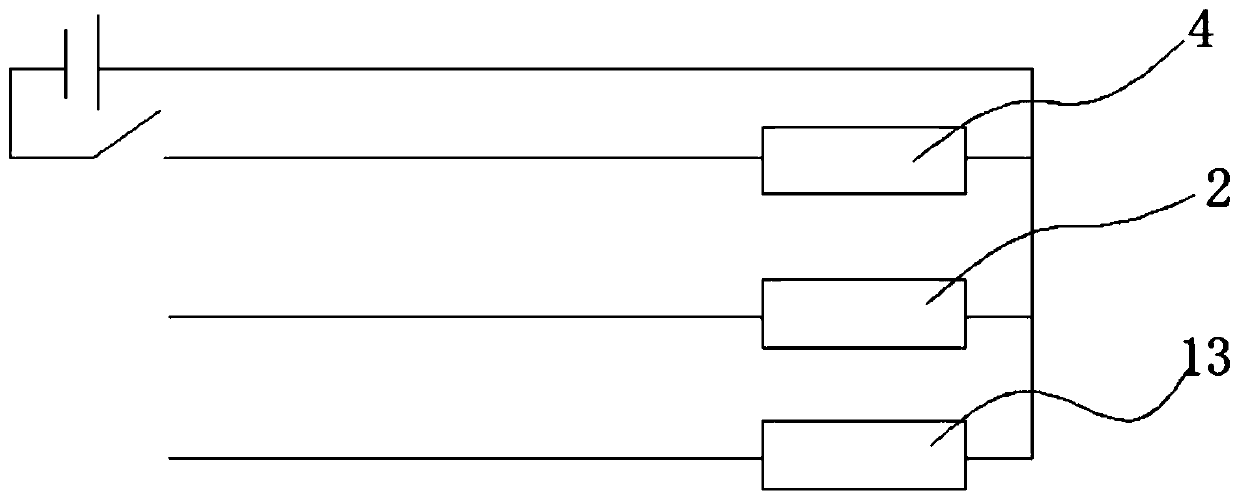

Switching voltage regulator with an improved range of input voltage

ActiveUS20070257643A1Improve rangeExtended input voltage rangeDc-dc conversionElectric variable regulationVoltage rangeInductor

A switching voltage regulator has a first switch, a second switch, and an inductor, which are coupled together to a switch node. A switch control system applies a drive signal for controlling the first and the second switches. A duty cycle detecting circuit detects a duty cycle of the drive signal. When the duty cycle is larger than a predetermined threshold, the duty cycle detecting circuit generates an over-threshold signal. When the duty cycle is smaller than the predetermined threshold, the duty cycle detecting circuit generates an under-threshold signal. In response to the over-threshold signal and the under-threshold signal, an oscillating signal adjusting circuit generates an adjusting current. An oscillating signal generating circuit generates and applies an oscillating signal to the switch control system. The oscillating signal has a period adjusted by the adjusting current.

Owner:GLOBAL MIXED MODE TECH

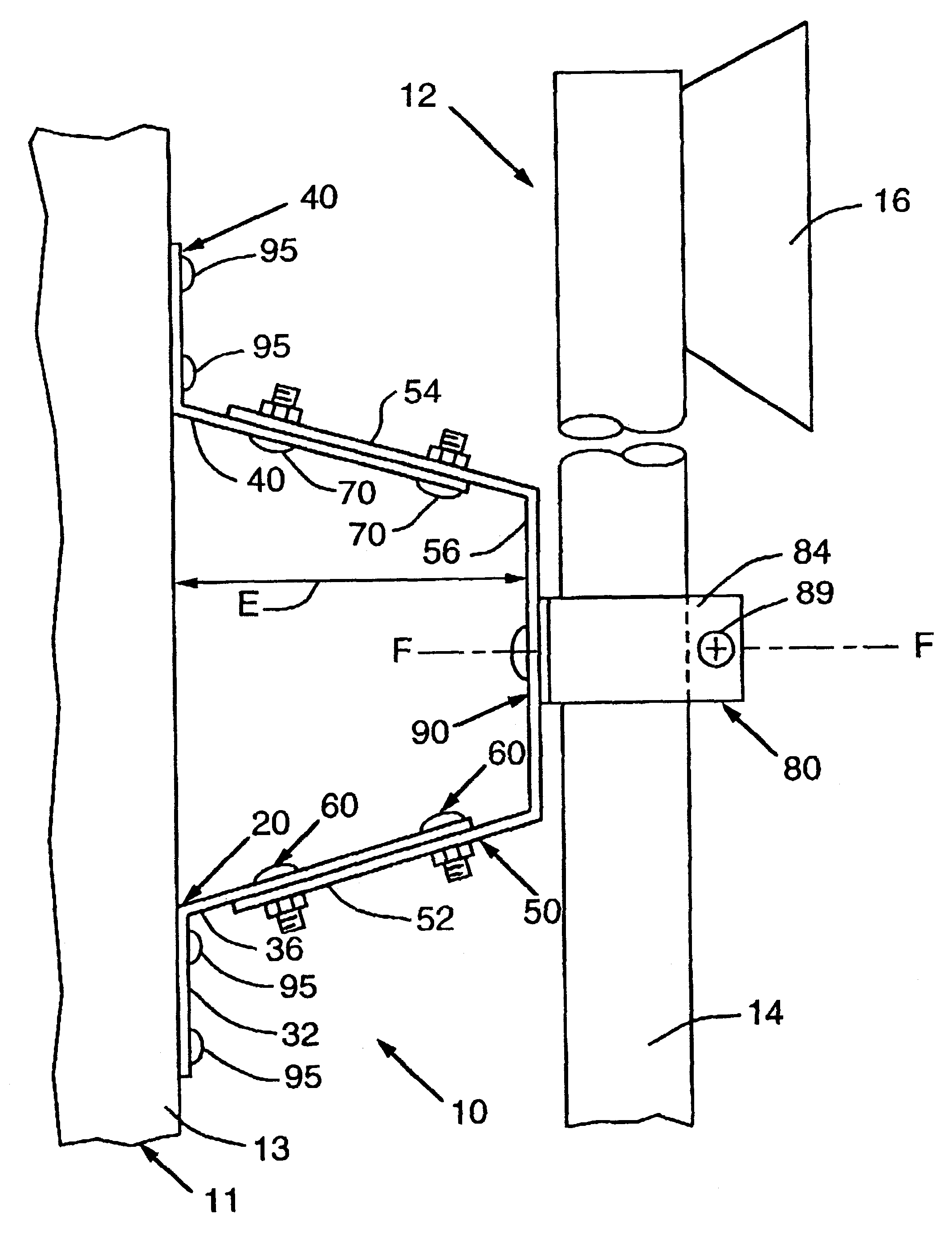

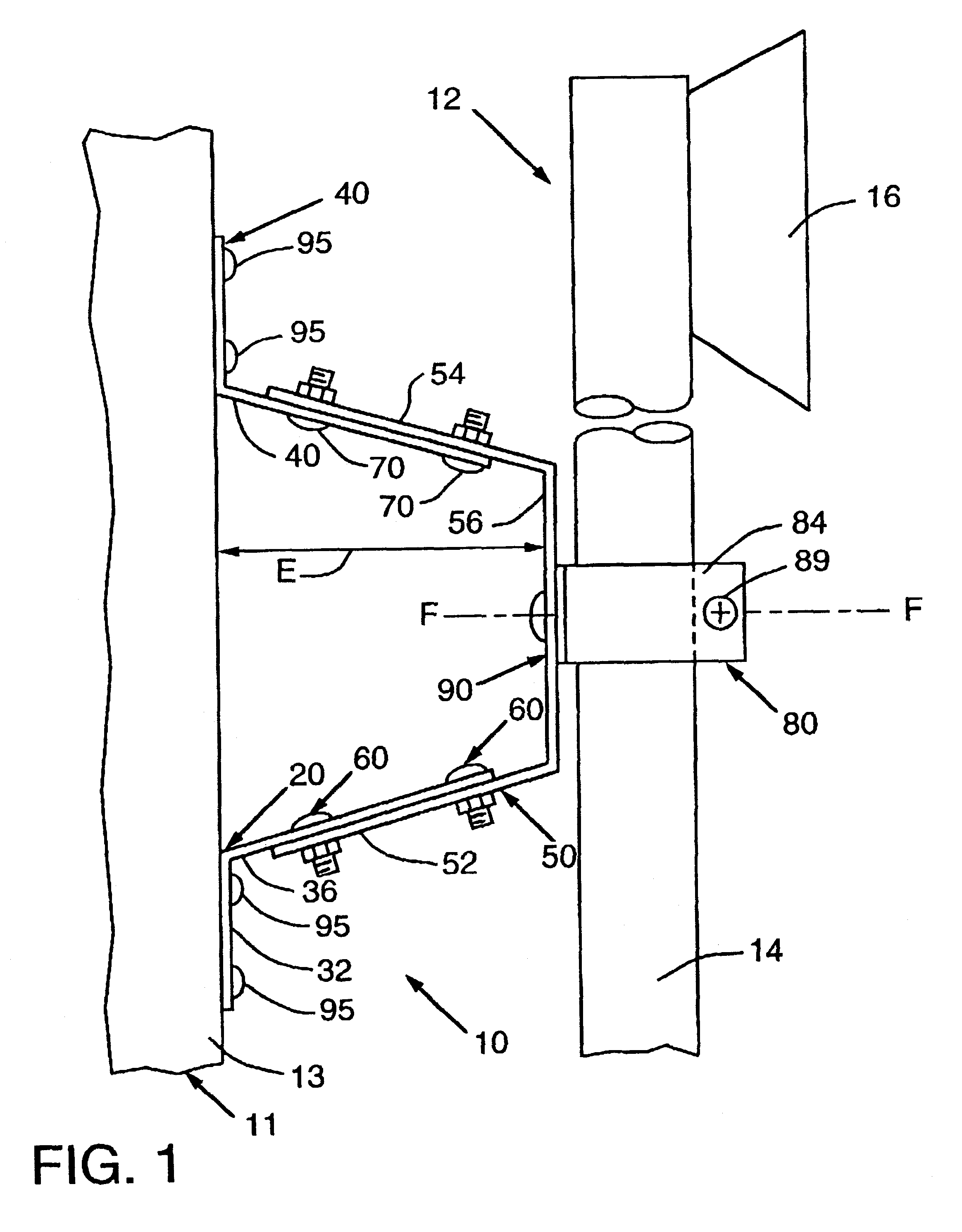

Adjustable antenna mounting apparatus

InactiveUS6480172B1Improve rangeIncrease rangeAntenna supports/mountingsElongated active element feedEngineering

Owner:BELLSOUTH INTPROP COR

Distance of flight spectrometer for MS and simultaneous scanless MS/MS

ActiveUS7041968B2Improve detection limitImprove precisionStability-of-path spectrometersTime-of-flight spectrometersTwo dimensional detectorImage resolution

