Preparation method of ammonia gas sensor based on polyaniline-vanadium carbide and as detection system and application of ammonia gas sensor

An ammonia gas sensor and detection system technology, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of inability to independently detect ammonia gas concentration information, poor detection sensitivity, large sensing resistance, etc., so as to improve portability and Integration, good responsiveness, the effect of improving the overall range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Sensor material preparation

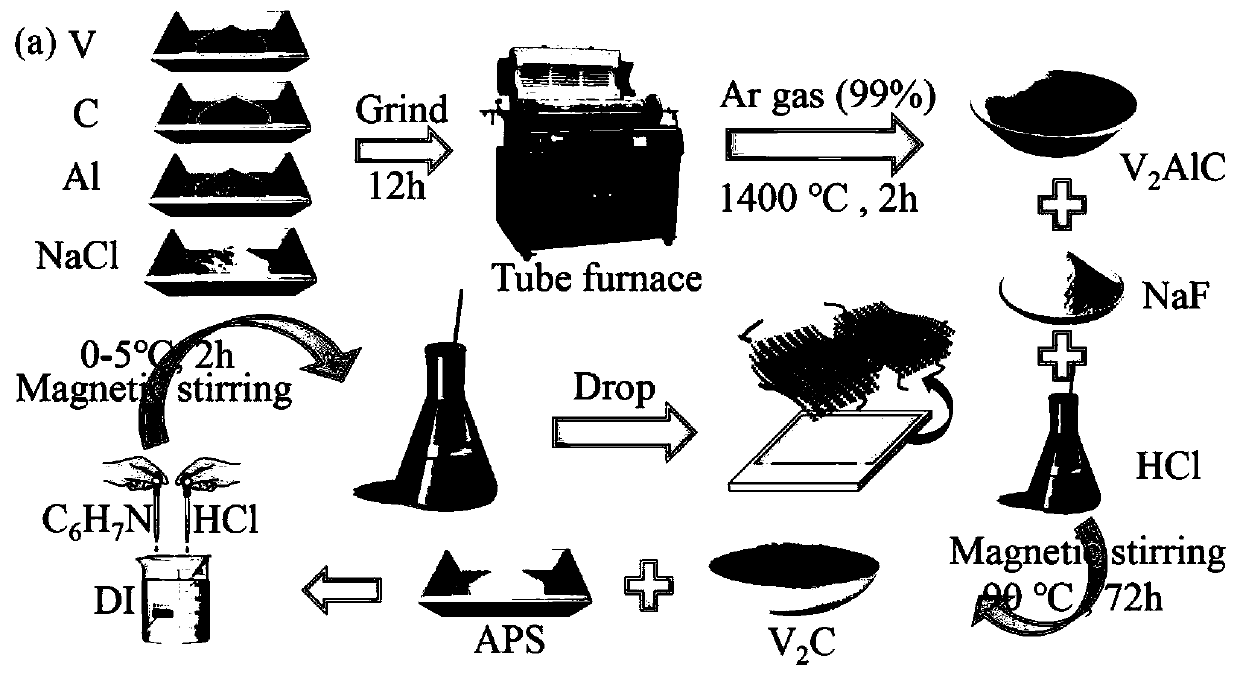

[0049] PANI-V 2 The fabrication process of C gas sensor is shown in Fig. 1(a). A method for preparing an ammonia sensor based on polyaniline-vanadium carbide, the surface of the gas sensor is made of polyaniline-vanadium carbide (referred to as PANI-V 2 C) Composite material, PANI-V 2 C resistance type ammonia gas sensor preparation step comprises three stages:

[0050] The first stage is achieved by placing V 2 AlC powder immersed in etching solution to make V 2 C MXene:

[0051] V 2 AlC powder is synthesized by molten salt method. V 2 The preparation method of AlC includes: 1. Weigh V, Al and C powders according to the molar ratio of 2:1.2:1, and weigh the sodium chloride NaCl powder according to the mass ratio of (2V / 1.2Al / C):NaCl=1:1; 2. Fully mix the powders in a ball mill for 12 hours; ③Put them into a tube furnace with an alumina crucible, and anneal at 1400°C for 2 hours in a flowing argon atmosphere of 99% v / v; ④Crush the ...