Owner:NEW MEXICO UNIV OF

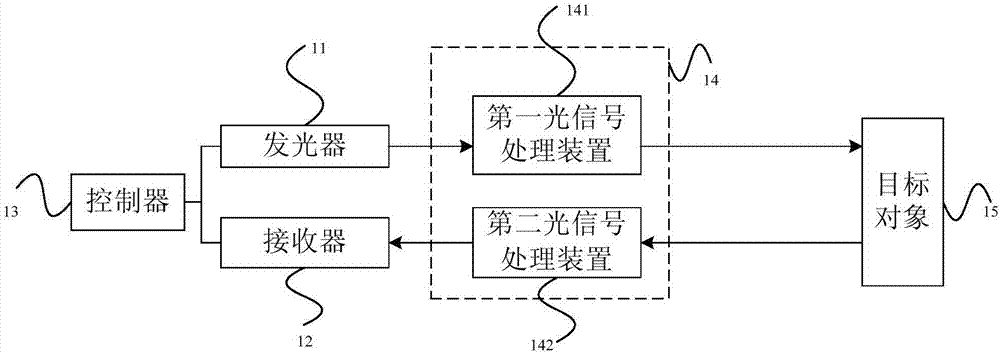

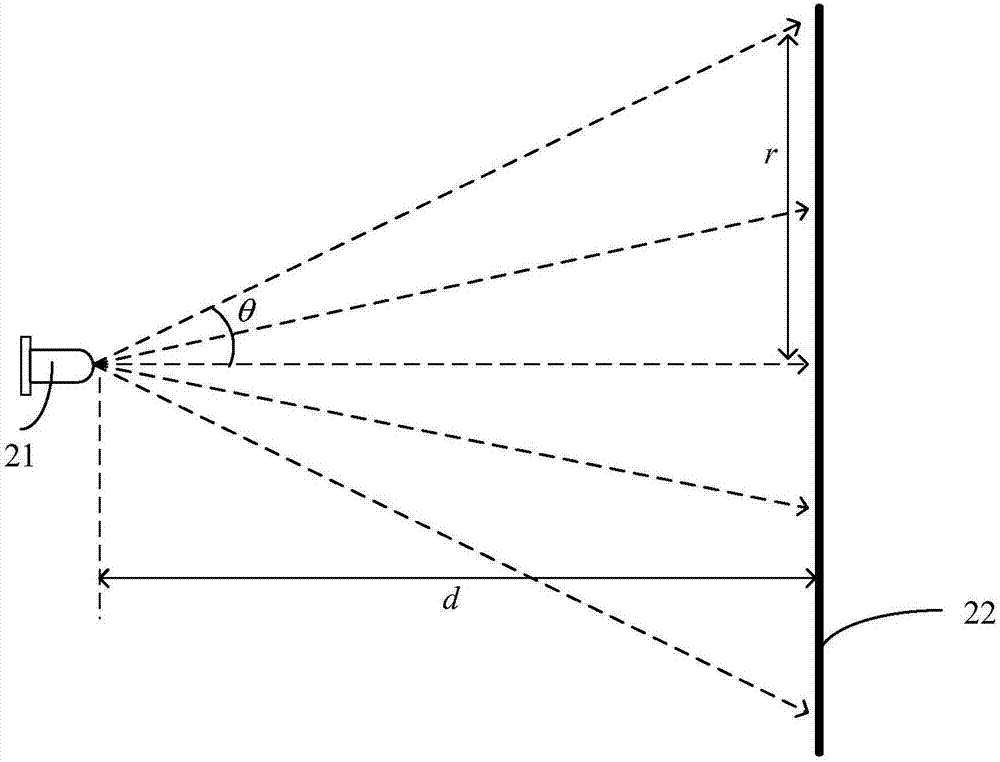

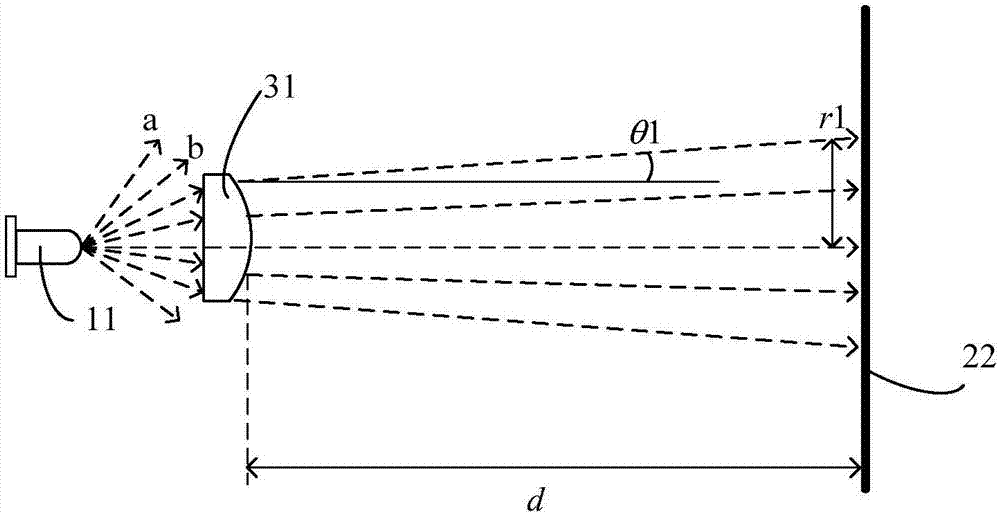

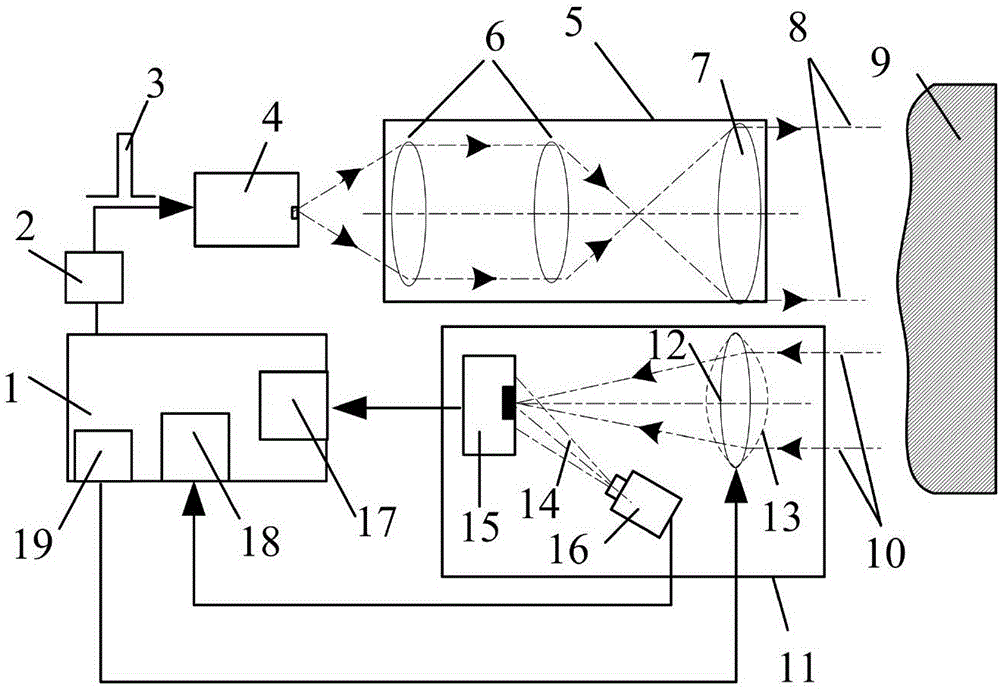

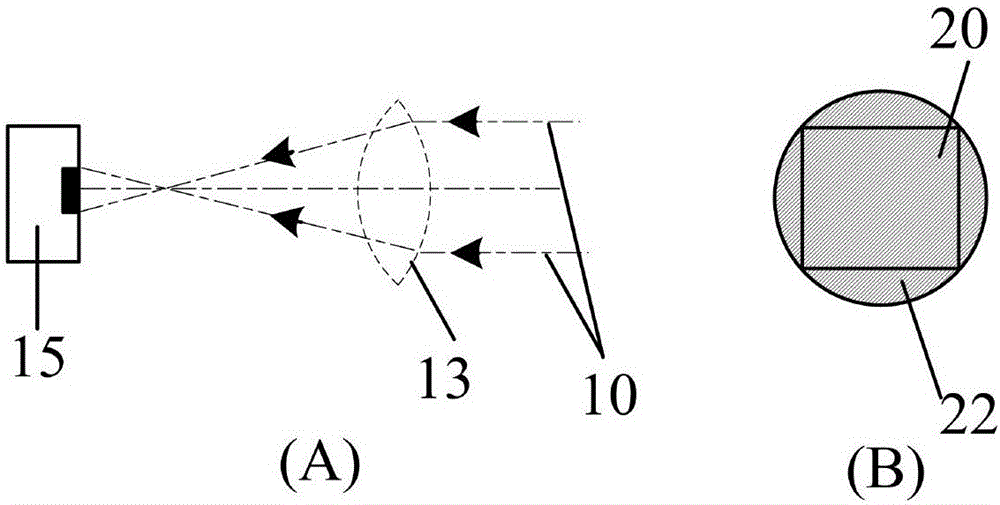

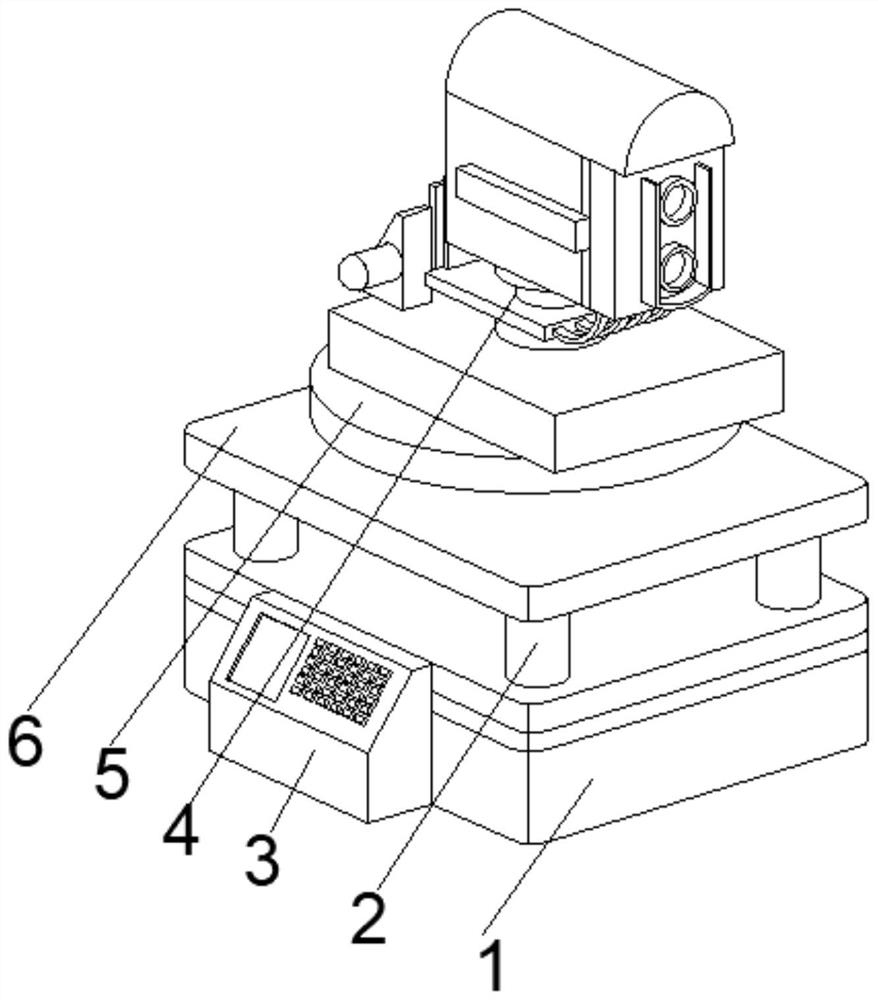

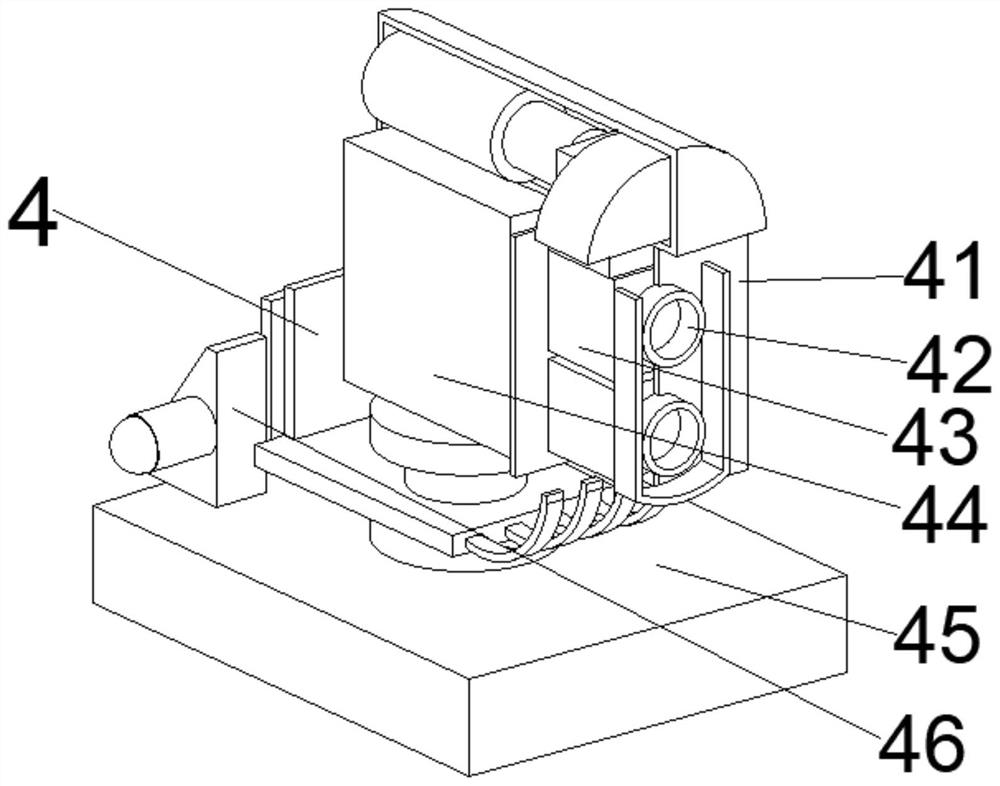

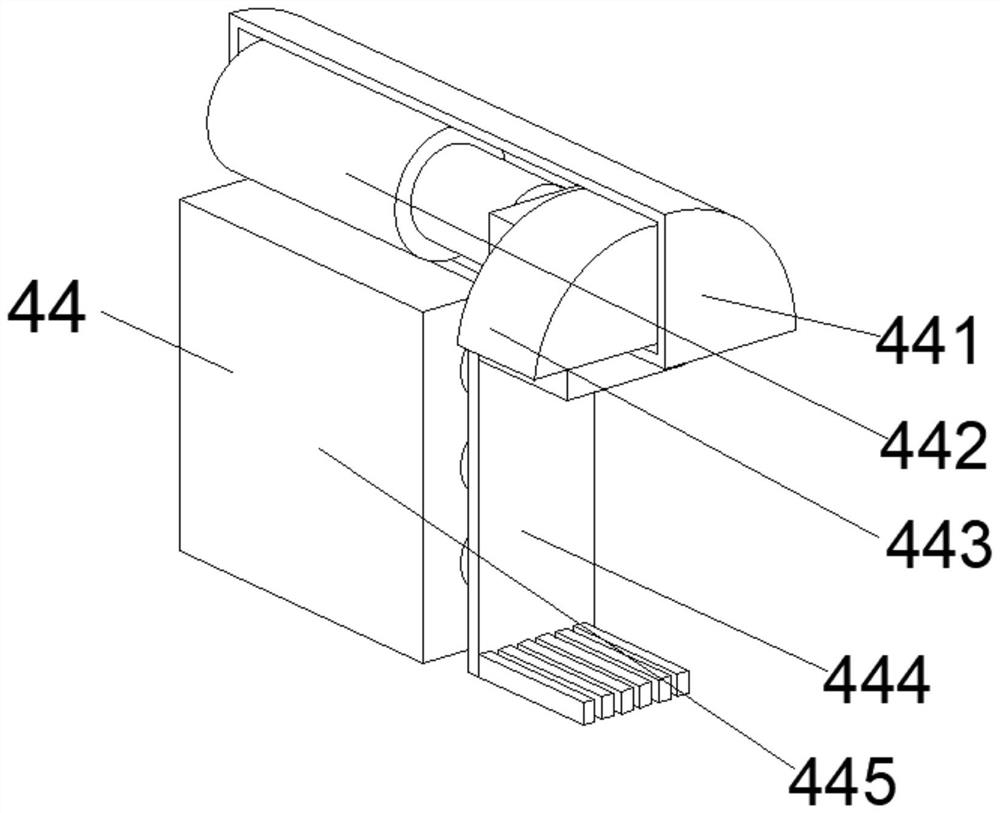

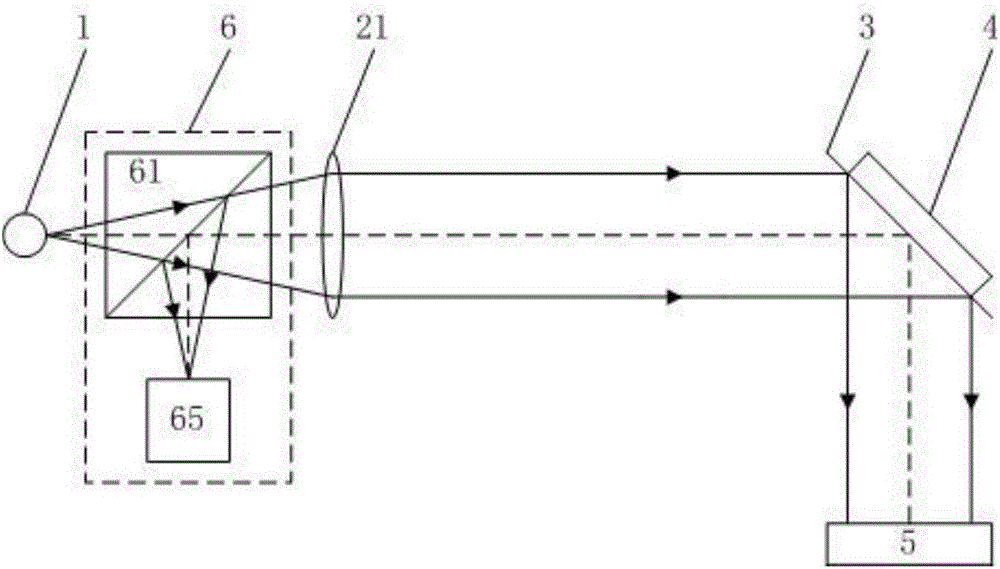

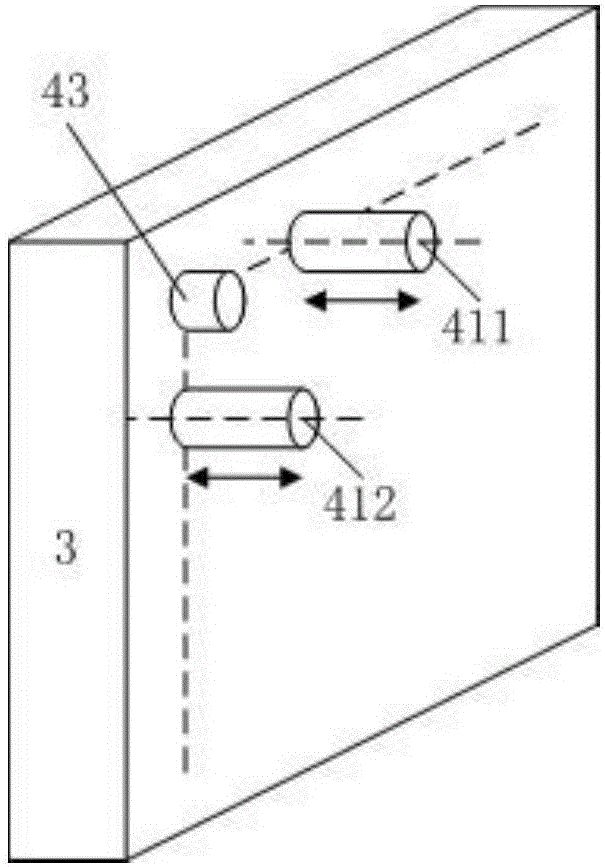

TOF distance measuring system and movable platform

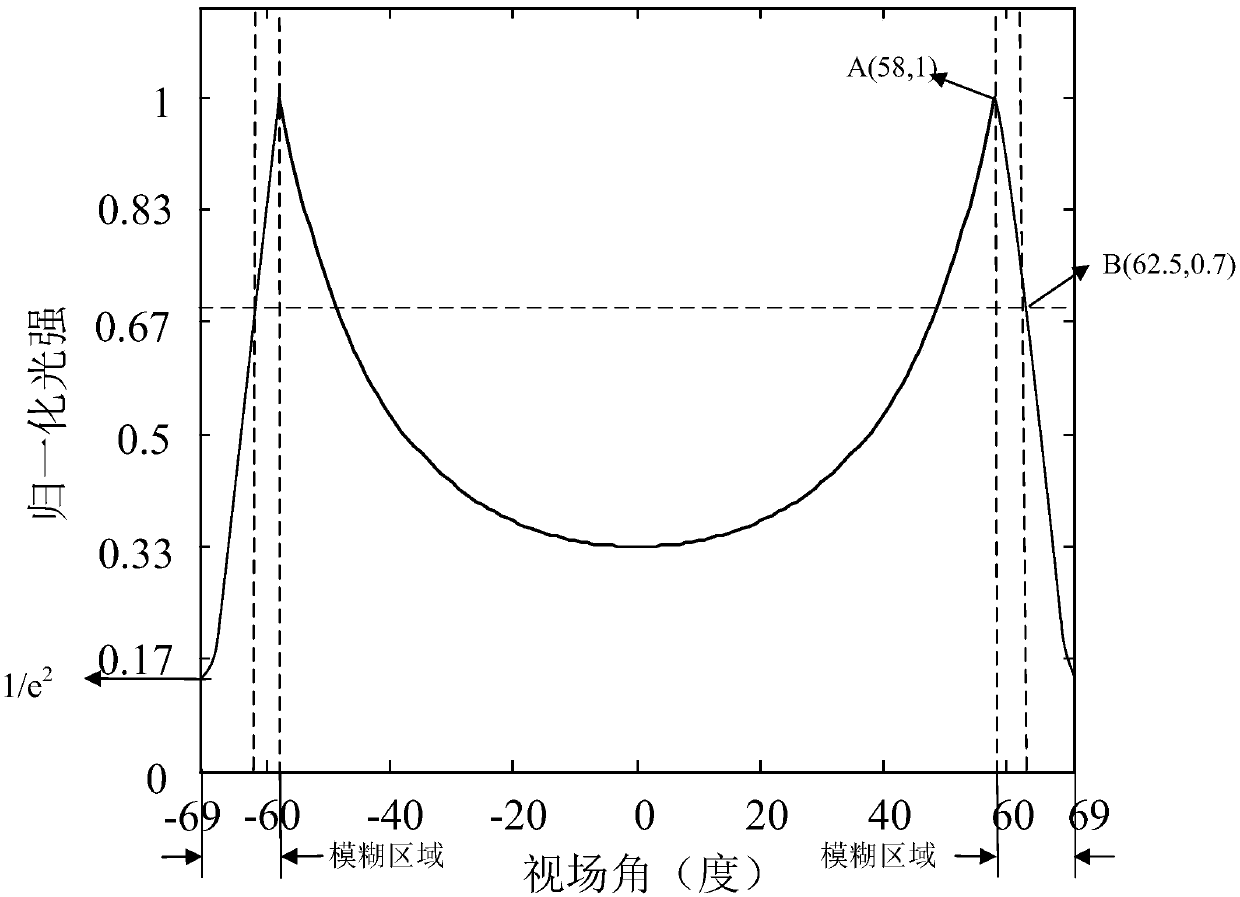

ActiveCN107076853AImprove signal-to-noise ratioImprove rangeElectromagnetic wave reradiationSignal-to-noise ratio (imaging)Signal processing

The invention provides a TOF distance measuring system and a movable platform. The TOF distance measuring system comprises a light emitter, a receiver, a controller, and an optical system. The optical system comprises at least one of a first optical signal processing device and a second optical signal processing device. Optical signals emitted by the light emitter are processed by the first optical signal processing device, and then the radiation power density of the optical signals emitted by the light emitter is improved. The optical signals reflected by a target object are processed by the second optical signal processing device, and the intensities of the optical signals reflected by the target object are improved. The radiation power density of the optical signals emitted by the light emitter is improved, and / or the intensities of the optical signals reflected by the target object received by the receiver are improved, and the signal to noise ratio of the TOF distance measuring system is improved, and the target object far away from the TOF distance measuring system is detected by the TOF distance measuring system, and therefore the distance measuring range of the TOF distance measuring system is improved.

Owner:SZ DJI TECH CO LTD

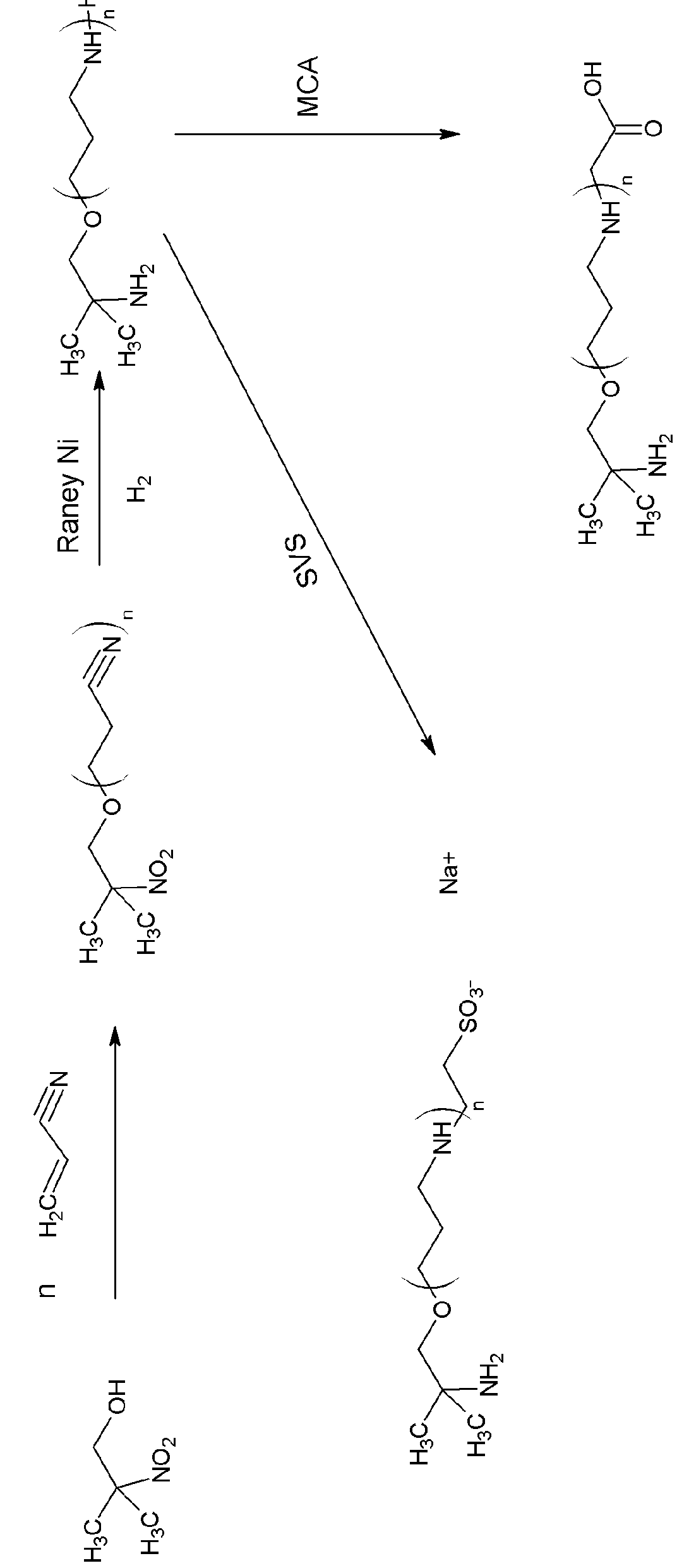

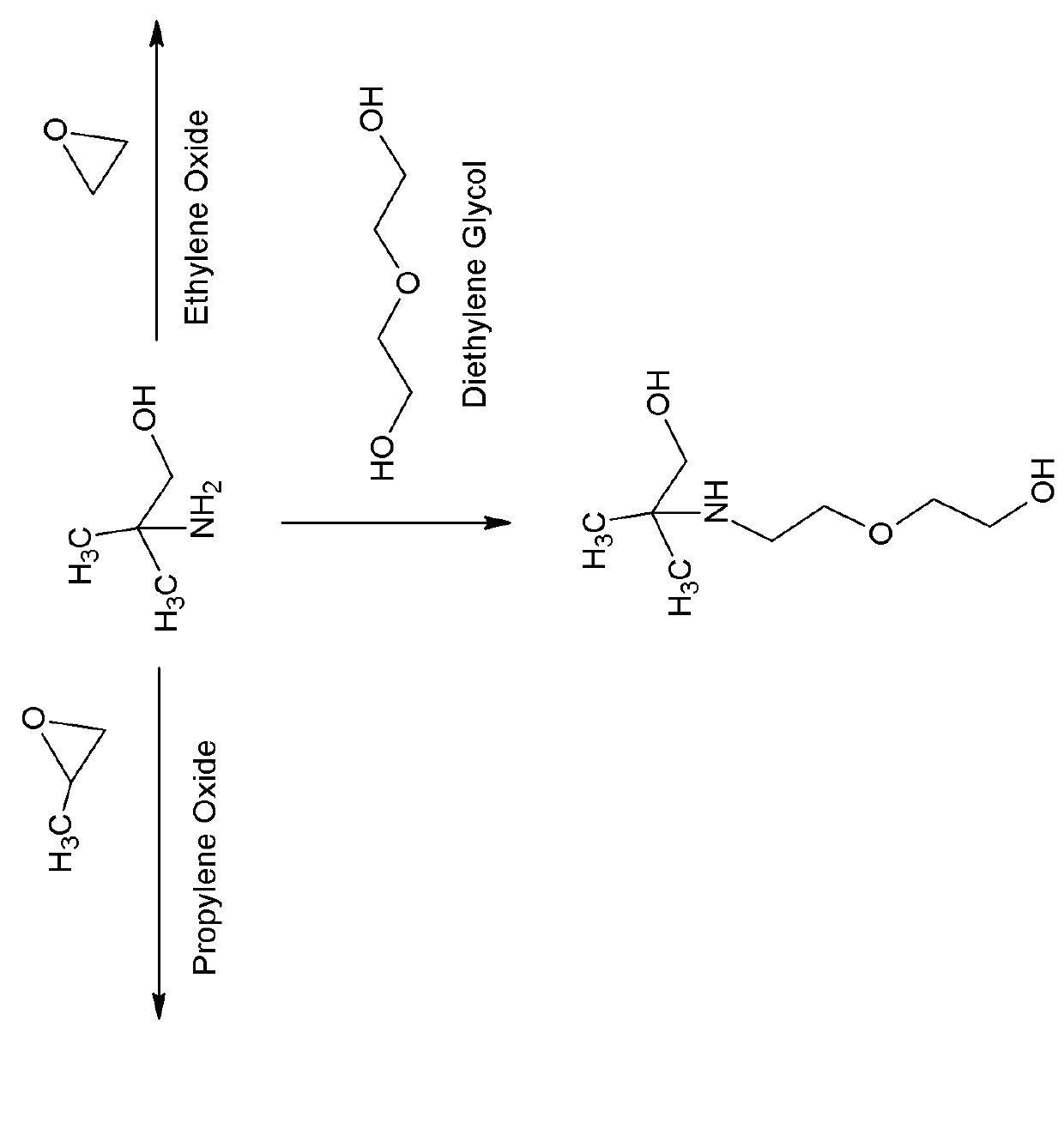

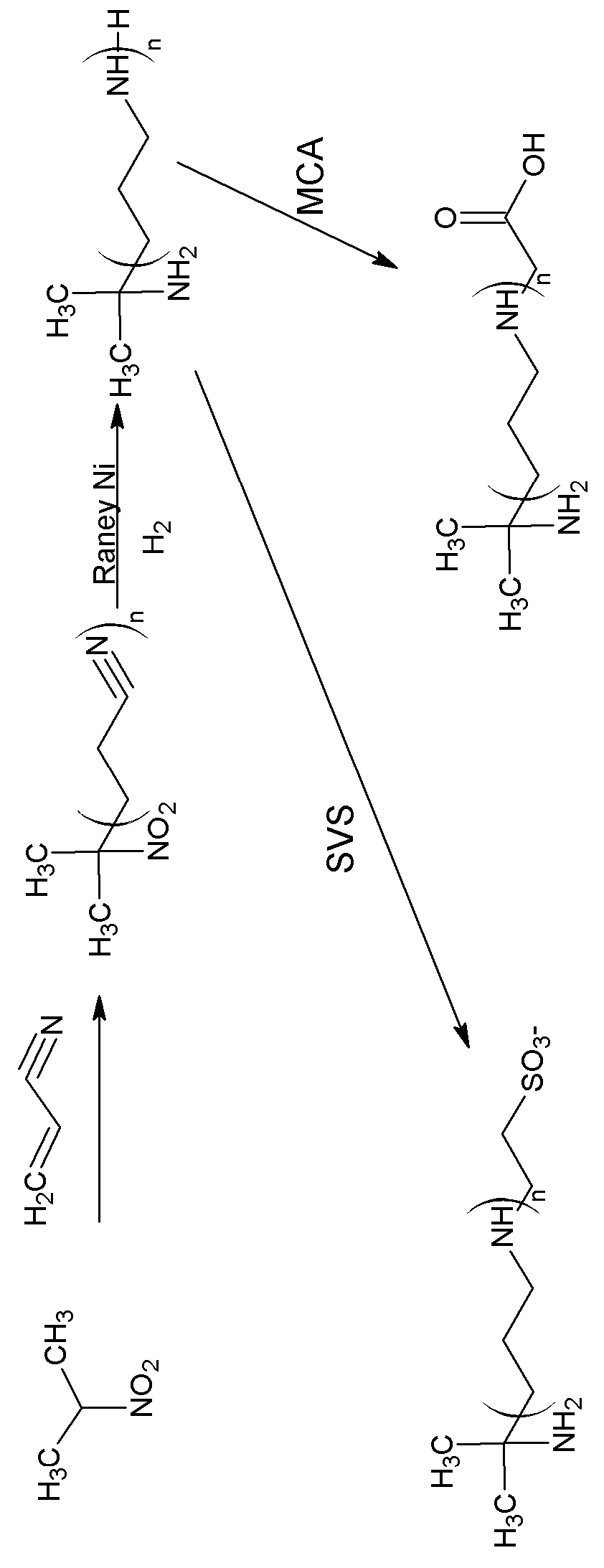

Biological buffers with wide buffering ranges

ActiveUS20160052868A1Improve rangeGreat buffering capacityNon-ionic surface-active compoundsOrganic compound preparationZwitterionChelation

Amines and amine derivatives that improve the buffering range, and / or reduce the chelation and other negative interactions of the buffer and the system to be buffered. The reaction of amines or polyamines with various molecules to form polyamines with differing pKa's will extend the buffering range, derivatives that result in polyamines that have the same pKa yields a greater buffering capacity. Derivatives that result in zwitterionic buffers improve yield by allowing a greater range of stability.

Owner:TPAT IP

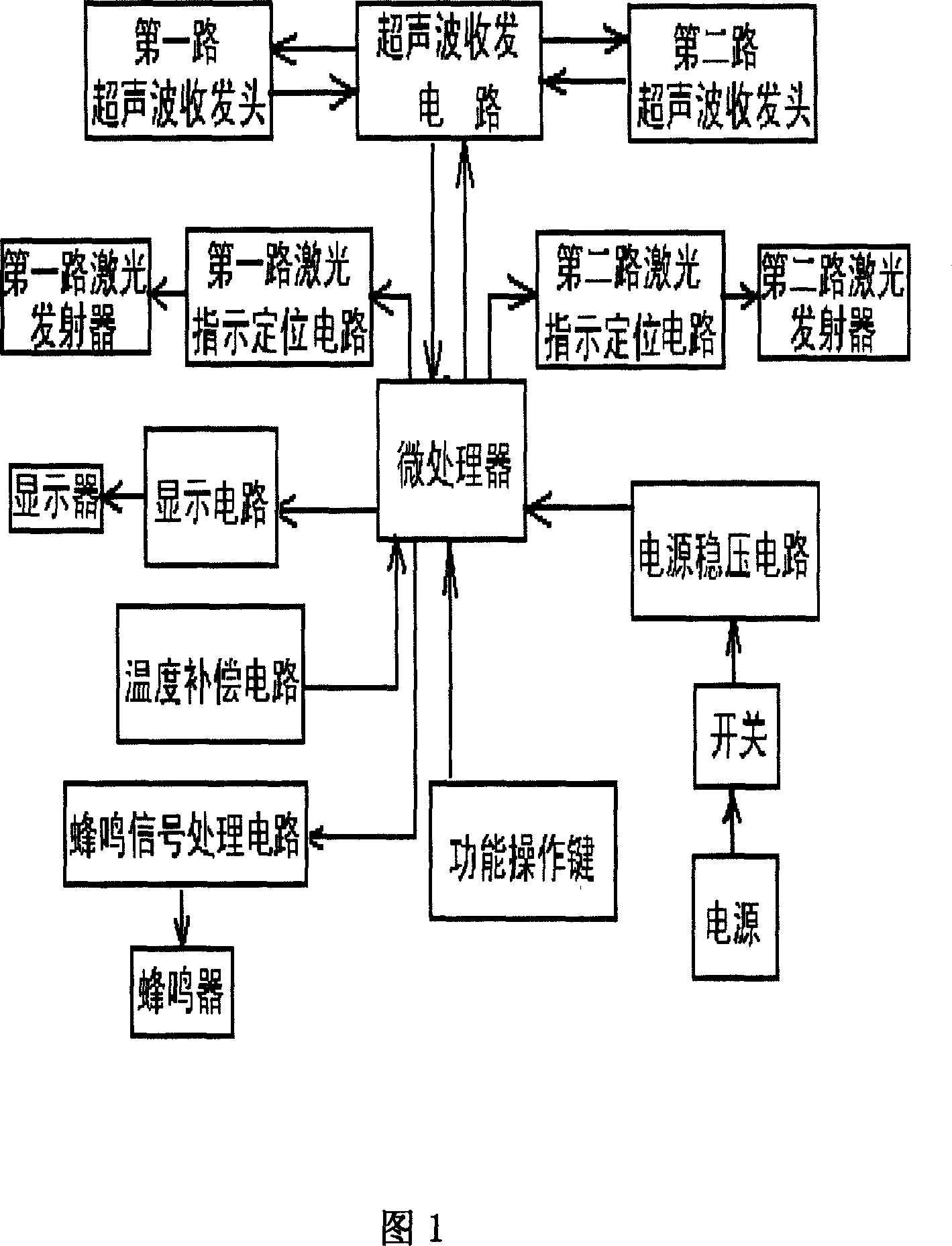

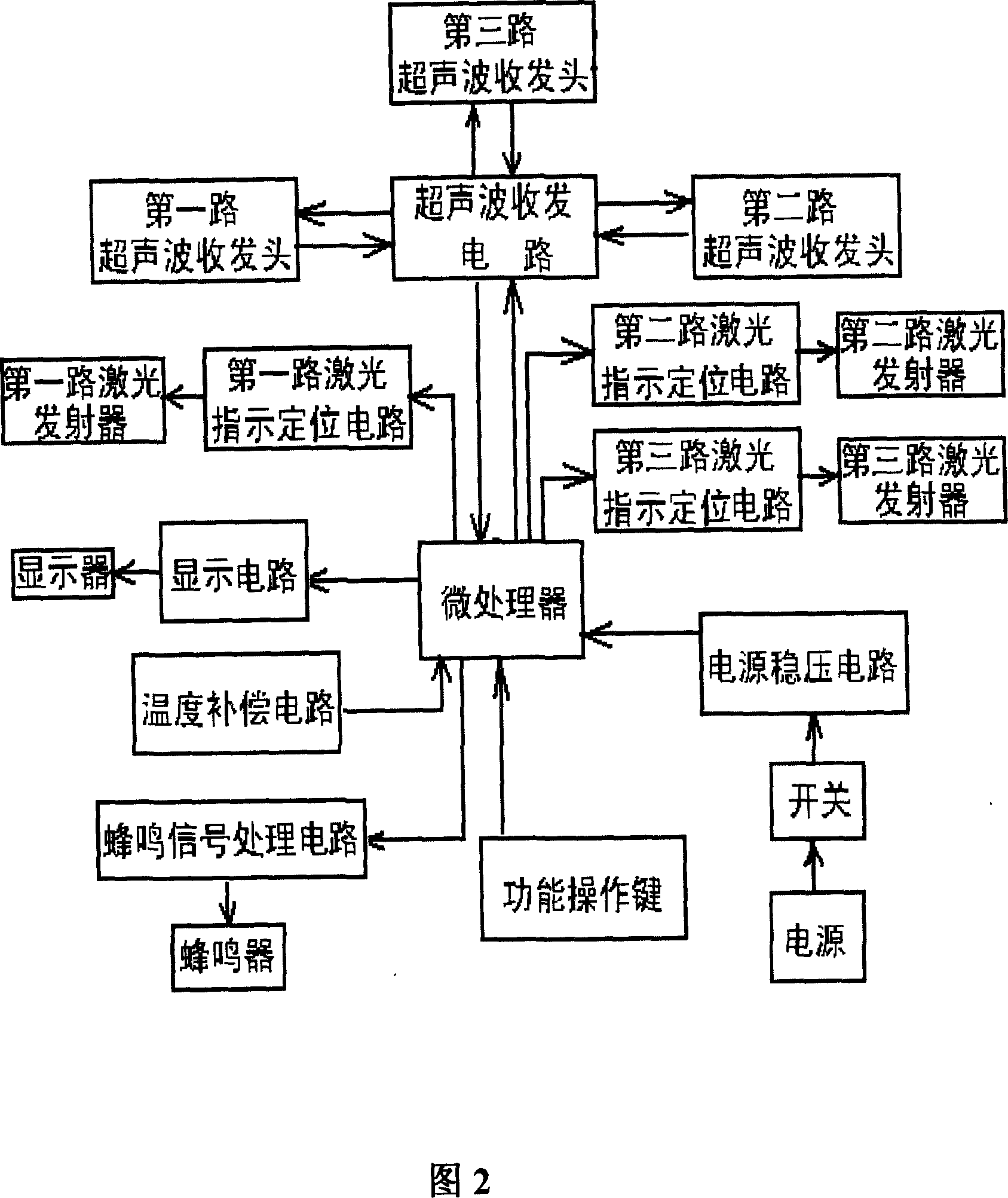

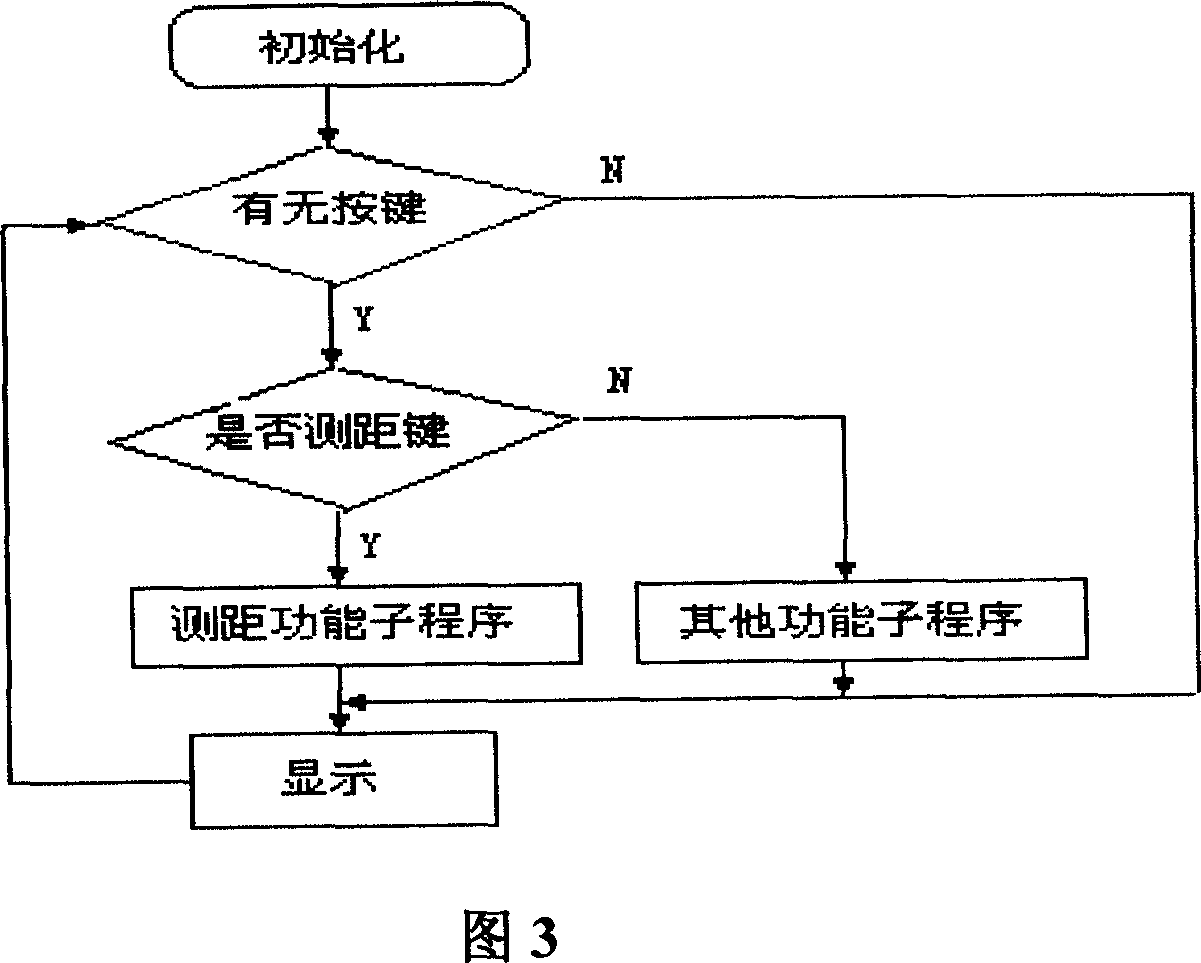

Method and apparatus for enlarging supersonic finding range

InactiveCN101029927AImprove rangeEasy to findPosition fixationAcoustic wave reradiationTransceiverEngineering

A method for increasing measurement distance of ultrasonic wave includes using two paths or above of ultrasonic waves to measure distance values of two or above directions through microprocessor and relevant channel and enabling to directly measure out distance sum of two and the same directions for making once measurement distance value be above 30m so as to increase measurement distance of ultrasonic wave under condition that performance of ultrasonic wave transceiver head is not changed.

Owner:YANCHENG KECHENG OPTOELECTRONICS TECH

Method and system for illuminating an indicator

InactiveUS20070253185A1Improve rangeGood lookingMeasurement apparatus componentsIlluminated signsEngineeringBright spot

A method and system are provided to illuminate an indicator, including indicators for electronic systems, appliances, and motor vehicle settings such as a visible temperature setting. Lighting efficiency is maximized, while light leaks, bright spots, shadows, internal reflections, color bleeds, and other undesirable visual effects are avoided. A lightbox having a cavity contains emitted light and transmits the light to an indicator. The indicator displays a system setting and an encoder varies the system setting. In an aspect, a light block and ramp are formed in the lightbox to uniformly dispense light to the indicator. A light dividing ridge formed in the lightbox separates the light dispensed to separate sections of the indicator. Further improvements include a tight fit formed between the indicator and a control knob, and a maximized indicator base area adjacent to the lightbox. The lightbox can also be integrated as part of a switchpad, reducing costs.

Owner:DELPHI TECH INC

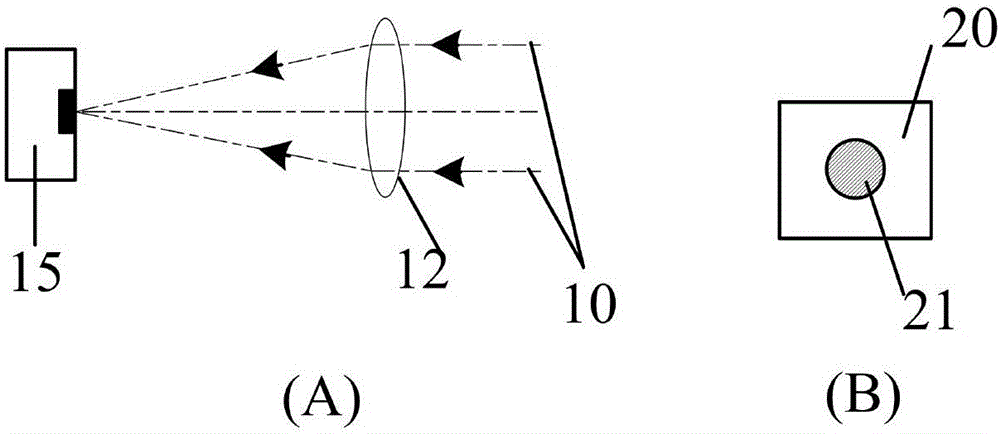

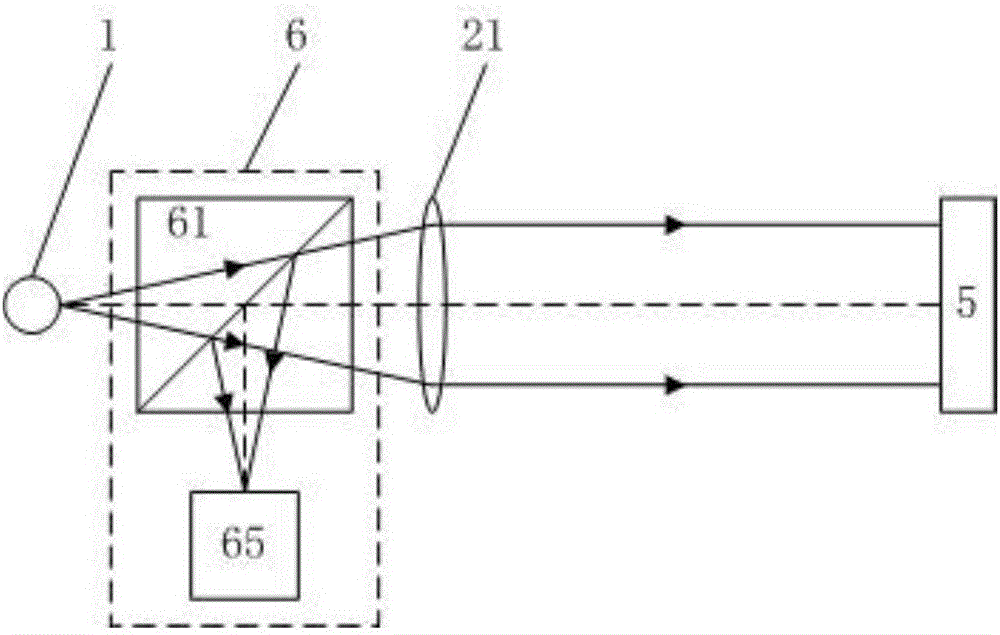

Self-adaptive closed loop adjustment laser range finding method and device

ActiveCN106646500AChange radius of curvatureChange focal lengthElectromagnetic wave reradiationLight spotClosed loop

The invention relates to a self-adaptive closed loop adjustment laser range finding method and device and belongs to the field of laser range finding. A liquid lens is used for replacing a common lens in a measurement system, liquid is used as a medium in the liquid lens, curvatures of two curved surfaces of the liquid lens can be changed via impressed voltage, a focal length of the liquid lens can be further changed, relative positions of light spots and a detector photosensitive surface are observed via use of an infrared camera, and therefore an aim of self-adaptive closed loop adjustment laser range finding can be attained; according to the self-adaptive closed loop adjustment laser range finding method and device, a self-adaptive closed loop can be used for controlling the liquid lens, curvature radiuses of the two curved surfaces of the liquid lens can be changed, the focal length of the liquid lens is therefore changed, and echo light spots are enabled to defocus; the method and device can help prevent problems of large energy design of the echo light spots, easy saturation of the detector and lowered precision during short quarter range finding operation. A range finding scope can therefore enlarged, and measurement precision can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

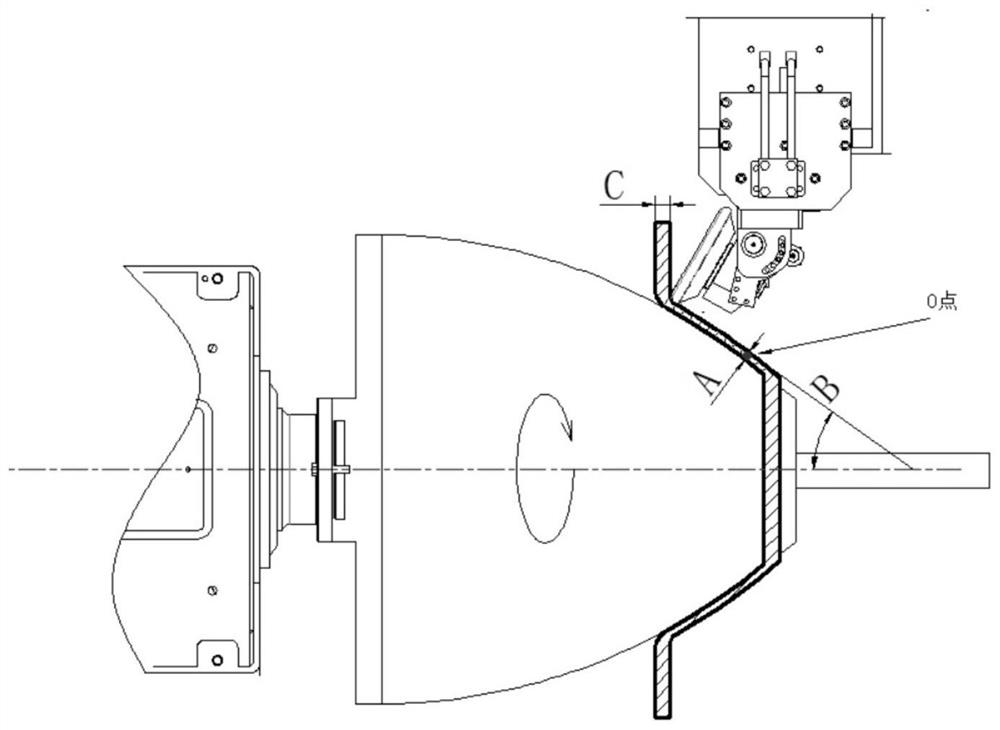

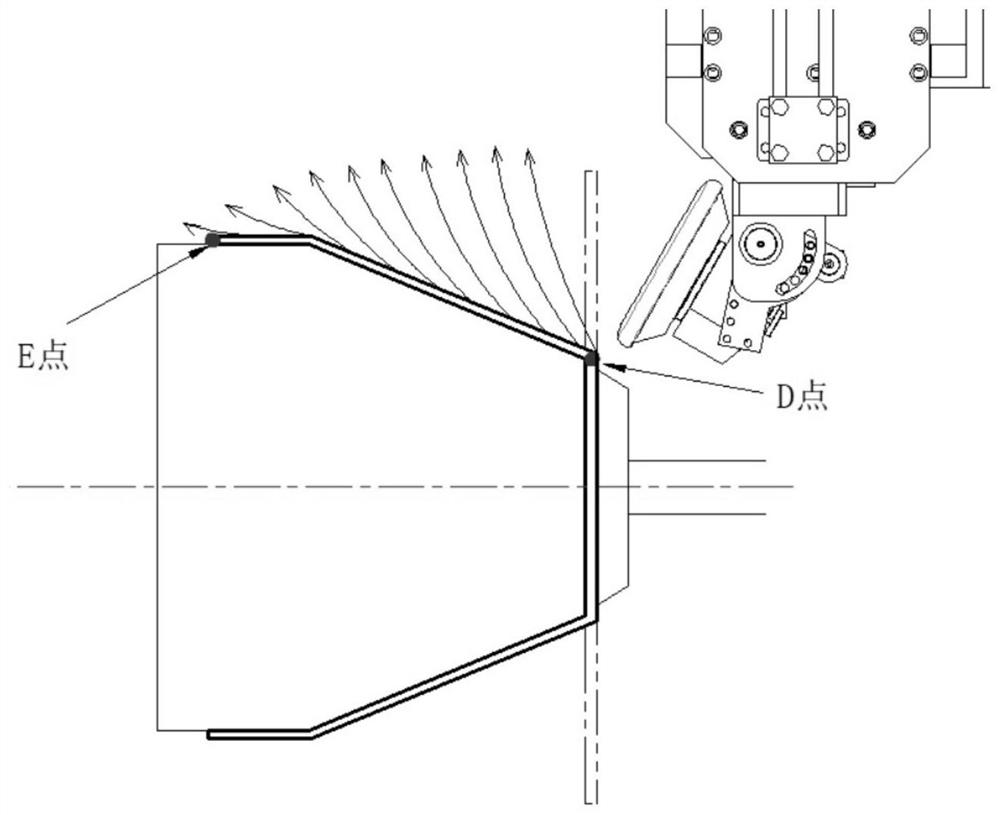

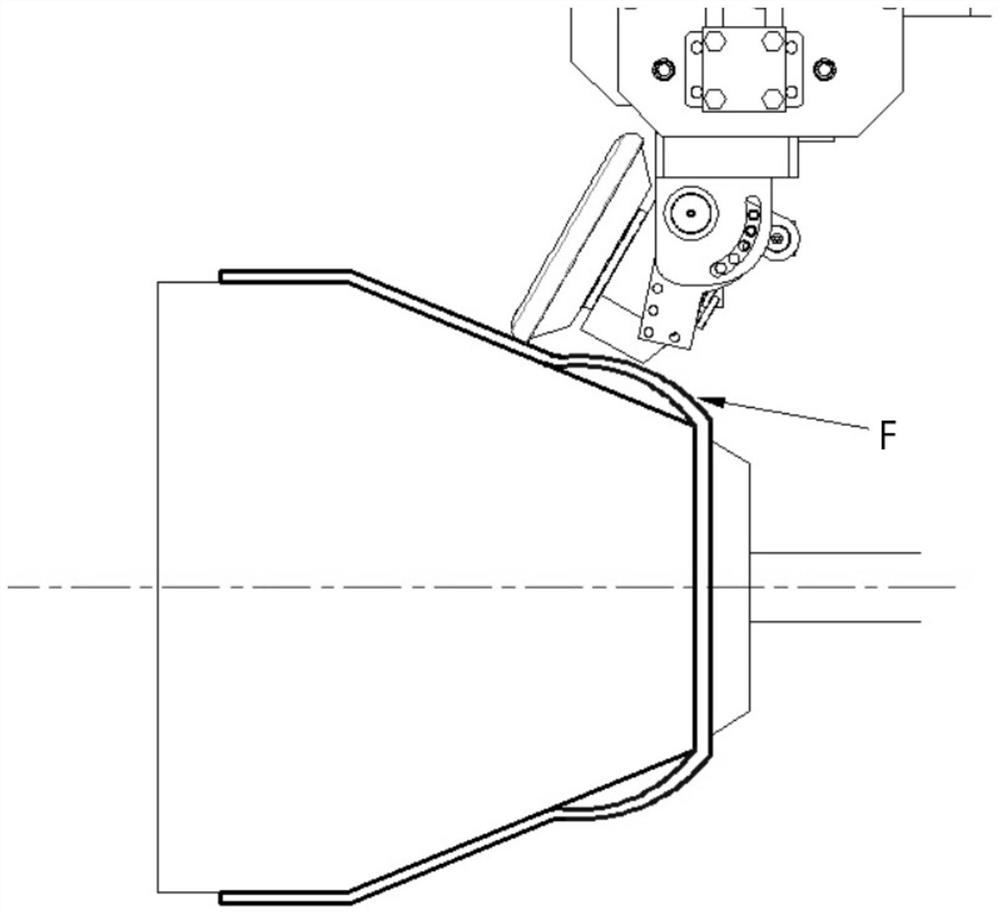

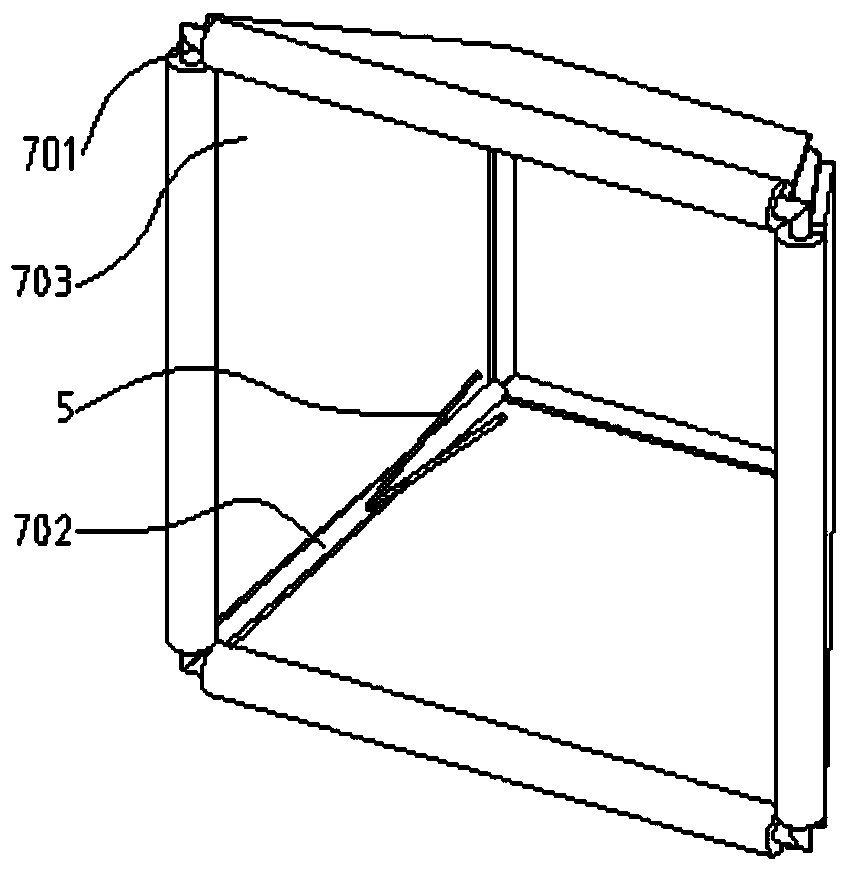

Method for overall seam welding of container

The invention discloses a method for overall seam welding of a container. The method specifically comprises the following steps that steel pretreatment and stamping are conducted, specifically, uncoiling is conducted on a steel coil, leveling on a flat plate is conducted, primary sanding and primary zinc painting are conducted, flat plate shearing and roller forming are conducted on a side plate,trimming deflashing and punching are conducted, flat plate shearing, bending forming, trimming deflashing and punching are conducted on a door plank and a front wallboard, plate rolling and strippingare conducted on a bottom cross beam and a bottom side beam, stripping is conducted before uncoiling is conducted, notch roller forming is conducted before sanding is conducted, other parts are subjected to flat plate shearing, cutting, notching and bending forming, a profile is subjected to profile sawing, primary sanding and primary zinc painting, and all parts are conveyed to corresponding table positions of a welding workshop after being stamped and manufactured. According to the method for overall seam welding of the container, the welding convenience of the container can be effectively improved and the using range of the container can be effectively enlarged; and the method changes a traditional container welding method to conduct welding, the welding strength of the container can beeffectively enhanced, and the container welding time is shortened.