Embodiment 2

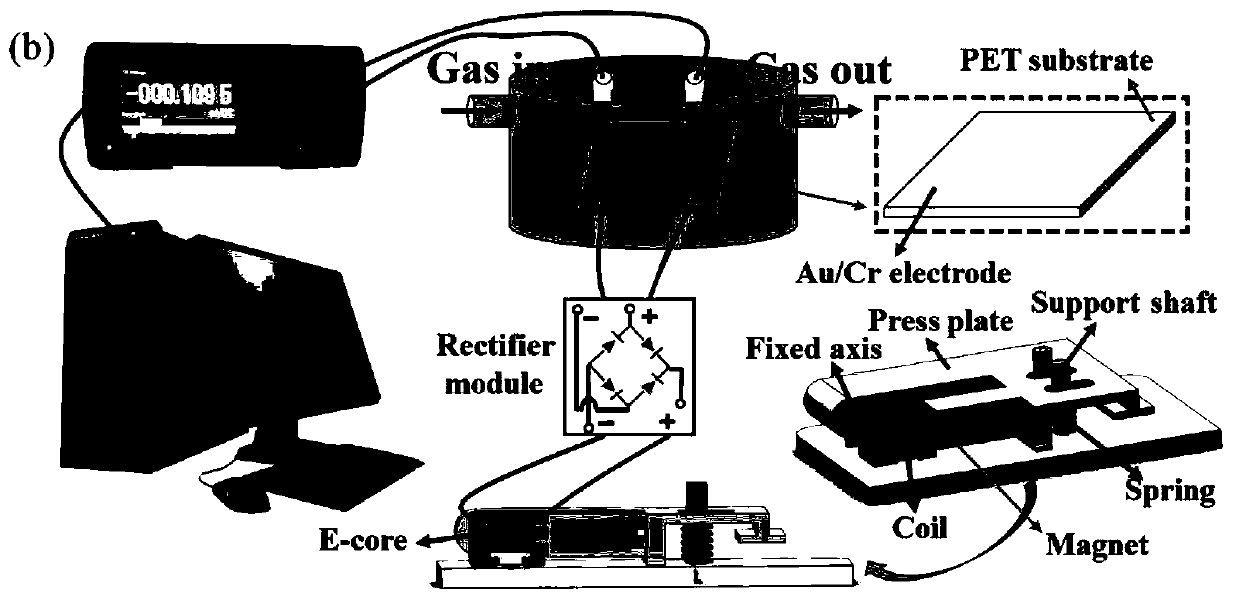

[0059] A detection system using the sensor obtained by the preparation method of Example 1, PANI-V 2 The C ammonia gas sensor is powered by a self-power supply device, and the obtained direct current drives the sensor, and the detection of the gas concentration is realized by measuring the electrical parameters of the sensor.

[0060] self powered device

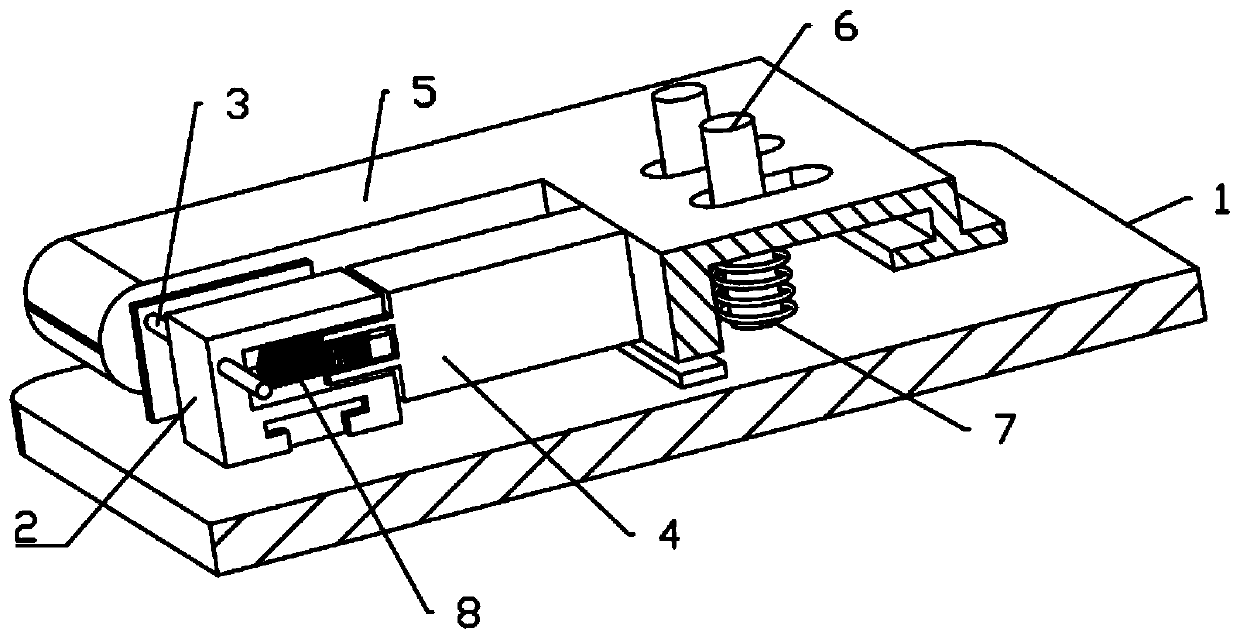

[0061] As shown in Figure 1(b), the self-powered device includes a bottom plate 1, an E-shaped iron core 2, a fixed shaft 3, a control magnet 4, a pressing plate 5, a support rod 6, a spring 7 and a coil 8, and the coil 8 is wound on an E-shaped On the middle pole plate of the iron core 2, the upper and lower magnetic poles of NS on the left side of the control magnet 4 and the upper, middle and lower pole plates on the right side of the E-shaped iron core 2 are respectively arranged in a cross manner, and the thickness of the magnetic poles is smaller than the distance between the pole plates; E The bottom of the type iron...

Embodiment 3

[0107]In this embodiment, the application of the polyaniline-vanadium carbide-based ammonia sensor detection system obtained by the above-mentioned preparation method is to use the sensor obtained by the above-mentioned preparation method or the above-mentioned detection system to package the circuit and set it on the sole of the tooling shoe, the floor of the livestock and poultry house or the body weight In the scale, it is respectively used in the field of ammonia detection in factories, ammonia detection in livestock breeding areas, and ammonia detection in household life.

[0108] Application of self-generating shoes

[0109] The above detection system capable of alarming is applied to detecting and alarming ammonia gas in various situations. Figure 6 (a) shows two examples. The above-mentioned alarm device is integrated, packaged and installed in the sole of the tooling shoe, which can be used to alarm when the ammonia gas exceeds the standard on the production site. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com