Owner:王文化

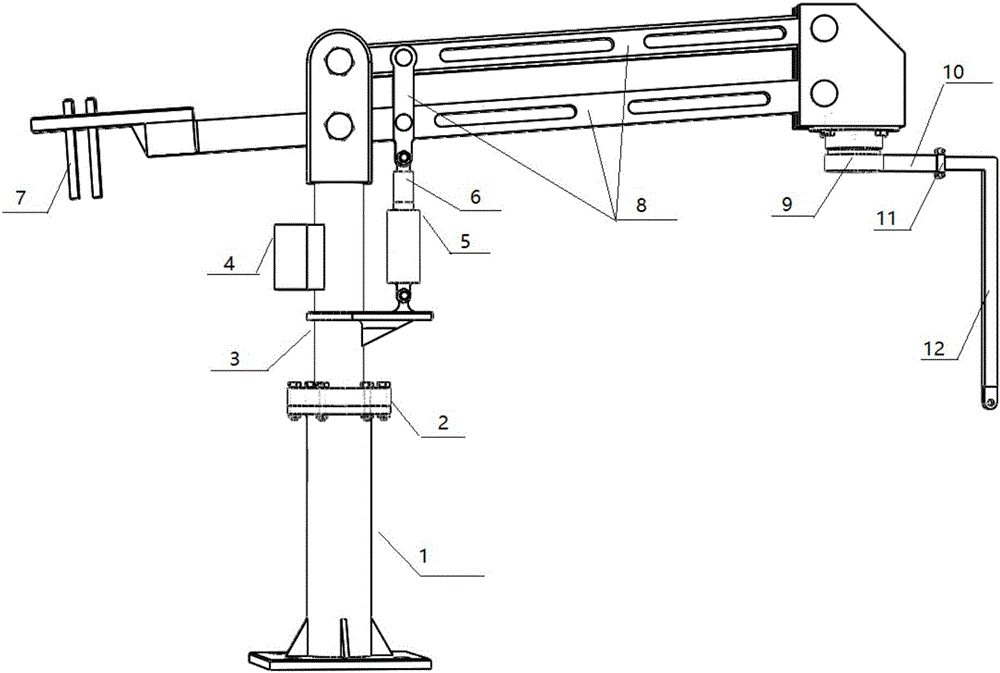

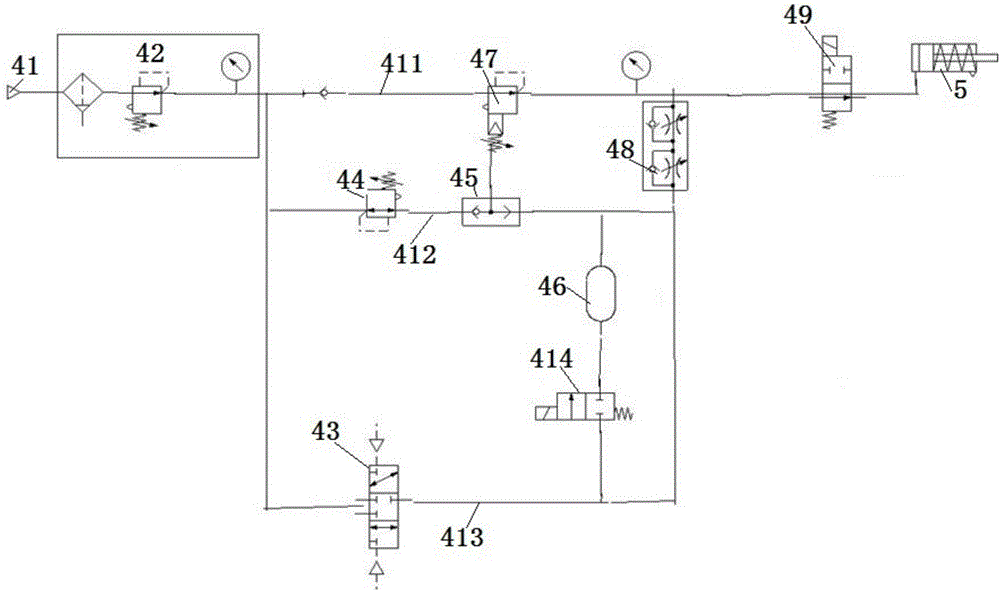

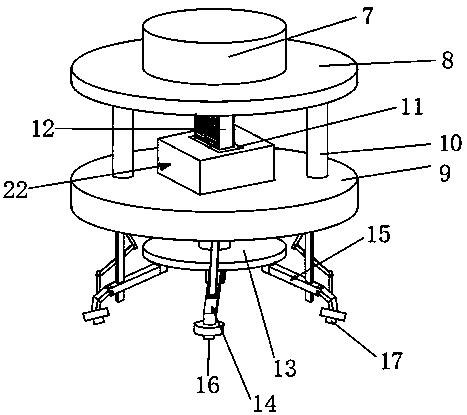

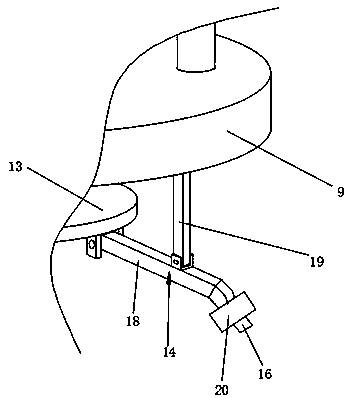

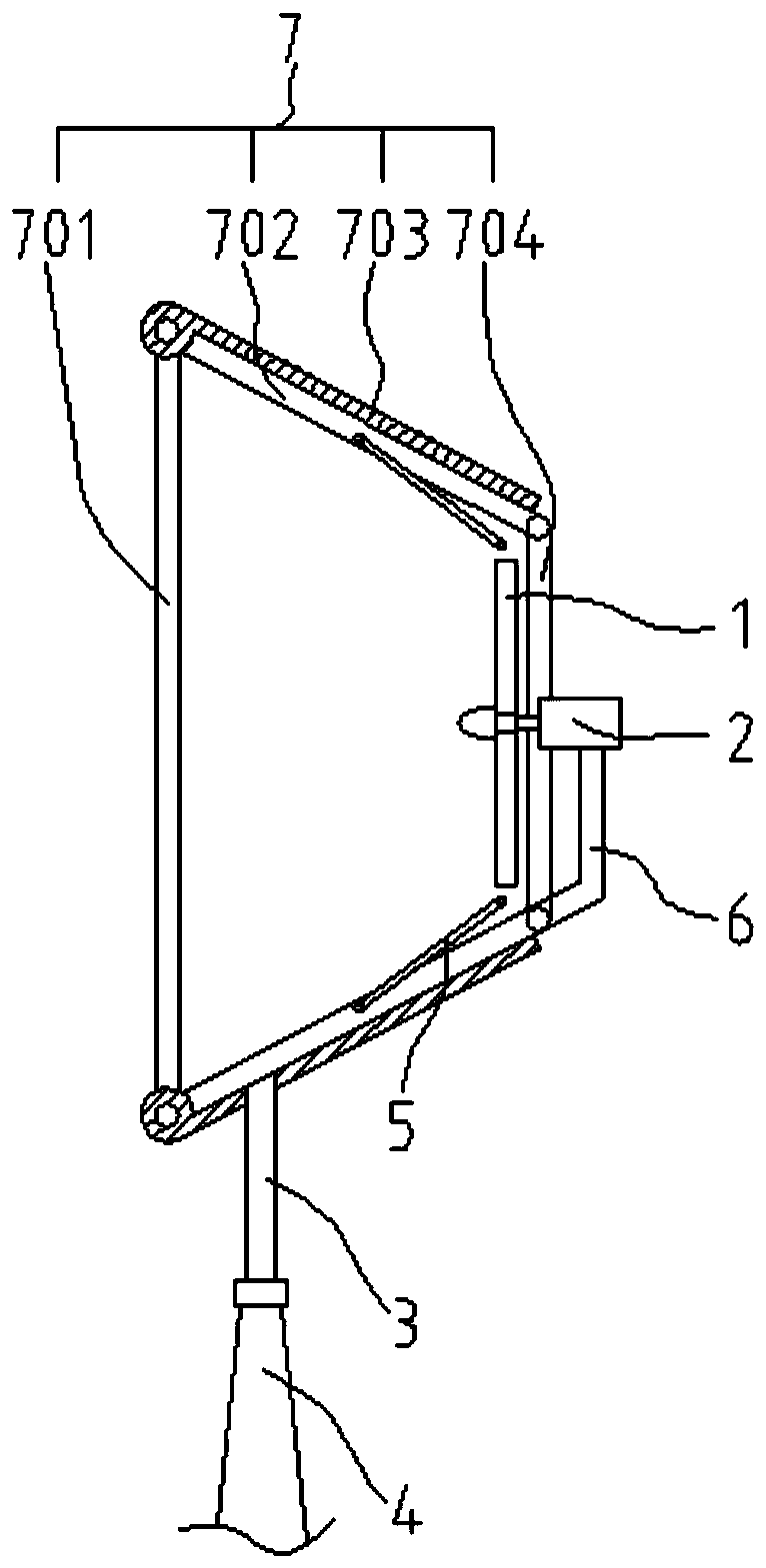

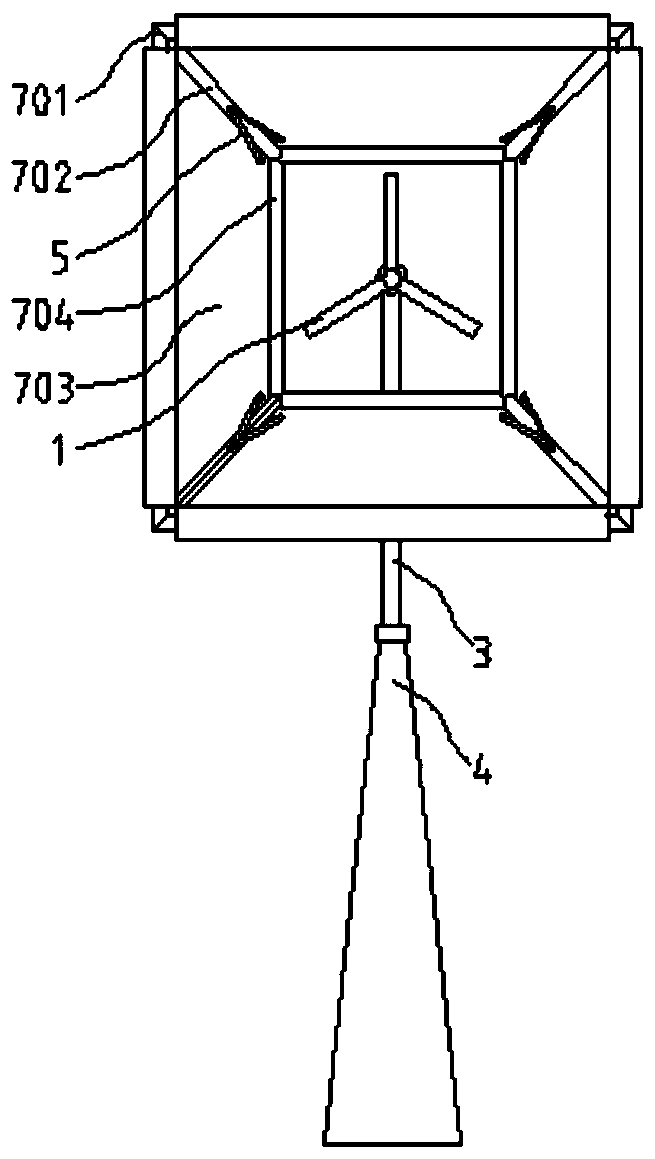

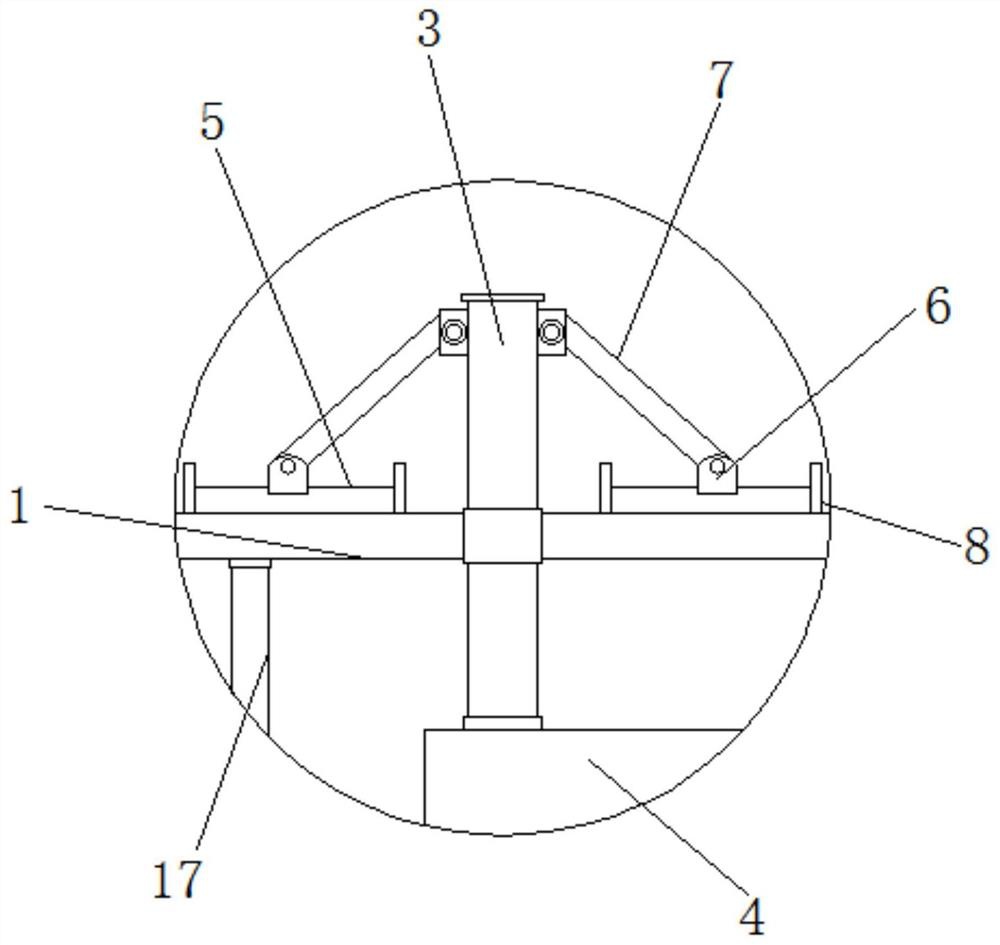

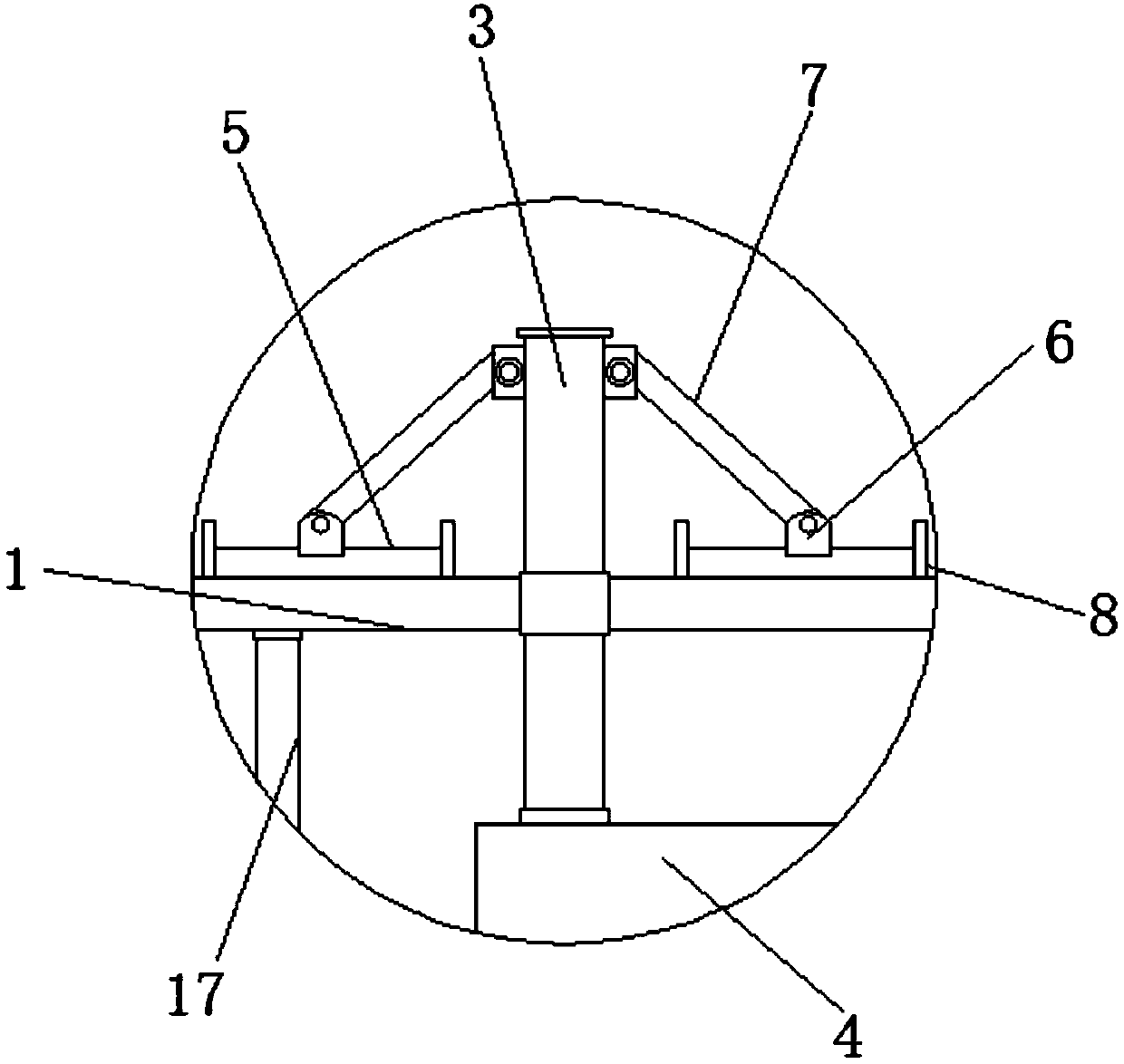

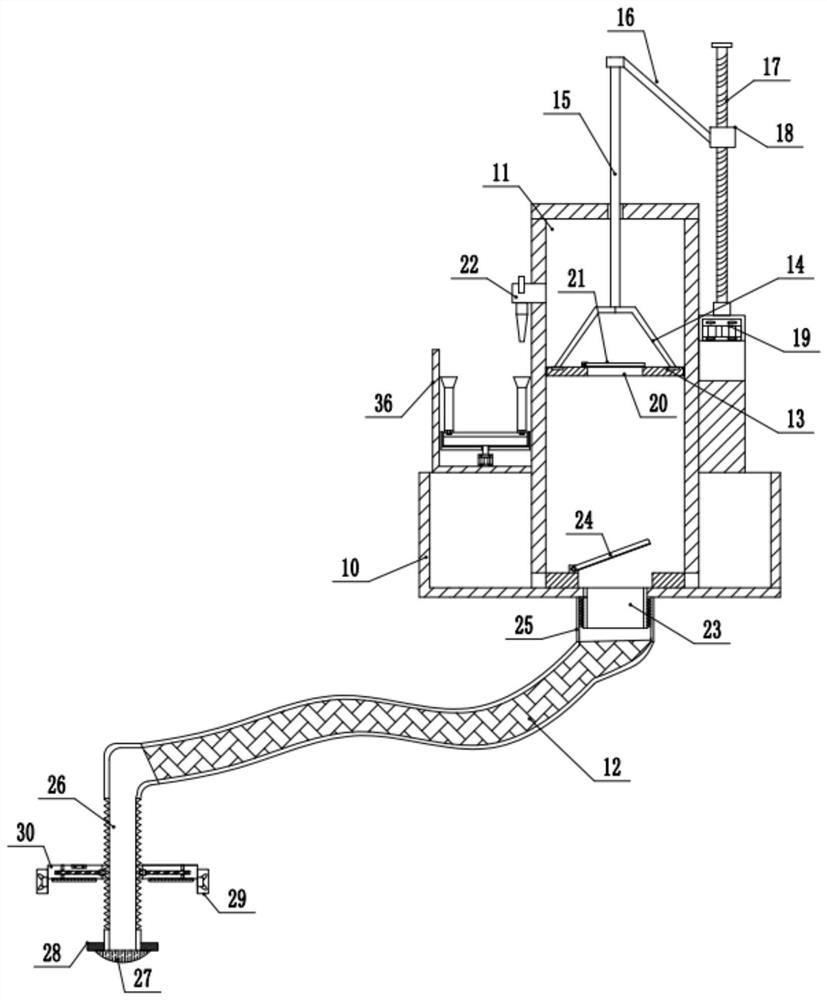

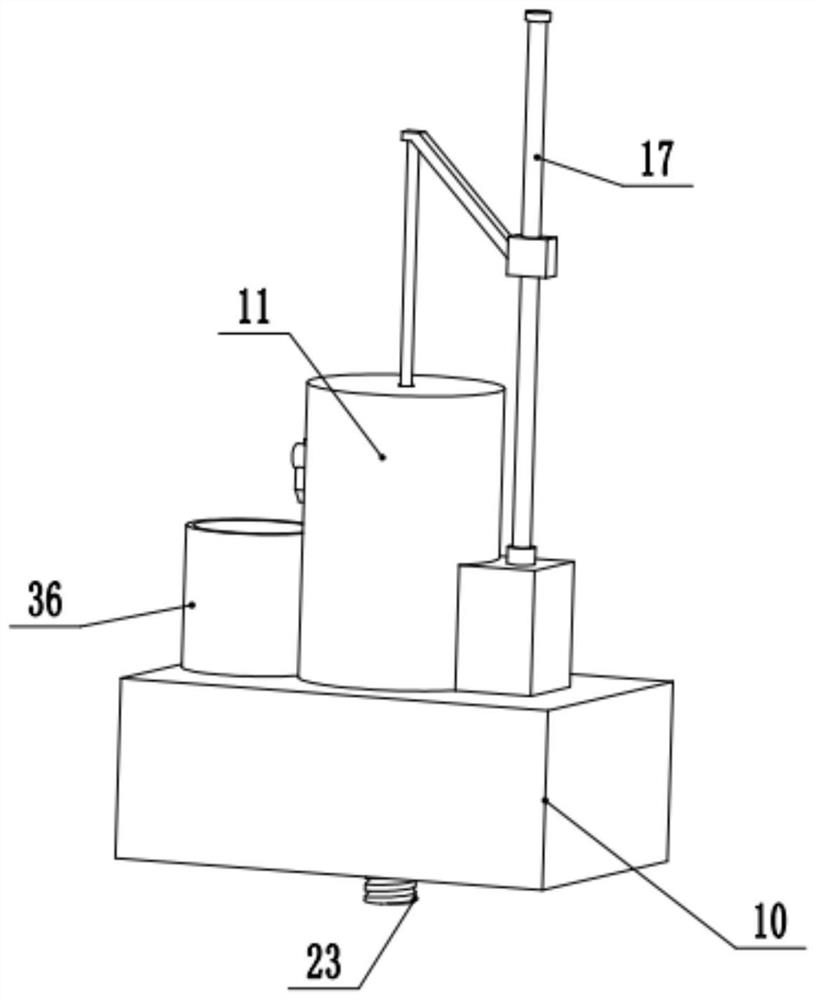

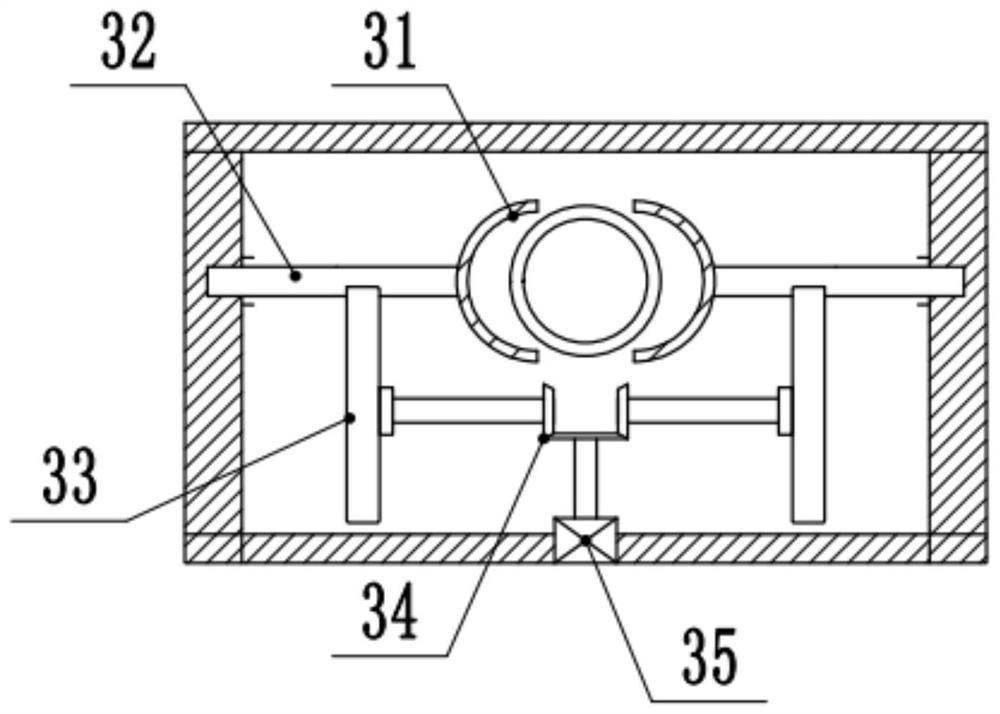

Load self-adaptive pneumatic balance hoisting device

InactiveCN106629429ASimple and reasonable structureEasy to liftCranesLoad-engaging elementsConstant loadAutomatic control

The invention relates to a load self-adaptive pneumatic balance hoisting device. The device comprises a lower base, an upper base which is connected with the lower base through a first in-built bearing, a four-bar linkage which is hinged to the top of the upper base, a pneumatic control system which is in transmission connection with the four-bar linkage, and a hoisting fixing unit and a heavy object block which are respectively arranged at the front end and the rear end of the four-bar linkage; the pneumatic control system comprises a pneumatic control box which is fixedly connected with the upper base and a pneumatic cylinder which is connected with the pneumatic control box; the top of a pneumatic rod of the pneumatic cylinder is hinged to the four-bar linkage. Compared with the prior art, the existing constant load hoisting is improved into variable load self-adaptive hoisting by the load self-adaptive pneumatic balance hoisting device; the technical advantage that the existing hoisting structure is simple and quick are reserved; the defects that the existing hoisting structure can only perform constant load hoisting, is low in efficiency and the like can be overcome; the overall structure is simple and compact; load self-adaptive automatic control can be realized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

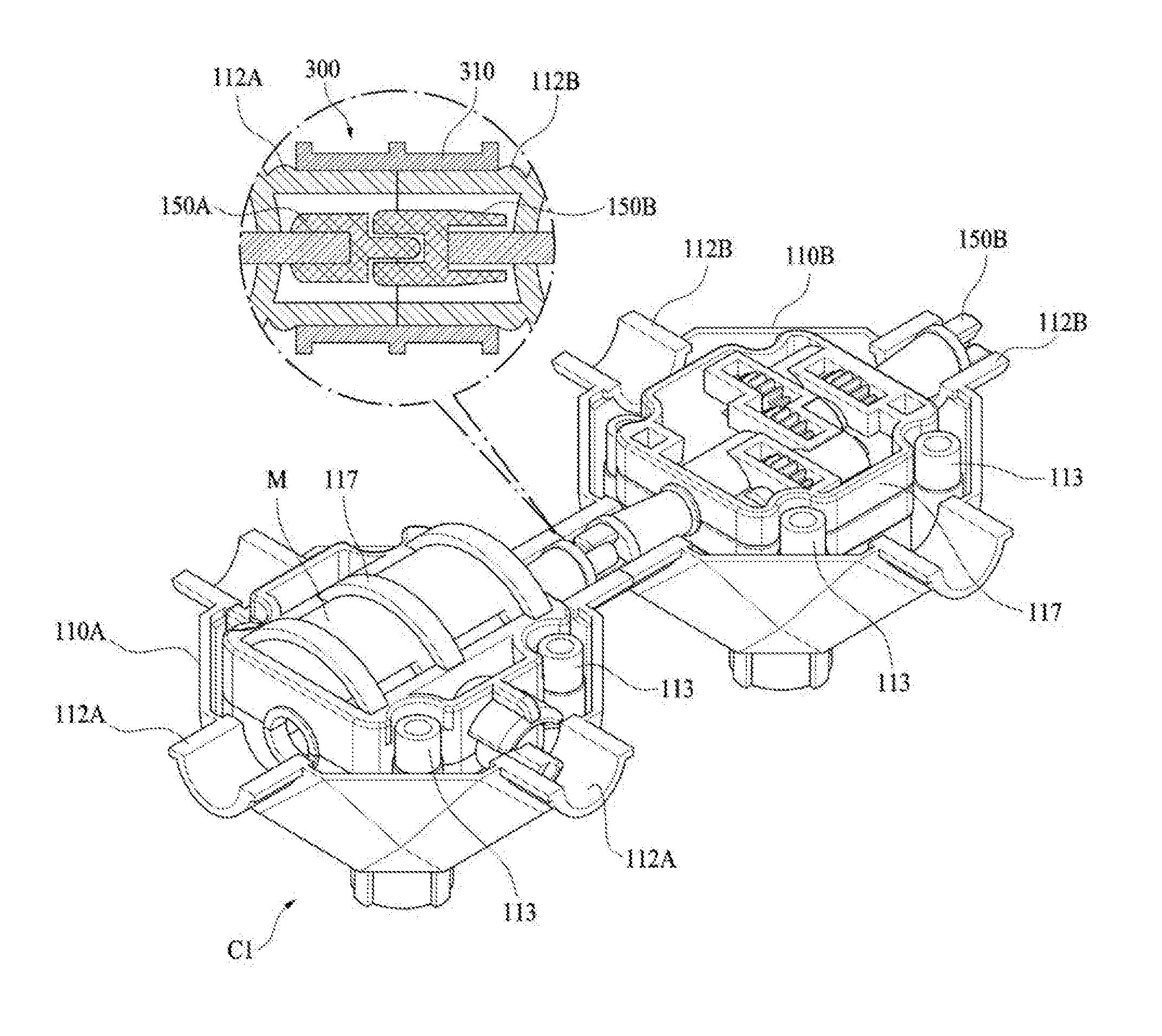

Power transmission apparatus and built-up type toy including the same

The present invention relates to a power transmission apparatus for transmitting power between components, and a built-up type toy including the same. The power transmission apparatus comprises: a housing having an operating space firmed therein; a connection hole that is open in at least one direction of the housing; a gear assembly that operates in the operating space of the housing and has a connecting link on one end thereof which is exposed to the outside through the connection hole; and a coupling tube for selectively interconnecting two connection holes of the power transmission apparatus and a counterpart power transmission apparatus connected thereto, wherein the connecting link of the power transmission apparatus and a counterpart connecting link are connected and interworked with each other in the interior of the coupling tube.

Owner:IQ KEY INC

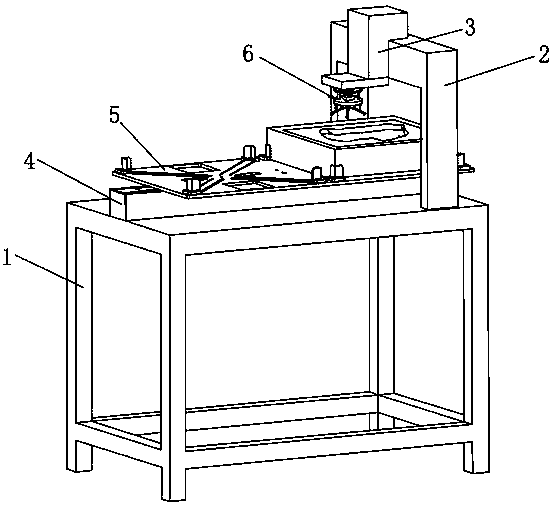

Multi-head glue spraying device for sand mold casting

The invention discloses a multi-head glue spraying device for sand mold casting. The multi-head glue spraying device for sand mold casting comprises a rack, a portal frame is arranged on the rack, a sliding block is arranged on the portal frame, a linear conveying sliding table is arranged on the rack, a multi-head glue spraying mechanism is arranged at the bottom of the sliding block, the multi-head glue spraying mechanism comprises a rotating seat which is arranged at the bottom of the sliding block, an upper base plate is arranged at the bottom of the rotating seat, a lower base plate is arranged below the upper base plate, a plurality of positioning rods are arranged between the upper base plate and the lower base plate; and a vertically-downward stroke sleeve is arranged in the middleof the lower base plate, a movable rod is arranged in the stroke sleeve, a lifting disc is arranged at the bottom of the movable rod, a plurality of first linkage frames and second linkage frames arearranged between upper base plates of the lifting disc, first atomization glue spraying heads are arranged on the first linkage frames, and second atomization glue spraying heads are arranged on thesecond linkage frames. According to the multi-head glue spraying device for sand mold casting, spraying an inner cavity of a sand mold is carried out through the multi-head glue spraying mechanism, and the multi-head glue spraying device has the characteristics of being wide in spraying face and uniform in spraying.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

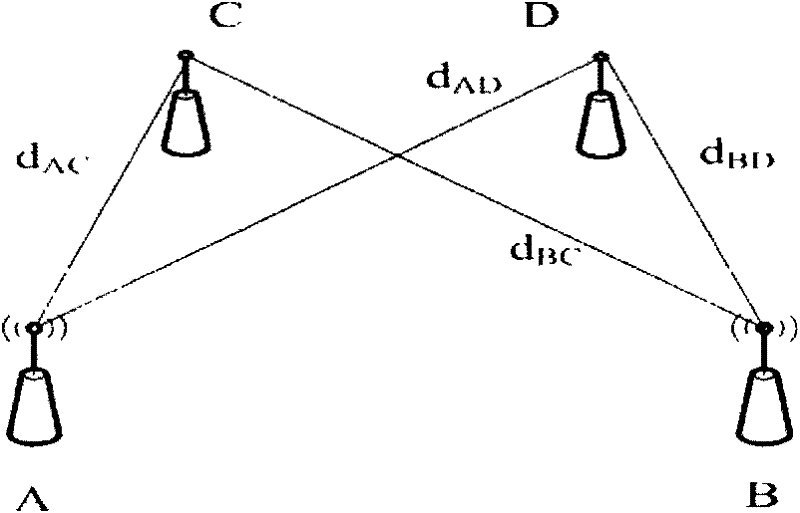

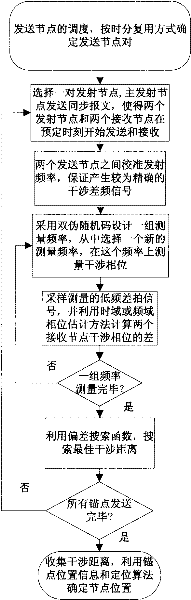

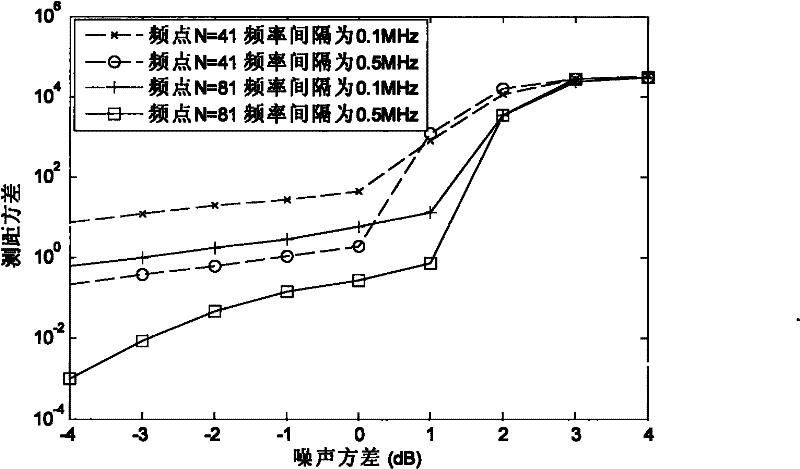

Measuring frequency selection method based on dual pseudo random code in radio interference positioning

InactiveCN102221695ANo need for added complexityImprove rangeRadio wave reradiation/reflectionPhase differenceComputer science

The invention relates to a measuring frequency selection method based on a dual pseudo random code in radio interference positioning. Three anchoring nodes with known positions and a node to be positioned are arranged; two anchoring nodes are set as emitting nodes; the other anchoring node and the node to be positioned are set as receiving nodes; and the method comprises the steps of emitting node frequency calibration, minimum frequency interval determination, measuring frequency candidate set design, frequency measuring sequence randomized design, emitting, receiving node time synchronization, interference envelope phase difference estimation, interference distance estimation and node position design. The inherent contradiction between the ranging scope and precision of equal-interval interference ranging is solved. In the method, measuring frequency intervals are skillfully arranged; a small frequency interval is used for expanding the period of a whole complete cycle; a big frequency interval is used for guaranteeing the ranging precision; and the interference distance estimation is not influenced by changing the measuring sequences of the frequencies. The measuring frequency selection method based on the dual pseudo random code in radio interference positioning can avoid interference, has anti-interference capacity and can be applied for military anti-interference positioning.

Owner:PLA UNIV OF SCI & TECH

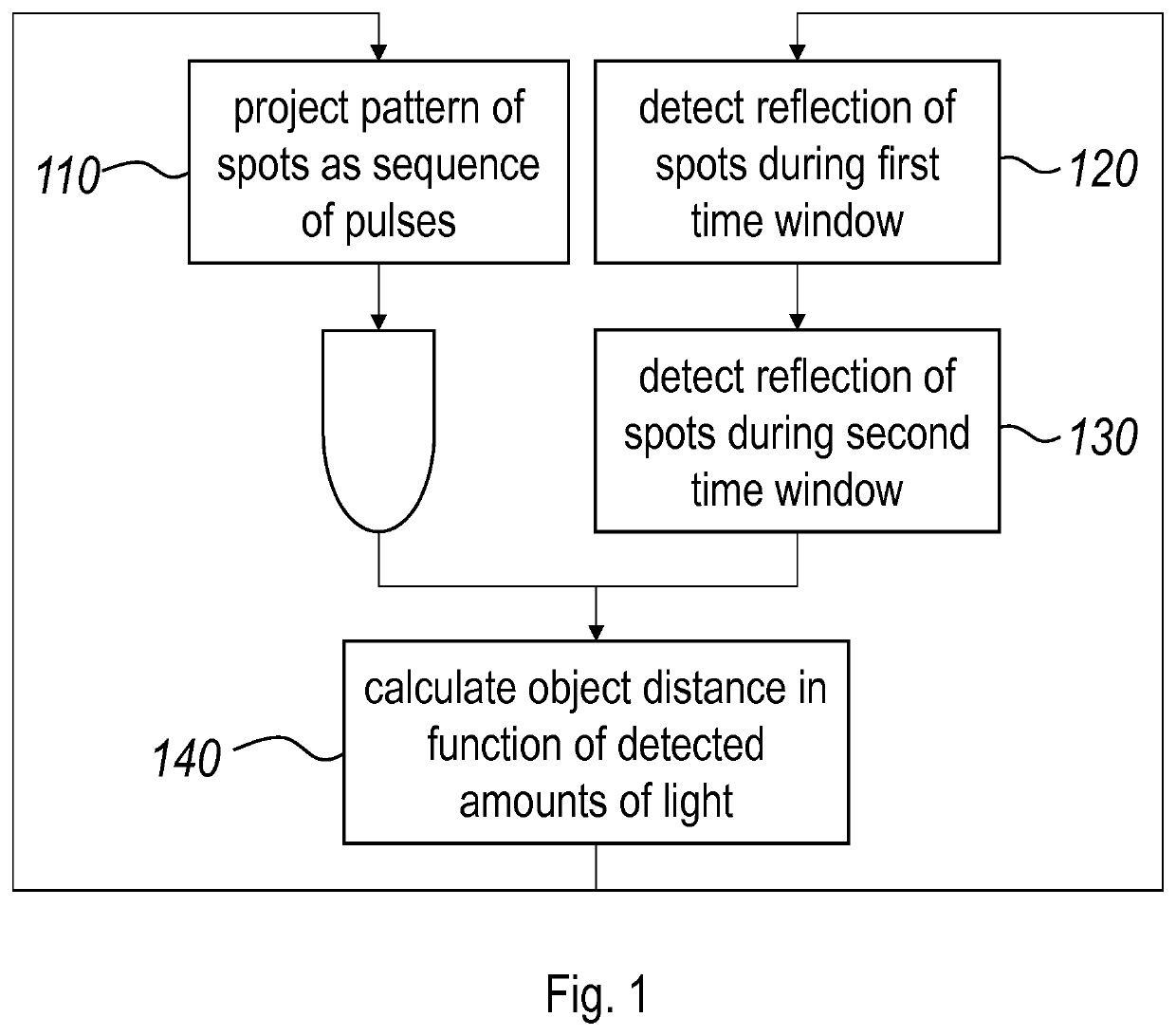

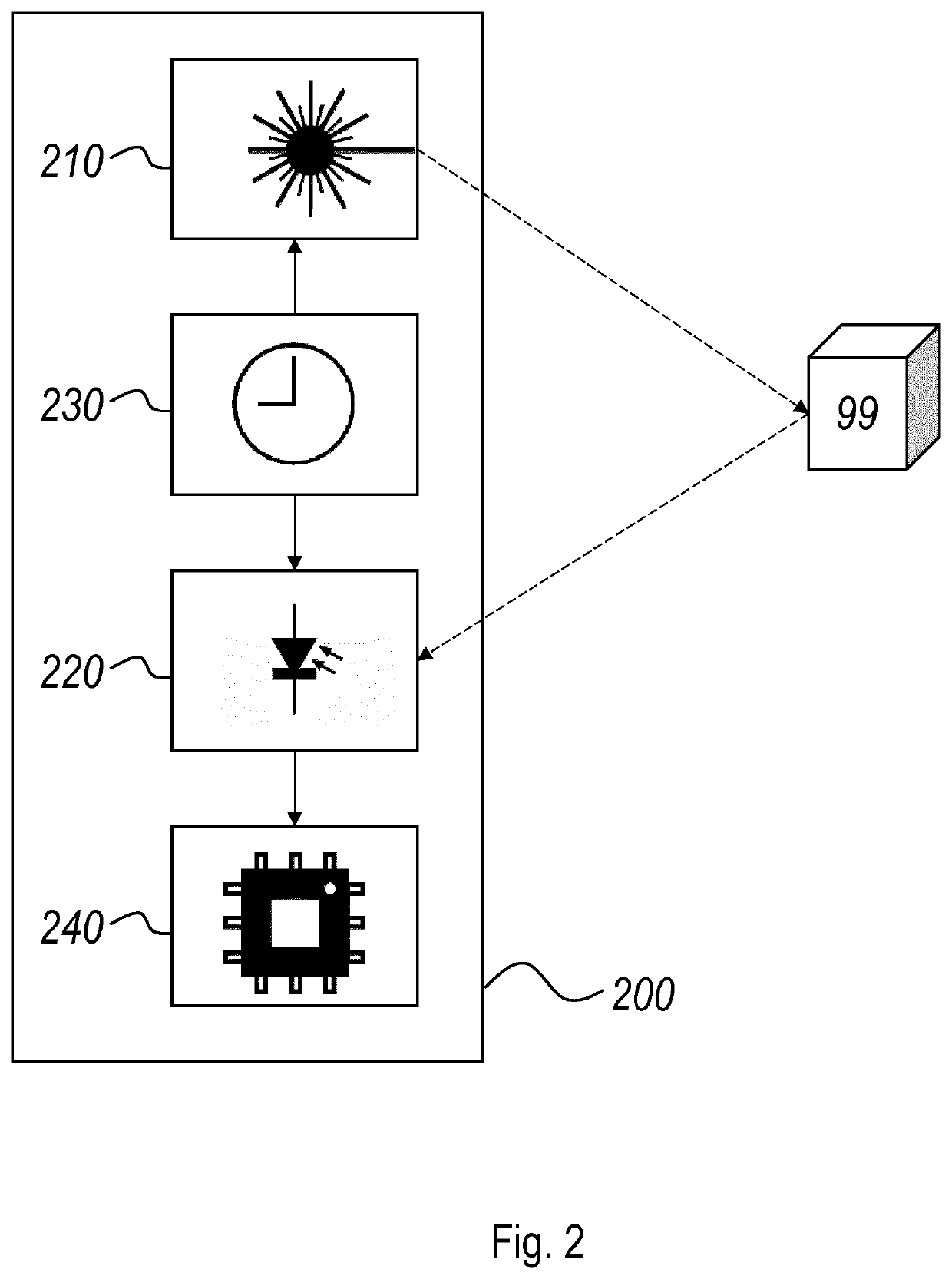

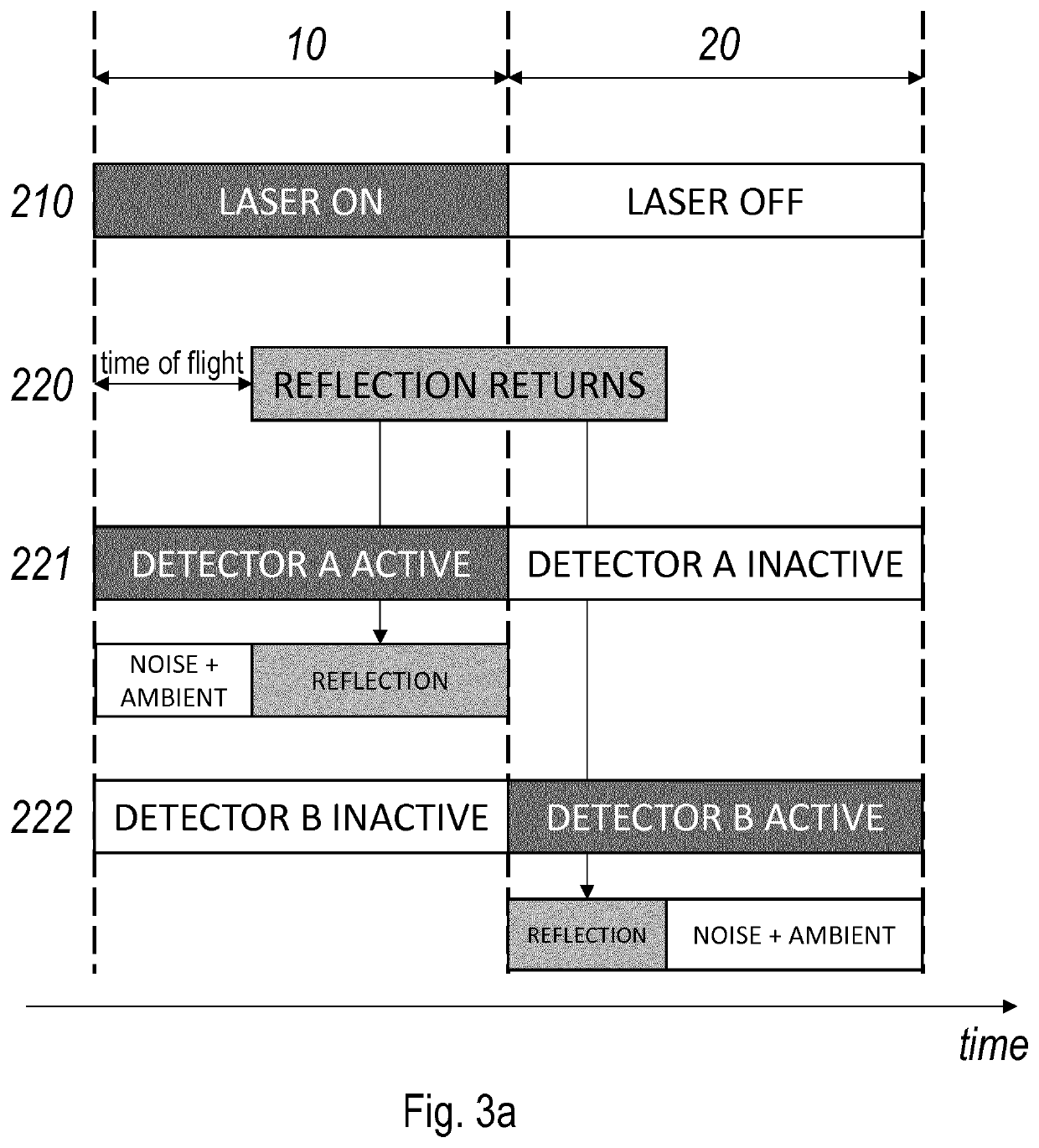

System and method for determining a distance to an object

The invention pertains to a system for determining a distance, comprising: a light source for projecting a pattern of discrete spots of laser light towards the object in a sequence of pulses; a detector comprising picture elements, for detecting light representing the pattern as reflected by the object in synchronization with the sequence of pulses; and processing means to calculate the distance to the object as a function of exposure values generated by said picture elements. The picture elements generate exposure values by accumulating a first amount of electrical charge representing a first amount of light reflected during a first time window and a second electrical charge representating a second amount of light reflected during a second time window. The system projects and detects for at least two consecutive sequences of pulses, each being operated with a different duration of said first time window and said second time window.

Owner:XENOMATIX NV

Control method of spinning pressure in spin forming and control system applied by same

InactiveCN111672959AImprove technical levelImprove molding efficiencyShaping toolsPressesControl systemControl engineering

The invention discloses a control method of a spinning pressure in spin forming and a control system applied by same. The control method comprises the following steps of by taking preset tracks as driving targets by spinning wheels for spin forming of a material in multiple passes, wherein the spinning wheels carry out curve interpolation to achieve position control through linked driving controlof an X-axis servo driving unit and a Y-axis servo driving unit; in spinning of at least final pass, by taking a separation distance between each spinning wheel and a driving rotary die which is 0 asa driving target, executing double modes of pressure control and position control to the spinning wheels, wherein when the thrusts of the spinning wheels reach a preset target pressure, pressure control is carried out on the spinning wheels to ensure that the separation distance between each spinning wheel and the driving rotary die is 0. The invention further relates to the control system appliedby the control method. By arranging the specific control method and control system, the technical level and the forming efficiency of spin forming are improved effectively.

Owner:AOKEN CNC EQUIP SUZHOU CO LTD

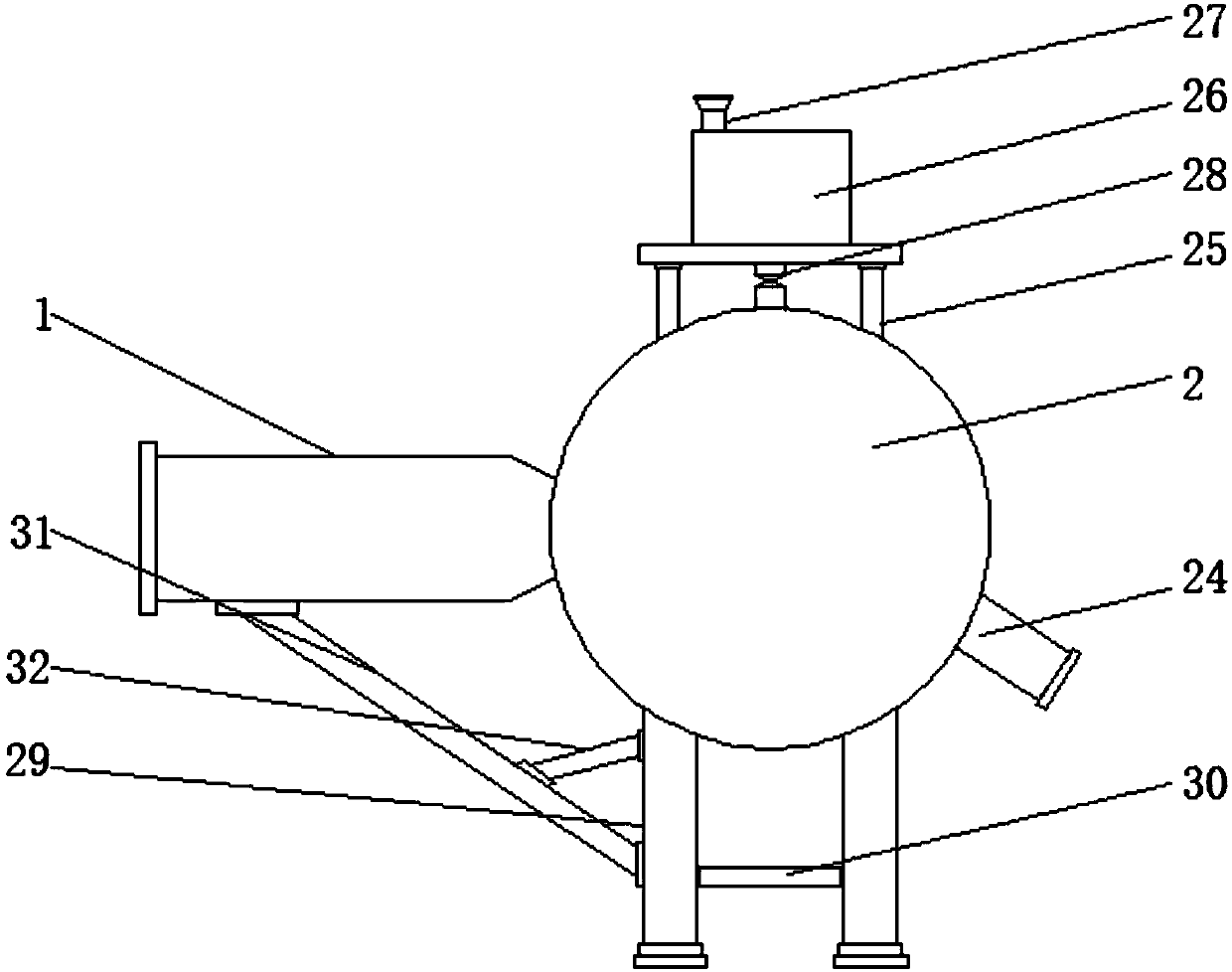

Venturi-type breeze and moderate wind electric generator

PendingCN109915313AIncrease profitImprove rangeMachines/enginesWind energy generationEngineeringTower

The invention relates to a venturi-type breeze and moderate wind electric generator. The venturi-type breeze and moderate wind electric generator comprises a wind gathering cover, a wind wheel, an engine room, a tower frame and a direction adjuster for adjusting the steering of the wind wheel, wherein the wind gathering cover comprises a contraction part; the direction adjuster comprises a direction adjusting shaft; the wind wheel is arranged nearby the tail end of the contraction part and is correspondingly connected to a transmission gear in the engine room through a rotating shaft; the contraction part is of a truncated pyramid structure formed by correspondingly connecting a first flaring frame, a first necking frame and a plurality of arris rods; a wind gathering plate is laid on eachside surface, corresponding to the truncated pyramid, of the outer side of the contraction part; the outer end of each wind gathering plate is rotatably connected to a side rod of the corresponding first flaring frame; and an elastic contracting device for tightening the side surface, fit to the truncated pyramid, of the wind gathering plate is arranged on each wind gathering plate. The venturi-type breeze and moderate wind electric generator can expand the range of working wind speed while achieving the effect of the breeze and moderate wind power generation, reduces the probability of damage to the electric generator when the wind speed is too large, and improves the utilization efficiency of wind energy.

Owner:王建成

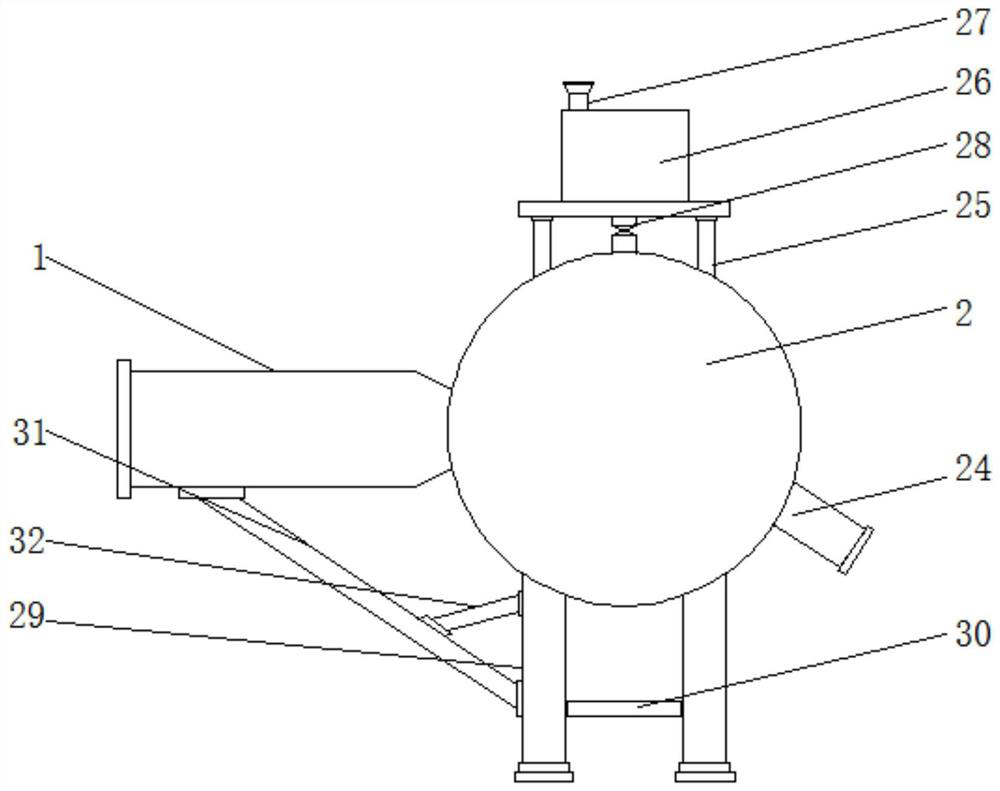

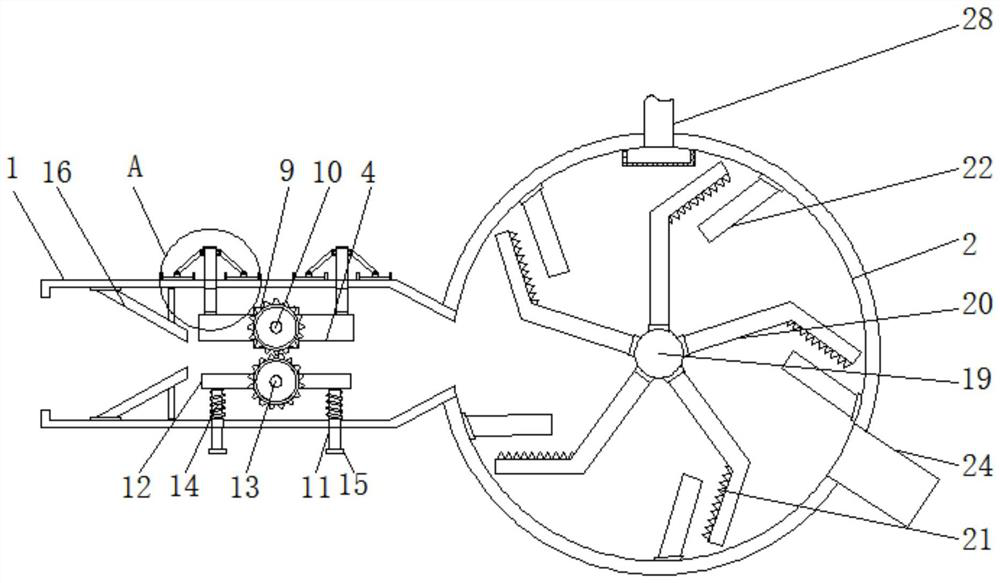

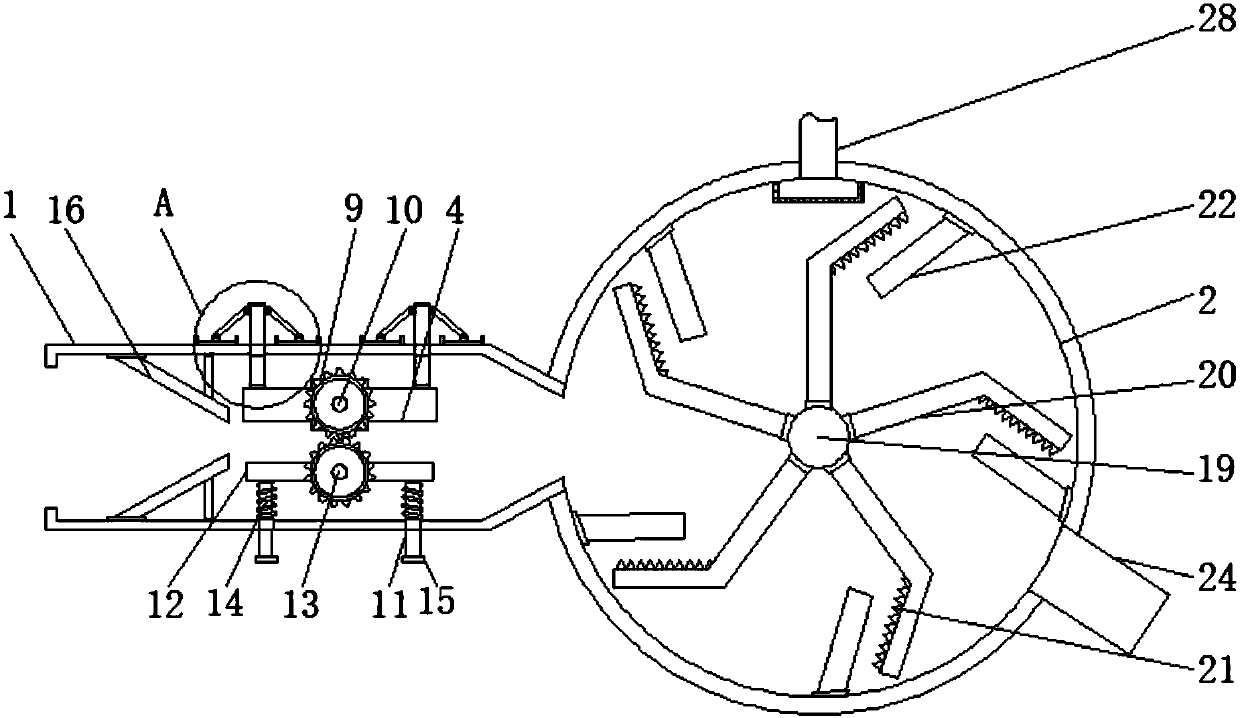

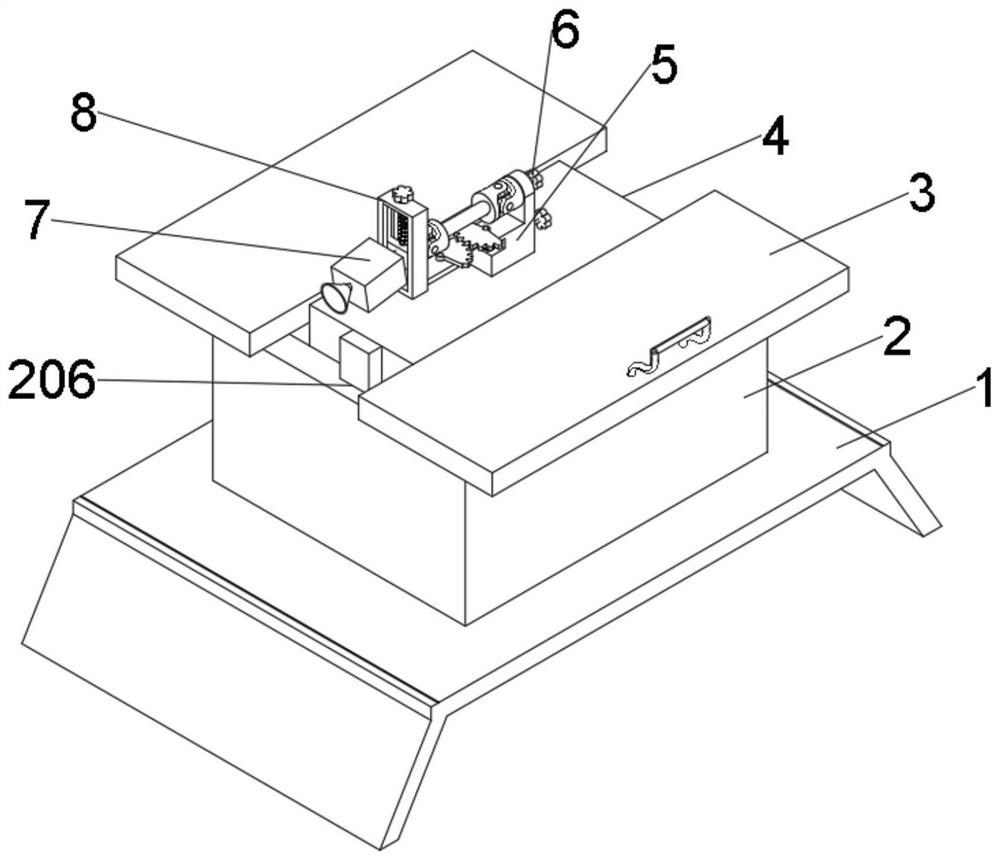

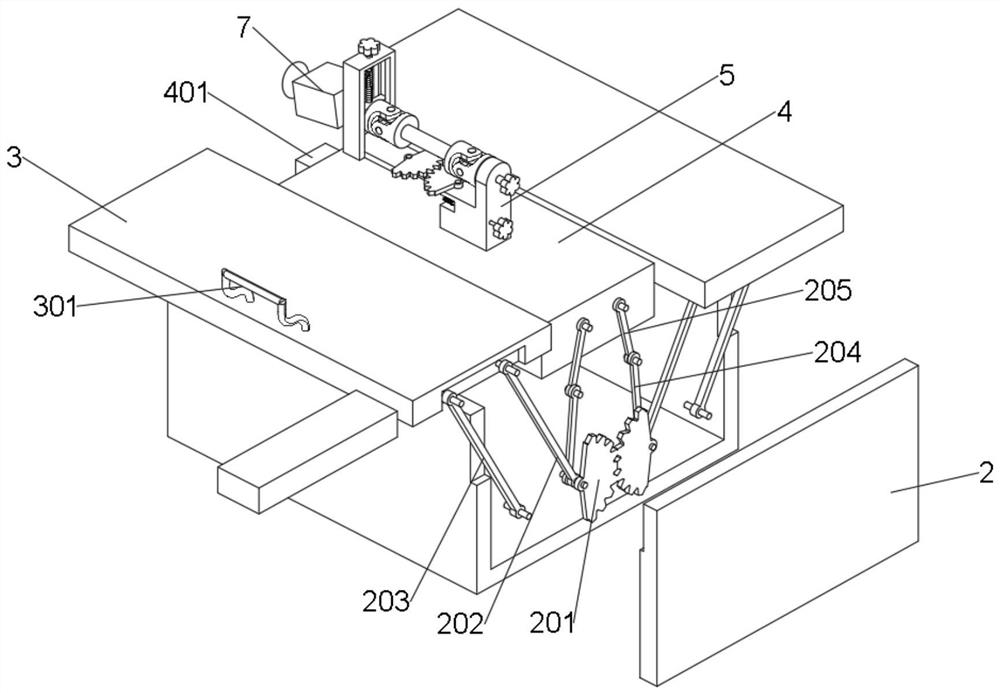

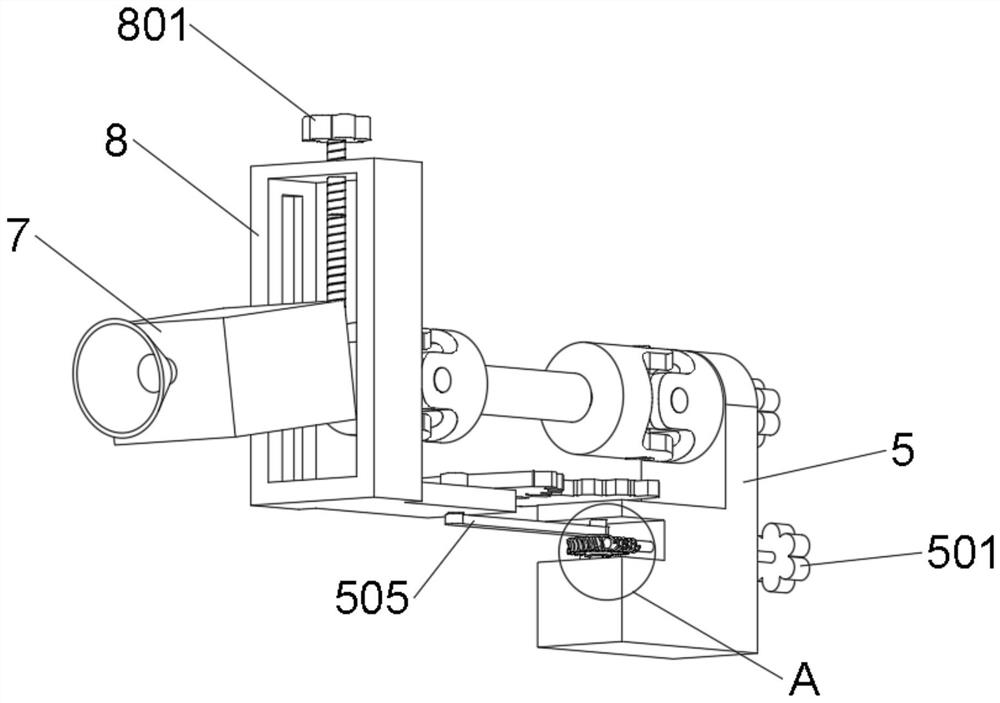

A High Efficiency Straw Feed Grinder

ActiveCN107711108BImprove processing efficiencyReduce processing difficultyFeeding-stuffCuttersAgricultural scienceAgricultural engineering

The invention discloses a straw forage pulverizer with high efficiency. The pulverizer comprises a smashing barrel. One side of the smashing barrel communicates with a cylindrical barrel; a rod body passes through the top of the smashing barrel; the rod body extends to one end of the interior of the smashing barrel to be fixedly connected with a fixing plate; slide plates are arranged on the top of the smashing barrel and fixedly connected to two sides of the rod body; a slide block is slideably connected to the top of each slide plate; and one end, getting far away from the slide block, of aslide rod is movably connected with one side of the surface of the rod body. The invention relates to the field of pulverizers. In the straw forage pulverizer with high efficiency, the rod body passesthrough the top of the smashing barrel; the rod body extends to one end of the interior of the smashing barrel to be fixedly connected with the fixing plate, so processing difficulty can be reduced and straws are smashed in advance and then processed; forage processing efficiency can be greatly improved and time and efforts can be saved; the rod body passes through the top of the smashing barrel,so use ranges can be enlarged, simple and convenient operation can be obtained; and the straw forage pulverizer with high efficiency is suitable for various people.

Owner:临沂文一诺知识产权运营有限公司

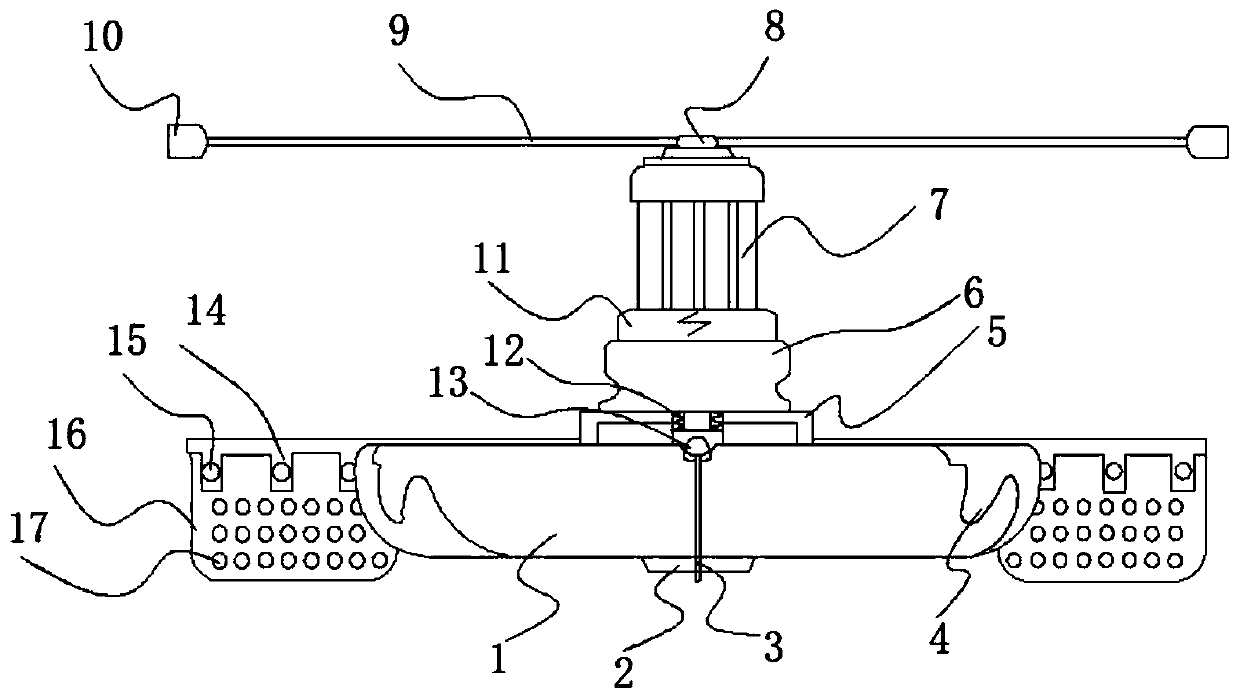

Stable and adjustable optical distance measuring device and method

ActiveCN114370848AImprove stabilityReduce ranging blind spotsOptical rangefindersEngineeringBlind zone

The invention discloses a stable and adjustable optical distance measuring device and method, and the device comprises a fixed pedestal, the middle part of the front surface of the fixed pedestal is fixedly connected with a control panel, the middle position of the top of the fixed pedestal is rotatably connected with a rotating platform, and the middle position of the top of the rotating platform is fixedly connected with a placement disc. The top of the placing disc is rotationally connected with a distance measuring device, and the two sides of the bottom of the rotating platform are rotationally connected with balance columns. According to the stable and adjustable optical distance measuring device and method, inclination caused by uneven stress during rotation of the rotating platform is prevented, the receiving and transmitting guide sleeve can rotate on the optical distance measuring device, the situation that light emitted by the optical distance measuring device is dispersed when leaving the receiving and transmitting guide sleeve, and consequently positioning of the distance measuring position is inaccurate is effectively avoided, and the positioning accuracy of the distance measuring device is improved. Therefore, ranging blind areas during ranging are reduced, the accuracy in the ranging process is improved, and the ranging distance can be adjusted conveniently.

Owner:昕锐至成(江苏)光电技术有限公司

Water purification aerator

InactiveCN110776151AShock mitigationImprove survival rateWaste water treatment from animal husbandryMultistage water/sewage treatmentActivated carbonLamp current

The invention discloses a water purification aerator, and belongs to the technical field of machinery. The water purification aerator includes a housing, the outer sidewall of the shell is fixedly connected with a floating block, a groove is formed in the inner sidewall of the floating block, activated carbon is connected to the inner sidewall of the groove in an embedded mode, the surface of thefloating block is provided with a plurality of groups of through holes, an air conveying pipe penetrates through the inner sidewall of the shell, the bottom of the shell is fixedly connected with an LED lamp, the current input end of the LED lamp is connected with the current output end of a motor box, the top of the shell is fixedly connected with a base, a damping shock absorber is fixedly connected to the inner sidewall of the base, a supporting base is fixedly connected to the outer sidewall of the top of the base, and a vacuum pump is fixedly connected to the top of the motor box. The LEDlamp is fixedly connected to the bottom of the shell, and the current input end of the LED lamp is connected with the current output end of the motor box, so illumination can be provided through theLED lamp at night, and a worker can observe the working condition of the machine body in real time.

Owner:喜德县特色产业保护协会

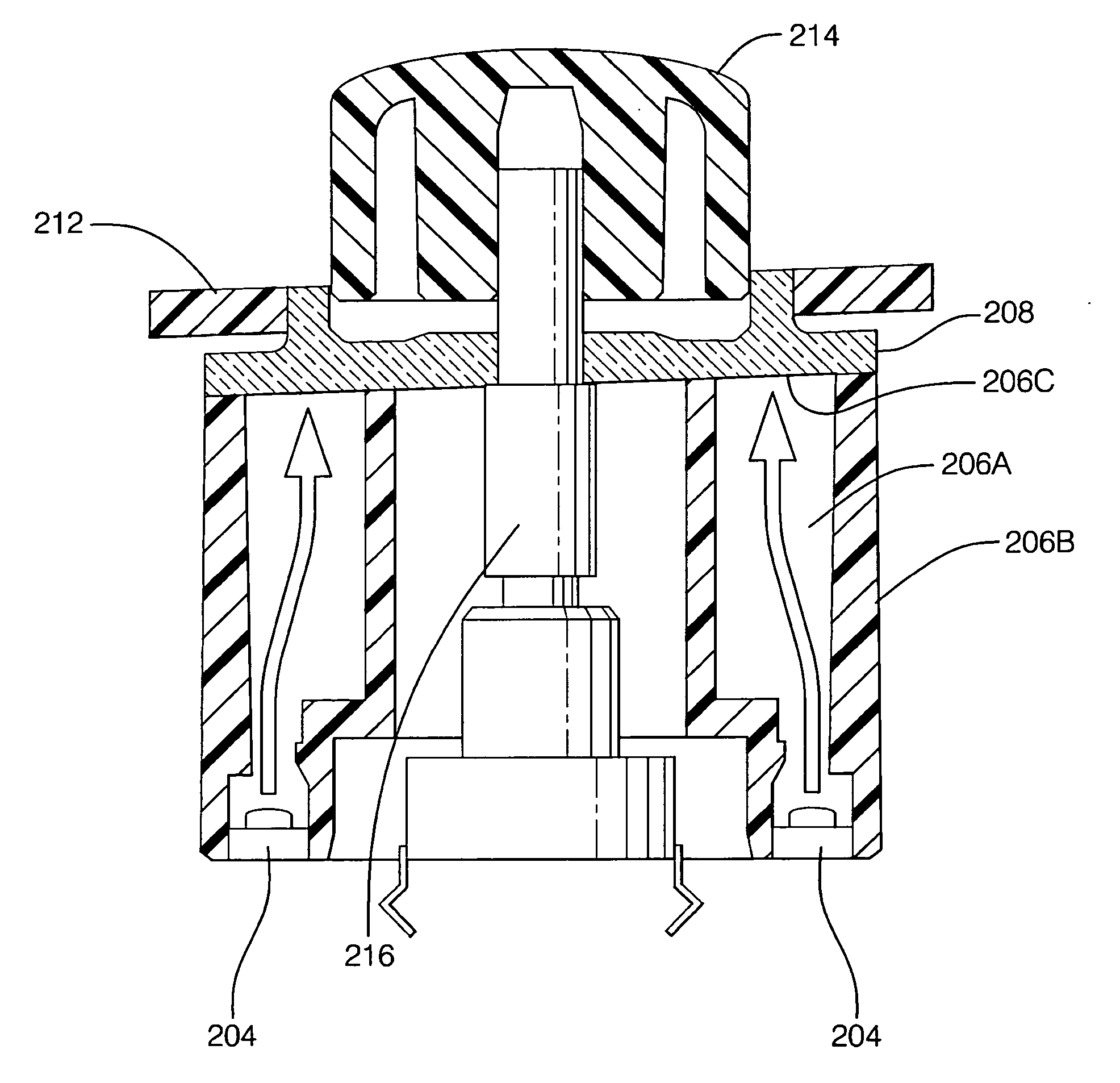

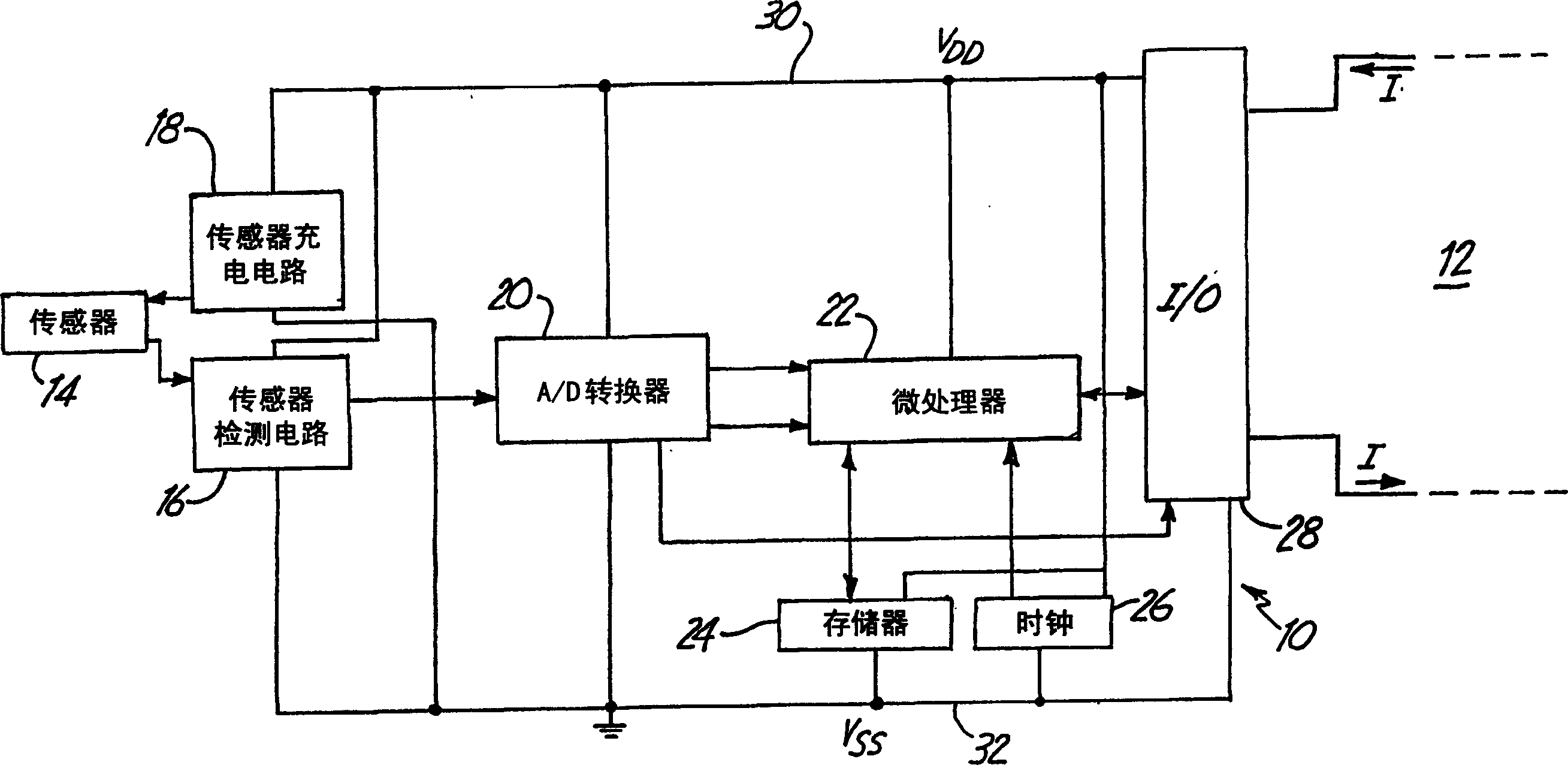

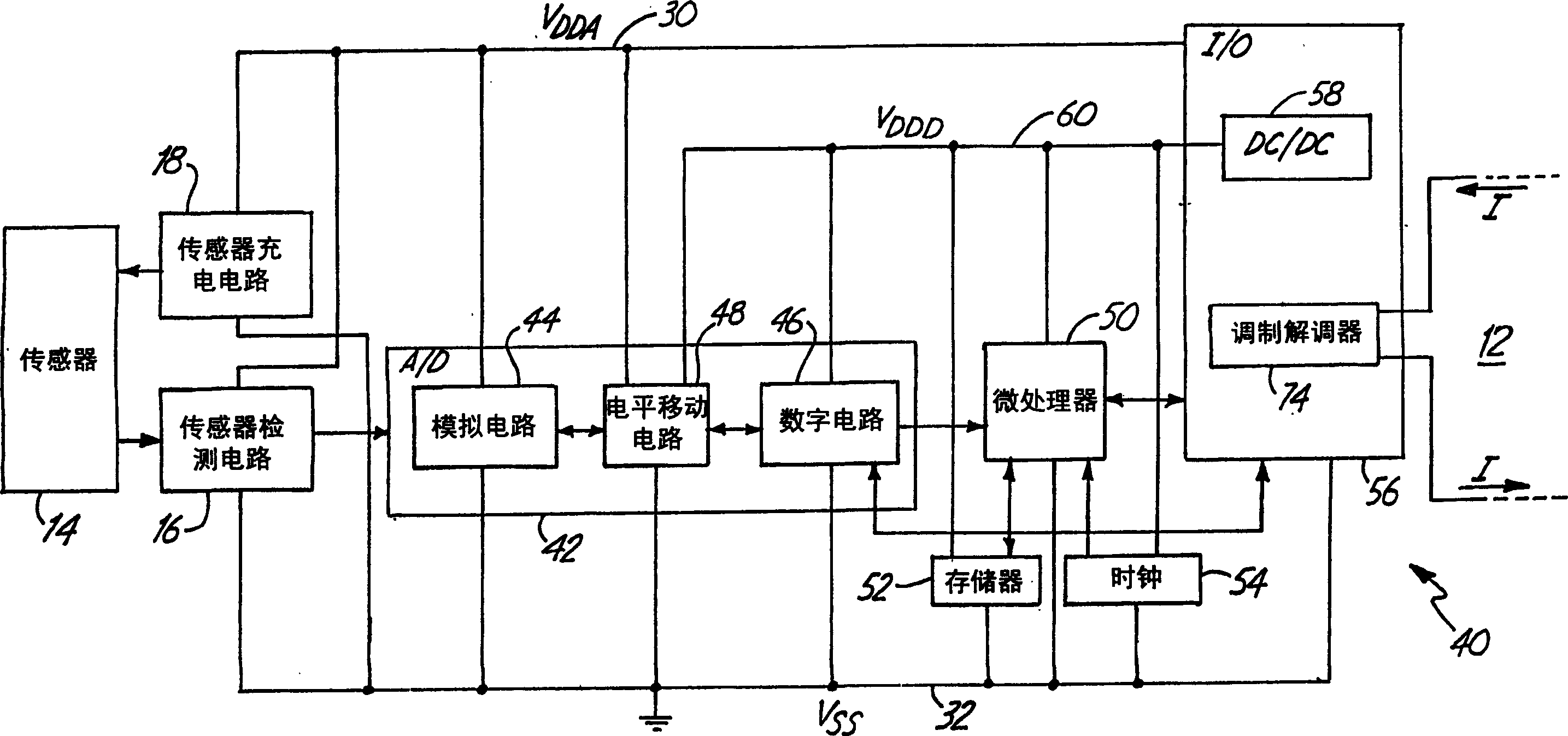

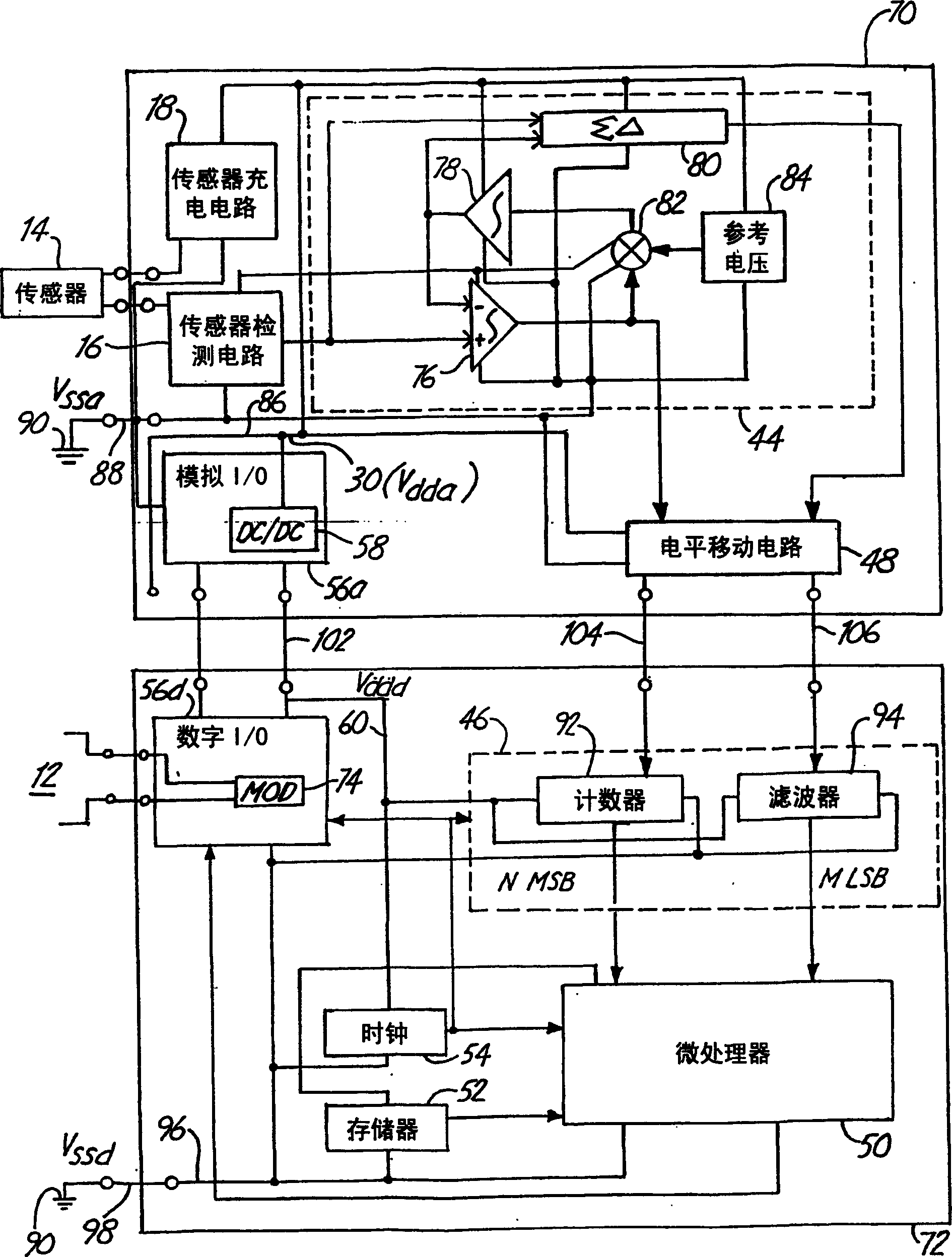

Multiple die industrial process control transmitter

InactiveCN1473289ALow operating powerImprove rangeElectric signal transmission systemsTelemetry/telecontrol selection arrangementsLevel shiftingModem device

A two-wire industrial process control transmitter includes a sensor (14), at least two integrated circuits (70, 72), and a level shift circuit (48). The first integrated circuit (70) contains the analog measurement circuit that includes a sensor detection circuit (16) and the analog portion (44) of a digital-to-analog convertor. The second integrated circuit (72) contains the digital system circuit that includes a modem (78) and the digital portion (46) of the analog-to-digital convertor. The first and second Ics may be powered at different voltage levels (Vdda, Vddd) to maximize the power of the analog circuit and improve resolution. Alternatively, the Ics may be powered at the same voltage level (Vddd), but the digital circuits are divided among several stacked dies (120, 122) to minimize the voltage for each digital circuit. In either case, the level shifting circuit (48) shifts the voltage level between the analog and digital circuits.

Owner:ROSEMOUNT INC

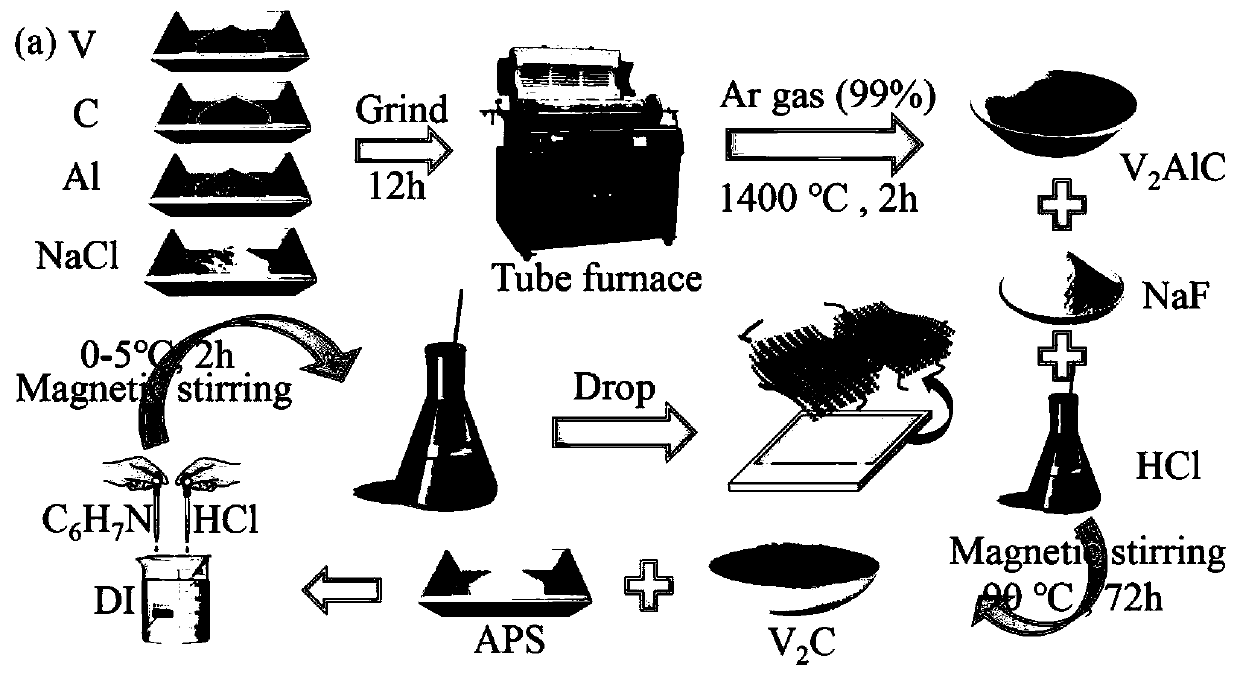

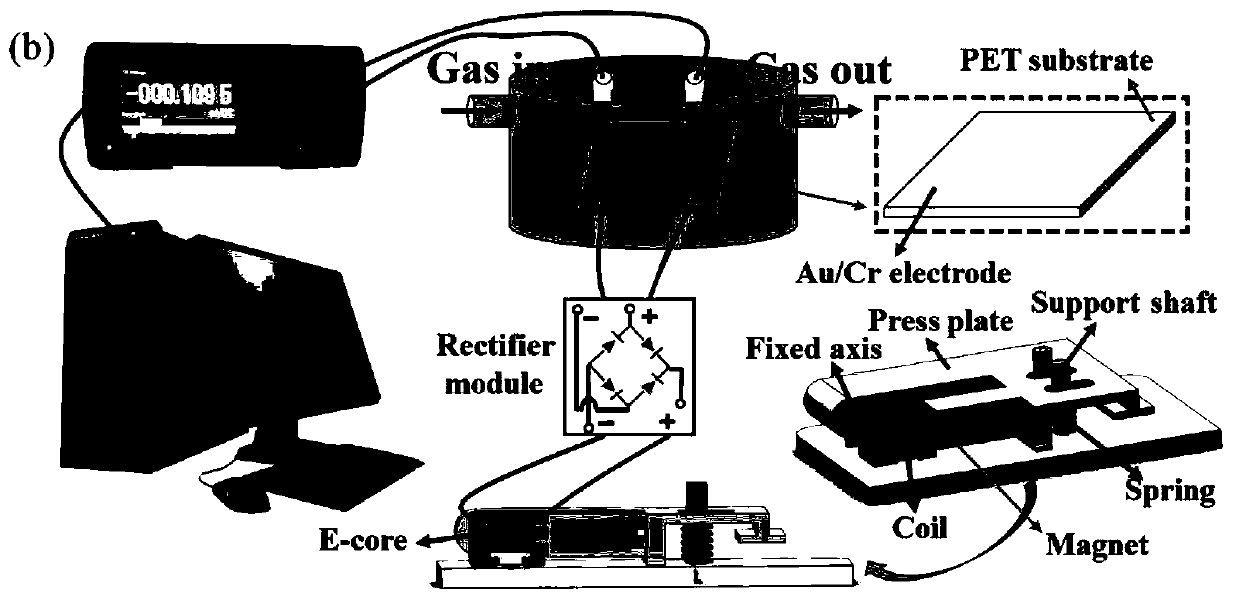

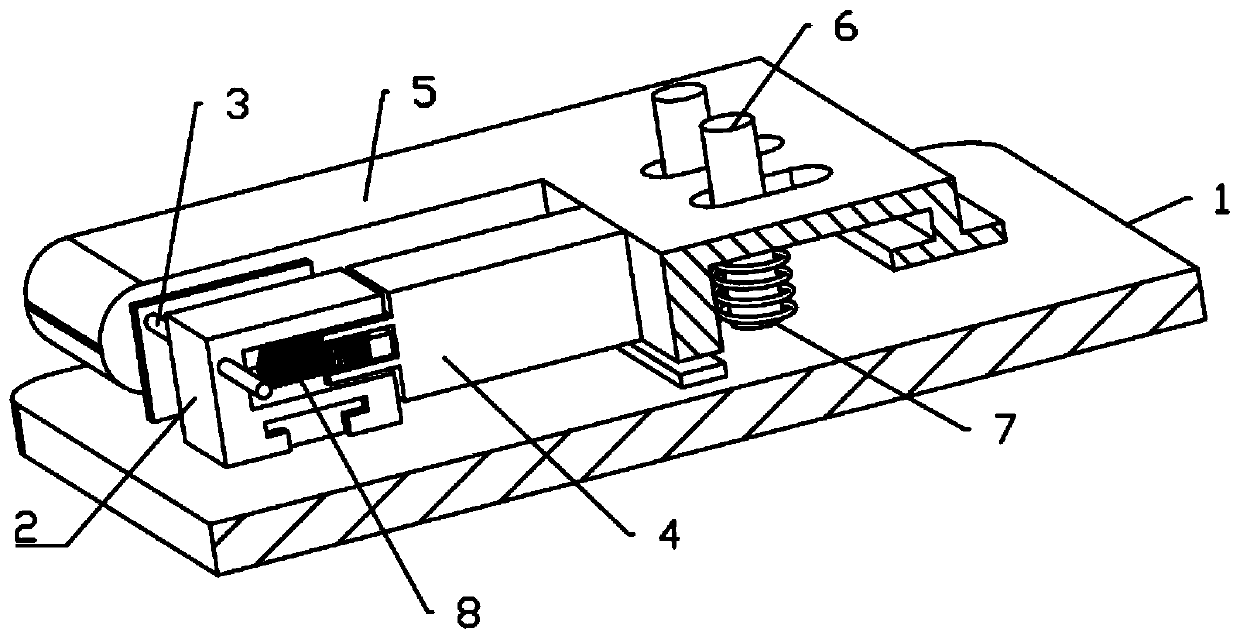

Preparation method of ammonia gas sensor based on polyaniline-vanadium carbide and as detection system and application of ammonia gas sensor

ActiveCN111307883ALow detection limitImprove responsivenessMaterial resistanceEngineeringSensor materials

The invention discloses a preparation method of an ammonia gas sensor based on polyaniline-vanadium carbide and a detection system and application of the ammonia gas sensor and belongs to the field ofsensor materials and gas detection systems. A polyaniline-vanadium carbide resistance type ammonia gas sensor is created by combining an MXene micro-nano composite material with a sensor, and the surface of the sensor adopts a PANI-V2C composite material, so that the response performance is improved, and the sensing resistance is reduced; the self-powered portable ammonia gas alarm system is alsocombined with the pressure-sensitive module, so that the self-powered portable ammonia gas alarm system can be expanded and applied to the field of industrial / animal husbandry ammonia gas carry-on detection.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Straw forage pulverizer with high efficiency

ActiveCN107711108AImprove processing efficiencyReduce processing difficultyFeeding-stuffCuttersBiochemical engineeringSlide plate

The invention discloses a straw forage pulverizer with high efficiency. The pulverizer comprises a smashing barrel. One side of the smashing barrel communicates with a cylindrical barrel; a rod body passes through the top of the smashing barrel; the rod body extends to one end of the interior of the smashing barrel to be fixedly connected with a fixing plate; slide plates are arranged on the top of the smashing barrel and fixedly connected to two sides of the rod body; a slide block is slideably connected to the top of each slide plate; and one end, getting far away from the slide block, of aslide rod is movably connected with one side of the surface of the rod body. The invention relates to the field of pulverizers. In the straw forage pulverizer with high efficiency, the rod body passesthrough the top of the smashing barrel; the rod body extends to one end of the interior of the smashing barrel to be fixedly connected with the fixing plate, so processing difficulty can be reduced and straws are smashed in advance and then processed; forage processing efficiency can be greatly improved and time and efforts can be saved; the rod body passes through the top of the smashing barrel,so use ranges can be enlarged, simple and convenient operation can be obtained; and the straw forage pulverizer with high efficiency is suitable for various people.

Owner:临沂文一诺知识产权运营有限公司

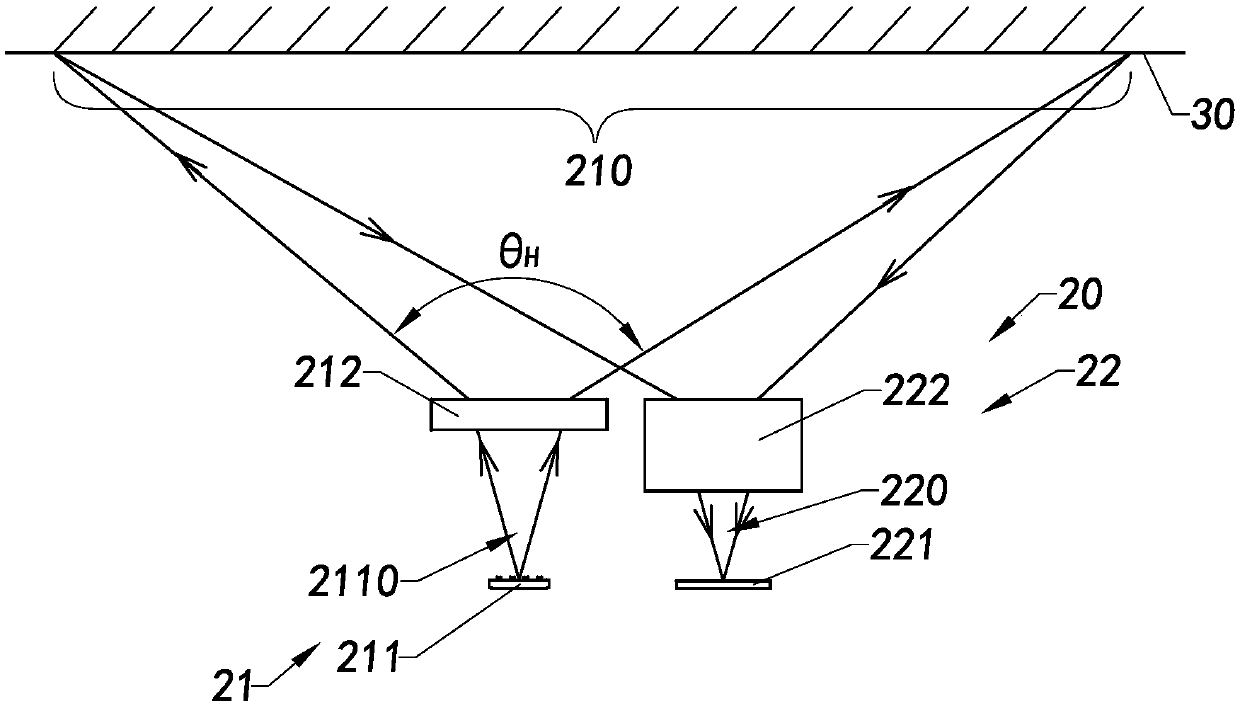

Laser large working distance auto-collimation device and method

ActiveCN106323200ALong working distanceIncreased autocollimation working rangeUsing optical meansMeasurement deviceLight beam

The invention belongs to the technical field of precision measurement and the field of optical engineering and specifically relates to a combination zeroing laser large working distance auto-collimation device and method. The device consists of a light source, a collimating mirror, a reflecting mirror and a feedback imaging system; according to the method, via adjustment of the reflecting mirror, a reflected light beam is enabled to return to a center of an image plane of the feedback imaging system; an angular deflection measurement device on the reflecting mirror is used for obtaining angular variation of a surface of an object being tested. Because the reflecting mirror is added in a traditional auto-collimation angle measurement system, a problem that measurement cannot be realized when light reflected by the object being tested is deviated from a measurement system can be prevented; an auto-collimation working scope can be expanded while working distance remains the same or working distance is increased while the auto-collimation working scope remains the same; via specific design of the collimating mirror, the feedback imaging system, the reflecting mirror and the like, the laser large working distance auto-collimation device is enabled to be simple in structure and low in manufacture cost; measurement operation can be conducted even in unstable measurement environments, and a technical advantage of rapid measurement can be gained.

Owner:HARBIN INST OF TECH

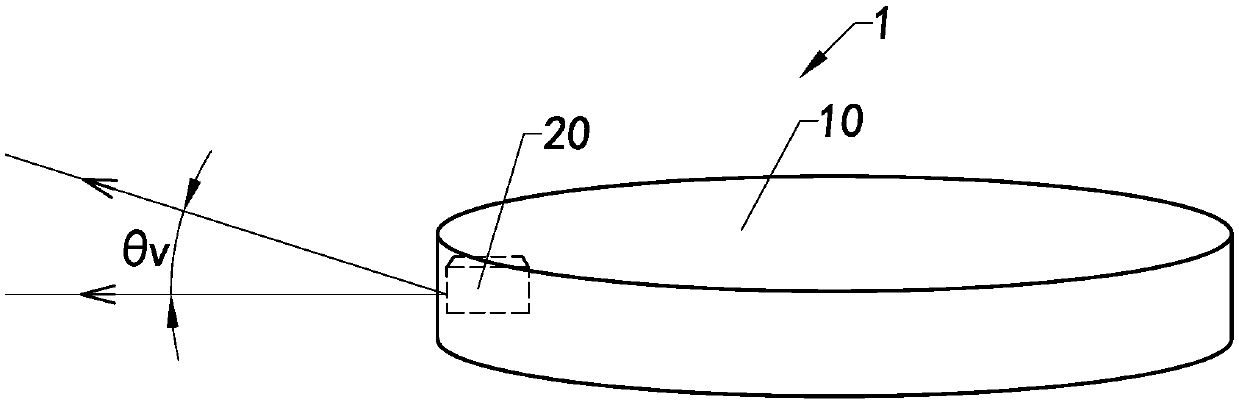

TOF module for sweeping robot and sweeping robot

PendingCN111374592AImprove light energy utilizationAffect the measurement resultCarpet cleanersFloor cleanersEngineeringLight field

The invention discloses a TOF module for a sweeping robot and the sweeping robot. The TOF module for the sweeping robot comprises a projection module and a receiving module. The projection module is suitable for being installed on a sweeping robot body and used for projecting an output light field, and the ratio of the angle of the output light field in the horizontal direction to the angle of theoutput light field in the vertical direction is greater than 10. The receiving module is suitable for being correspondingly installed on the sweeping robot body and used for receiving the reflected receiving light field, and therefore the TOF principle is applied to conduct distance measurement.

Owner:YUYAO SUNNY OPTICAL INTELLIGENCE TECH CO LTD

Sampling device for water conservancy project river water detection

InactiveCN112525607AEasy to operateImprove convenienceWithdrawing sample devicesBall screwStructural engineering

The invention relates to the technical field of water conservancy projects, and discloses a sampling device for water conservancy project river water detection. The device comprises a base, a water taking cylinder, an output pipe and a water inlet pipe; a set of transverse piston plates are slidably connected to the middle of the water taking cylinder, a through hole penetrating up and down is formed in the middle of each piston plate, a set of first movable cover plates are hinged to the left side of the top of each through hole, a set of connecting frames with the cross sections being of a T-shaped structure are fixedly installed at the tops of the piston plates, and a set of vertical lifting rods are fixedly connected to the tops of the connecting frames. The upper sides of the liftingrods movably penetrates through the top of the water taking cylinder, the top ends of the lifting rods are fixedly connected with a set of nuts towards the lower right side through connecting rods, and the nuts are slidably connected to a ball screw arranged on the right side of the water taking cylinder; a group of second movable cover plates are hinged to the left side of the inner bottom of thewater taking cylinder on the upper side of the water inlet pipe; the bottom end of a folding pipe communicates with a set of vertical telescopic pipes, and a set of horizontal floating plates are arranged in the middles of the telescopic pipes.

Owner:秦文

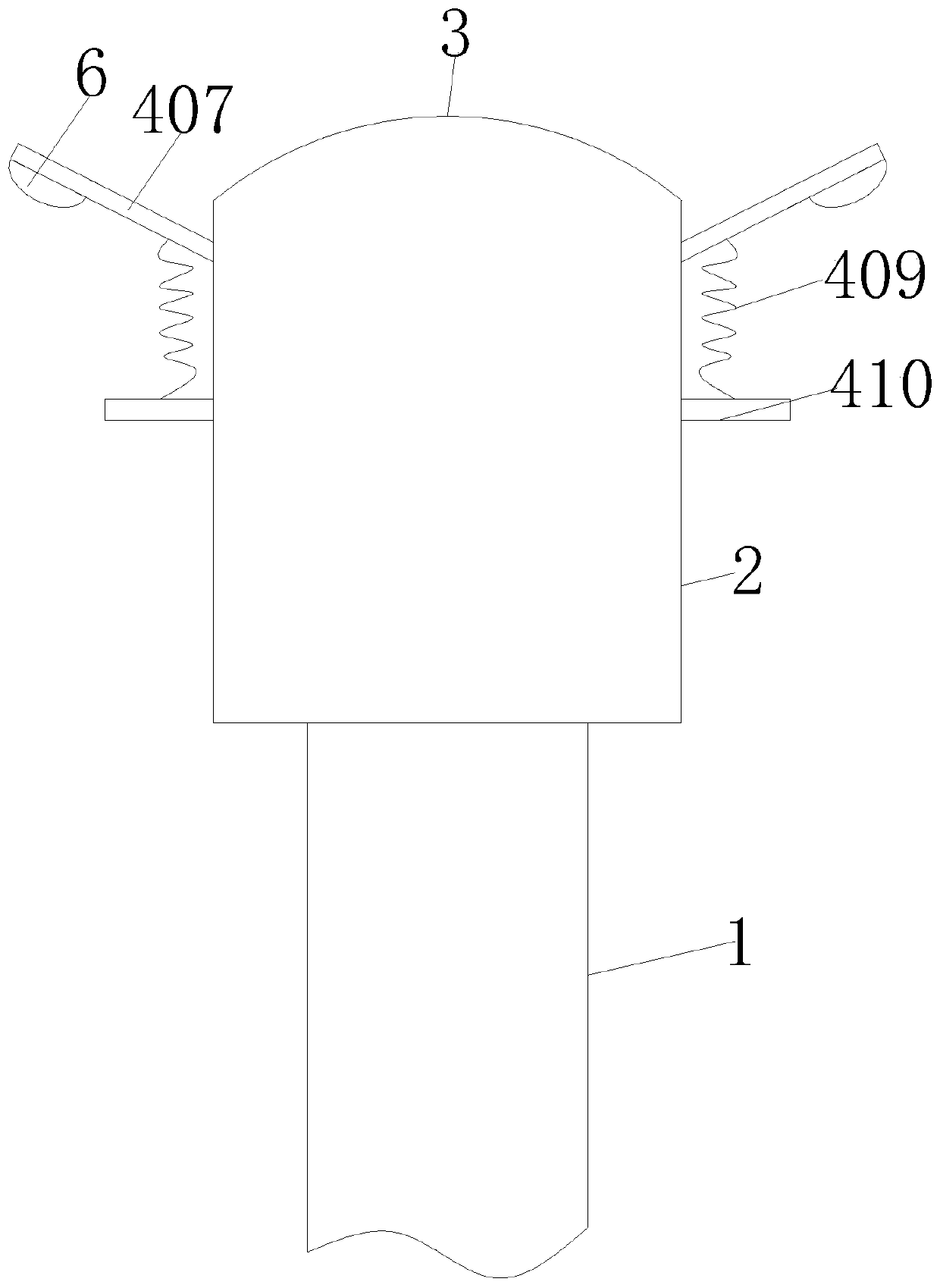

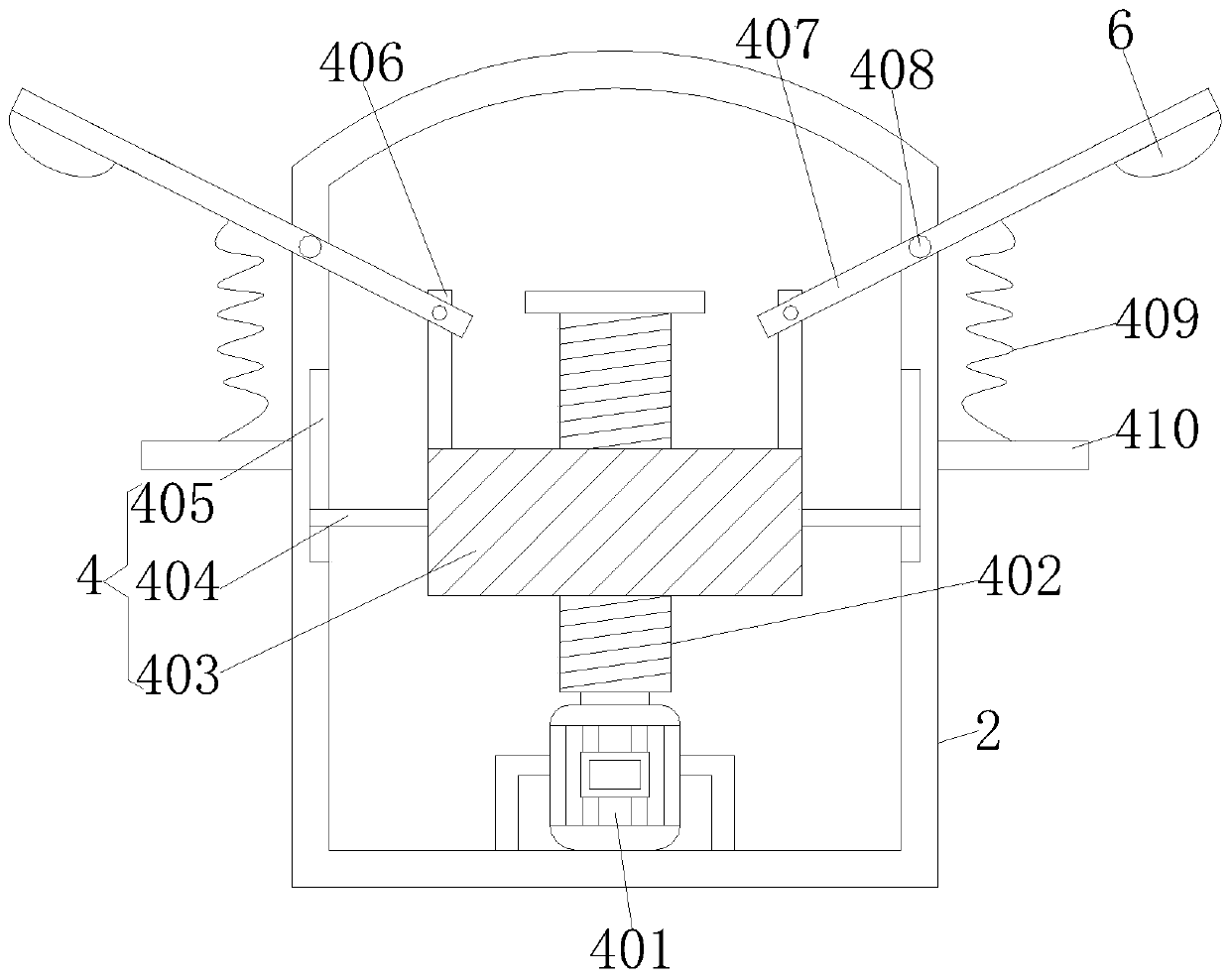

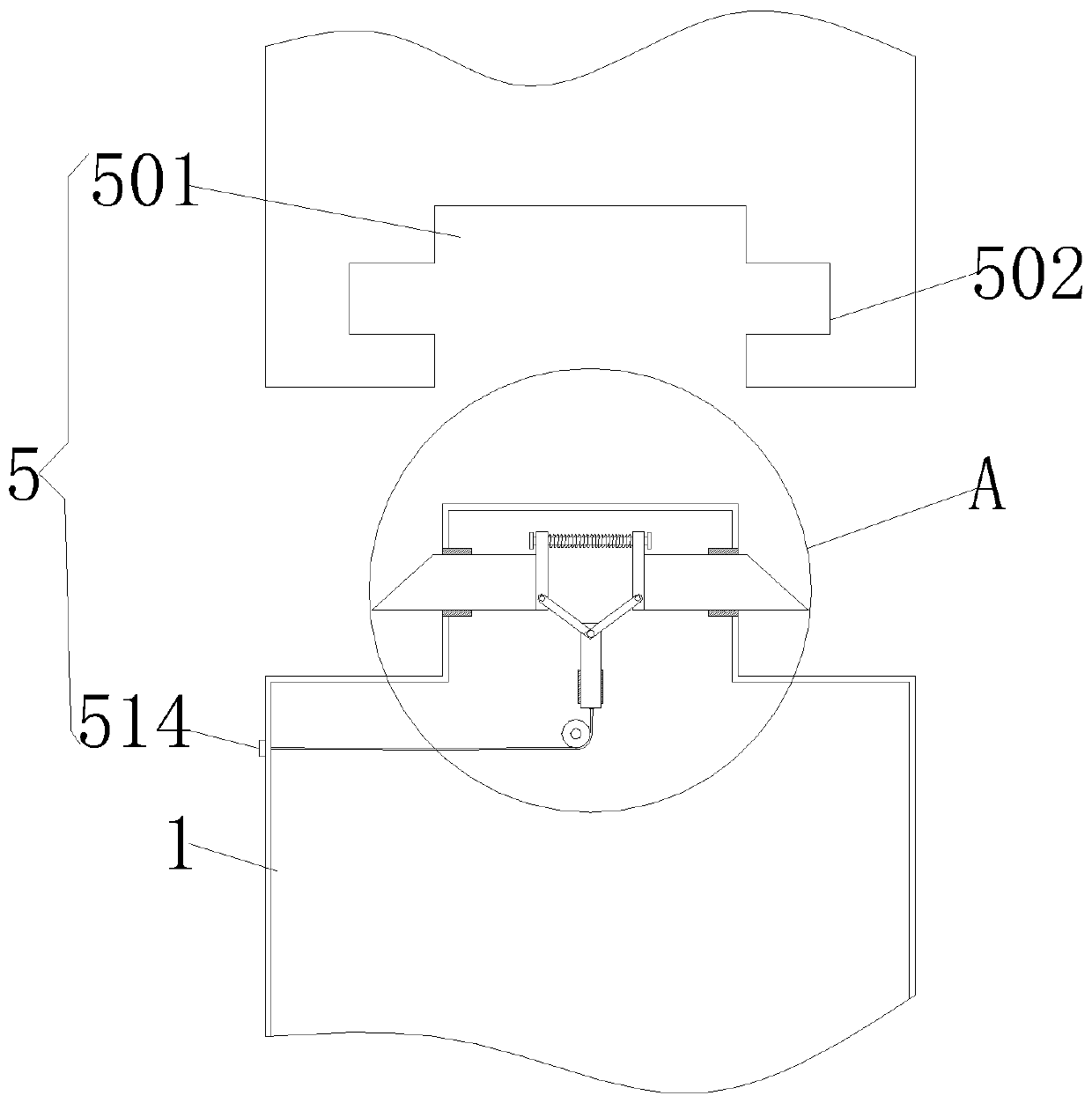

Parking lot lighting device convenient to install

InactiveCN110966548AEasy to adjustConvenient lighting angleLighting support devicesFixed installationLamp shellStructural engineering

The invention provides a parking lot lighting device convenient to install, and relates to the technical field of parking lot lighting devices. The parking lot lighting device convenient to install comprises a supporting column, a fixing box, an arc-shaped top plate, an adjusting device, an installing device and a lamp shell; the fixing box is fixedly installed at the top end of the supporting column through the installing device, and the arc-shaped top plate is fixedly installed at the top of the fixing box. The adjusting device and the installing device are arranged in a matched manner; themultifunctionality of the lighting device is improved; the included angle between the lamp shell and the vertical direction can be adjusted through the adjusting device; the illumination range is further expanded, the lighting device can adjust different inclination angles according to needs to avoid irradiation dead angles, the supporting column and the lighting device can be rapidly installed ata high speed through the installing device, disassembly is easy, and bulb replacement or maintenance in the later period is facilitated.

Owner:陕西铭泊停车服务有限公司

New energy vehicle based on Internet-of-vehicles and having ultrasonic ranging function

InactiveCN112644396AReduce blindnessImprove rangeVehicle componentsAcoustic wave reradiationNew energyGear wheel

The invention discloses a new energy vehicle based on the Internet-of-vehicles and having an ultrasonic ranging function, and belongs to the technical field of automobiles. The new energy vehicle based on the Internet-of-vehicles and having an ultrasonic ranging function comprises an automobile top cover, the upper end of a rotating shaft penetrates through an F-shaped fixing base to extend to the outside and is sleeved with an incomplete gear B, and the lower end of the rotating shaft penetrates through a limiting rod to extend into the F-shaped fixing base and is sleeved with a worm wheel. A pin shaft in the middle of the incomplete gear C penetrates through the interior of the adjusting frame, extends to the exterior and is coaxially connected with the limiting rod, through close fit of the structures, the ultrasonic ranging body is not limited to ranging in the fixed direction, a driver can adjust the horizontal direction of the ultrasonic ranging body according to the actual situation or the parking space situation. Different distance measurement alarm requirements under different conditions are met, the situation that a vehicle is unknown after being damaged due to special conditions is greatly reduced, the distance measurement range is expanded, and the distance measurement flexibility is improved.

Owner:柯文毫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com